Bomet Libra User manual

------------ -------------

OWNER'S MANUAL

WARRANTY CARD

SPARE PARTS CATALOGUE

1-BEAM PLOUGH mounted

Libra

U 068 - 3-furrow plough

U 068/1 - 4-furrow plough (3+1)

U 068/2 - 4-furrow plough

U 068/3 - 5-furrow plough (4+1)

PRIOR TO STARTING WORK, PLEASE READ

THIS OPERATING INSTRUCTIONS

BOMET®

Spółka z ograniczoną odpowiedzialnością

Spółka Komandytowa

07-100 Węgrów, ul. B. Joselewicza 2

tel. (0 prefix 25) 691 78 06

Printing date: 08/01/2018

Węgrów 2017, Edition 3, Eng

Original manual

Copying of the manual or its parts is allowed only with the written permission of Bomet®

- 1 -

BOMET®

Spółka z ograniczoną odpowiedzialnością

Spółka Komandytowa

07-100 Węgrów, ul. B. Joselewicza 2

tel. (0 prefix 25) 691 78 06

DECLARATION OF CONFORMITY

for a machine

According to the Ordinance of Minister of Economy of 21 October 2008 (Journal of Laws [“Dziennik Ustaw”] No 199, item

1228) and European Union Directive 2006/42/WE of 17 May 2006 (Journal of Laws [Dz. U.] UE L157 p. 24-86)

we declare with full responsibility that the machine:

Machine:

1-BEAM PLOUGH MOUNTED

Type/model:

U 068

Year of production:

201 ....

Function:

Cultivation of soil, ploughing, reversing and crushing soil

to which this declaration relates, is in conformity with:

the Ordinance of Minister of Economy of 21 October 2008 on essential

requirements for machines (Journal of Laws [“Dziennik Ustaw”] No 199, item 1228)

and European Union Directive 2006/42/WE of 17 May 2006

Person responsible for technical documentation of the machine: Andrzej Sińczuk, ul. B. Joselewicza 2, 07-100 Węgrów

Following harmonized standards have been applied:

PN-EN ISO 12100:2012

PN-EN ISO 4254-1:2016E

This Declaration of Conformity WE loses its validity if the product is misused or modified

without proper authorization.

THE MANUAL CONSTITUTES MACHINE BASIC EQUIPMENT!

Węgrów, .......................................

..........................................................

Place and date of issue

Name and function of the signatory

- 2 -

- 3 -

BOMET®

Spółka z ograniczoną odpowiedzialnością

Spółka Komandytowa

07-100 Węgrów, ul. B. Joselewicza 2

tel. (0 prefix 25) 691 78 06

DECLARATION OF CONFORMITY

for a machine

According to the Ordinance of Minister of Economy of 21 October 2008 (Journal of Laws [“Dziennik Ustaw”] No 199, item

1228) and European Union Directive 2006/42/WE of 17 May 2006 (Journal of Laws [Dz. U.] UE L157 p. 24-86)

we declare with full responsibility that the machine:

Machine:

1-BEAM PLOUGH MOUNTED

Type/model:

U 068

Year of production:

201 ....

Function:

Cultivation of soil, ploughing, reversing and crushing soil

to which this declaration relates, is in conformity with:

the Ordinance of Minister of Economy of 21 October 2008 on essential

requirements for machines (Journal of Laws [“Dziennik Ustaw”] No 199, item 1228)

and European Union Directive 2006/42/WE of 17 May 2006

Person responsible for technical documentation of the machine: Andrzej Sińczuk, ul. B. Joselewicza 2, 07-100 Węgrów

Following harmonized standards have been applied:

PN-EN ISO 12100:2012

PN-EN ISO 4254-1:2016E

This Declaration of Conformity WE loses its validity if the product is misused or modified

without proper authorization.

THE MANUAL CONSTITUTES MACHINE BASIC EQUIPMENT!

Węgrów, .......................................

..........................................................

Place and date of issue

Name and function of the signatory

- 4 -

W A R R A N T Y C A R D

1-beam plough mounted type U068

Serial number ................................................

Date of production ........201 ....

Inspector signature ...............................................

Date of sale ..................................................

Seller signature .......................................

...................................................

Seller stamp

CAUTION: It is seller’s obligation to fill in the warranty card and complaint forms carefully (legibly).

Lack of e.g. date of sale or stamp of sales point will put the user at risk of not acknowledging

possible complaints. Warranty card with any written corrections or filled in illegibly –is invalid.

Warranty proceedings rules

1. A user is understood as a natural or legal person purchasing an agricultural equipment and a

seller –as a corporate unit providing equipment to the user and a manufacturer - as a producer

of agricultural equipment.

2. Manufacturer ensures good quality and efficient operation of the plough, to which the warranty

card is attached.

3. Any defects or damage of the plough shall be fixed free of charge at the place of the purchaser

in the period of 12 months from the sales date.

