Bona Power Scrubber User manual

REV 3/11

English 2

To reduce the risk of fire, electric

shock, or injury:

–Do not leave appliance when

plugged in. Unplug from outlet when

not in use and before servicing.

–TO REDUCE THE RISK OF ELEC-

TRIC SHOCK-USE INDOORS

ONLY

–Do not allow to be used as a toy.

Close attention is necessary when

used by or near children.

–Use only as discribed in this manu-

al. Use only manufacturer`s recom-

mended attachments.

–Do not use with damaged cord or

plug. If appliance is not working as it

should, has been dropped, dam-

aged, left outdoors, or dropprd into

water, return it to a service center.

–Do not pull or carry by cord, use

cord as a handle, close a door on

cord, or pull cord around sharp edg-

es or corners. Do not run appliance

over cord. Keep cord away from

heated surfaces.

–Do not unplug by pulling on cord. To

unplug, grasp the plug, not the cord.

–Do not handle plug or appliance

with wet hands.

–Do not put any object into openings.

Do not use with any opening

blocked; keep free of dust, lint, hair,

and anything that may reduce air

flow.

–Keep hair, loose clothing, fingers,

and all parts of body away from

openings and moving parts.

–Turn off all controls before unplug-

ging.

–Use extra care when cleaning on

stairs.

–Do not use to pick up flammable or

combustible liquids, such as gaso-

line, or use in areas where they may

be present.

–Connect to a properly grounded

outlet only. See Grounding Instruc-

tion.

This appliance must be grounded. If it

should malfunction or breakdown,

grounding provides a path of least re-

sistance for electric current to reduce

the risk of electric shock. This appli-

ance is equipped with a cord having an

equipment-grounding conductor and a

grounding plug. The plug must be in-

serted into an appropriate outlet that is

properly installed and grounded in ac-

cordance with all local codes and ordi-

nances.

Improper connection of the equipment

grounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are

in doubt as to whether the outlet is

properly grounded. Do not modify the

plug provided with the appliance-if it

will not fit the outlet, have a proper out-

let installed by a qualified electrician.

This appliance is for use on a nominal

120-volt circuit and has a grounding at-

tachment plug that looks like the plug il-

lustrated in illustration A. Make sure

that the appliance is connected to an

outlet having the same configuration as

the plug. No adaptor should be used

with this appliance.

1 Grounded outlet

2 Grounded outlet Box

3 Grounded Pin

Safe operation is in the responsibility of

the operator.

The operator shall be familiar with the

operation and function of all controls

and instruments before operating the

unit.

Before operating the unit, operators

shall have read and be familiar with the

operator’s manual for the particular unit

being operated and they shall also

abide by the safety rules and practices

in the following paragraphs.

Before operating any unit, the operator

shall be familiar with unusual operating

conditions which may require addition-

al safety precautions or special operat-

ing instructions.

Before starting to operate the unit be in

operating position.

Do not start or operate the unit, any of

its functions or attachments, from any

place other than from the designated

operators position.

Before leaving the operator’s position:

A bring the unit to a complete stop;

B if the unit must be on an incline,

block the wheels.

Maintain a safe distance from the edge

of ramps, platforms, and other similar

working surfaces.

Do not add to, or modify the unit.

Do not block access to fire aisles, stair-

ways or fire equipment.

IMPORTANT SAFETY IN-

STRUCTIONS

READ ALL INSTRUCTIONS

BEFORE USING.

WARNING

WARNING

SAVE THESE INSTRUCTIONS

GROUNDING INSTRUCTIONS

WARNING

CONNECT TO A PROPERLY

GROUNDED OUTLET ONLY

OPERATINGSAFETYRULES

AND PRACTICES

Operator Responsibility

General

3English

If the unit is found to be in need of re-

pair or in any way unsafe, or contrib-

utes to an unsafe condition, the matter

shall be reported immediately to the us-

er’s designated authority, and the unit

shall not be operated until it has been

restored to safe operating condition.

If during operation the unit becomes

unsafe in any way, the matter shall be

reported immediately to the user’s des-

ignated authority, and the unit shall not

be operated until it has been restored

to safe operating condition.

