Dionex ASE 150 User manual

ASE®150

Accelerated Solvent Extractor

Operator's Manual

Document No. 065207

Revision 02

September 2008

©2008 by Dionex Corporation

All rights reserved worldwide.

Printed in the United States of America.

This publication is protected by federal copyright law. No part of this publication

may be copied or distributed, transmitted, transcribed, stored in a retrieval system, or

transmitted into any human or computer language, in any form or by any means,

electronic, mechanical, magnetic, manual, or otherwise, or disclosed to third parties

without the express written permission of Dionex Corporation, 1228 Titan Way,

Sunnyvale, California 94088-3603 U.S.A.

DISCLAIMER OF WARRANTY AND LIMITED WARRANTY

THIS PUBLICATION IS PROVIDED “AS IS” WITHOUT WARRANTY OF

ANY KIND. DIONEX CORPORATION DOES NOT WARRANT,

GUARANTEE, OR MAKE ANY EXPRESS OR IMPLIED

REPRESENTATIONS REGARDING THE USE, OR THE RESULTS OF THE

USE, OF THIS PUBLICATION IN TERMS OF CORRECTNESS, ACCURACY,

RELIABILITY, CURRENTNESS, OR OTHERWISE. FURTHER, DIONEX

CORPORATION RESERVES THE RIGHT TO REVISE THIS PUBLICATION

AND TO MAKE CHANGES FROM TIME TO TIME IN THE CONTENT

HEREINOF WITHOUT OBLIGATION OF DIONEX CORPORATION TO

NOTIFY ANY PERSON OR ORGANIZATION OF SUCH REVISION OR

CHANGES.

TRADEMARKS

AutoSeal is a trademark of Dionex Corporation. ASE 150 is a registered trademark

of Dionex Corporation.

Acrobat, Adobe, and Adobe Reader are registered trademarks of Adobe Systems,

Incorporated.

C-2000 and Hastelloy are registered trademarks of Haynes International, Inc.

PEEK is a trademark of Victrex PLC.

Perlast is a registered trademark of Precision Polymer Engineering, Ltd.

Teflon and Viton are registered trademarks of E. I. duPont de Nemours & Company.

PRINTING HISTORY

Revision 01, April 2008

Revision 02, September 2008

Doc. 065207-02 9/08 i

1 • Introduction

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Safety Messages and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Safety and Regulatory Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Safety Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2•Description

2.1 Operating Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.2 Sample Cells and Rinse Cells . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.3 Collection Vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.1.4 Solvent Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.5 Waste Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 ASE 150 Extraction Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4 Method Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.5 Preprogrammed Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Contents

