Spearhead MULTICUT 820 User manual

Spearhead MULTICUT 820

1

MULTICUT 820

7th Edition –October 2013

Part No. 8999026

Spearhead MULTICUT 820

2

Spearhead

MULTICUT 820

Handbook

7th Edition –October 2013

Important Note

The information contained in this manual is correct at the time of publication.

However, in the course of constant development, changes in specification are

Inevitable. Should you find the information given in this book different to the

Machine it relates to please contact the “After Sales Department” for advice.

© Spearhead Machinery Limited 2004

Please ensure that this manual is handed to the operator before using the

machine for the first time. The operator must fully understand the contents

of this manual before using this machine.

(If the machine is resold the Manual must be given to the new owner.)

Spearhead Machinery

Green View

Salford Priors

Evesham

Worcestershire

WR11 8SW

Tel: 01789 491860

Fax: 01789 778683

www.spearheadmachinery.com

enquiries@spearheadmachinery.com

Spearhead MULTICUT 820

3

CE Declaration of Conformity,

Conforming to EU Machinery Directive

2006/42/EC

We, Spearhead Machinery Ltd, Green View, Salford Priors,

Evesham, Worcestershire, WR11 8SW hereby declare that:

Product

……………………………………………..…………………………

Product Code

……………………………………………..…………………………

Serial No

……………………………………………..……..………………….

Type

……………………………………………..…………………………

Manufactured by: Alamo Manufacturing Services (UK) Limited, Station

Road, Salford Priors, Evesham, Worcestershire, WR11 8SW

Complies with the required provisions of the Machinery Directive

2006/42/EC. The Machinery Directive is supported by the following

harmonized standards:

BS EN ISO 14121-1 (2007) Safety of Machinery –Risk Assessment,

Part 1: Principles Part 2: Practical Guide and Examples of Methods.

BS EN ISO 12100-1 (2010) Safety of Machinery –Part 1: Basic

Terminology and Methodology Part 2: Technical Principles.

BS EN 349 (1993) + A1 (2008) Safety of Machinery –Minimum

Distances to avoid the Entrapment of Human Body Parts.

BS EN 953 (1998) Safety of Machinery –Guards General

Requirements for the Design and Construction of Fixed and Movable

Guards.

BS EN 982 (1996) + A1 (2008) Safety Requirements for Fluid Power

Systems and their Components. Hydraulics.

The EC Declaration only applies if the machine stated above is used in

accordance with the operating instructions.

Signed

(On behalf of Spearhead Machinery Ltd)

Status

General Manager

Date

………………………………………………

Spearhead MULTICUT 820

4

Contents

Contents 4

Safety 5

Introduction 8

Tractor Requirements 8

Attaching To The Tractor 8

Setting Up Your Machine 9

Operation 12

Transportation 13

Machine Protection 14

Servicing & Maintenance

Safety First 15

Daily 16

Every 8 Hours 17

Torque Settings 17

Regularly 18

Blades 18

Slip Clutch Settings 19

Skids 23

Storage 23

Trouble Shooting Guide 24

Spearhead MULTICUT 820

5

Safety Recommendations

Beware of the following Potential Dangers associated with the use of

this machine:

Becoming trapped when hitching or unhitching

Machine overbalancing when wing is raised.

Getting caught on rotating power take off (PTO)

Being hit or caught by any moving part, e.g. Blades, drive shaft and wings.

Being hit by flying debris or machine parts due to machine damage

Machine overbalancing when not in use

Injection of high pressure oil from damaged couplings or hydraulic hoses

Accidents due to collision with other machines, or debris left on road

Beware of free-swinging blades over centering and falling when wings are

folding.

ALWAYS:

Ensure the operator has read this handbook and has been trained to use the

machine.

Ensure all safety guards are in place and all tractor windows closed.

Impact resistant shielding to the tractor is recommended

Before leaving the tractor cab always ensures that the wings are firmly on the

ground, no weight is on the machine’s hydraulics and the rotor has stopped

spinning.

Check that all guards are properly fitted and there are no damaged or loose

parts. Particular attention should be given to the blades to ensure they are not

damaged, cracked or missing

Inspect work area for wire, steel posts, large stones and other dangerous

materials and remove before starting work.

Ensure that all warning labels are always visible and that they are not

damaged, defaced or missing.

Fit locking pins to height and strap to wings before transport and before

unhitching when applicable.

Wear ear defenders if operating without a quiet cab or with the cab windows

open

Ensure tractor guards are fitted correctly and are undamaged

Work at a safe speed, taking into account terrain, passing vehicles and

obstacles

Spearhead MULTICUT 820

6

Ensure that the tractor meets the minimum weight recommendations of the

machine manufacturer and that ballast is used if necessary

Check that machine fittings and couplings are in good condition

Follow the manufacturer’s instructions for attachment and removal of machine

from the tractor

Ensure blades are of the type recommended by the manufacturer, are

securely fitted and are undamaged

Ensure hydraulic pipes are correctly routed to avoid damage from chafing,

stretching, pinching or kinking.

Check condition of tyres and tightness of wheel nuts.

Ensure all blades have stopped spinning before folding wings into transport

position.

Disengage the machine, stop the engine and remove the key before leaving

the tractor cab for any reason

Clean up any debris left at the work site.

Ensure that when you remove the machine from the tractor it is secured in a

safe position using the stands provided.

NEVER:

Never operate the machine with other people present, as it is possible for

debris, including stones, to be discharged from the front and rear.

Never operate the machine until you have read and understood this

Handbook and are familiar with the controls.

Never use a machine that is poorly maintained or has guards that are

damaged or missing

Never allow an inexperienced person to operate the machine without

supervision.