Do not make repairs or adjustments

unless specifically authorized to do so.

Operation of the unit may be hazard-

ous if maintenance is neglected or re-

pairs, rebuilds, or adjustments are not

performed in accordance with the man-

ufacturer’s design criteria. Therefore,

maintenance facilities (on or off pre-

mises), trained personnel, and detailed

procedures shall be provided.

Maintenance and inspection of the unit

shall be performed in conformance with

the following practices:

A a schedules planned maintenance,

lubrication, and inspection system

shall be followed; consult the manu-

facturer’s recommendations.

B only trained and authorized person-

nel shall be permitted to maintain,

repair, adjust, and inspect the unit,

and in accordance with manufactur-

er’s specifications.

Avoid fire hazards and have fire protec-

tion equipment present in the work ar-

ea. Do not use open pans of fuel or

flammable cleaning fluids for cleaning

parts.

Any unit not in safe operating condition

shall be removed from service.

Fire Prevention: The unit shall be kept

in a clean condition and reasonably

free of lint, excess oil, and grease.

Noncombustible agents are preferred

for cleaning the unit. Flammable liquids

[those having flash points at or above

100°F (37,8°C)] are not allowed. Pre-

cautions regarding toxicity, ventilation,

and fire hazard shall be appropriate for

the agent or solvent used.

Nameplate Visibility: The unit type des-

ignations as shown on the nameplate

and the type markers shall not be cov-

ered over with paint so that their identi-

fication information is obscured.

Please read and comply

with these instructions prior

to the initial operation of your appli-

ance. Retain these operating instruc-

tions for future reference or for

subsequent possessors.

Safety instructions 4

Function 4

Proper use 4

Environmental protection 4

Operating elements 5

Before Commissioning 5

Operation 6

Maintenance and care 7

Troubleshooting 7

Specifications 9

Accessories 10

Warranty 10

Spare parts 10

Before using the appliance for the first

time, read and observe these operating

instructions and the accompanying

brochure: Safety information for brush

cleaning units and spray-extraction

units, 5.956-251.

The following symbols are used in this

operating manual:

Danger

Indicates an immediate threat of dan-

ger. Failure to observe the instruction

may result in death or serious injuries.

몇Warning

Indicates a possibly dangerous situa-

tion. Failure to observe the instruction

mayresult in lightinjuriesordamage to

property.

Note

Indicates useful tips and important in-

formation about the product.

The appliance is used for the wet

cleaning or polishing of level floors.

Two brush rollers located opposite of

each other clean the floor by means of

the added detergent liquid. A working

width of 16 in. (400 mm) and a capacity

of 10.5 qts (10 l) each of the fresh and

dirt water reservoirs allow for effective

cleaning.

The power supply operation allows a

high capacity without a restriction of the

working time.

Note

The appliance can be equipped with

various accessories depending on the

cleaning task. Please request our cata-

logue or visit us on the Internet.

Use this appliance only as directed in

these operating instructions.

–The appliance may only be used for

the cleaning of hard surfaces that

are not sensitive to moisture and

polishing operations.

The application temperature ranges

from 41°F1 to 104°F (+5°C to

+40°C).

–The appliance is not suited for the

cleaning of frozen grounds (e.g. in

cold stores).

–The appliance may only be

equipped with original accessories

and spare parts.

–The appliance has been designed

for the cleaning of floors inside or or

covered surfaces. With respect to

other applications the usage of al-

ternative brushes must be checked.

–The appliance is not intended for

the cleaning of public traffic routes.

Operator care of the unit

MAINTENANCE AND RE-

BUILD PRACTICES

FIRE SAFETY STANDARD

Contents

Safety instructions

Symbols

Function

Proper use

Environmental protection

The packaging materials

are recyclable. Please do

not throw packaging in the

domestic waste but pass it

on for recycling.

Old units contain valuable

recyclable materials. Batter-

ies, oil and similar substanc-

es may not be released into

the environment. Therefore

please dispose of old units

through suitable collection

systems.