ASE 150 Operator’s Manual

ii Doc. 065207-02 9/08

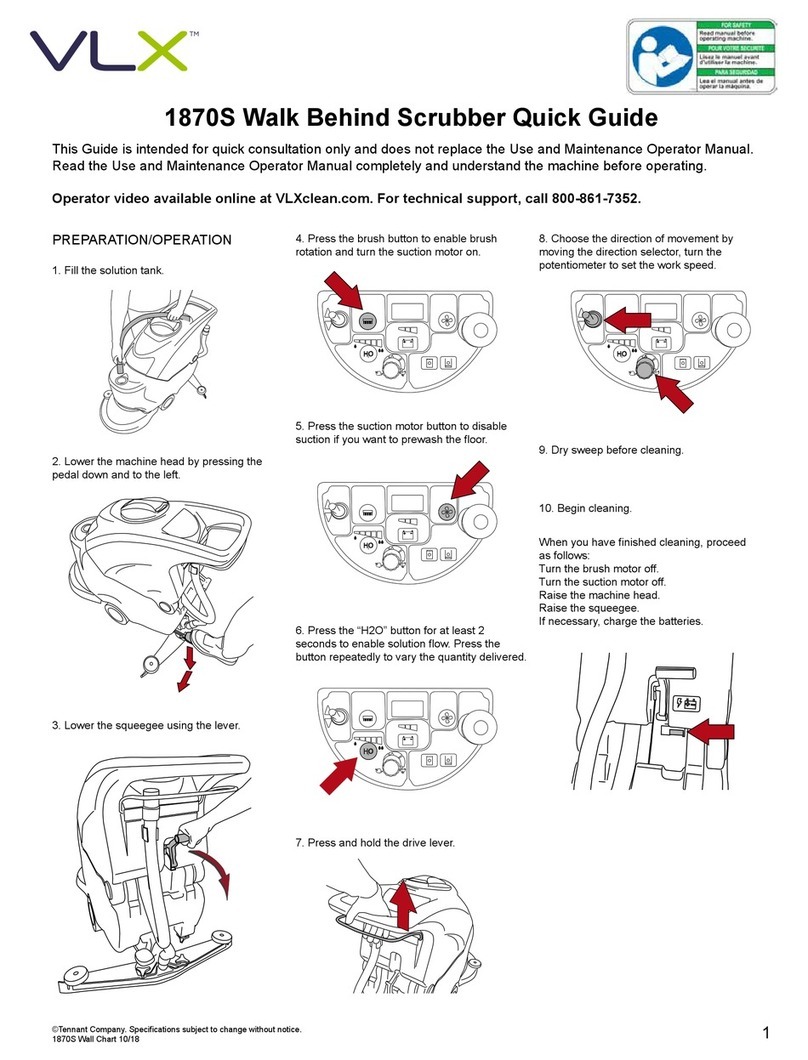

3 • Operation and Maintenance

3.1 Preparing to Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

3.1.1 Selecting and Preparing Solvent . . . . . . . . . . . . . . . . . . . . . . . .25

3.1.2 Filling the Solvent Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.1.3 Preparing the Sample . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.1.4 Installing the Cell Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.1.5 Filling the Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

3.1.6 Installing the Collection Vessel . . . . . . . . . . . . . . . . . . . . . . . . .39

3.1.7 Installing the Waste Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.2 Running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.2.1 Selecting the Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.2.2 Selecting the Cell Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

3.2.3 Verifying the Cell Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

3.2.4 Starting the Run and Checking the Oven Status . . . . . . . . . . . .43

3.2.5 Installing the Sample Cell in the Cell Holder . . . . . . . . . . . . . .44

3.2.6 Completing the Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

3.3 Performing Post-Run Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

3.3.1 Cleaning the Sample Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

3.3.2 Processing Extracts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

3.4 Stopping a Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

3.5 Rinsing/Priming the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3.6 Editing a Custom Method (Methods 1 through 24) . . . . . . . . . . . . . . . .49

3.7 Developing a New Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Contents

Doc. 065207-02 9/08 iii

3.8 Performing Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.8.1 Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.8.2 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.8.3 Annual Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.9 Shutting Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4 • Troubleshooting

4.1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.2 Liquid Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4.3 Gas Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4.4 Stopped System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5•Service

5.1 Replacing Tubing and Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.2 Replacing the Cell End Cap Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.3 Replacing the Cell End Cap O-Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

5.4 Removing the Right-Side Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.5 Replacing Pump Check Valve Cartridges . . . . . . . . . . . . . . . . . . . . . . . 75

5.5.1 Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.5.2 Removing the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

5.5.3 Removing the Check Valves and Cartridges . . . . . . . . . . . . . . 76

5.5.4 Installing New Check Valve Cartridges . . . . . . . . . . . . . . . . . . 77

5.5.5 Reinstalling the Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . 77

5.5.6 Cleaning the Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

ASE 150 Operator’s Manual

iv Doc. 065207-02 9/08

5.5.7 Reinstalling the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

5.5.8 Completing the Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

5.6 Replacing Pump Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.6.1 Before Beginning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.6.2 Removing the Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