4. Any revealed defects or damages shall be reported in person, by post mail or by phone.

5. If during warranty period, a necessity of performing 3 warranty repairs occurs, and the product

will still reveal defects disabling its usage according to its intended use, the purchaser is entitled

to have the product exchanged into a new, flawless one or refund.

6. If the manufacturer, a seller and a user will not establish another deadline for considering the

complaint, exchanging the product or refund, it should be made within 14 days from the date of

reporting it by the user.

7. Warranty repairs do not cover repairs caused by:

- using the plough inconsistently with the manual and intended use,

- acts of God or others for which the manufacturer does not take responsibility.

These repairs can be made only at the expense of the user, purchaser.

8. The manufacturer can cancel warranty on the product in case of stating:

- introducing structural changes,

- occurring any damages caused by acts of God,

- lack of necessary records or made by one’s own any records in the warranty card,

-using the plough inconsistently with intended use or manual.

CAUTION!

Complaint about the reversible plough will not be recognised if the plough is aggregated to a

tractor with too much power. The maximum allowable power for individual ploughs:

3-furrow plough - 100 hp, 4-furrow plough - 132 hp and 5-furrow plough - 165 hp

- 5 -

Complaint form no 1

1-beam plough mounted U 068 / ..........

Serial number ................................................ Date of sale

..................................................

………………………………………………………….

seller’s signature and stamp

Complaint protocol number ...........................

Complaint form no 2

1-beam plough mounted U 068 / ..........

Serial number ................................................ Date of sale

..................................................

………………………………………………………….

seller’s signature and stamp

Complaint protocol number ...........................

Complaint form no 3

1-beam plough mounted U 068 / ..........

Serial number ................................................ Date of sale

..................................................

………………………………………………………….

seller’s signature and stamp

Complaint protocol number ...........................

- 6 -

After repair I received technically efficient machine

on .............................................

……………………………………………………..

user’s signature

Notices:

.......................................................................................................................

.......................................................................................................................

.......................................................................................................................

After repair I received technically efficient machine

on .............................................

……………………………………………………..

user’s signature

Notices:

.......................................................................................................................

.......................................................................................................................

.......................................................................................................................

After repair I received technically efficient machine

on .............................................

……………………………………………………..

user’s signature

Notices:

.......................................................................................................................

.......................................................................................................................

.......................................................................................................................

- 7 -

IDENTIFICATION

1-BEAM PLOUGH MOUNTED

1-beam plough mounted of U068 series has a rating plate, fitted in the front part of

the plough frame. Basic data which serves for identification of the machine: manufacturer’s

name, machine symbol, serial number, year of production, is put there.

Data placed on the rating plate serves for identification of the plough and ought to

correspond to the following data, filled in during the sales.

Symbol U068 / ............

Year of production 201 ....

Serial number ................................................

IT IS ADVISED THAT THE SUPPLIER OF MACHINES, BOTH NEW AND

USED ONES, KEEP THE SIGNED BY THE PURCHASER CONFIRMATION OF

RECEIPT OF manual ALONG WITH THE MACHINE.

MANUAL IS THE BASIC EQUIPMENT OF THE MACHINE

KEEP THIS INSTRUCTION FOR FUTURE REFERENCE

CAUTION!

When lending the machine to another person, the manual shall be

attached to the machine.

- 8 -

TABLE OF CONTENTS

W A R R A N T Y C A R D.............................................................................................................4

1. INTRODUCTION ........................................................................................................................9

2. INTENDED USE OF THE PLOUGH...........................................................................................9

3. SAFETY PRECAUTIONS AND WARNINGS............................................................................10

3.1. Symbols: meaning and application....................................................................................10

3.2. Expected use.....................................................................................................................10

3.3. Description of residual risk.................................................................................................10

3.4. Estimation of residual risk.................................................................................................11

3.5 Regulations for occupational health and safety...................................................................11

3.6. Standard conformity ..........................................................................................................14

3.7. Manufacturer’s responsibility and guarantee......................................................................14

3.8. Noise and vibrations..........................................................................................................14

3.9 Safety signs and captions...................................................................................................15

4. USAGE REGULATIONS ..........................................................................................................16

4.1. General information...........................................................................................................16

4.2. Construction and operation of the plough..........................................................................16

4.3. Equipment and fittings.......................................................................................................17

4.4. Preparing the tractor to work .............................................................................................17

4.5. Preparing the plough to work.............................................................................................18

4.6. Aggregation of the plough with a tractor ............................................................................18

4.7. Safety instructions.............................................................................................................19

4.7.1. Initial adjustment.............................................................................................................19

4.7.2. Operation with the mounted plough................................................................................20

4.7.3. Plough adjustment..........................................................................................................21

5. TECHNICAL OPERATION.......................................................................................................23

5.1. Instruction on maintenance of the plough..........................................................................23

5.2. After-seasonal maintenance..............................................................................................23

5.3. Plough storage..................................................................................................................23