English 4

1 Lock for solution tank

2 Switch for brush drive

3 Solution switch

4 Solution hose

5 Dust filter (suction)

6 Lock of pushing handle

7 Release button for the transport

wheel

8 Bearing wheel

9 Push handle

10 Strain relief clamp

11 Support of the transport wheel

12 Clip

13 Solution tank

14 Recovery tank

15 Push-button for squeege change

16 Shut off float

17 Button for brush change

18 Chassis

19 Squeegee

20 Brushes

21 Rotating handle for brush contact

pressure

22 Pedal to lower squeegee

23 Electrical plug

24 Carrying handle for recovery tank

25 Solution tank cover

ÎSlide the upper slider half onto the

lower slider half.

몇Warning

Riskofdamage.Donot pinchthecable

during the installation.

ÎAlign the borings (2 possible height

adjustments).

ÎConnect the slider halves to the lock

screws, discs and star grips.

ÎFasten the cable to the slider using

clips.

ÎInsert the transport wheel axles into

the borings on the appliance and

lock them.

The brushes must be installed before

the initial operation (see "Maintenance

works").

Operating elements

24

25

Before Commissioning

Installing the pushing handle

Installing the transport wheels

Installing the Brushes

5English

Note

To take the brush drive out of opera-

tion, immediately release brush drive

switch.

몇Warning

Risk of damage. Only use the recom-

mended detergents. With respect to

different detergents the operator bears

the increased risk regarding the opera-

tional safety and danger of accident.

Only use detergents that are free from

solvents, hydrochloric acid and hydrof-

luoric acid.

Note

Do not use highly foaming detergents.

Observe the meter mixing notes.

Recommended detergents:

ÎOpen the cover of the solution tank.

ÎPour in water/detergent mixture.

Maximum temperature of the liquid

120°F (50°C)

Note

The solution tank cover can be used to

meter the detergent. The capacity of

thecoveruptothemark represents1%

of the fresh water reservoir capacity.

ÎClose the cover of the solution tank.

ÎPlace the slider vertically.

ÎPosition the rotary handle for the

brush contact pressure in the drive

position.

ÎUse the pushing handle to push the

appliance to the place of use.

ÎPlace the slider vertically and tilt the

lock up.

ÎInstall the transport wheels.

ÎTilt the appliance to the side and

drive it to the place of use on its

transport wheels.

If the transport wheels hinder the use of

the appliance:

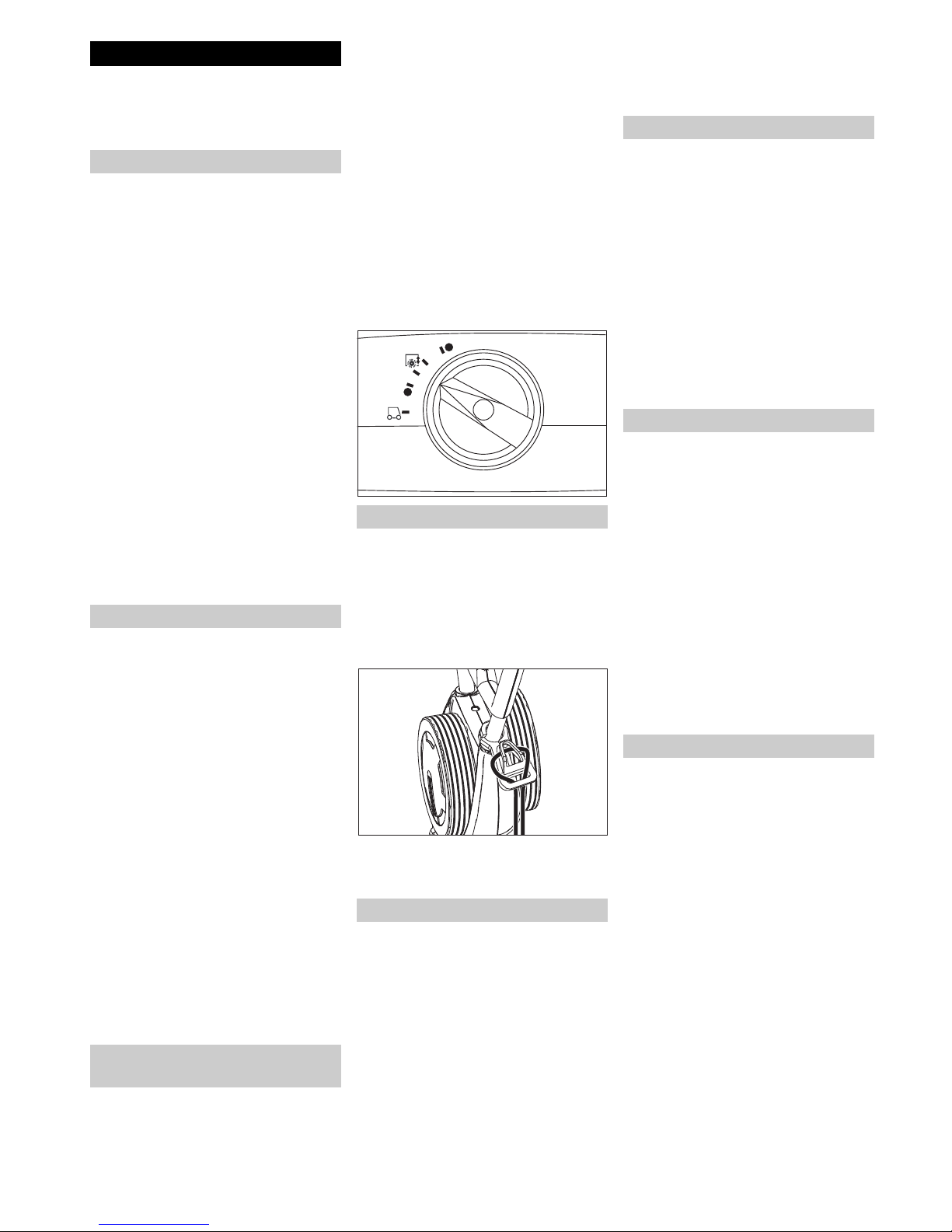

ÎPress the transport wheel release

button and pull the transport wheel

out.

ÎInsert the transport wheels into their

holder until they stop.

ÎPlace the slider vertically.

ÎAdjust the rotary handle of the

brush contact pressure to the de-

sired value.

Note

Carry out the initial cleaning attempts

with less contact pressure. Increase

contact pressure step-by-step until the

desired cleaning result is achieved. A

correct setting of the contact pressure

reduces the wear and tear of the brush-

es.

The brush drive is switched off when

there is overload.

When cleaning with microfibre rollers,

the contact pressure must not be ad-

justed higher than the position men-

tioned below. With a higher contact

pressure, there is a danger of destroy-

ing the microfibre rollers.

Danger

Checkthemainscablesofthemachine

each time before using the machine to

see that it is not damaged. Never op-

erateamachinewithdamagedcables.

Get the damaged cables replaced by

an electrician.

ÎInsert the looped end of the exten-

sion cable in the strain relief hook.

ÎPlug in the mains plug.

ÎIf the detergent solution is to be vac-

uumed off after the cleaning pro-

cess, use squeegee lowering pedal.

ÎSwivel the slider toward the opera-

tor - the chassis is retracted and the

brushes touch the floor.

ÎTurn on the brushes by using the

switch for the brush drive.

ÎTurn on the brush irrigation by using

the switch for the detergent solu-

tion.

ÎMove the appliance over the sur-

face to be processed by the slider.

몇Warning!

Risk of damage to the floor covering.

Do not operate the appliance on the

spot.

ÎSwivel the slider toward the opera-

tor - the chassis is retracted and the

brushes touch the floor.

ÎTurn on the brushes by using the

switch for the brush drive.

ÎMove the appliance over the sur-

face to be processed by the slider.

몇Warning!

Risk of damage to the floor covering.

Do not operate the appliance on the

spot.

Note

To polish under furniture, remove the

solution tank and recovery tank.

ÎRelease the switch for detergent so-

lution.

ÎPush the appliance forward for an-

other 3-6 ft (1-2 m) to draw off resid-

ual water.

ÎRelease the brush drive button.

ÎPress the pedal to lower the vac4u-

um bar.

ÎPlace the slider vertically - the

brushes are elevated.

ÎDisconnect the mains plug.

몇Warning

Danger of deforming the brushes.