5.6.3 Replacing the Piston High-Pressure Seal . . . . . . . . . . . . . . . . .79

5.6.4 Replacing the Piston Air Seal . . . . . . . . . . . . . . . . . . . . . . . . . .81

5.6.5 Reinstalling the Pump and Completing the Procedure . . . . . . .83

5.7 Replacing the Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . .84

5.8 Rebuilding the Static Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

5.8.1 Removing the Static Valve from the System . . . . . . . . . . . . . .88

5.8.2 Disassembling the Static Valve Body . . . . . . . . . . . . . . . . . . . .90

5.8.3 Installing the New Seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

5.8.4 Reassembling the Static Valve . . . . . . . . . . . . . . . . . . . . . . . . .93

5.8.5 Reinstalling the Static Valve . . . . . . . . . . . . . . . . . . . . . . . . . . .97

5.9 Replacing the Source Needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

5.10 Replacing the Main Power Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

A • Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

A.1 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

A.2 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

A.3 Physical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

A.4 Pneumatic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

A.5 Front Panel Display and Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Contents

Doc. 065207-02 9/08 v

A.6 Sample Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

A.7 Collection Vessels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

A.8 Interior Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

B • Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

B.1 Facility Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

B.2 Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

B.2.1 Connecting the Nitrogen Gas Source . . . . . . . . . . . . . . . . . . . 108

B.2.2 Connecting the Drain Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

B.2.3 Checking the Oven Voltage Switches. . . . . . . . . . . . . . . . . . . 110

B.2.4 Connecting the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . 111

B.2.5 Checking Pressure Readings . . . . . . . . . . . . . . . . . . . . . . . . . . 112

B.2.6 Connecting the Solvent Reservoir. . . . . . . . . . . . . . . . . . . . . . 113

B.2.7 Installing the Waste Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

B.2.8 Adjusting the Cell Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

B.2.9 Selecting Setup Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

B.2.10 Rinsing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

C • User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

C.1 Operational Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

C.1.1 Menu Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

C.1.2 Status Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

C.1.3 Setup Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

C.1.4 Method Editor Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

ASE 150 Operator’s Manual

vi Doc. 065207-02 9/08

C.2 Diagnostic Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

C.2.1 Diagnostics Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

C.2.2 Sensors Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .132

C.2.3 Regulators Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

C.2.4 Hydrocarbon Sensor Screen . . . . . . . . . . . . . . . . . . . . . . . . . . .134

C.2.5 Extraction Counters Screen . . . . . . . . . . . . . . . . . . . . . . . . . . .135

C.2.6 Moduleware Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

D • Reordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

E • Theory of ASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

E.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

E.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .143

E.3 Method Optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

E.3.1 Sample Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .145

E.3.2 Extraction Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .148

E.4 Method Development . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .151

E.5 Selectivity in ASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .152

E.6 References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .157

Doc. 065207-02 9/08 1

1 • Introduction

1.1 Overview

The ASE®150 Accelerated Solvent Extractor is a system for extracting either

organic or inorganic compounds from a variety of solid or semisolid samples at a

variety of pH values. The ASE 150 can be used with organic solvent, aqueous

buffer, water, and small amounts of mineral acids. The ASE 150 accelerates the

traditional extraction process by using solvent at elevated temperatures and

pressures. Pressure is maintained in the sample cell to maintain the heated solvent

in a liquid state during the extraction. After heating, the extract is rinsed from the

sample cell into a collection vessel and is ready for analysis.

Figure 1-1. ASE 150 Accelerated Solvent Extractor

Waste Collection Vessel

Solvent

Reservoir

Sample Cell

and Oven

Location

ASE 150 Operator’s Manual

2Doc. 065207-02 9/08

The ASE 150 is designed to minimize the amount of solvent used without

sacrificing the speed of extraction or ease of operation. Samples are extracted one

at a time, and the extraction process is typically completed in 15 to 25 minutes.

All functions are controlled from the ASE 150 front panel.

Built-in safety diagnostics monitor the system during operation. If a problem

occurs, the front panel displays an error message that identifies the problem. In

addition, the method currently running is aborted and basic system functions are

shut down until the situation is corrected.

