17

Parts List 1

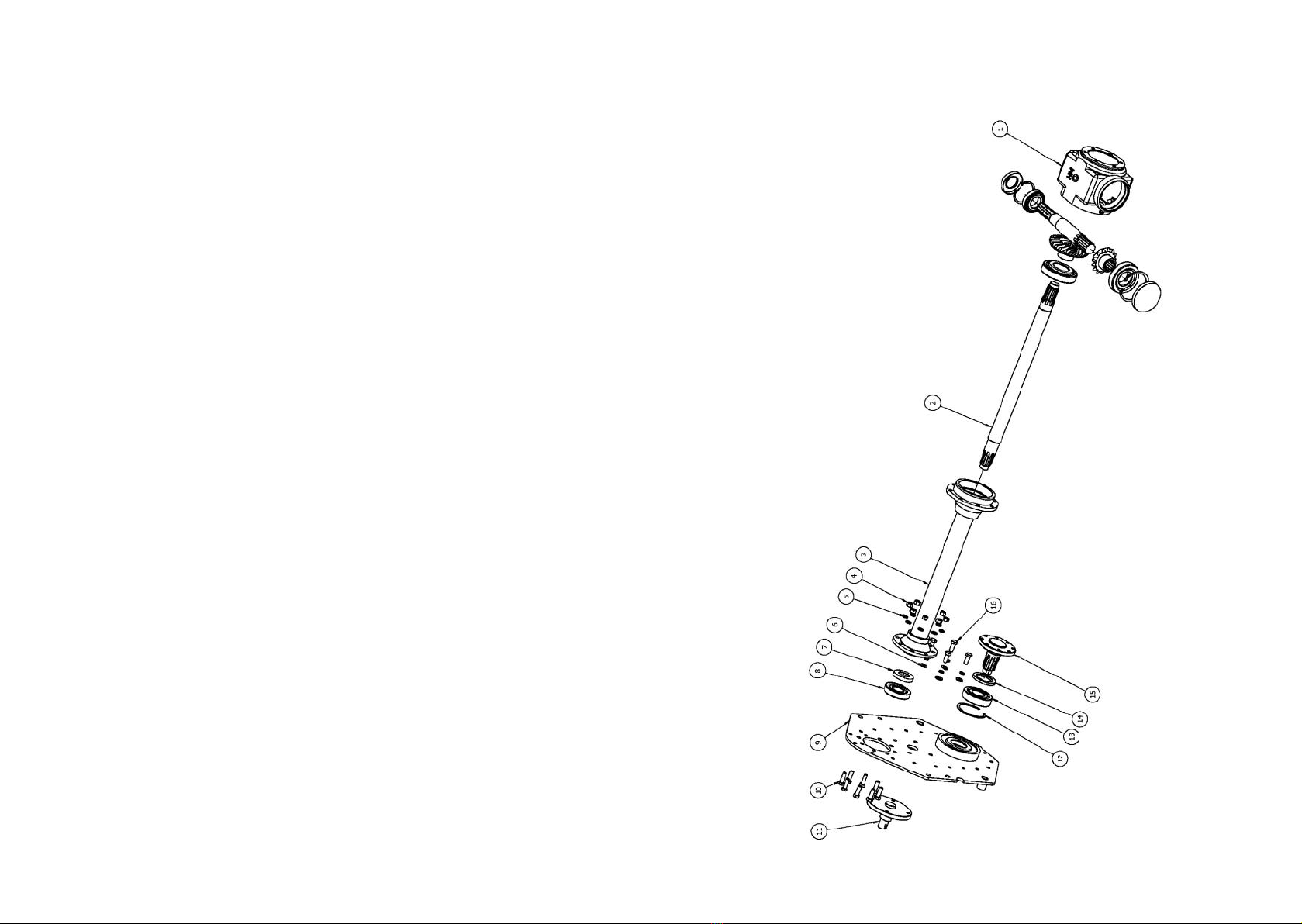

Diag

No. Number Part Number Part Description Qty

1-4803170002 1G-125.01.001 125 gear box and transmission 1

1-6803190150 1G-150.01.001 150 gear box and transmission 1

2703190207 1G150.04-03 Top gear 1

3703190206 1G150.04-02-1Intermediate middle gear 1

4703190205 1G150.04-01 Lower gear 1

5703190183 1G-150.01.102 Rubber gear guard gasket 1

6803190159 1G-150.01.012-1Gear guard cover 1

7703190235 1G-150.01.131 Nut M30x1.5 3

8506050068 GB858-30 Round nut lock washer M30 3

9511022614 GB276-6208 Deep groove bearing 2

10 506060191 GB893.1-80 Check ring 1

11 510013218 GB3452.1-G-28X3.55 O ring seal 1

12-4803170004 1G-125.00.011-2Blade rotor shaft 125 1

12-6803190006 1G-150.00.011-2Blade rotor shaft 150 1

13 803190120 1G-150.00.018 Stand support leg/bracing bar 1

14 703140007 ZL-25.103 Right angle pin 1

15-1803190102 1G-150.00.016 A frame plate right 125/150 1

16-1703190139 1G-150.00.106 A frame cover plate 1

17 703400179 FTL.125.124A Lower linkage pin 2

18 501011113 GB5783-M10X30 Bolt half thread M10 25

19 501010763 GB5782-M12X100 Bolt half thread M12 1

20 501010778 GB5782-M16X55 Bolt half thread M16 6

21-1803190111 1G-150.00.017 A frame plate left 125/150 1

22 506010059 GB97.1-16 Plain washer M16 6

23 506030039 GB93-16 Spring washer M16 6

24 503010049 GB6170-M16 Hex nut M16 6

25 703140006 MZ105.130 Spacer bush 1

26 501011126 GB5783-M12X30 Bolt M12 9

27 703140005 MZ105.115 Locking shim 1

28 511022652 GB276-6306 Deep groove bearing 1

29 501011858 GB5785-M12x1.25x35 Bolt half thread M12 12

30 510020427 GB13871-FB-35x62x12 Oil seal 1

31-3703190126 1G-150.00.103 125 left blade 18

31-4703190126 1G-150.00.103 150 left blade 21

18