When switching off the appliance, take

the load off the appliance by placing

the slider vertically.

ÎOpen the locks for the Solution

tank.

ÎTilt the carrying handle for the re-

covery tank towards the side.

ÎLift up the solution tank and carry it

to the disposal site.

몇Warning

Please observe the local provisions re-

garding the wastewater treatment.

ÎRemove the cover of the solution

tank and pour out the liquid via the

notch.

Operation

Chemical filling

Driving to the Place of Use

Short distances on even surfaces

Longer distances on uneven surfac-

es

Adjust the brush contact pres-

sure

Establish mains contact

Cleaning

+

-

Polishing

Shutting Down the Appliance

Emptying the Solution tank

English 6

Note

If the recovery tank is full the float clos-

es the suction channel. The suction op-

eration is interrupted. Empty the

recovery tank.

ÎRemove the solution tank, as de-

scribed above.

ÎLift up the recovery tank and carry it

to the disposal site.

몇Warning

Please observe the local provisions re-

garding the wastewater treatment.

ÎPour out dirty water.

ÎRinse the recovery tank with clear

water.

ÎIf you want to transport the appli-

ance on a vehicle secure it from

slipping.

To reduce the required space, the

pushing handle can be folded or disas-

sembled:

ÎRelease the star grips of the push-

ing handle fastening.

ÎUnscrew the star grips, remove the

screws and take off the upper push

handle half.

Danger

Risk of injury!

Pull the plug from the mains before car-

rying out any tasks on the appliance.

몇Warning

Risk of damage to the appliance on ac-

count of water leakage. Drain out dirty

water and the remaining free water be-

fore wokring at the machine.

몇Warning

Riskof damage. Donotwashdownthe

appliance with water and do not use

aggressive detergents.

ÎPour out dirty water.

ÎRinse the recovery tank with clear

water.

ÎEmpty the solution tank.

ÎFill the solution tank with clear water

and rinse the appliance to avoid

residue buildup.

ÎRemove the remaining water from

the solution tank.

ÎCheck the seal in the ball valve in

the solution tank.

ÎCheck the lint filter, clean if required

ÎLet the tanks dry prior to closing

them to prevent odor.

ÎClean the outside of the appliance

with a damp cloth which has been

soaked in mild detergent.

ÎClean the squeegee, check for wear

and replace the squeegee if re-

quired.

ÎCheck the brushes for wear, re-

place if required.

ÎClean the water distribution bars

above the brushes.

ÎCheck the condition of the seals be-

tween the appliance and the recov-

ery tank; replace if required.

ÎClean the brush tunnel.

ÎHave the prescribed inspection car-

ried out by the customer service.

ÎLift the squeegee by activating the

pedal for the squeegee lowering.

ÎPress the push-button for the

squeegee change toward the inside

- the squeegee will release.

ÎPull off the squeegee downwards.

ÎRemove the screw springs and in-

stall the new squeegee.

ÎAlign the new squeegee so that the

locking nose points toward the cen-

tre of the appliance.

ÎInsert the screw springs into the re-

ceptacle on the appliance.

ÎInsert the squeegee into the appli-

ance and lock it in.

ÎRepeat process on the second

squeegee.

Note

Regular exchanges of the two squee-

gee will improve the scraping effect

and will prolong their life.

ÎLay the device on its side.

ÎPress the brush change key and si-

multaneously tilt the brush roller

downwards.

ÎPull out the brushes roller.

ÎPlace the new brush roller on the

driver and lock into place.

To ensure a reliable operation of the

appliance maintenance contracts can

be concluded with the competent

Windsor sales office.

In case of danger of frost:

ÎEmpty the solution and recovery

tank .

ÎPush the button for detergent solu-

tion until no more water is expelled.

ÎStore the appliance in a frost-pro-

tected room.

Danger

Risk of injury!

Pull the plug from the mains before car-

rying out any tasks on the appliance.

몇Warning

Risk of damage to the appliance on ac-

count of water leakage. Drain out dirty

water and the remaining free water be-

fore wokring at the machine.

In case of faults that cannot be reme-

died using the table below please con-

tact the customer service.