5.4. Working parts exchange....................................................................................................24

5.5. Detection and removal of failure........................................................................................25

5.6. Lubrication instruction........................................................................................................25

6. TRANSPORTATION ON PUBLIC ROADS ..............................................................................26

6.1. Plough transportation by means of transport .....................................................................26

6.2. Transportation of the plough on the tractor........................................................................26

7. DISASSEMBLY........................................................................................................................27

8. TOTALLING .............................................................................................................................27

9. TECHNICAL CHARACTERISTICS ..........................................................................................27

SPARE PARTS CATALOGUE.....................................................................................................28

- 9 -

1. INTRODUCTION

This manual aim is to make a user acquainted with a proper operation, usage and

adjustment of the mounted plough. Its aim is also warning about existing or possible

threats. The manual also contains information on preparation of the plough for operation

and for transportation on public roads.

Strict compliance with recommendations included in the content of the manual will

ensure long-term and non-failure operation and contribute to reduction of operating costs

of the machine.

Each section of the instruction (according to the contents) presents proper issues in

detail. If there is any unclear information for the user, they can obtain exhaustive

explanation by writing to the manufacturer’s address (the address is on the cover) – you

are asked to give: exact address of the purchaser of the machine, machine symbol, serial

number, year of production, year and number of issuing the manual.

Terms used in the manual: left side, right side, back and front –refer to the settings

of an observer with his face turned according to the direction of the machine drive.

Warranty proceedings regulations and rights resulting from them, are given in the

warranty card, attached to each plough.

2. INTENDED USE OF THE PLOUGH

1-beam mounted ploughs of U068 series with width variable adjustment are

intended to operate exclusively in the agriculture. Using it for other purposes shall be

understood as using it against the intended use. Ploughs are designed to perform

ploughing of flat fields, on all soil types - from light to heavy and not stony soils. On stony

soils it is recommended to use ploughs of U068 series with automatic protection against

overload in the form of a suspension spring or a shear bolt. Plough can be operated

separately or in cooperation with a tillage tool e.g. with a tubular roller. Meeting

requirements referring to operation of the machine, its maintenance and repairs according

to recommendations of the manufacturer and strictly complying with them state the

condition of using it according to the intended use.

The machine shall be employed, operated and repaired only by people acquainted

with its detailed characteristics and with procedures in the field of safety.

Regulations concerning accident prevention and all the basic regulations in the field

of occupational health and safety and also traffic regulations should be always abided by.

Unauthorized structural modifications introduced to the tool without the

manufacturer’s consent may absolve the manufacturer from liability for any resulting

damages and harms.

1-beam mounted ploughs are intended for performing middle-deep and deep

ploughing of all soils with humidity enabling proper operation. The ploughs should be

aggregated only with tractor classes recommended by the manufacturer (see technical

characteristics) equipped with suspension category II or III and standard ballasts of the

front axle to keep the required controllability factor (s ≥ 0.2).

- 10 -

3. SAFETY PRECAUTIONS AND WARNINGS

3.1. Symbols: meaning and application

In the present manual symbols are used in order to draw the reader’s attention and

stress certain particularly important aspects requiring discussion.

DANGER

This indicates danger, with a possible serious accident risk. Not obeying

recommendations marked with this sign may cause a situation of a serious risk of

sustaining an injury by the operator and/or people nearby! Obey strictly these

recommendations!

CAUTION

The symbol indicates possibility of damaging the machine or other object and

demands to be cautious. It is the advice which should be paid special attention!

REMEMBER

The symbol indicates advice or notice regarding key functions or useful information

concerning proper functioning of the machine.

3.2. Expected use

1-beam mounted ploughs of U068 series have been designed, built and adjusted for

operation in agricultural production for farming - ploughing on flat fields, on all types of soil

with moisture enabling proper operation. If there are stony soils, it is recommended to use

ploughs of U068 series with automatic protection securing the body against damage.

Operation with a plough can be performed on slopes up to 8.5°. Ploughs should be

aggregated only with tractors classes recommended by the manufacturer, see technical

characteristics.

REMEMBER

Regulations concerning the intended use and configurations, provided for this

machine are the only ones, which are exclusively allowed. The machine shall not be

employed for other purposes than those, which have been provided for it. The

regulations given in this manual do not substitute obligation towards present

regulations with force of a statute, referring to standards concerning safety and

prevention from misadventure, but they summarize them.

3.3. Description of residual risk

Residual risk results from wrong or incorrect behaviour of the plough operator. The

greatest danger can occur in performing following activities:

-operation of the plough by minors and also people not acquainted with the manual

or not having qualifications for driving an agricultural tractor,

-operation of the plough by people with a disease, in a state indicating for using

alcohol or narcotic drugs,

-transport and operation without proper safety measures,

-aggregation of the plough with a tractor if the operator is between the machine and

the tractor at the engine working,

-operation when people or animals stay within the range of operation of the assembly

tractor + machine,

-maintenance and adjustment at the plough when the tractor engine is working and

the plough is not protected against falling down.

