Bona Plus User manual

To register your machine

visit Bona.com/register

Bona®Power Station Plus

OPERATING MANUAL

Bona®Power Station Plus Manual

2

Bona.com

800.872.5515

For a new manual contact:

Bona US

24 Inverness Place East, Suite 100

Englewood, CO 80112

Tel +1 303.371.1411

+1 800.872.5515

Fax +1 303.923.1461

www.Bona.com

Foreword

3

Table of Contents

Foreword 2

Table of Contents 3

Technical Data 4

Material Specication 4

Electrical Requirements & Wiring Instructions 5

Directions 6

Maintenance, Service & Repairs 6

Maintenance 6

Service 6

Spare parts and exploded views 6

Warranty 7

4

Bona.com

800.872.5515

Bona®Power Station Plus Manual

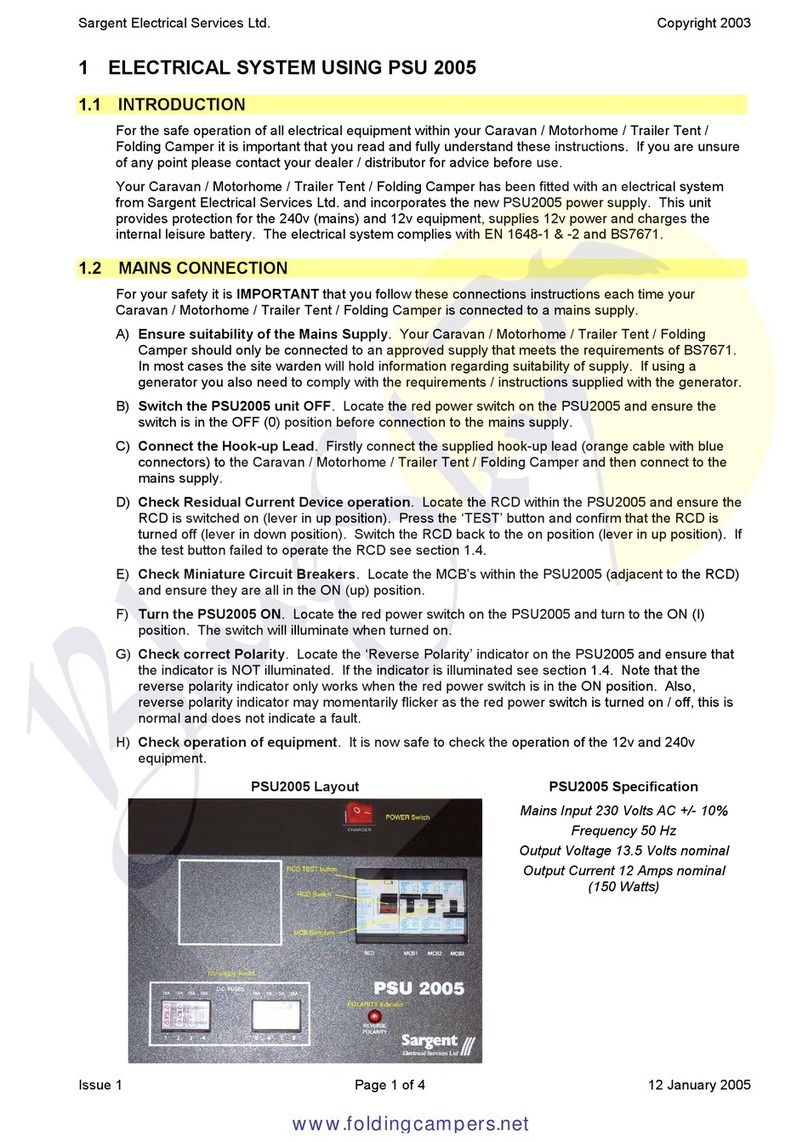

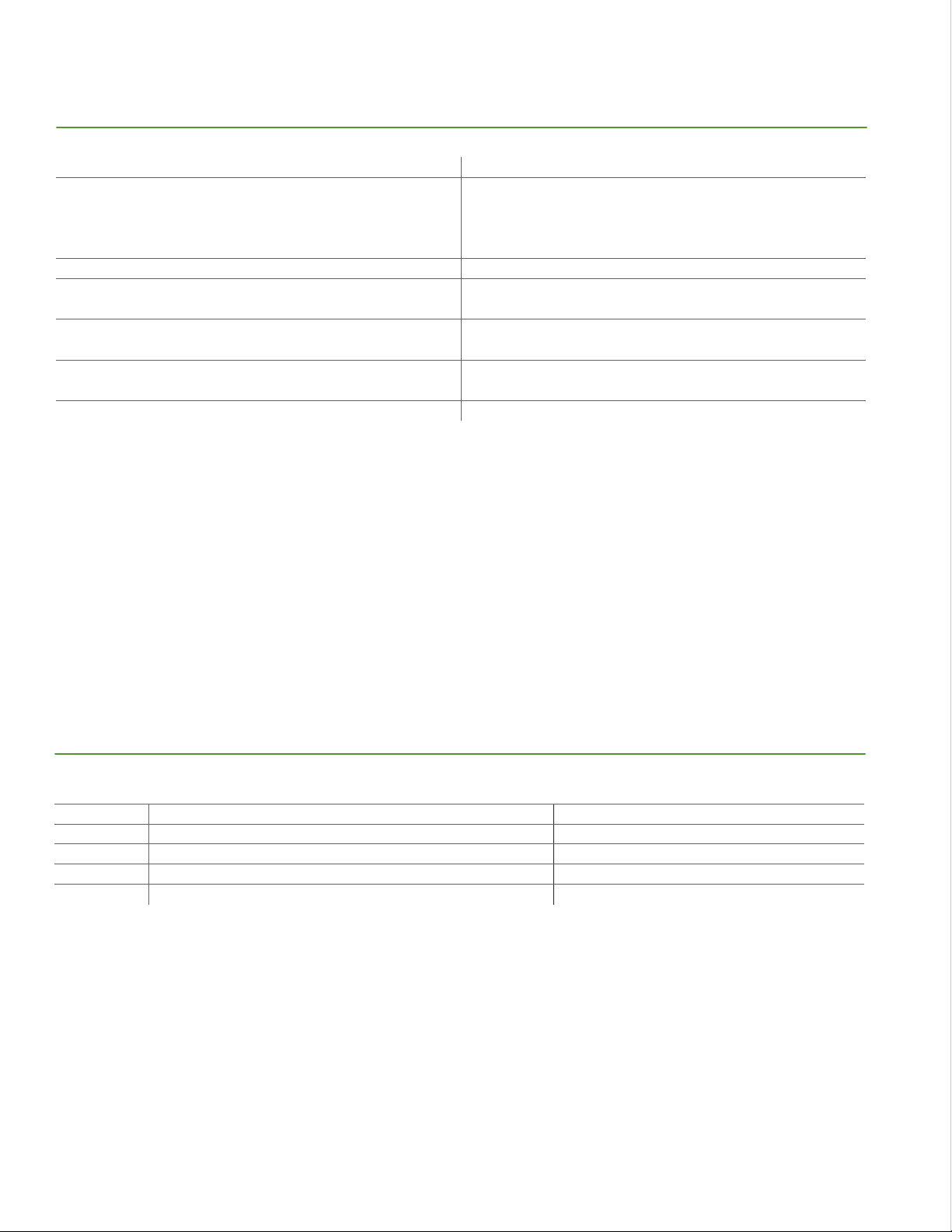

Technical Data

Material Specication

Electrical Capacity: 7.2 KVA

Working Capacity:

• 30 AMPS via the 230-volt output receptacle

• 20 AMPS via the twin outlet receptacle (all outlets work

simultaneously, see special instructions in "Electrical

Requirements & Wiring Instructions)

Input: (1) 4-wire, GFI, 230 volt/30 AMP twist-lock

Output: • (1) 3-wire, 230 volt 30 AMP twist-lock

• (1) 115 volt 20 AMP duplex, straight leg receptacle

Pigtail: 230 volts 30 AMP twist-lock with 10-4 cable to connect

Bona®Power Station Plus to the power supply

Dimensions: 5-7/8"W x 12-7/8"H x 5"D

Weight: 29 lbs.