Draining the Recovery tank

Transport

Maintenance and care

Maintenance schedule

After the work

Monthly

Yearly

Maintenance Works

Replacing the squeegee

Replacing the brushes

Maintenance contract

Frost protection

Troubleshooting

7English

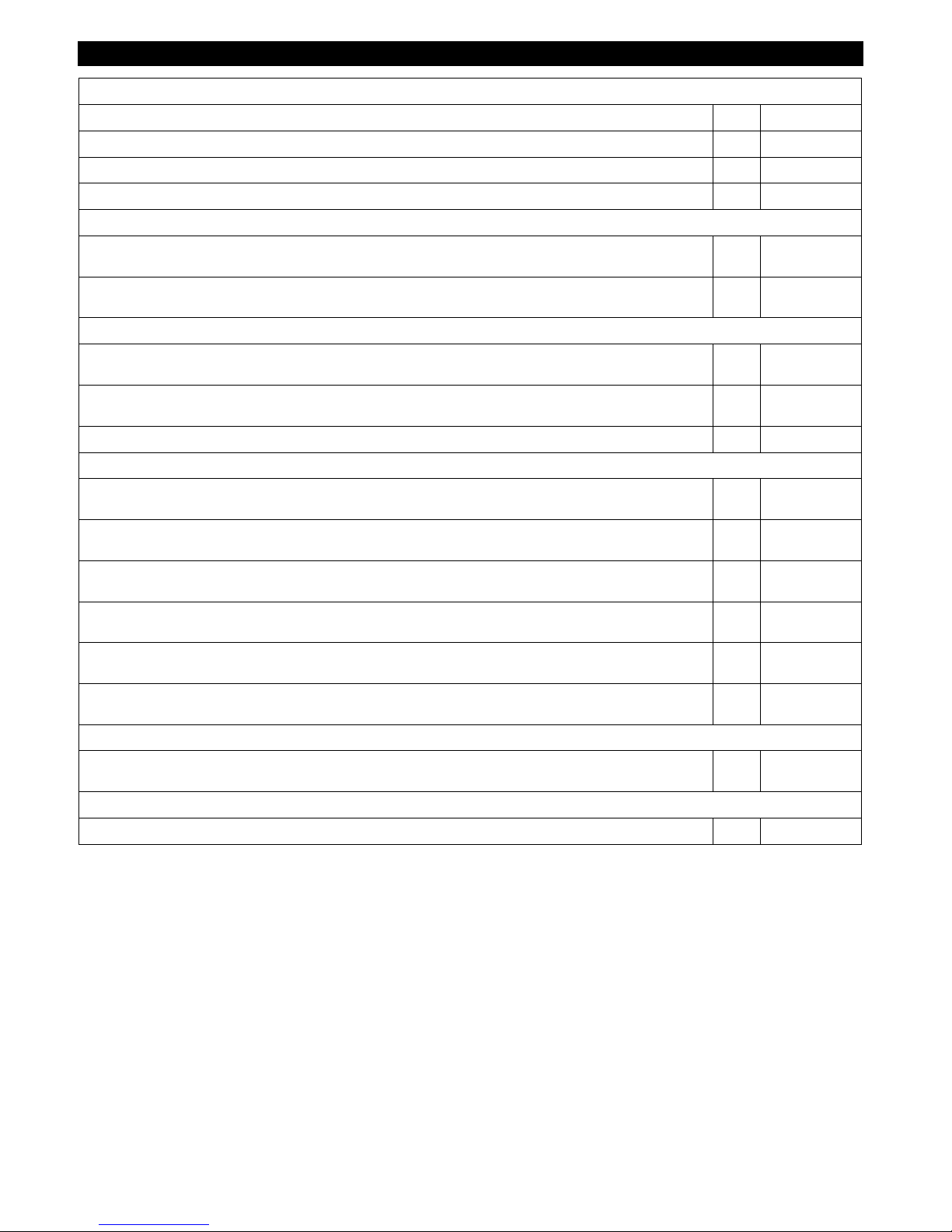

Faults

Error Remedy

Appliance cannot be started Check if the mains plug is connected.

Socket fuse rating too low, look for proper socket.