Never use or fit a machine onto a tractor if it doesn’t meet the manufacturer’s

specification.

Never use a machine if the hydraulic system shows signs of damage.

Never attempt to detect a hydraulic leak with your hand, use a piece of card.

Never allow children to play on or around the machine at any time.

Never attempt any maintenance or adjustment without first disengaging the

PTO, lowering the wings to the ground, stopping the tractor engine and

applying the tractor parking brake.

Never leave the cab without removing the ignition key.

Never operate the tractor or any controls from any position other than from

the driving seat.

Never stop the engine with the PTO engaged.

Never operate with blades missing.

Never operate PTO above recommended speed, 1000 r.p.m.

Never operate with wire around the rotor. Stop immediately.

Never use the wing raised which may throw debris towards the cab.

Never attempt to use the machine for any purpose other than that it was

designed for.

Never transport with the PTO engaged.

Never enter the working area of the machine (risk of injury!).

Never engage the P.T.O with wings folded.

Spearhead MULTICUT 820

7

Safety

Warning

Avoid fluid escaping

under pressure. Consult

technical manual for

services procedures.

Warning

Danger –flying objects

keep safe distance from

the machine as long as

the engine is running.

Warning

Stay clear of mower blade

as long as engine is

running.

Warning

Stay clear of swinging

area of implements.

Warning

Shut off engine and remove

key before performing

maintenance or repair work.

Warning

Check all nuts are tight

every 8 hours.

Warning

Carefully read operator’s

manual before handling this

machine. Observe

instructions and safety rules

when operating.

Spearhead MULTICUT 820

8

Introduction

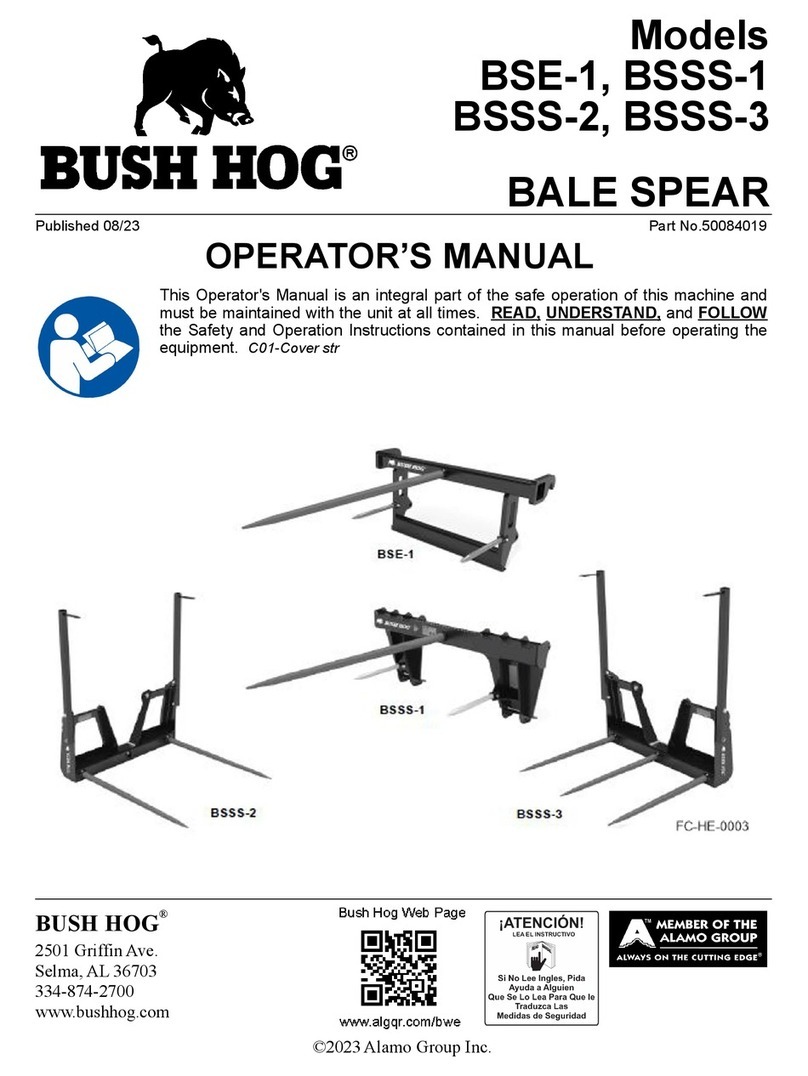

The Spearhead 820 is a heavy-duty rotary mower for a set-aside, stubble and

pasture topping. By carefully following the instructions in this handbook, the 820 will

give many years of trouble free operation.

Safety First

Never start using the machine until the handbook has been read and understood.

The 820 rotary mower is a potentially lethal machine if used incorrectly and it is

essential that the operator fully understands the working before starting up.

Tractor Requirements

Spearhead recommend tractors of plus 150 hp.

A clevis drawbar must be used. Do not use the pick-up hitch.

The tractor should have a minimum weight of 6000 kg.

The tractor should have a 1,000rpm p.t.o. 1 ¾ “ – 20 spline.

Two external hydraulic services are required, single acting for height control

and double acting for wings with float facility.

Attaching To The Tractor

It is essential to ensure that the tractor lift arms cannot foul the p.t.o. shaft, even

when the tractor is on full lock. It is advisable to remove them altogether if there is

any doubt.

The tractor drawbar should be extended to its maximum not less then 400mm from

the p.t.o. This will enable turning in work without damaging the drive shaft. Never

attach the mower using the

pick-up hitch as this will cause damage to

the drive shaft.