- 11 -

When describing residual risk of the plough, the plough is treated as a machine, which

since the moment of starting the production, has been designed and manufactured

according to the present technique condition.

3.4. Estimation of residual risk

During operation of the plough, threat and residual risk can be limited to the

minimum when such recommendations are abided by:

-careful reading the manual,

-prohibition of people staying on the plough during operation and transport,

-prohibition of people staying between the tractor and the plough when the tractor

engine is working,

-all adjustment, maintenance and lubrication of the plough shall be performed only at

the tractor engine stopped,

-repairs of the plough performed only by people trained in this field,

-operation of the machine by people who have qualifications to drive agricultural

tractors and are familiar with the manual of the machine

-protection of the plough against children access.

Although BOMET®company takes responsibility for pattern-designing and

construction in order to eliminate danger, certain risk elements during mounted plough

operation are unavoidable.

1) Danger of being caught or hurt by the frame edges or sharp edges of the

ploughshare or mouldboard wing during aggregation or changing transportation-operation

position and inversely.

2) Danger of being hurt or caught by a support wheel or a tillage tool. No part of the

body should be situated between the support wheel with a tillage roller and the frame or

near the plough during operation. Unauthorized persons should not be near the working

plough.

3) Danger of wound or abrasion by sharp working elements of the machine during

performing maintenance or adjustment resulting from improper position of the operator

during these activities.

4) Danger of being crushed or hit by the hitch for tillage tools as a result of the

operator's improper position during maintenance and adjustment.

5) Danger of liquid spurt under high pressure from the hydraulic system when

changing the plough working width.

6) Danger of turning over the machine during storage or transportation. When

stored to keep stability, the plough should be set on the flat ground leaning on the copying

wheel and plough bodies. The plough shall be aggregated only with tractor classes

recommended by the manufacturer.

3.5 Regulations for occupational health and safety

CAUTION

In order to avoid threats, before starting operation of the plough, please

read the present manual and follow these rules concerning threats and

safety measures:

- 12 -

General regulations

Apart from this manual, one shall also follow traffic regulations and occupational safety

and health regulations.

Warnings (pictograms) placed on the plough give advice concerning safety of the user

and other people, and avoiding accidents.

When driving on public roads, it is obligatory to follow regulations included in Highway

Code.

It is recommended to cooperate with a tractor equipped with a cabin or a protective

frame.

Before each using the machine, it is necessary to check if all elements of the plough are

in a good condition. Damage incurred shall be fixed without delay and possible

deficiencies filled up.

Avoid staying within the range of the working plough.

Before leaving the tractor cabin and before each activity made at the plough, stop the

tractor engine, remove the key from the ignition switch.

The plough shall be stored in a dry room, on the tough and flat ground. During lowering

the plough onto the ground, keep particular caution. Danger of injury!!!

Aggregation

Keep particular caution during connecting the plough with a tractor and during its

disconnection.

It is forbidden to stay between the plough and a tractor during any activities performed

with a hydraulic system lever.

While aggregating the plough with a tractor, it is forbidden to stay between the tool and

the tractor at the tractor engine working.

During performing any maintenance at the plough, it is necessary to stop the engine,

remove the key from the ignition switch and pull the handbrake.

Pivots of the plough suspension system shall be secured only with the use of typical

protection in the form of cotter pins.

The plough shall be aggregated only with recommended tractor classes equipped with

front axle ballasts.

The plough can be operated by a person with qualifications allowing for using

agricultural tractors.

During aggregation, keep the minimum load of the tractor front.

CAUTION

Operation with a tractor of another class than recommended by the manufacturer may

cause threat of stability loss in operation or in stoppage.

Tractor front axle load cannot be less than 20% of the tractor’s weight.

Maintenance

A plough can be operated by a person with qualifications allowing for using agricultural

tractors and acquainted with the manual of the plough.

All maintenance (lubrication, repairs, cleaning etc.) shall be performed with the plough

lowered onto the ground, the tractor engine stopped, key taken out from the ignition

switch and handbrake pulled.

It is not allowed for other people not acquainted with the manual to operate the plough.

It is not allowed for children and people after drinking alcohol to operate the plough.

The plough shall be raised onto the tractor suspension system easily, without jerks or

vibrations.

Raise the plough upwards each time when turning and making returns.

Work with a plough on slopes with gradient exceeding 8.5is not allowed.

- 13 -

At each getting off the tractor by the operator, leave the plough in the lowered position.

Removing clogs can be performed after lowering the tool onto the ground and turning

off the tractor engine.

It is not allowed to use tractor reverse gear during work, when the tool is in the working

position.

It is necessary to keep terms of exchange of hydraulic hoses unconditionally.

Due to natural wear of the material, flexible hydraulic hoses must be exchanged

periodically every 4 years since their date of production. On hydraulic hoses there is the

date of production; year and the number of the week.