Insufficient water quantity Check fresh water level, refill tank if necessary.

Clean the ball valve in the solution tank.

Check and ensure that the solution tank is seated properly on the appliance.

Filter in the solution tank is plugged, clean filter.

Check hoses for blockages; clean if required.

Insufficient vacuum perfor-

mance

Empty the recovery tank.

Check and ensure that the solution tank is seated properly on the wastewater reservoir.

Check seals on the solution tank, clean if necessary.

Clean the seals between the appliance and the recovery tank and check for tightness,

replace if required.

Clean the lint trap.

Clean the squeegee blades on the squeegee tool, replace if required

Suction channel plugged, clean.

Check if the vacuum bar is plugged, remove plug if required

Insufficient cleaning result Increase brush contact pressure.

Check the brushes for wear, replace if required.

Use brush rollers suited for the type of dirt and floor covering.

Brushes do not turn Check if foreign matters block the brushes; remove foreign matter if required.

Reduce contact pressure.

Overcurrent protective switch was triggered. The overcurrent protective switch will al-

low the operation after max. one minute.

Appliance vibrates. Brush rollers are deformed because they were not unloaded by tilting the slider verti-

cally when parking the appliance; replace brush rollers.

English 8

Specifications

Power

Nominal voltage V/Hz 120 / 60

Average power consumption W 1100

Suction engine output W500

Brush engine output W1700

Vacuuming

Cleaning power, air quantity Cfm

l/s

42,2

20

Cleaning power, negative pressure psi

kPa

1,45

10

Cleaning brushes

Working width in

mm

15.15

400

Brush diameter in

mm

3.77

96

Brush speed 1/min 650

Dimensions and weights

Theoretical surface cleaning performance yd²

m²/h

478

400

Fresh/dirty water tank volume GAL

l

2.64

10

Length (without pushing handle) in

mm

20.5

520

Width (without squeegee tool) in

mm

18.5

470

Height (without pushing handle) in

mm

15

380

Weight (without tank contents) lbs

kg

46.1

30

Noise emission

Sound pressure level (EN 60704-1) dB(A

)

71

Machine vibrations

Vibration total value (ISO 5349) m/s² 1,0

9English

–Only use accessories and spare

parts which have been approved by

the manufacturer. The exclusive

use of original accessories and orig-

inal spare parts ensures that the ap-

pliance can be operated safely and

troublefree.

–At the end of the operating instruc-

tions you will find a selected list of

spare parts that are often required.

Accessories

Order No.

Piece

Machine requires

piece

Brush roller, red (medium, stan-

dard)

For cleaning slightly dirtied or sensitive floors. 4.762-249.0 1 2

Brush roller, green (grit) For cleaning heavily dirtied floors. 4.762-252.0 1 2

Brush roller, orange (high/ low) For scrubbing structured floors (safety tiles, etc.). 4.762-251.0 1 2

Brush roller, white (soft) For polishing floors. 4.762-250.0 1 2

Pad roller shaft For intake of roller pads. 4.762-228.0 1 2

Pad, very soft, white For cleaning and polishing sensitive floorings. 6.369-727.0 1 2

Pad, soft, yellow For polishing floors. 6.369-724.0 1 2

Pad, medium soft, red For cleaning slightly dirtied floors. 6.369-726.0 1 2

Pad, hard, green For cleaning normal to heavily dirtied floors. 6.369-725.0 1 2

Microfibre roller To remove grey tint 4.114-003.0 1 2

Vacuum bar, standard 4.777-323.0 1 2

Vacuum bar, oil-resistant 4.777-322.0 1 2

Extension cable 20 m 6.647-022.0 1 1

Spare parts

Table of contents

Other Bona Scrubber manuals

Popular Scrubber manuals by other brands

Renown

Renown REN08027-VP owner's manual

Space Television

Space Television HD/MH-HD+A manual

Nilfisk-ALTO

Nilfisk-ALTO SCRUBTEC R 466 user manual

Abicor Binzel

Abicor Binzel xFume Advanced operating instructions

Tomcat

Tomcat CARBON 26'' Disk operating instructions

Advance acoustic

Advance acoustic SC900 Operating guidelines