for

driver's weight.

When the

front

ajuster blocks are at the

lowest elevation more weight is dis-

tributed on skis, at the highest position

the weight is transfered

from

the skis to

the track. The rear adjuster blocks

should be adjusted to suit the driver

preference. (The spark plug socket is an

ideal tool to turn adjuster blocks).

Caution: Always

turn

left

side adjuster

blocks in a clockwise direction, the right

side blocks in a counter-clockwise direc-

tion. Left and right adjuster blocks

of

each adjustment must always be set at the

sameelevation.

34

3/4"

Track Tension (Slide Suspension)

~

00

Lift

rear of vehicle and support it

off

the

ground.

Allow

slide to extend normally.

A gap of

3/4"

should exist between slider

shoe and

bottom

inside of track. If track

tension is too loose, the track

will

have a

tendency to thump. Too much tension

will result in power loss and excessive

stresses

on suspension components.

If

n\,-

cessary

to adjust, loosen or tighten ad-

juster bolts located on inner side

of

rear

idler wheels.

Note: Track tension and alignment are

inter-related. Do

not

adjust one

without

the other.

Track Alignment (SIide Suspension)

~

00

After

track tension has been corrected

start the engine and accelerate slightly so

that track turns slowly. Check that track

is well centered and turns evenly. To cor-

rect, loosen the lock

nut

and tighten the

adjuster

bolt

on side where track isclosest

to

the

frame.

Tighten lock

nut

and

recheck alignment.

Warning:

Before checking track align·

ment,

ensure

that the track is free of all

particles

which could be thrown out

while track is rotating. Keep hands, feet

and clothing clear of track.

The Ski-Doo snowmobile should be

stored in such a way that track does

not

stay in contact

with

cement

floor

or

bare ground.

Lift

rear of vehicle

until

track is clear

of

ground the support

with

brace or trestle.

Note: The track should be rotated

periodically, (every 40 days).

(black)

(light

grey)

Normal

(Brownish)