1.2 About This Manual

1.2.1 Overview

The electronic version (i.e., PDF file) of the ASE 150 operator’s manual

contains numerous hypertext links that can take you to other locations

within the file. These links include:

•Table of contents entries

•Index entries

•Cross-references (underlined in blue) to sections, figures, tables, etc.

If you are not familiar with how to navigate PDF files, refer to the Help

system for Adobe® Acrobat® or Adobe Reader®for assistance.

Chapter 1

Introduction Introduces the ASE 150; explains the conventions used in

this manual, including safety-related information.

Chapter 2

Description Describes ASE 150 operating features and the extraction

process.

Chapter 3

Operation and

Maintenance

Provides operating instructions and routine preventive

maintenance procedures.

Chapter 4

Troubleshooting Lists error messages and how to troubleshoot them; lists

operating problems and how to resolve them.

Chapter 5

Service Provides step-by-step instructions for routine service and

parts replacement procedures that the user can perform.

Appendix A

Specifications Provides specifications and installation site requirements.

1 • Introduction

Doc. 065207-02 9/08 3

1.2.2 Safety Messages and Notes

This manual contains warnings and precautionary statements that can

prevent personal injury and/or damage to the ASE 150 when properly

followed. Safety messages appear in bold type and are accompanied by

icons, as shown below.

Messages d’avertissement en français

Appendix B

Installation Describes how to install the ASE 150.

Appendix C

User Interface Illustrates and describes the display screens on the ASE

150 front panel.

Appendix D

Reordering

Information

Lists spare parts for the ASE 150.

Appendix E

Theory of ASE Describes the theory behind performing extractions with

ASE.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury. Also used to identify a situation or

practice that may seriously damage the instrument, but will not cause

injury.

Indicates that the function or process of the instrument may be

impaired. Operation does not constitute a hazard.

Signale une situation de danger immédiat qui, si elle n'est pas évitée,

entraînera des blessures graves à mortelles.

ASE 150 Operator’s Manual

4Doc. 065207-02 9/08

Warnhinweise in Deutsch

Notes

Informational messages also appear throughout this manual. These are

labeled NOTE and are in bold type.

NOTE NOTES call attention to certain information. They alert

the user to an unexpected result of an action, suggest

how to optimize instrument performance, etc.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures graves à mortelles.

Signale une situation de danger potentiel qui, si elle n'est pas évitée,

pourrait entraîner des blessures mineures à modérées. Également

utilisé pour signaler une situation ou une pratique qui pourrait

gravement endommager l'instrument mais qui n'entraînera pas de

blessures.

Bedeutet unmittelbare Gefahr. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zum Tod oder

schwerwiegenden Verletzungen führen.

Bedeutet eine mögliche Gefährdung. Mißachtung kann zu kleineren

oder mittelschweren Verletzungen führen. Wird auch verwendet, wenn

eine Situation zu schweren Schäden am Gerät führen kann, jedoch

keine Verletzungsgefahr besteht.

1 • Introduction

Doc. 065207-02 9/08 5

1.3 Safety and Regulatory Information

The ASE 150 was manufactured by Dionex Corporation at the following location:

527 Lakeside Drive, Sunnyvale, CA 94088-3603 U.S.A. The ASE 150 is designed

for solvent extraction applications and should not be used for any other purpose.

Operation of an ASE 150 in a manner not specified by Dionex may result in

personal injury.

If you have a question regarding appropriate usage, contact Dionex before

proceeding. In the U.S., call 1-800-346-6390 and select the Technical Support

option. Outside the U.S., call the nearest Dionex office.

1.4 Safety Labels

The cTUVus Mark safety label and the CE Mark label on the ASE 150 indicate

that the ASE 150 is in compliance with the following standards.

EMC Susceptibility and Emissions

•EN 61326-1:2006

Safety

•CAN/CSA-C22.2 No. 61010-1:2004

•EN 61010-1:2001

•UL 3101-1/10.93

•UL 61010-1:2004

The symbols below appear on the ASE 150 or on ASE 150 labels.

