Safety Rules 4

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident preven-

tion are dependent upon the awareness, con-

cern, judgement, and proper training of person-

nel involved in the operation, transport, mainte-

nance and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.”We ask you to be

that kind of operator.

TRAINING

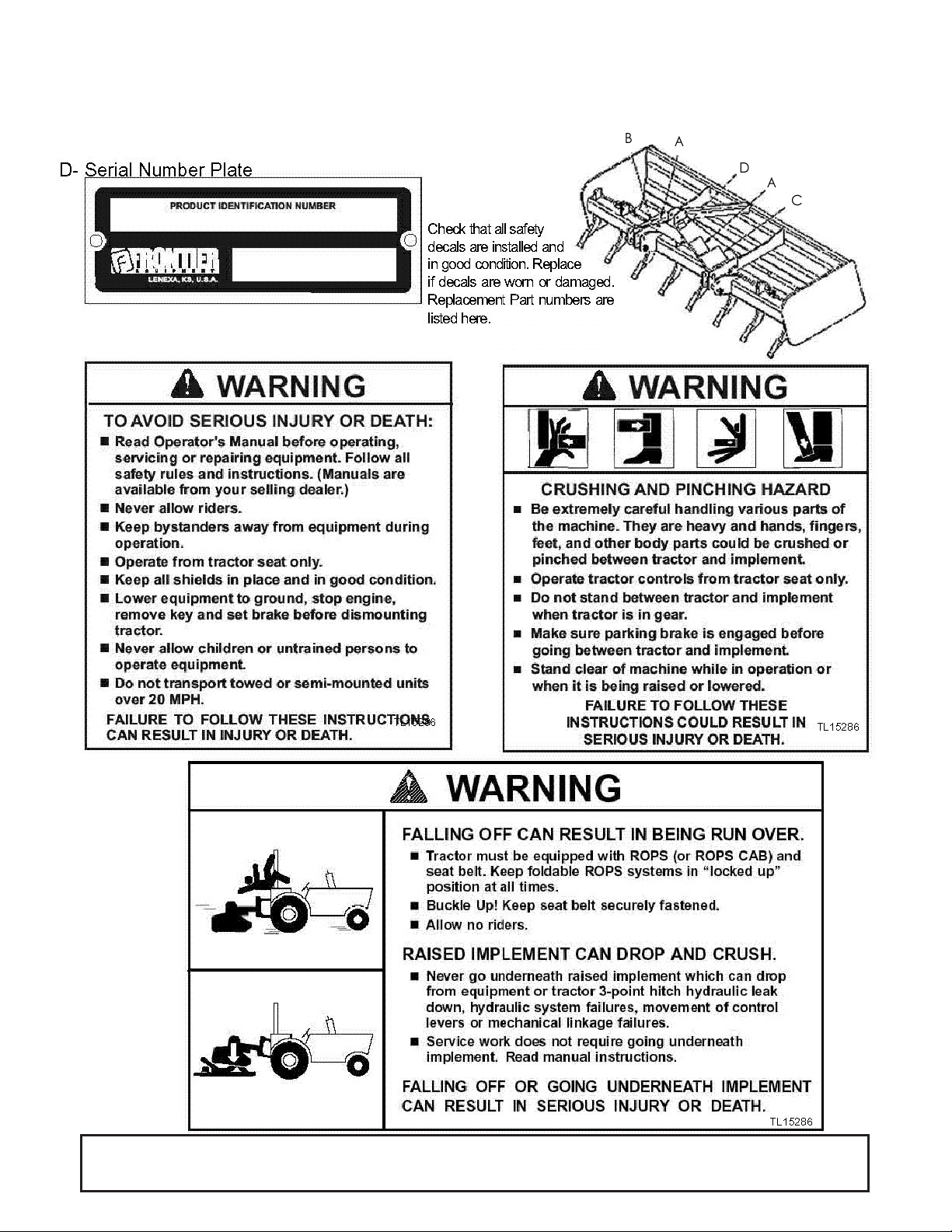

• Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information.

(Replacement manuals are available from sell-

ing dealer.) Failure to follow instructions or

safety rules can result in serious injury or

death.

• If you do not understand any part of this man-

ual and need assistance, see your dealer.

• Operators must be instructed in and be capa-

ble of the safe operation of the equipment, its

attachments, and all controls. Do not allow any-

one to operate this equipment without proper

instructions.

• Never allow children or untrained persons to

operate equipment.

• Train all new personnel and review instruction’s

frequently with existing workers. A person who

has not read and understood all operating and

safety instructions is not qualified to operate the

machine. An untrained operator exposes himself

and bystanders to possible serious injury or

death.

PREPARATION

• Always wear relatively tight and belted clothing to

avoid getting caught in moving parts.Wear sturdy,

rough-soled work shoes and protective equip-

ment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropri-

ate.

• Make sure attachment is properly secured,

adjusted, and in good operating condition.

• Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt

securely fastened. Falling off power unit can

result in death from being run over or crushed.

Keep foldable ROPS system in “locked up”

position at all times.

• A minimum 20% of tractor and equipment

weight must be on the tractor front wheels

when attachments are in transport position.

Without this weight, tractor could tip over, caus-

ing personal injury or death. The weight may be

attained with a loader, front wheel weights, bal-

last in tires or front tractor weights. Weigh the

tractor and equipment. Do not estimate.

TRANSPORTATION

• Always comply with all state and local laws

governing highway safety and lighting and

marking requirements.

• Never allow riders on power unit or attach-

ment.

• Do not operate or transport on steep slopes.

• Use extreme care and reduce ground speed

on slopes and rough terrain.

• Do not operate or transport equipment while

under the influence of alcohol or drugs. Consult

your doctor about operating this machine while

taking prescription medications.

OPERATION

• Never go underneath equipment (lowered to

the ground or raised) unless it is properly

blocked and secured. Never place any part of

the body underneath equipment or between

Safety Rules continued on next page.