Fit the nylon washer between the mower

drawbar and the tractor clevis, as shown, to

reduce wear between the two parts. The

nylon washer is a replaceable wearing part.

Warning

Do not attach machine to pick

up hook. This will damage the

P.T.O. shaft

Spearhead MULTICUT 820

9

Setting Up Your Machine

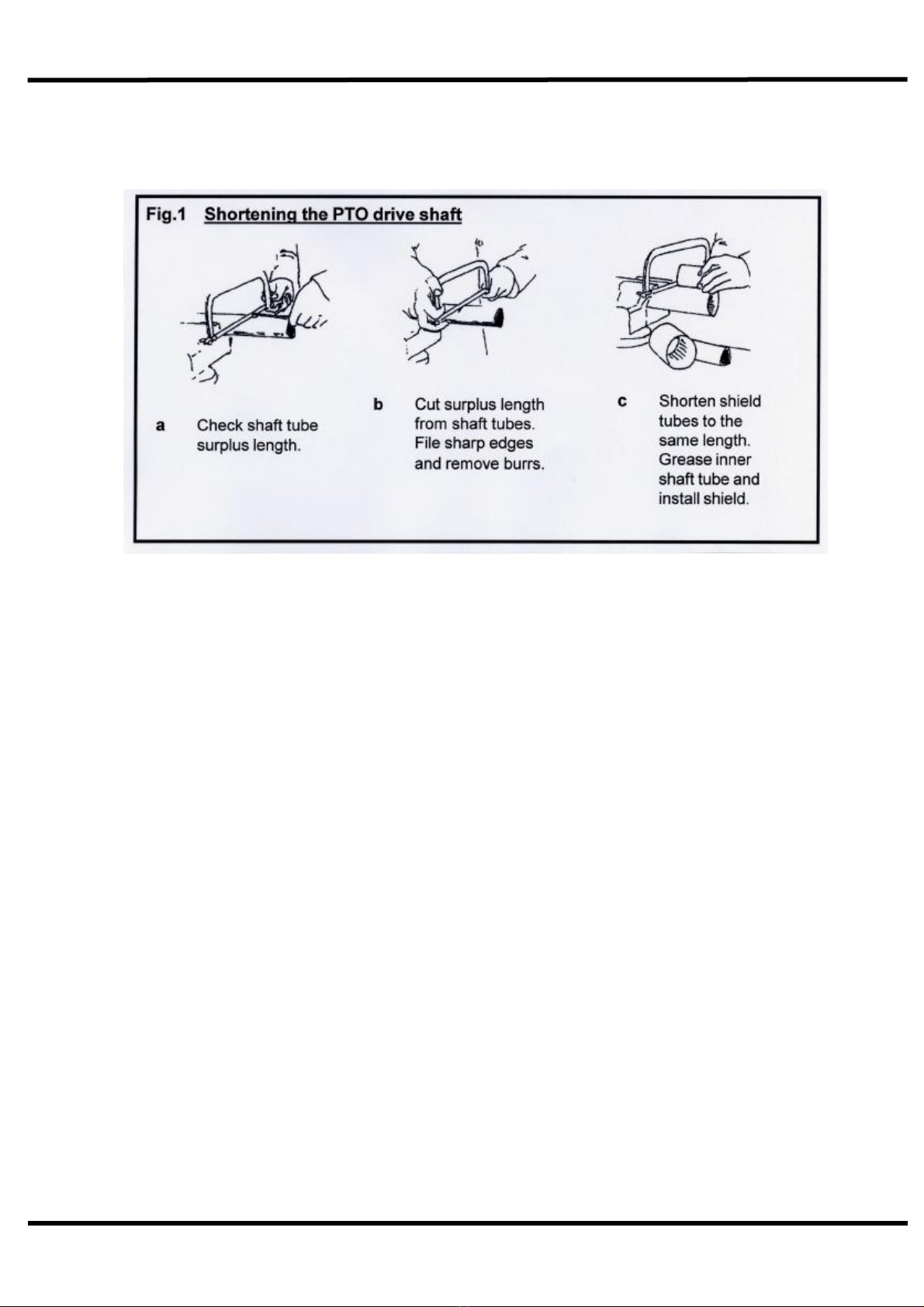

Before fitting the PTO for the first time, it may be necessary to adjust the length.

There should be maximum engagement of the sliding tubes without bottoming at the

shortest operation position. To check, first connect the mower to the tractor. Pull the

PTO shaft apart and connect to the tractor PTO output shaft and the gearbox input

shaft. Hold the half shafts next to each other in the shortest working position. If

necessary, shorten the inner and outer guard tubes equally (Fig. 1). Shorten the

inner and outer sliding profiles by the same length as the guard tubes. File all sharp

edges and remove burrs. Grease sliding profiles.

To fit the PTO, first clean and grease. Press pins on the yoke and simultaneously

push the PTO drive shaft onto PTO shaft of the tractor until pins engage.

The PTO shaft is fitted with a non-rotating safety guard. It should be secured to the

machine and tractor with the two retaining chains provided.

Connect the three hydraulic hoses, two wing hoses to a double acting service, with a

dump facility. This is particularly important for the spool valve that operates the wings

as, when in work the wings must be able to follow the ground contours. The 3rd hose

for the height ram only requires a single acting spool.

Spearhead MULTICUT 820

10

Setting Up Your Machine

Levelling –Front To Rear

Once coupled to the tractor, check the mower is cutting level from the front to the

rear of the machine. This is important to ensure each rotor will cut at the same height

(Fig. 3). The machine has adjustable tie bars that can be lengthened to lower the

front or shortened to raise the front of the machine by turning barrel nut (Fig. 2).

