1.General Introduction ............................................................................................1

2.Proper usage ............................................................................................................2

3..Introduction of the product...............................................................................4

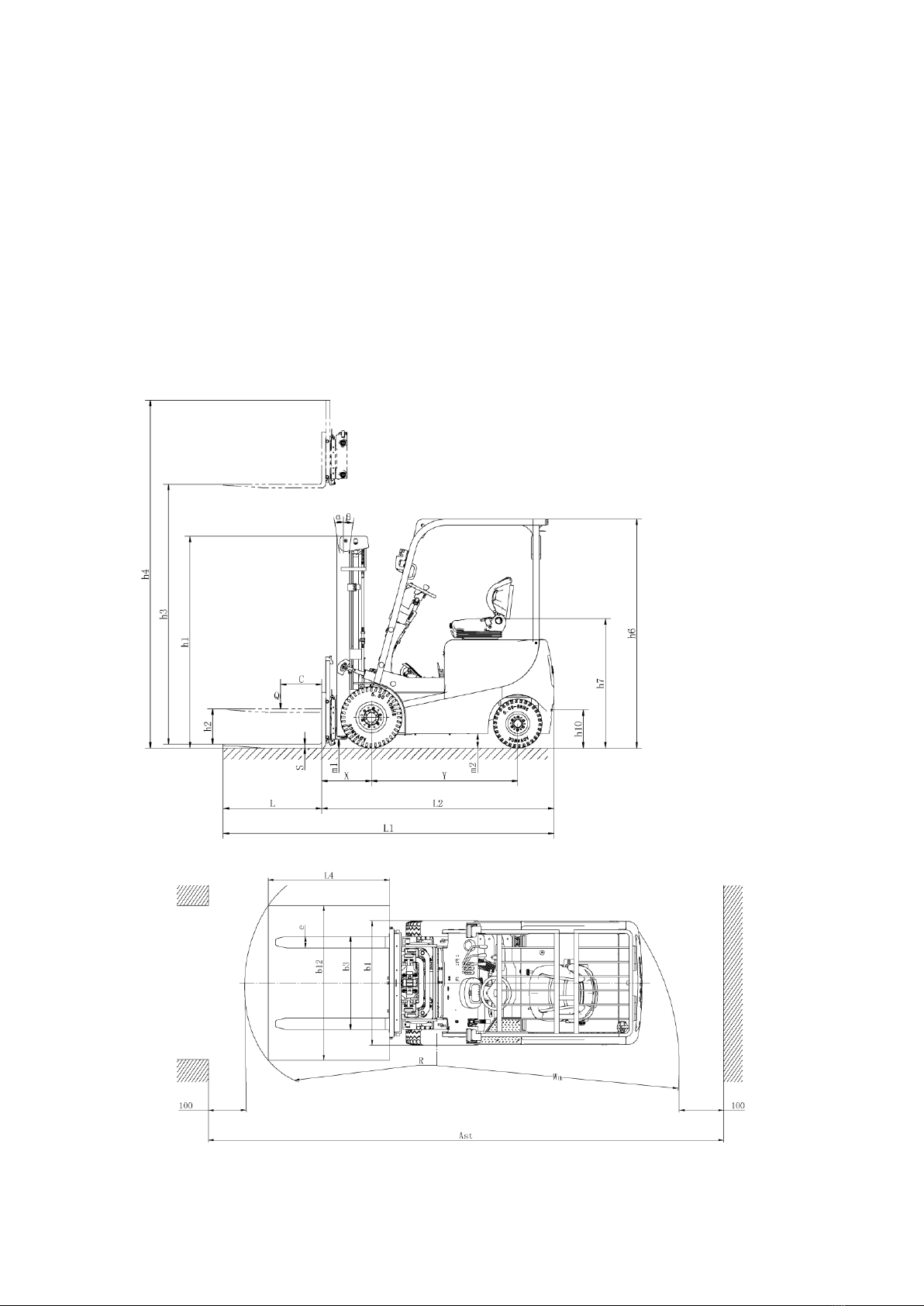

3.1Model overview............................................................................................................ 4

3.2Product Schematic diagram&Parameter............................................................ 4

4.The Schematic diagram of Operating Mechanism ......................................5

5.Structure ,Principle and Adjustment of main parts of forklift...............7

5.1Drive system .................................................................................................................. 8

5.2Steering system ............................................................................................................ 9

5.3 Brake structure &Brake Schematic....................................................................12

5.4 Operating system......................................................................................................21

5.5 Electric system...........................................................................................................22

5.6 Hyraulic system.........................................................................................................24

6.Electrical Schematic diagram.......................................................................... 25

7.Hydraulic Schematic diagram......................................................................... 26

8.Operating Specification..................................................................................... 27

8.1 Sart ,Running and Parking ..................................................................................27

8.2 Steering wheel angle front and rear adjustment..........................................28

8.3 Pedal accelerator operation..................................................................................28

8.4 Pedal brake operation.............................................................................................28

8.5Use of emergency power off safety switch ......................................................28

8.6 Use of Horn and Reversing horn.........................................................................28

8.7 Hydraulic joystick operation................................................................................29

8.8 Battery display...........................................................................................................29

8.9 Handling & Stacking operation............................................................................29

9.Maintain Introduction ....................................................................................... 30