People operating agricultural equipment should be equipped with working clothes and

footwear, and personal protection measures appropriate for existing threats e.g. gloves.

Transportation

Transportation of a plough by means of transport from the manufacturer to a sales

person or a customer is described in the section ‘Transportation on public roads’ in

detail. One shall remember safety rules during the loading and proper fixing of the

plough on a car trailer. Hooks for ropes or chains are marked with pictograms.

The plough transported on public roads must be equipped with portable light and

warning devices and a triangular sign for low-speed vehicles, fixed in special handles on

the plough frame, see details in section ‘Transportation on public roads’.

It is forbidden to transport any people or items on the plough frame.

Due to the length of the plough and a fixed connection with the tractor, keep caution

especially at returns during operation and turnings during transportation on public roads

with regard to overlapping of the tool.

Keep extreme caution while making a turn of a tractor with a mounted plough, both

during transportation and also while making returns in the field, especially when there

are any people or items nearby.

Driving speed of the tractor with the plough during transportation cannot exceed:

- when driving on hardened roads with flat surface –15 km/h,

- when driving on field ways –10 km/h.

Storage

Disconnecting the plough from the tractor can take place only after the tractor engine

stopped, key removed and the handbrake pulled.

The plough shall be stored in a dry room, on the tough and flat ground. During lowering

the plough onto the ground, keep particular caution - danger of being injured!!!

During storage the plough should be leant firmly on the bodies and the wheel. The

plough should be stored in places where there is no possibility of accidental injury on

the flat ground, preferably under a roof.

The plough shall be stored in a clean condition.

Threat!

Pay attention to sharp endings of ploughshares, mouldboard wings and disc coulter –

danger of being hurt, keep caution during operations and maintenance of the plough.

Others

It is not allowed to use the plough for other purposes than given in the manual.

CAUTION

Not following these rules may cause threat to the operator and other people and also

may cause damage to the plough. Any damage resulting from not following these

rules is the only responsibility of the user.

- 14 -

3.6. Standard conformity

The machine has been designed and made in accordance with standards

concerning safety in the machine industry, valid on the day of marketing the mounted

plough. Particularly, following legal acts and harmonized standards have been taken into

account:

2006/42/WE - Directive on machinery safety introduced by the Ordinance of Minister of

Economy on 21 October 2008 (Journal of Laws [“Dziennik Ustaw”] No 199, item 1228).

PN-EN ISO 12100:2012P - Machinery. Safety. General principles for design. Risk

assessment and risk reduction.

PN-EN ISO 4254-1:2016E –Agricultural machinery. Safety. Part 1: General

requirements (orig).

PN-ISO 730-1+AC1:1996P –Wheeled agricultural tractors. Rear three-point

suspension system. Categories 1, 2, 3 and 4.

PN-ISO 2332:1998P –Tractors and agricultural machinery. Mounting machinery on a

three-point suspension system. Free space zone.

PN-ISO 3600:1998P –Tractors, agricultural and forest machinery, mototools. Manual.

Contents and form.

PN-ISO 11684:1998P –Tractors, agricultural and forest machinery, mototools. Safety

and warning signs. General principles.

3.7. Manufacturer’s responsibility and guarantee

In relation to described in this manual machine types, BOMET®company does not

acknowledge any civil responsibility towards:

-improper or inconsistent with the manufacturer’s recommendations using the machine,

-using the machine in a way breaking domestic law concerning safety and preventing

from unfortunate accidents,

-non-compliance or improper following regulations cited in this manual,

-making unauthorized changes in the machine,

-using the machine by unqualified staff,

-using spare parts that are not original.

As long as the purchaser wants to make use of warranty, he should strictly follow

recommendations and regulations given in the manual. In particular:

-he should work only in the given ranges of the machine operation,

-he should always perform unchangeable and thorough maintenance,

-only operators with proper abilities and qualifications shall be allowed to use the

machine,

-he should use only original spare parts recommended by the manufacturer.

3.8. Noise and vibrations

During the operation of a plough for the operator there is no threat caused by noise

contributing to the loss of hearing because the plough is an inactive tool and the workplace

of the operator is in the tractor cabin. The tractor and not the machine is the source of

noise.

There is no threat caused by vibrations when working with a plough because it is an

inactive tool and the operator’s workplace is located in the tractor cabin where the seat is

amortized and properly ergonomically shaped.

- 15 -

3.9 Safety signs and captions

1-beam mounted ploughs of U068 series of BOMET®company are equipped with

all devices that ensure safe work. Where it is not possible to secure dangerous places

entirely due to the proper operation of the plough, there are warning signs –pictograms

which indicate for possibility of danger and present manners of avoiding it.

In table 1 pictograms placed on the machine and their meaning have been

specified. Safety pictograms should be protected against being lost and against loss of

legibility. Lost or illegible signs and captions should be replaced with new ones. It is

required that new assemblies employed during repair were marked with all safety signs

predicted by the manufacturer. If you want to buy pictograms, write to the manufacturer’s

address and give the sign number (according to the table 1), version and year of issuing

this manual.