Alternating current

Primary protective conductor terminal

Secondary protective conductor terminal

ASE 150 Operator’s Manual

6Doc. 065207-02 9/08

Power supply is on

Power supply is off

Hot surface

Indicates a potential hazard. Refer to the operator’s manual for

an explanation of the hazard and how to proceed.

Doc. 065207-02 9/08 7

2 • Description

2.1 Operating Features

Figure 2-1 illustrates the main operating features of the ASE 150 Accelerated

Solvent Extractor.

Figure 2-1. ASE 150 Operating Features

1Solvent Reservoir

Control Panel

2

Door OPEN Lever

4

5

6

3

1

2Oven

Sample Cell

Waste Bottle

Collection Vessel

(250-mL bottle shown)

Drip Tray

Needle UP/DOWN Switch

3

4

5

6

7

8

9

7

8

9

ASE 150 Operator’s Manual

8Doc. 065207-02 9/08

Solvent Reservoir

A 2-liter solvent reservoir is installed in a recess on top of the ASE 150. The

recess contains a plastic liner that collects any solvent leaks or spills that may

occur and directs them through a drain tube to the rear panel. A drain hose

connects to the drain tube and is routed to a waste container.

Sample Cell

Before a sample is run or a rinse cycle is performed, a sample cell or rinse cell

must be installed in the cell holder on the inside of the cell door. To access the cell

holder, push down on the OPEN lever and then pull open the door.

Oven

The oven is located behind the cell door. This area also houses the AutoSeal™

tips, which seal the cell during a run.

Control Panel

The ASE 150 control panel includes a display screen and a membrane keypad,

which are used to control ASE 150 operation.

Waste Bottle

The waste bottle is a 250-mL collection bottle that is sealed with a special built-in

cap assembly.

Needle Up/Down Switch

The UP/DOWN toggle switch controls the position of the source and vent needles.

When the needles are in the “down” position, they pierce the collection vessel

septum. The source needle allows the extract to flow from the sample cell into the

collection vessel. The vent needles allow displaced gases to escape to the waste

bottle and the system vent.

Drip Tray

A pull-out drip tray is installed below the oven to collect any liquid leaks that may

occur during a run or rinse cycle.

Collection Vessel

After each extraction, the collection vessel (either a 250-mL collection bottle or a

60-mL collection vial) contains solvent and the analytes extracted from the

sample.

2 • Description

Doc. 065207-02 9/08 9

Safety Shields

The doors on the waste and collection vessel compartments are safety shields that

protect operators in the rare case of a bottle or vial breakage. The doors must be

closed for safe operation.