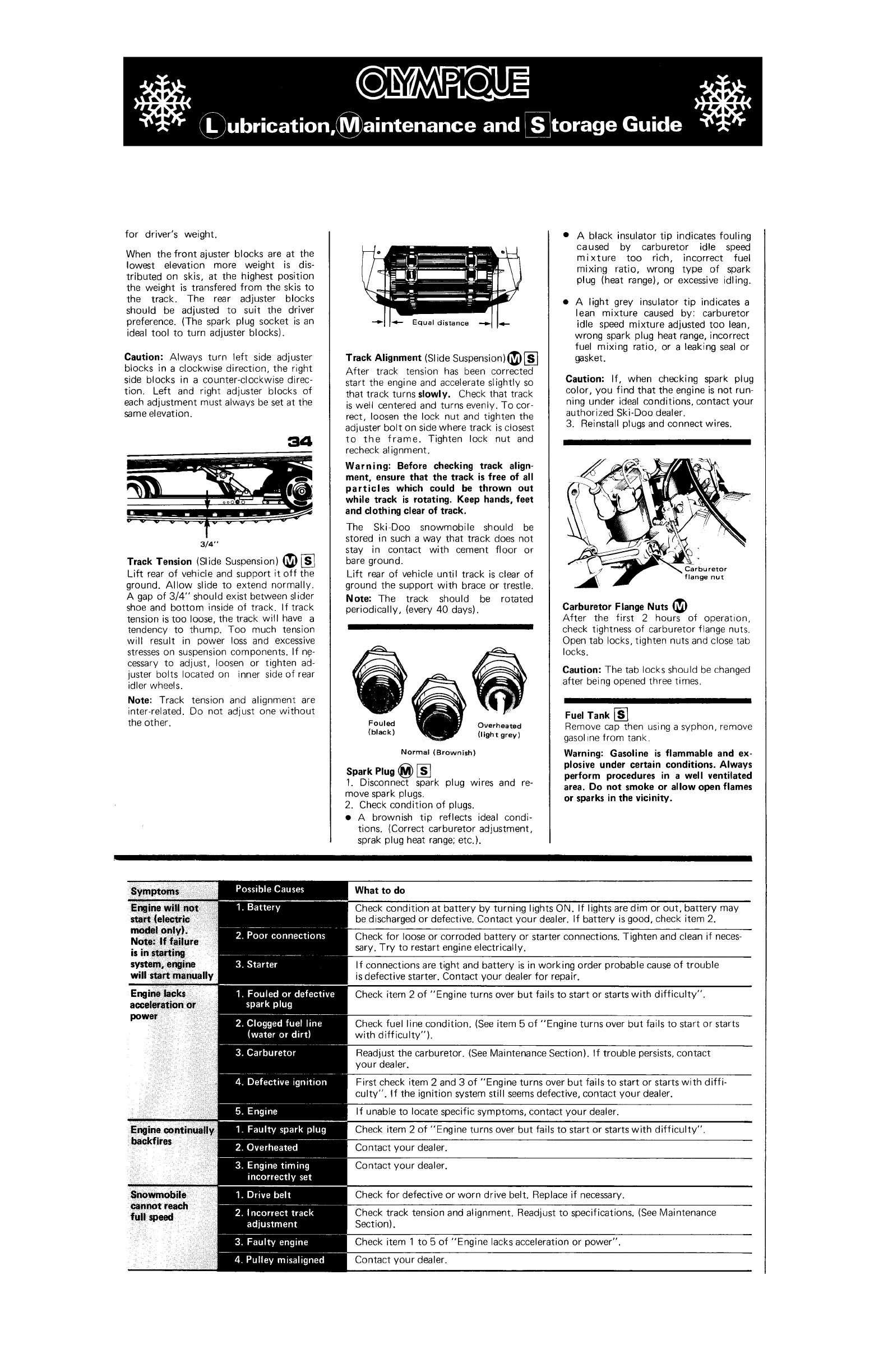

Spark Plug @

00

1. Disconnect spark plug wires and re-

move spark plugs.

2. Check

condition

of

plugs.

• A brownish

tip

reflects ideal condi-

tions. (Correct carburetor adjustment,

sprak plug heat range; etc.l.

• A black insulator

tip

indicates fouling

caused by carburetor idle speed

mixture

too

rich, incorrect fuel

mixing

ratio,

wrong

type

of

spark

plug (heat range), or excessive idling.

• A light grey insulator

tip

indicates a

lean

mixture

caused by: carburetor

idle speed

mixture

adjusted

too

lean,

wrong spark plug heat range, incorrect

fuel mixing ratio, or a leaking

seal

or

gasket.

Caution:

If,

when checking spark plug

color,

you

find

that

the engine is

not

run-

ning under ideal conditions, contact

your

authorized Ski-Doo dealer.

3. Reinstall plugs and connect wires.

Carburetor FlangeNuts

~

After

the first 2 hours of operation,

check tightness of carburetor flange nuts.

Open tab locks, tighten nuts and close tab

locks.

Caution: The tab locks shouId be changed

after being opened three times.

Fuel Tank

00

Remove cap then using a syphon, remove

gasoline from tank.

Warning: Gasoline is flammable and ex-

plosive

under certain conditions. Always

perform

procedures

in a well ventilated

area. Do not smoke or allow open flames

or

sparks

in the vicinity.

What to do

Check

condition

at battery by turning lights ON. If lights are dim or

out,

battery may

be discharged or defective. Contact

your

dealer. If battery is good, check item 2.

Check

for

loose or corroded battery or starter connections. Tighten and clean if

neces-

sary.

Try

to restart engine electrically.

If connections are

tight

and battery is in

work

ing order probable cause

of

trouble

isdefective starter. Contact

your

dealer

for

repair.

Check item 2

of

"Engine turns over

but

fails to start or starts

with

difficulty".

Check fuel line

condition.

(See

item 5

of

"Engine turns over

but

fails to start or starts

with

difficulty").

Readjust the carburetor. (SeeMaintenance Section).

If

trouble persists, contact

your

dealer.

First check item 2 and 3

of

"Engine turns over

but

fails

to

start or starts

with

diffi-

culty".

If

the ignition system still

seems

defective, contact

your

dealer.

If

unable to locate specific symptoms, contact

your

dealer.

Check item 2

of

"Engine turns over

but

fails to start or starts

with

difficulty".

Contact

your

dealer.

Contact

your

dealer.

Check

for

defective or

worn

drive belt. Replace if necessary.

Check track tension and alignment. Readjust to specifications. (SeeMaintenance

Section).

Check item 1 to 5

of

"Engine

lacks acceleration or

power".

Contact

your

dealer.