Once satisfied the mower is cutting level, tighten locking nuts.

Levelling –Wings LH & RH

With the machine in the working position and the wings folded down it may be

necessary to alter the height of the wing to ensure each rotor is cutting level.

Between each axle there is an adjustable link shortening this will raise the cutting

height of the wing rotor and blades. We recommend the wing is set 12-25mm higher

then the centre.

Warning

The machine is set at the factory with the centre deck 1” (25mm) higher at

the front and the wings ½” (12mm) higher to the centre section, when

mounted on the tractor drawbar at 16” (400mm).

When operating over uneven ground it is recommended to raise the front

of the machine by adjusting the tie bars to prevent scalping or damage to

the blades.

Spearhead MULTICUT 820

11

Setting Up Your Machine

Height

To adjust the minimum cutting height, first raise the machine to take the weight off

the centre height bar, lengthen the bar by turning the barrel and raising the minimum

height stop. Lower the machine onto this stop to the new set cutting height. This

adjustable barrel only controls the minimum cutting height, however the operator may

raise and lower the machine via the hydraulic cylinder whilst the machine is in

operation.

Wings

Before attempting to raise (Fig. 5) or lower the wings always ensure the machine is

on level ground. To unfold the wings from transport position, first charge/pressurise

the rams with oil before releasing the locking strap. Then power the wings over

centre with the aid of the double acting rams. Lower both wings on the ground and

release the hydraulic pressure by placing the spool in float position.

Warning

Do not pressurise the wing rams out once the wing wheels have

contacted the ground. This will cause unnecessary strain on

the machine and may result in damage not covered under

warranty.

Fig.5 Wings

Warning

Do not attempt to raise or lower the wings until the machine is on level

Ground. Never travel before both wings are either fully down or fully

Up and the transport strap is correctly fitted.

Spearhead MULTICUT 820

12

Operation

Once ready for work, raise the mower cutting height and slowly engage the PTO with

the tractor engine at low revs to prevent shock damage to the machine. Slowly

increase the engine revs to achieve the recommended PTO speed of 1000r.p.m. If at

any time serious vibration occurs, stop the engine immediately and check the

lades, following all safety precautions. Select a sensible forward speed bearing in

mind the density of growth, the terrain, and the available horsepower.

The quality of finish is determined by the forward speed, i.e. a slow speed will

produce a high quality of cut, where as faster forward speeds are used when high

output is first priority.

When in work, always ensure the hydraulic spool valve that operates the folding of

the wings is in float position to enable the wings to freely follow all contours of ground

(Fig. 6).

Whilst operating it is possible to continue working when turning as the 820 Rotary

Cutter is fitted with a constant velocity joint on PTO shaft. However take care not to

run the rear tractor wheel against the mower draw bar as this will result in serious

damage to the tractor, the mower and, in particular, the PTO shaft. The constant

velocity joint on the input PTO shaft, allows the PTO to be left in gear whilst turning

out of work, e.g. on the headlands. It is important not to turn sharply when the

machine is in work as this will over-strain and shorten the life of the constant

velocity joint.

When operating in confined areas it is possible to cut going backwards, but it is

advisable to slightly raise the machine, particularly if in scrub, where there is the risk

of hitting hidden solid obstacles obscured by dense undergrowth.

Always exercise particular care when operating over uneven ground surfaces. Do not

allow the blades and blade holder to frequently hit the ground.

Do not allow debris to build upon the cutting decks in dry conditions as this can be a

fire hazard, in wet conditions it will place unnecessary strain on the machine and may

foul the drive shaft causing damage.

Fig. 6 contours

of the ground

Warning

Do not run the machine with the wings raised. The risk of

debris and machine parts being ejected is greater as the

chain skirting is ineffective in this position.

Spearhead MULTICUT 820

13

Transportation

First disengage the PTO drive and ¾ raise the machine, fold the wings fully and

secure with transport strap (Fig. 7). Never transport along public highways with the

wings only supported by the hydraulics.

Please observe Public Highway Regulations, concerning the towing of implements,

and securely attach a registration and lighting board.

Warning

Avoid transporting machine at high speed over rough ground

Maximum speed on highway –20mph (30kph).