Standard (included on delivery)

Key Article Article Number

A Bona®Power Station Plus AM0002417

B 10' 10-4 cable AS1200145 (Order per linear foot)

C 230 volts 30 AMP twist-lock AS1200114

D Operating Manual

We congratulate you on your purchase of the Bona®Power Station Plus, a safe and convenient way to protect

your valuable oor sanding equipment from high -or low-voltage power situations. Use it as a power center to

centrally connect your installation and oor sanding equipment. Use it to effectively run your oor sanding and

vacuuming equipment and adjust the power for your 230V units if your power supply drifts from the desired

voltage range.

Carefully read through the entire user manual before you begin working with the machine. This machine is

intended for professional use only.

5

Electrical Requirements

& Wiring Instructions

DANGER means: You or other staff can suffer a serious injury or death if the instructions marked

with DANGER on this machine or in these user instructions are ignored or not followed. Read the

entire user manual before you use the machine.

DANGER: Failure to properly ground the Bona®Power Station Plus can result in

serious injury and death.

The Bona®Power Station Plus is a buck/boost transformer. It

provides the operator of a 220V wood oor sanding machine the

opportunity to buck down or boost up the voltage as needed to

provide the optimum voltage required to operate the motor on

the sanding machine properly. Bona sanding equipment requires

230V service as the optimum power feed.

The Bona Power Station Plus also provides a 110V duplex outlet

located on the unit's front face as a convenience to the end-user

to operate a small hand tool, buffer, or vacuum product. The Bona

Power Station Plus is a four-wire system providing two 110V hot

leads, a neutral return wire, and a ground wire. This four-wire

arrangement allows for the inclusion of the 110V duplex outlet,

which permits use simultaneously with the 220V outlet on the

transformer. When properly connected to a four-wire 220V/230V

service such as a Residential dryer or stove outlet, the Bona

Power Station Plus will operate as intended.

However, when the Bona Power Station Plus is connected to an

existing three-pronged dryer or stove outlet by a three-wire

pigtail setup (two 110V hot legs and a ground wire), the 110V

duplex outlet on the Bona Power Station Plus will be rendered

useless. The 220V motor will run properly in this arrangement and

will be properly grounded.

For the 110V duplex to work and be properly grounded, there

must be a FOURTH wire (the white return wire) to complete the

circuit. Concerning the above-mentioned three-wire pigtail, a

four-pronged female connector can be attached to the end of the

three-wire cable, which can be connected to the four-pronged

male connector coming from the four-wire line on the input side of

the Bona Power Station Plus. Because this three-wire pigtail has

no "return white wire," the 110V duplex will be rendered useless.

If the product user wishes to activate the 110V duplex, the user

must revert to a four-wire arrangement.

A certied electrician must install a four-wire drop with a four-

pronged female NEMA connector to connect to the four-wire cable

and male connector coming from the Bona Power Station Plus. Do

not attempt this if you are not a certied electrician.

Three-pronged dryer and stove outlets were the standard service

outlets for residential construction until around 1998 when NEMA

standards changed to the four-wire system. When using the Bona

Power Station Plus, employ a certied electrician to make any

additional electrical connections to any job site electrical service

that will not allow the sanding equipment operator to connect the

Bona Power Station Plus following the product's intended use.

If the sanding equipment operator chooses to have a certied

electrician prepare an electrical service connection using a three-

wire, three-pronged plug, it must be understood that the 110V

convenience duplex will not be operable.