Table 1. Safety signs and captions

No

Pictogram

Meaning

Location

1

2

3

4

1.

(Rating plate)

Rating plate

At the front of the frame

2.

Before operating the machine, read

the manual

On the plough frame

3.

Caution. Before operation turn off

the engine and remove the key from

the ignition switch

On the plough frame

4.

Do not stay near the lift rods, while

controlling the lift

On the plough frame

5.

Danger of crushing hands. Do not

reach crushing area if the elements

can be in motion

On the roller movable arms

6.

Caution. Threat of liquid spurt under

high pressure.

On the plough frame near the

hydraulic hoses

7.

Danger of hurting a leg. Keep the

safe distance from ploughshare,

disc sharp endings

On the plough frame

8.

Marking places of loading hooks

On the plough frame

9.

Marking lubrication points

On the plough frame

10.

Company logo

On the plough frame

- 16 -

4. USAGE REGULATIONS

4.1. General information

1-beam mounted ploughs of U068 series are produced in series as 3-furrow and 4-

furrow ploughs with the possibility of mounting an attachment with 1-furrow. They are

adjusted to work on terrain slopes not exceeding 8.5and cooperate with tractors

equipped with suspension system category II or III (see technical characteristics –table 4)

equipped with wheel standard ballasts. User having the tractor, enabling the use of force

adjustment of the ploughing depth, should use this adjustment, which allows for saving

about 10% of fuel.

4.2. Construction and operation of the plough

1-beam mounted ploughs of U068 series (figure 1) are tools mounted on the tractor

three-point suspension system. Construction of the ploughs is modular, i.e. they have the

same structural elements but only differ in the number of bodies and the size of the frame.