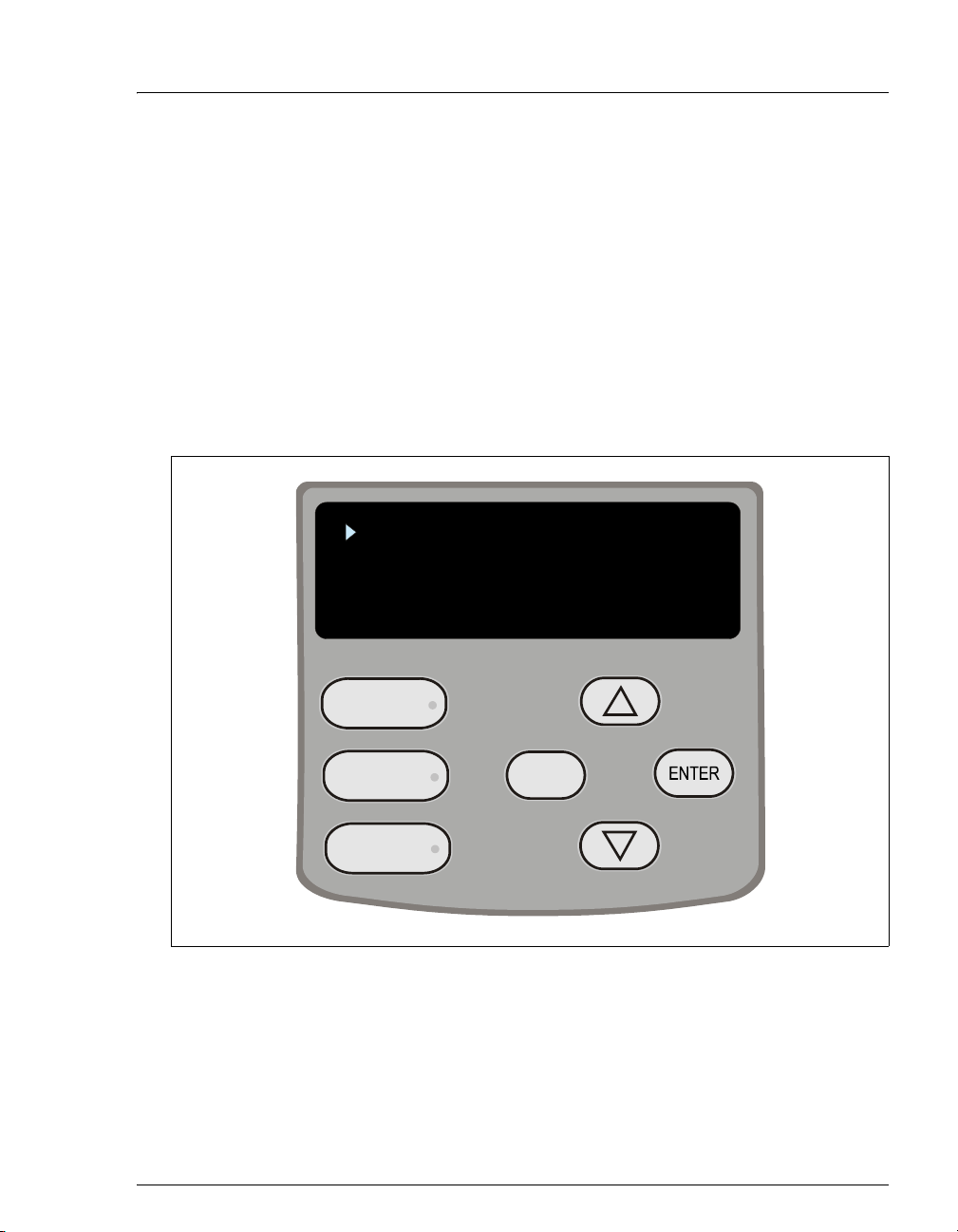

2.1.1 Control Panel

Use the control panel screen and buttons to control ASE 150 operation.

The screen displays status and operating information. You can edit any

field on the screen that contains a blinking cursor. A field without a

blinking cursor is for display only.

Figure 2-2. ASE 150 Control Panel

STATUS

SETUP

METHOD EDITOR

DIAGNOSTICS

START

RINSE

STOP

MENU

ASE 150 Operator’s Manual

10 Doc. 065207-02 9/08

Button Function

Starts the currently selected method. The LED starts flashing

when the oven is within 1 °C of the set point, indicating it is

okay to load the sample cell into the oven. During the method

run, the LED is lighted, but does not flash. When the method

finishes running (or is aborted), three beeps are emitted and

the LED turns off. See Section 2.4 for details about methods.

Starts a rinse cycle in which about 5 mL of solvent is pumped

through the system. During the rinse cycle, the LED is

lighted. When the rinse cycle is complete (or is aborted),

three beeps are emitted and the LED turns off.

Note: Always install a rinse cell and a collection vessel

before starting a rinse cycle. See Section 3.5 for instructions.

Interrupts the currently running method or rinse cycle and

displays the ABORT screen. Pressing the button lights the

LED. The LED turns off when you select an option on the

ABORT screen. See Section 3.4 for details.