Fig. 7 Transportation position

Spearhead MULTICUT 820

14

Machine Protection

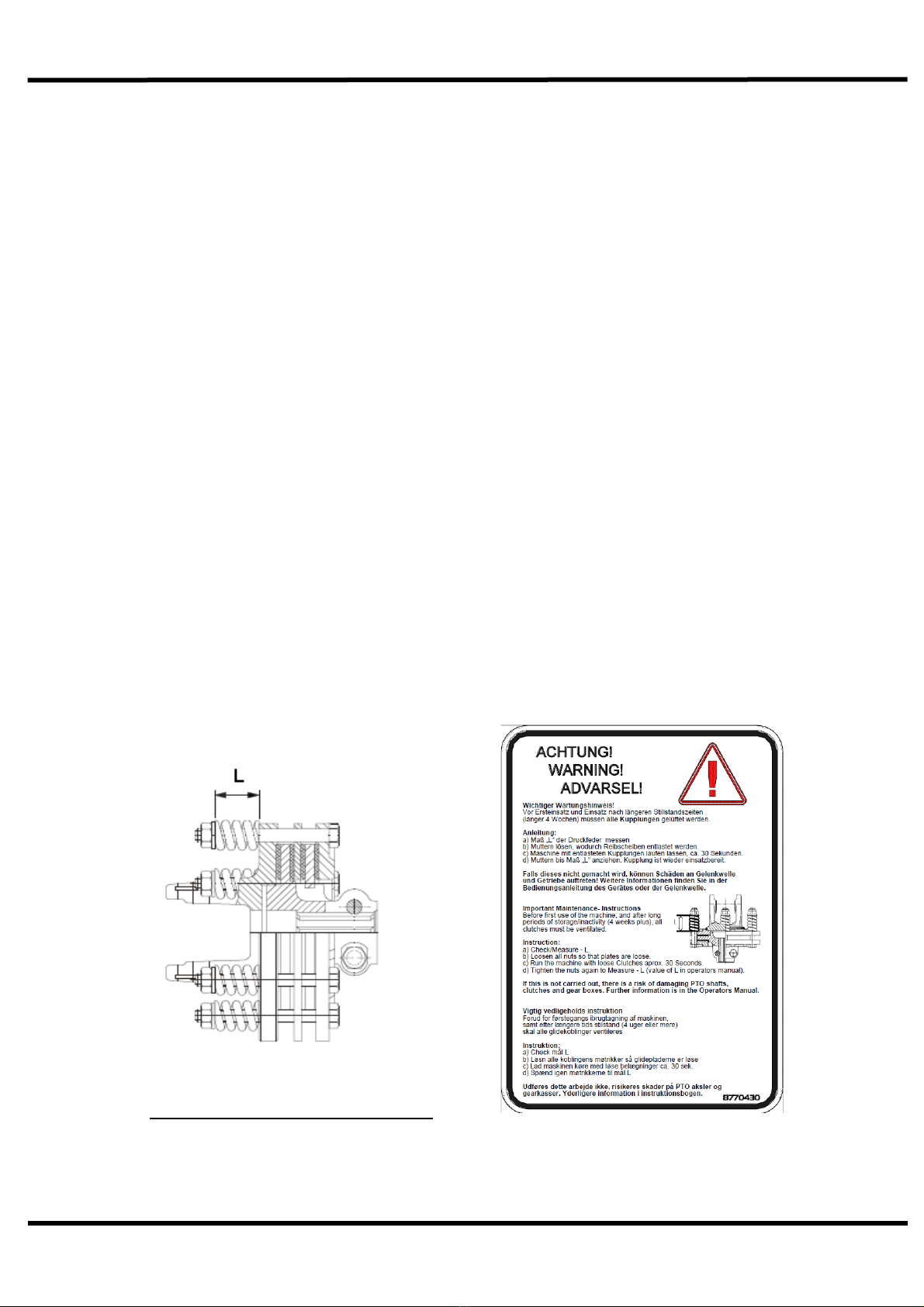

When the machine is delivered new, the slip clutch tensioning bolts will be

purposely left loose after initial PDI at Spearhead. This is to force the clutches

to be slipped and reset before the customer uses their machine for the first

time.

Refer to clutch settings on page 19/20/21.

To prevent gearbox damage all rotors are protected by slip clutches fitted to each of

the five drive shafts. When cutting in extreme conditions where stumps, rocks and

other such solid objects are likely to be found it is recommended that the operator

reduces the engine revs to allow the blades to pivot more easily when striking solid

objects, fit stump jumper plates to lower blade carriers, and procede with caution.

The clutch settings should not be altered without reference to Service and

Maintenance. Never over-tighten the pressure springs on the slip clutches (Fig. 8) as

this could result in severe damage to the gearbox and drive lines, as well as

invalidating the warranty.

If the machine has been laid up for any length of time, there is a risk of the

clutch plates rusting and seizing together. Never operate the machine in this

condition, as there will be no protection to the driveline and gearboxes against

shock loading. To free the clutch plates first slacken all pressure spring bolts and run

up the machine for a short period, deliberately try to cause the clutch to slip. Finally

re-tighten the tension spring bolts to their original length, taking great care not to

over-tighten. Alternatively refer to page 19/20/21.

If in any doubt, consult Spearhead’s Service Department or your local Spearhead

Dealer for further advice.

Fig. 8b Slip Clutch (WALTERSCHEID)

Spearhead MULTICUT 820

15

Service & Maintenance

Safety First

Never leave the tractor seat without first disengaging the PTO and

stopping the engine.

Ensure all rotating parts have stopped turning.

Never attempt any repairs, maintenance, service or any other

checks with the machine carried on the tractor hydraulics.

Always fully lower to the ground, or securely prop the machine on

substantial servicing stands.

Always replace all guards and retaining chains after

servicing/maintenance completed.

It is imperative that the following checks are carried out in order not to

invalidate your warranty; these are carried out before the first

operation, after the first hour, then after 4 hours.

These checks are:

1. Wheel nuts and tyre pressure (60psi).

2. Gearbox bolts, including the splitter box.

3. Oils in all the 6 gearboxes.

4. Blade bolts are fully tightened and in particular the 5 castle headed

nuts on the 5 blade rotors.

5. Retaining bolts on the drive shafts.

6. Grease all points including drive shaft tubes.

7. After the first 50 hours drain and the gearboxes of oil. Replace

with EP90 gear oil.

8. All other nuts and bolt

Warning

Never carry out any servicing or maintenance work without

first disengaging the PTO and then stopping the tractor

engine before leaving the seat.

On delivery of your machine check that the dealer has

completed the P.D.I form, ensure the warranty registration

form is completed and returned.