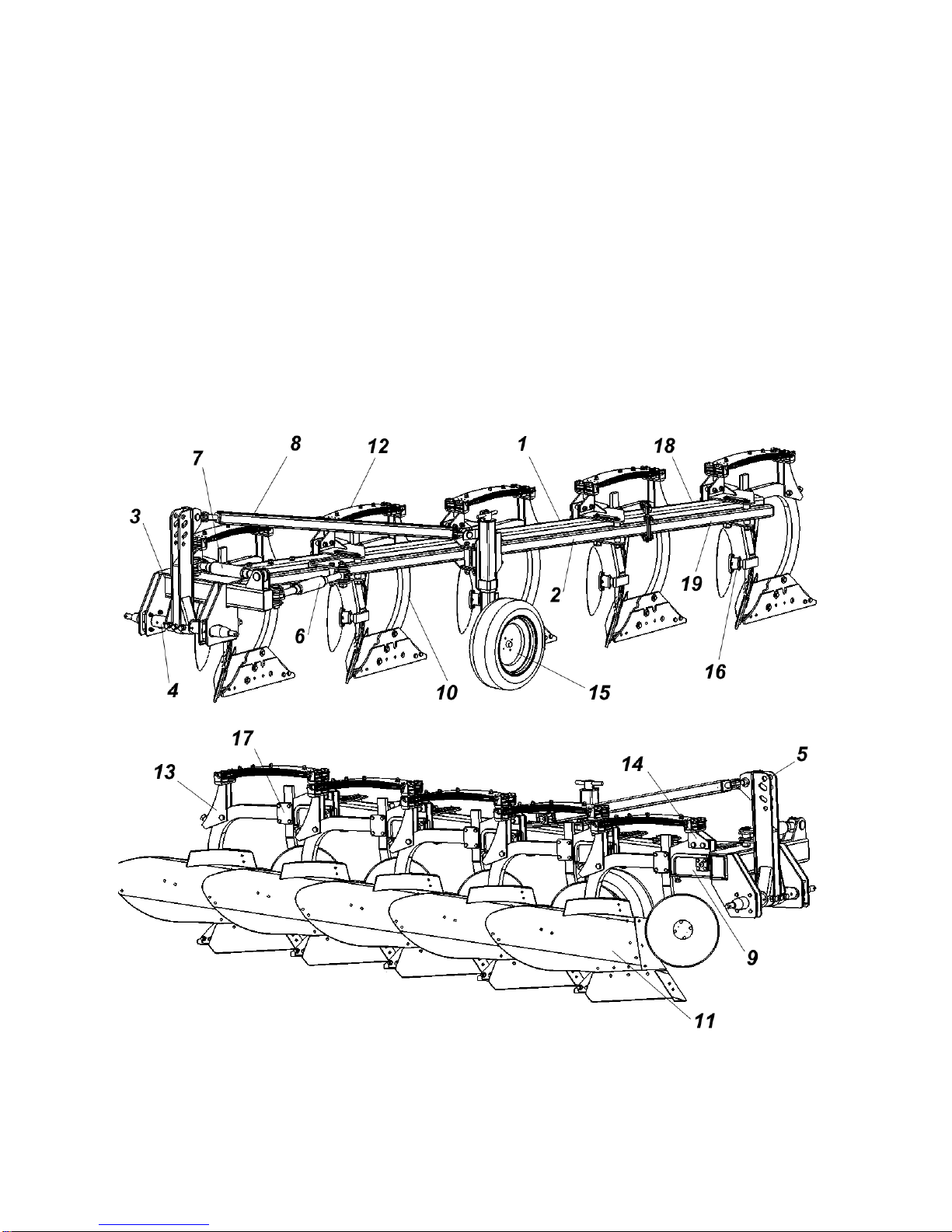

Figure 1. 1-beam plough - general construction: 1 - main frame, 2 - subframe, 3 - coupler head, 4 -

suspension axle, 5 - three-point suspension system rack, 6 - longitudinal adjustment screw (or

hydraulic actuator), 7 - transversal adjustment screw, 8 - stay, 9 - body handle, 10 - leg, 11 - body,

12 - suspension spring, 13 - spring rear handle, 14 - spring front handle , 15 - support wheel, 16 -

disc skimmer, 17 - skimmer handle, 18 - body main frame +1, 19 - body subframe +1

- 17 -

Mounted ploughs of U068 series are connected to a tractor with the use of three-point

suspension system consisting of the suspension axle with a rack which is supported by the

long stay. The suspension axle is mounted in the hitches of the coupler head with the use

of bearings which enable its movement and tilting. On the suspension axle there is a rack

with top connecting openings mounted. Coupler head with three-point suspension system

is equipped with two adjustment screws which enable width adjustment of the first furrow -

transversal adjustment (pos.7 Fig. 1) and changes in the angle setting the main beam -

longitudinal adjustment (pos.6 Fig. 1). Leg handles are connected with an auxiliary beam

of ploughing width adjustment, allowing to change the width of the groove from 30 cm to

50 cm on all bodies at the same time using a turnbuckle or a hydraulic actuator (pos.6).

The plough body leg is mounted in the frame handle by pivots and suspension springs

which protect them against overload. As a standard, plough bodies are equipped with split

bolt mouldboards and ploughshares with interchangeable chisels. In addition, plough

bodies can be equipped with a strip chipper, which is designed to cut the top layer of soil

and throw it onto the bottom of the groove and thus better covering plant residues. Skid of

the last body is equipped with a screwed heel.

Copying wheel setting the ploughing depth is mounted in the handle of the third

body and along with the change in the furrow width there is also shifting of the wheel to the

direction corresponding with the direction of ploughing. Ploughs of U068 series are

equipped with handles, in which there are light devices and a triangular warning sign

installed.

Optionally, the plough bodies can be equipped with disc skimmers mounted on the

body beam with the use of clamp grips, allowing for easy adjustment.

4.3. Equipment and fittings

The manufacturer delivers the plough for sale assembled. The manual with a spare

parts catalogue and a warranty card are delivered along with the machine by the

manufacturer.

REMEMBER

Manual with a spare parts catalogue comprise basic equipment of the plough.

1-beam plough can be optionally equipped with a disc skimmer. Basic equipment

of the machine does not involve portable light and warning devices and a triangular sign

for low-speed vehicles which are available at agricultural equipment storehouses.

Each user of a plough shall have light and warning signs, in working order, and a

triangular sign for low-speed vehicles (sign description is available in the section

‘Transportation’). Not having them during transportation may result in an accident. For

damage incurred during an accident the user of the machine is responsible.

4.4. Preparing the tractor to work

Preparation of a tractor to cooperation with a plough consists in checking its general

efficiency in accordance with the tractor manual (pay particular attention to the proper

operation of the suspension system). It is mandatory to aggregate the plough with

recommended tractor classes equipped with standard ballasts of front axle and rear

wheels in accordance with data given in the technical characteristics of the tractor. Air

pressure, particularly in rear tires of the tractor should be equal in both wheels and in

accordance with the tractor’s manual!

- 18 -

Figure 2. Position of the lower rods

Before suspension of the machine, lower rods of the tractor’s suspension system

shall be set in lower position at the same height (distance between joints and the ground is

minimum 200 mm). Rods set at the equal height from the ground facilitate mounting the

plough on the tractor.

4.5. Preparing the plough to work

Preparation of a new 1-beam plough to operation and after storage period (e.g. after

winter) consists in checking its technical condition and most of all durability of connections

of working elements with the frame. In case of stating damage or worn elements it is

necessary to exchange them into new or regenerated ones. Otherwise, it can lead to

reduction of the tool work quality.

CAUTION

It is forbidden for the operator to stay between the tractor and the machine at the tractor

engine running. The plough shall be raised easily, without jerks or vibrations.