Exits the screen currently displayed and returns to the screen

one level up in the hierarchy. For example, if the METHOD

EDITOR screen is displayed, pressing MENU returns you to

the MENU screen. See Figure C-1 for an overview of the

screens.

When the cursor is in an editable field, pressing MENU

discards any change and reverts to the previously selected

parameter.

Selects the field the cursor is currently pointing to. On the

MENU or DIAGNOSTICS screen, this selects and displays a

different screen. On other screens, pressing ENTER moves

the cursor from the left margin to the first field in that line

that can be edited; it also changes the normal cursor into the

blinking editing cursor.

When the cursor is in an editable field, pressing ENTER saves

the parameter currently displayed in the field.

Table 2-1. ASE 150 Control Panel Button Functions

START

RINSE

STOP

MENU

2 • Description

Doc. 065207-02 9/08 11

2.1.2 Sample Cells and Rinse Cells

NOTE Appendix D contains part numbers for cells, bottles,

vials, and other accessories.

Sample Cells

Sample cells consist of a cell body and two interchangeable caps, which

are screwed onto each end of the cell body. The cell body and end caps

are made of the same material. Inside each end cap is a frit in the same

material as the cell, as well as a PEEK™ seal. During a run, the cell end

caps are compressed by the oven to form a tight seal between the caps and

the cell body.

Each cell end cap contains an external O-ring. Teflon® O-rings

(P/N 049457, pkg. of 50) are standard. Use Viton® O-rings (P/N 056325,

pkg. of 50) for dioxins and other high temperature applications.

