BOMBARDIER ski-doo BLIZZARD 298 1981 User manual

Other BOMBARDIER Snowmobile manuals

BOMBARDIER

BOMBARDIER Elite 1981 User manual

BOMBARDIER

BOMBARDIER ski-doo MX-Z Blair MORGAN Owner's manual

BOMBARDIER

BOMBARDIER Ski-Doo Alpine User manual

BOMBARDIER

BOMBARDIER ski-doo Tundra Scandic 2004 Series Install guide

BOMBARDIER

BOMBARDIER ski-doo Elite 1974 User manual

BOMBARDIER

BOMBARDIER ski-doo RV 340 L/C 1977 User manual

BOMBARDIER

BOMBARDIER ski-doo Alpine 1972 User manual

BOMBARDIER

BOMBARDIER Alpine 1987 User manual

BOMBARDIER

BOMBARDIER ski-doo T'NT F/A 340 1973 User manual

BOMBARDIER

BOMBARDIER Ski-Doo 1978 Series User manual

BOMBARDIER

BOMBARDIER ski-doo OLYMPIQUE 300 1974 User manual

BOMBARDIER

BOMBARDIER ski-doo Elite 2004 Manual

BOMBARDIER

BOMBARDIER ski-doo Nordic 640ER 1973 User manual

BOMBARDIER

BOMBARDIER Ski-Doo Alpine 74 1959 User manual

BOMBARDIER

BOMBARDIER ski-doo elan 250 1981 User manual

BOMBARDIER

BOMBARDIER Skandic R 1987 User manual

BOMBARDIER

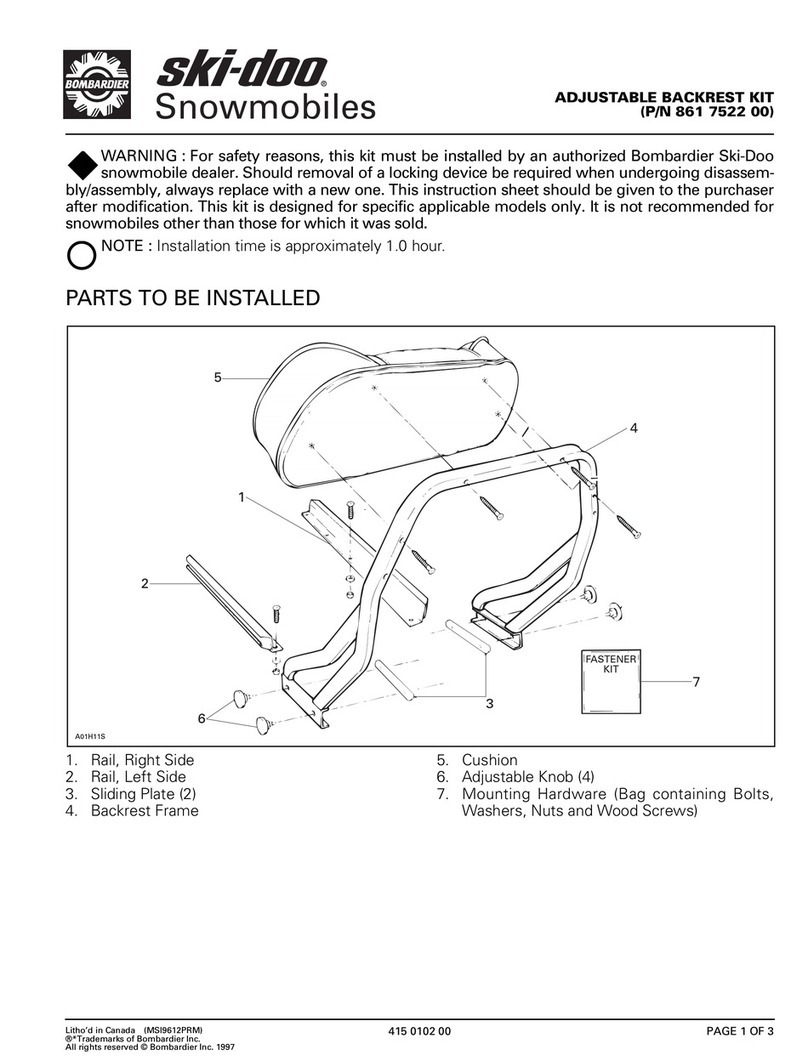

BOMBARDIER 861 7522 00 User manual

BOMBARDIER

BOMBARDIER Ski-doo MX ZX 440 Manual

BOMBARDIER

BOMBARDIER ski-doo Elite 1973 User manual

BOMBARDIER

BOMBARDIER ski-doo elan 250 1980 User manual

Popular Snowmobile manuals by other brands

BRP

BRP Ski-Doo MXZ 120 2023 Operator's manual

Arctic Cat

Arctic Cat ZR 900 Series 2006 Operator's manual

Arctic Cat

Arctic Cat Wildcat EFI Mountain Cat 1994 Service manual

Ski-Doo

Ski-Doo Formula Plus 1985 Operator's manual

Arctic Cat

Arctic Cat Cougar Service manual

Yamaha

Yamaha SnoScoot SXR2NJ Operator's manual