In addition, it is necessary to:

- check screw connections, in case of backlash tighten the nuts,

- check if the copying wheel, adjustment screws and adjusting spindle move easily and

without jamming, in case of stating jamming of the supporting wheel, it shall be

uninstalled, cleaned and lubricated,

- lubricate the plough in accordance with recommendations (see section "Lubrication

instruction").

CAUTION

All maintenance in the plough shall be performed before installing it on the tractor.

4.6. Aggregation of the plough with a tractor

When connecting the plough to a tractor, it is necessary to make sure that:

- tractor lower rods are below plough suspension studs,

- connecting points of the tractor and plough are in the same category,

- in the transportation and working positions, lower and upper connecting points of the

plough with a tractor three-point suspension system are set in a vertical plane,

- during operation side stops of the lower rods allow for small clearance of the plough to

the sides, but during transportation side clearance of rods must be eliminated noting that

there is no collision between the tool and the surface of rear wheels and construction

elements of the tractor.

When mounting the plough on the tractor, perform following activities:

- disassemble a tool latch bar from lower rods of the tractor three-point suspension

system,

- drive to the machine frame close enough with the tractor,

- turn off the tractor engine, remove the key from the ignition switch and pull

handbrake,

- install tractor lower rods onto the suspension axle studs and secure them with typical

cotter pins,

- using a pivot, link the upper connector of the tractor with the plough frame rack and

secure with a typical cotter pin,

Table of contents

Other Bomet Tractor Accessories manuals

Popular Tractor Accessories manuals by other brands

Cozy Cab

Cozy Cab A-11836 installation instructions

Avantco

Avantco A21257 Operator's manual for Attachment

Avantco

Avantco A436473 Operator's manual for Attachment

Wallenstein

Wallenstein GE Series Operator's manual

Kongskilde

Kongskilde MT 3975 instruction manual

Tiger

Tiger TRIPLE FLAIL JD5 M T4F Series Mounting and operating instructions

Grouser Products

Grouser Products New Holland TC 40 installation instructions

Land Pride

Land Pride STB1560 Operator's manual

Frontier

Frontier BOX BLADES Series Operator's manual

GOLDONI

GOLDONI 32 Operation and maintenance

Degelman

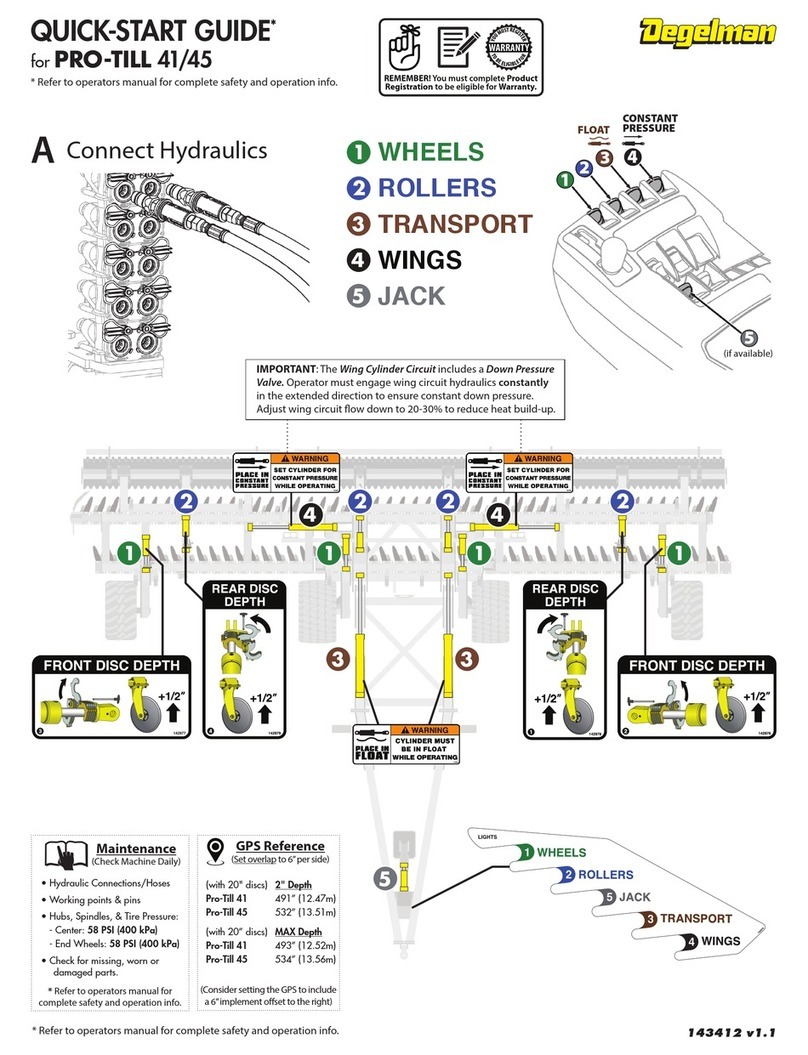

Degelman PRO-TILL 41 quick start guide

Winton

Winton WRT Series owner's manual