NEVER connect the neutral and ground wires in a four-wire cable

to accommodate a three-pronged plug. This incorrect connection

can result in electrical shock due to improper grounding.

Bona®Power Station Plus Manual

6

Bona.com

800.872.5515

Directions

The Bona® Power Station Plus is the safe, inexpensive and convenient way to protect your valuable oor sanding equipment from high

or low-voltage power situations. Use it as a power center to centrally connect your installation and oor sanding equipment. Use it to

effectively run your oor sanding and vacuuming equipment and adjust the power for your 230V units if your power supply drifts from

the desired voltage range.

You have the choice of using the Bona Power Station Plus as a static power center for your 230V and 115V equipment or as a buck/

booster for the 230V equipment when the circumstances dictate. Read the LED meter occasionally to see if the voltage feed from

your primary power source has changed enough to warrant a boost or decrease in power. The 115-volt (non-boosted) outlet offers

a convenient 20 Amp power source protected internally via a circuit breaker with an external reset button (This circuit breaker offers

equipment protection from power surges).

Maintenance, Service & Repairs

To keep the machine in a safe and functioning condition, perform maintenance on the machine regularly. Always disconnect the power

cable to the machine before cleaning, changing tools, performing maintenance, or replacing worn parts.

The Bona®Power Station Plus is a high-quality machine and is tested by authorized test staff at the factory before delivery. However,

electrical and mechanical parts wear down and age during long-term use. Only Bona's original parts may be used because the machine

is considered unique; otherwise, safety functions can become impaired. When you contact Bona or staff approved by Bona in the event

of a fault or to order spare parts, always specify the type and serial number of your machine. This information is located on the data

plate of the machine. The machine may never be cleaned using a high-pressure washer or hose.

To locate a list of spare parts and exploded views for the Bona Power Station Plus and other machines in our product range, visit

http://spareparts.bona.com/

During the factory warranty period, repairs may only be carried out by Bona or staff approved by Bona. Other repairs (after the warranty

period) of mechanical or electrical parts on the machine may only be carried out by Bona or staff approved by Bona who has experience

and knowledge concerning safety regulations.

Maintenance

Service

Spare parts and exploded views

7

Warranty

There is a 24 month factory warranty (from the date of invoice) against material and manufacturing faults. In the event of a warranty

claim, the machine or agreed upon part must be returned to Bona or staff approved by Bona with paid freight for warranty testing and

for potential repair or replacement under warranty. During the factory warranty period, repairs may only be carried out by Bona or staff

approved by Bona. We do not undertake any other form of compensation or liability to damages.

THE WARRANTY DOES NOT COVER

• Consumable materials such as wheels, electrical cables, abrasives, lamps, etc.

• Indirect damage, damage and errors that occur due to external damage, accidents, and/or repairs performed outside of our

knowledge and approval, or damages for another reason outside of our control.

• Transport damage or transport costs. In the event of transport damage it is up to the receiver to contact the relevant transport

company for compensation.

• Cases of incorrect use, overloading, carelessness or poor maintenance

• The use of parts produced by another company outside of our control.

• Electrical components, if the voltage variations are beyond those set out in the technical specication.

• If payment for the machine is not made according to the agreement.

REV 052421

Bringing out the best in hardwood oors.

At Bona, we are committed to the lifetime of hardwood oors. We are devoted to providing solutions that keep

a oor perfect during its entire life. Through our long commitment and constant search for innovation we offer

lasting, sustainable results for professionals and oor owners.

Bona is a family-owned company founded in 1919. With its headquarters in Sweden, Bona is now present in

more than 90 countries all over the world through subsidiaries and distributors. We provide products for the

installation, maintenance and renovation of hardwood oors throughout their lifetime. Today we have solutions

for professionals, homeowners and prenished manufacturers.

B

O

N

A

S

Y

S

T

E

M

To register your machine visit

Bona.com/register

Bona.com • 800.872.5515

@bona_pro

@bonauspro

Bona Professional

Table of contents