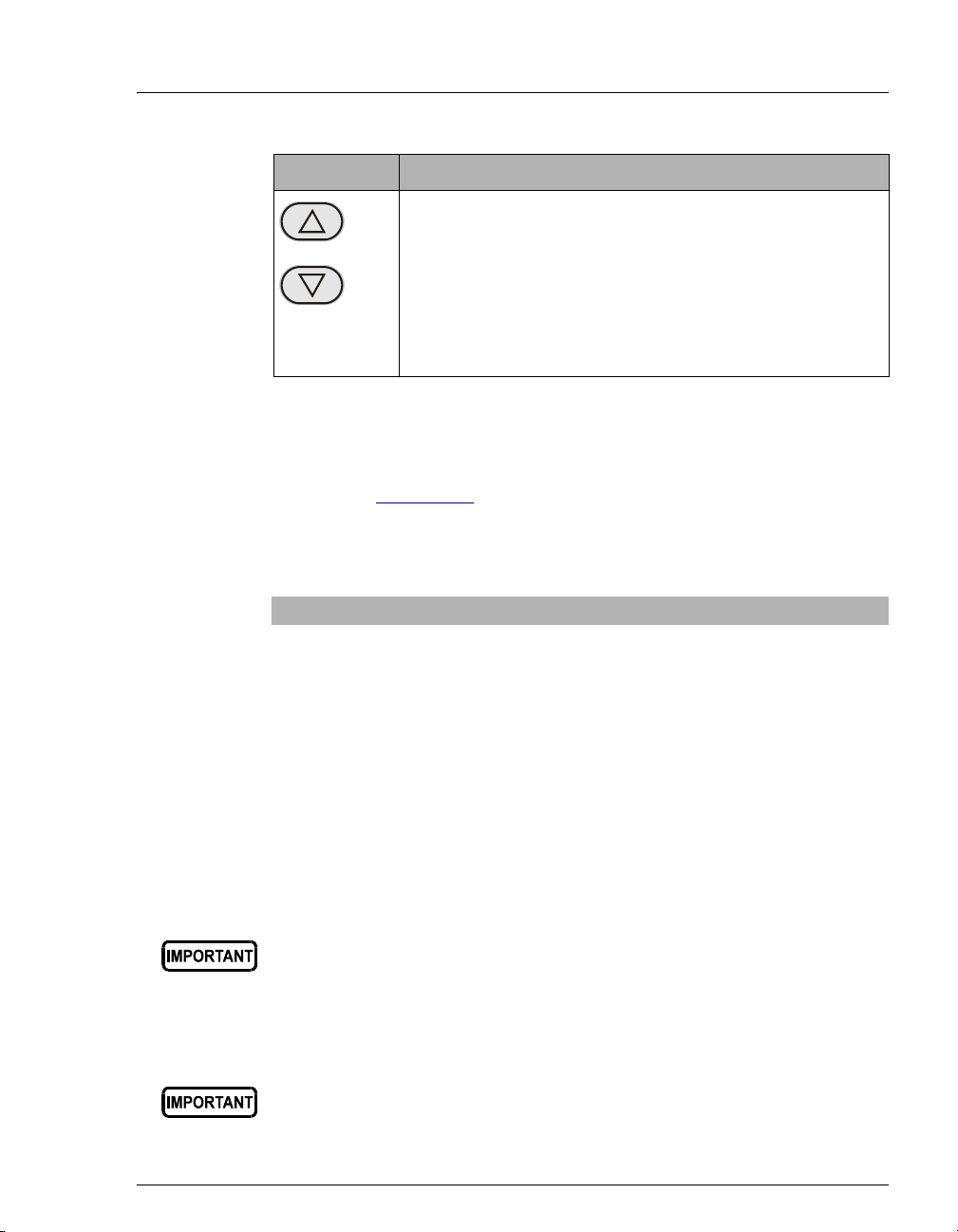

Moves the cursor, in the direction of the arrow, to the next

selectable line on the display (if any).

When the cursor is in an editable field, pressing an arrow

button displays the next or previous parameter or numeric

value allowed for the field.

Note: Pressing and holding down an arrow button moves the

cursor continuously through the allowed settings.

Cell Material Sizes Available (mL) Used For

Stainless steel 1, 5, 10, 22, 34, 66, and

100

Extractions with solvents

Zirconium 66 and 100 Extraction of basic or acidic

matrices, and extractions with

solvents

Always tighten the cell end caps by hand. Use of a wrench or other

tool can damage the cell, as well as the seals inside the cell end caps.

If Viton external O-rings are installed on the cell end caps, do not use

acetone or other ketones.

Button Function

Table 2-1. ASE 150 Control Panel Button Functions (Continued)

ASE 150 Operator’s Manual

12 Doc. 065207-02 9/08

Rinse Cells

Rinse cells are similar in appearance to sample cells, but are blue in color.

During a rinse cycle, solvent passes directly through the rinse cell and

into the collection vessel. For more information about rinse cycles, see

Section 3.5.

The rinse cell size must be matched to the size of the sample cell, as

indicated in the table below.

Ordering Sample Cells in Other Sizes

To perform a run with a cell in a different size than the size originally

ordered, order the cells from Dionex. You will also need to order the

Startup Kit appropriate for the new cell size. For cell and Startup Kit part

numbers, see Appendix D.

Note that installation of a different sample cell size will require a few

additional changes:

•Reposition the cell holder to accommodate the new sample cell size,

if required. For instructions, refer to Section B.2.8.

•Before beginning a run, specify the new cell size on the SETUP screen

(see Section C.1.3).

Use this rinse cell: With this sample cell:

Short (P/N 060174) 1 mL, 5 mL, 10 mL, 22 mL, 34 mL

Medium (P/N 060175) 66 mL

Long (P/N 060176) 100 mL

Table of contents

Popular Scrubber manuals by other brands

Sana

Sana EUJ-702 user manual

HAKO

HAKO Scrubmaster B400 R operating manual

Black & Decker

Black & Decker S500 instruction manual

Lincoln Electric

Lincoln Electric LFA 3.0 Installation and user manual

SapphireScientific

SapphireScientific Dri-Eaz HVE3000 owner's manual

Nilfisk-Advance

Nilfisk-Advance Adfinity 20D Instructions for use