Spearhead MULTICUT 820

16

Servicing & Maintenance

Daily

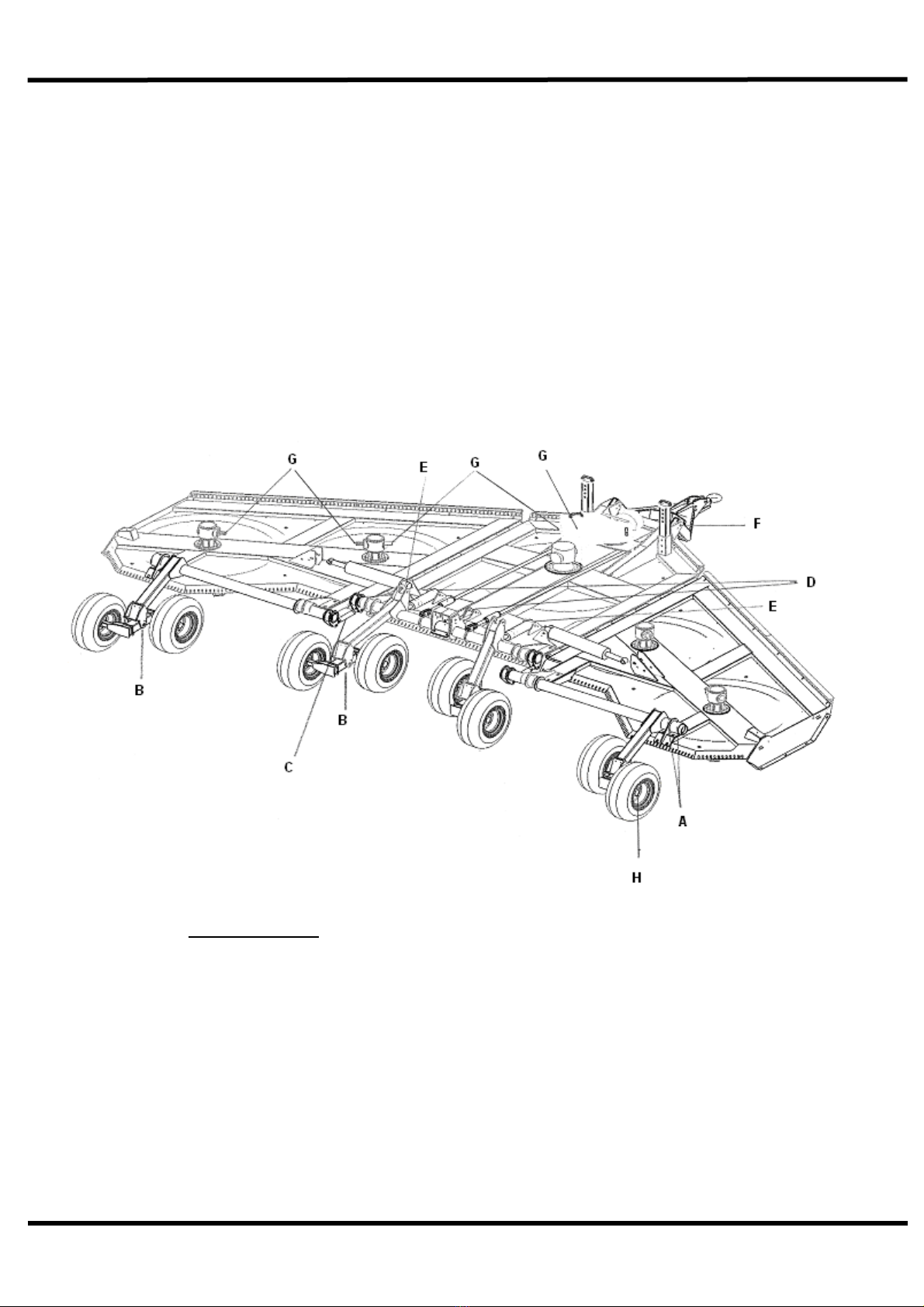

Grease all grease points, including rear axle pivot points (Fig. 9a), axle hinge

(Fig. 9c), wheel arms (Fig. 9b), and front draw bar pivot (Fig. 9f).

Check bolts are tight on all gearboxes.

Check condition of blades and blade bushes ensure all retaining bolts are

fully tight.

Check wheel nuts are tight.

Check tyre pressures - 60 P.S.I

Check gearbox oil, replenish with EP90 gear oil as necessary to the correct

level line on the dipsticks provided with each gearbox.

Fig.9. Greasing points

A. Rear axle pivot point.

B. Wheel arm pivot point.

C. Axle adjuster.

D. Height stop.

E. Hydraulic rams

F. Drawbar

G. Drive shaft

H. Wheel bearings

Spearhead MULTICUT 820

17

Service & Maintenance –Every 8 hours

Dismantle and clean the main input P.T.O shafts sliding surfaces and re-

grease; failure to do this will result in serious damage to the splitter gearbox.

Grease all universal joints, (Fig. 10) paying particular attention to the constant

velocity joint. If under-greased this constant velocity joint will soon fail.

Grease the wing drive shaft tubes, (note the hole in the plastic tubing for

access).

Lubricate the retaining collar on all the drive shaft guards (Fig. 10).

Grease PTO inner tube and push pins (Fig. 10).

Check all bolts are tightened to the correct Torque (Fig.11).

Torque Settings

The Torque figures given below are recommended maximum settings only.

Size:

Tensile strength:

Description:

Torque setting:

Nm.

M16

8.8

Gearbox bolts

280

M24

8.8

Axle clamps

750

M24

8.8

Blade bolts

540-800

Wheel nuts

270

For maximum life and performance, the CV body must be greased regularly. Lubricate with

the driveline in a straight position - up to 30 pumps of grease may be required.

The metal drive tubes must be greased to operate properly.

Shielding is subject to damage from abuse and weathering. Replace all damaged

components and all shielding removed during maintenance.

Do not use PTO adapters with CV drivelines. Replace special taper pin bolts only with

genuine OEM parts, periodically check tightness of nuts.