Parts List 1 (Continued)

Diag.

No Number Part Number Part Description Qty

32-3703190125 1G-150.00.102 125 right blade 18

32-4703190125 1G-150.00.102 150 right blade 21

33-2803190051 1G-150.00.014 right-side plate 1

34 803190127 1G-150.00.104 Bearing cover plate 1

35 503010047 GB6170-M12 Nut M12 15

36 506030037 GB93-12 Spring washer M12 27

37 501011125 GB5783-M12X25 Bolt M12 4

38 803190048 1G-150.00.013 Skid/sliding board 2

39 501011128 GB5783-M12X40 Bolt M12 4

40 703190124 1G-150.00.101 Adjusting plate for skid 2

41 506010056 GB97.1-10 Plain washer M10 4

42 501011141 GB5783-M14X35 Bolt M14 10

43 506010058 GB97.1-14 Plain washer M14 12

44 506030038 GB93-14 Springwasher M14 13

45 503010048 GB6170-M14 Nut M14 9

46 501011111 GB5783-M10X20 Bolt M10 18

47 506030036 GB93-10 Spring washer M10 42

48 803190201 1G-150.01.136 End cap gearbox shaft 1

49 703190230 1G-150.00.130A V lower gearbox mounting plate 2

50 703190143 1G-150.00.109A V upper gearbox press plate 2

51 501011143 GB5783-M14X45 Bolt M14 4

52 506010057 GB97.1-12 Plain washer M12 6

53 508050061 GB91-3X28 Split/cotter pin 3

54-4703170133 1G-125.00.105 Back rod/rail (L1310) 125 1

54-6703190135 1G-150.00.105 Back rod/rail (L1560) 150 1

55-4803170025 1G-125-012-2Back shield 125 1

55-6803190027 1G-150-012-2Back shield 150 1

56 703190232 1G-150.00.147 Hexagonal steel rod 1

57 703340017 ZL-25.104 Big R pin 2

58 503010763 DIN985-M12 Nut M12 2

59 703190231 1G-150.00.145 Adjusting rod bracket 1

60 506010062 GB97.1-22 Plain washer 4

61 703190234 1G-150.00.149A Spring φ35X100 2

62 703190233 1G-150.00.148 Adjustment rod/tube 1

63 503010046 GB6170-M10 Hex nut M10 24

64-4803170060 1G-125.00.015 Body plate 125 1

64-6803190062 1G-150.00.015 Body plate 150 1