Fig. 10

Primary Input Shaft

Spearhead MULTICUT 820

18

Servicing & Maintenance

Regularly

Check there is no wrapping of string, plastic, grass or other debris between

rotor boss and gearbox oil seal.

Inspect gearbox seals for leaks.

Clear grass and other debris from the deck.

Regularly check the rotor boss retaining castle nut for tightness. First remove

the split pin, select the correct size socket in 3/4” drive and fully tighten the

nut. When replacing the split pin, do not slacken the nut to align the hole,

always tighten. Failure to regularly check this nut will result in serious wear to

hub, which is expensive to repair.

It is most important that all gearbox bolts are regularly checked to be

very tight. When the machine is new there will be a ‘bedding in’ period

where very frequent checking is important.

Blades

Caution! When carrying out maintenance work on or near the blades be careful

of free-swinging blades over-centering and falling. It is recommended that

protective clothing including hardhat and goggles are worn.

The blades can be re-sharpened by grinding the cutting edges, care must be taken

that the blades are of the same weight and length after grinding. Do not overheat

when grinding as this will affect the hardness of the blades. All the blades are free

swinging and swivel on hardened steel bushes, which are replaceable. When

replacing blades, it is important that blades are replaced in sets, in order to retain

balance of the rotor. Bushes must be replaced when new blades are to be fitted.

If the blades are showing any signs of severe wear, damage or cracking, they must

be replaced immediately. Never attempt to weld the blades, as this will make them

very brittle thus extremely dangerous. Do not take risks with the cutting blades - if in

doubt, replace.

Spearhead MULTICUT 820

19

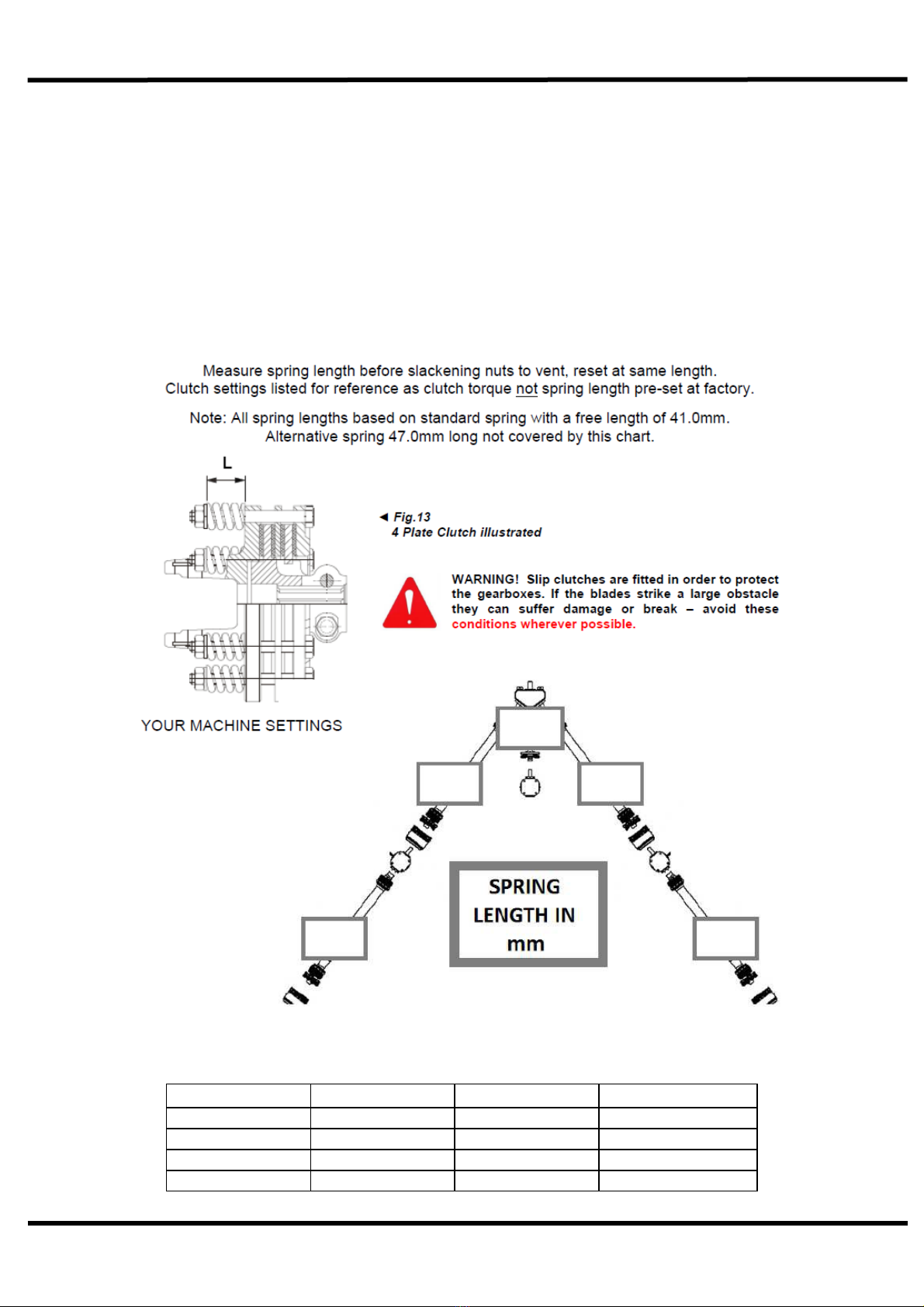

Servicing & Maintenance

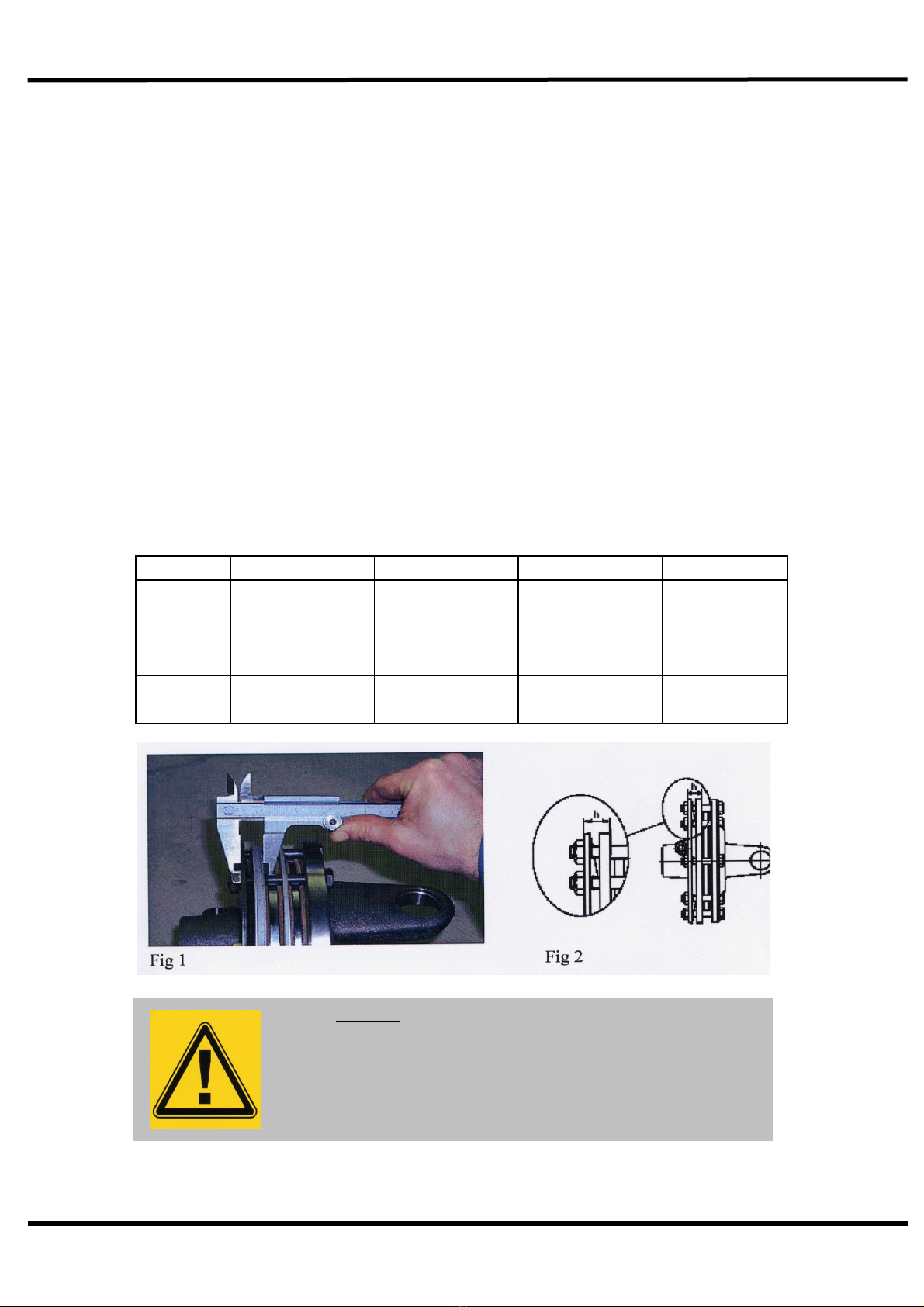

Slip Clutch Settings

We recommend that friction clutches be stored in a dry place with the spring pressure

released. In use, the compression of the spring has to be adjusted periodically to

compensate for lining wear and to maintain the setting at the original value.

Check the condition of the friction discs before use and following periods of storage.

Release the tension from the spring, turn the clutch while holding the gearbox shaft

stationary. Adjust the spring compression to the original setting (fig. 1).

Following seasonal use, unload the spring tension and stone clutch assembly in a dry

place. Check condition of friction linings and reset spring compression to original

height before use.

Should the assembly overheat due to frequent or prolonged clutch slipping, dismantle

for inspection. The original thickness of the lining is 3.2mm, replace them when worn

to 2.5mm. Clean up all contact surfaces and replace any damaged components

before assembly.

BONDIOLI Manufacture (Belleville Spring)

Fig. No.

Position

Part No.

Setting ‘h’

Machine

2

Centre

5770043

18.5 mm (fig 1)

820

2

Inner wing

5770213

19 mm (fig 1)

820

2

Outer wing

5770214

18 mm (fig 1)

820

Warning

The slip clutch is there to protect the gearbox. If the

blades strike a large obstacle they may get damaged or

break - avoid these conditions.

Spearhead MULTICUT 820

20

Servicing & Maintenance

Slip Clutch Settings

WALTERSCHEID Manufacture (Coil Spring)

Check the condition of the friction discs before use and following periods of storage.

Release the tension from the spring, turn the clutch while holding the P.T.O to ensure

hub is not seized to linings.

Clutch settings below are for reference only. Measured spring lengths should be

used first.

Position

Part No.

Setting ( L )

Machine

Centre

5770441

35.0 mm

820

Centre

5770468

38.1 mm

820

Inner wing

5770442

37.8 mm

820

Outer wing

5770443

37.5 mm

820

Table of contents

Other Spearhead Tractor Accessories manuals