3

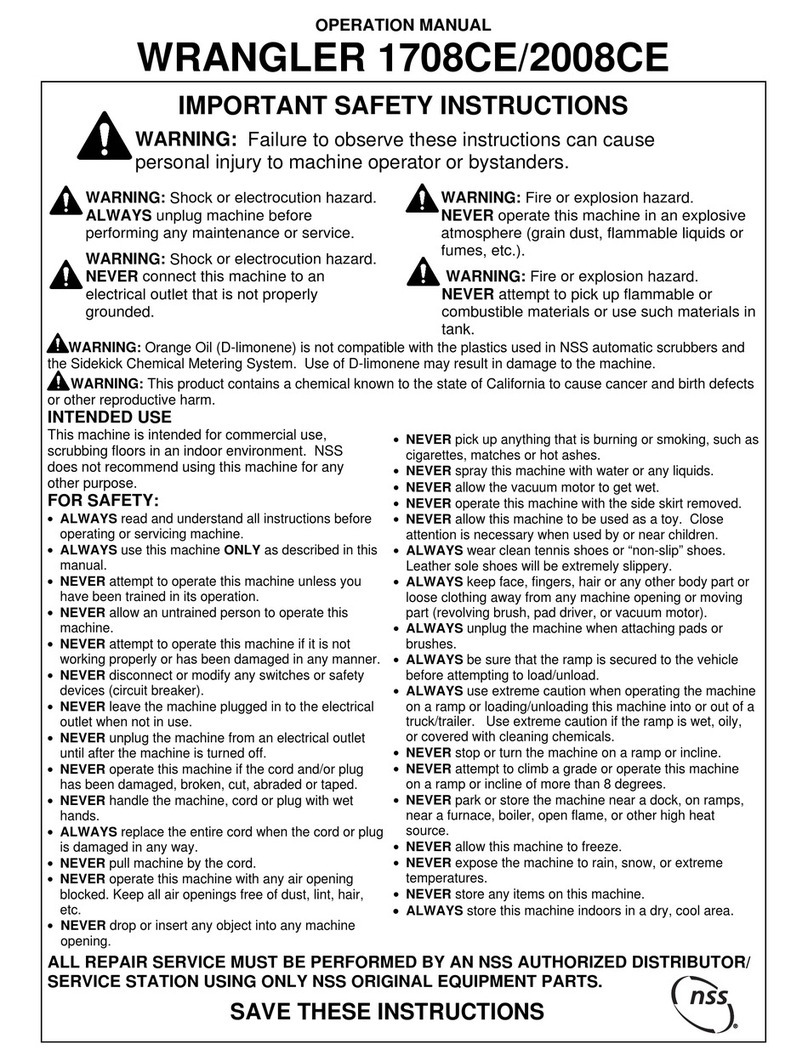

MACHINE INSPECTION

•Carefully unpack the Wrangler 1708/2008 and recycle

all packing materials.

•Inspect machine for damage or missing

components. If damage is found, contact the local

freight company and file a freight claim.

DAILY USE

The Wrangler 1708/2008 is very maneuverable and is

designed to scrub floors as you operate the machine

from behind. Always dust mop the floor before

scrubbing. You may also need to preclean some types

of spills or stains before scrubbing. Plan your work so

that you make long, straight paths with the fewest

amount of turns possible. Remove as many obstacles

as possible from the area to be scrubbed. The Wrangler

1708/2008 is designed for light to medium scrubbing.

Consult your local NSS distributor for more complete

procedures and chemical advice.

MACHINE COMPONENTS AND

OPERATION

Battery Package (see safety instructions)

The Wrangler 1708/2008 is a 24 volt system with two

(2) 12 volt, 115 amp hour batteries. Consult your local

NSS authorized distributor for application

recommendations.

To install the batteries:

•Batteries are heavy, use two people to install.

•Turn off all the switches.

•Empty all liquids from recovery tank.

•Step on foot pedal at front of machine to release tanks.

Lift tanks up and tilt back to rest on handles.

•Refer to wiring diagram on bottom of tanks. Align

batteries in compartment as shown on diagram.

•Install battery cables as shown on wiring

diagram. Tighten all bolts and hex nuts with a wrench.

•CAUTION: Do not touch two terminals with a wrench.

•Loose or improper battery connections will cause

battery or machine damage and possible

personal injury.

To charge the batteries:

•Charge machine after every shift or whenever batteries

are 75% expended.

•Turn off all the switches.

•Disconnect battery connectors below user control

panel.

•Connect lower connector from batteries to

connector from automatic battery charger.

•Needle on charger gauge should jump within 30

seconds to working level.

•Needle on machine battery gauge should not move

when machine is plugged into charger –batteries will

not be charged.

•NSS supplied battery chargers are automatic and

will shut off when charging cycle is complete.

Solution Tank

The solution tank is the lower part of the machine

body. The tank has a capacity of 8 gallons (30

litters) and is filled by pouring the water and cleaning

chemicals through the mesh covered opening and

filter at the front of the machine. Drain the solution

tank through the solution valve or the sight hose at

the rear of the machine.

To prepare the solution tank:

•Never use water over 140°F (60°C).

Excessively hot water may damage components

such as the tanks.

•Pour all liquids through mesh filter at the front of

the solution tank.

•Put 1 to 2 gallons of clean water into the solution

tank first to help dilute the chemicals and prevent

excess sudsing.

•Do not put strip solution in solution tank. Apply

with mop and bucket and rinse with clean water in

solution tank.

•Consult your local NSS distributor for complete

chemical advice. Dilute the cleaning chemicals

according to the manufacturer’s instructions.

•Add the cleaning chemicals to the solution tank

and fill with water as needed.

Recovery Tank

The recovery tank is the upper part of the machine

body. The tank has a capacity of 10 gallons (38

liters). The recovery tank is closed by a rectangular,

clearview lid assembly. The recovery tank has a

foam-sensitive float shut-off assembly. As the water

or foam level rises, the float ball will rise and shut off

the air flow of the vacuum motor to the squeegee. It

does not shut off the vacuum motor. Drain the

recovery tank through the black hose at the rear of

the machine.

To prepare the recovery tank:

•Always use a defoamer to protect the vacuum

motor of this machine. Every time you empty the

recovery tank, we recommend that you add at

least 4 to 6 ounces of defoamer chemical into the

recovery tank before resuming work. Vacuum the

defoamer into the empty recovery tank through the

squeegee vac hose.

•Make sure the recovery tank drain hose is tight on

the plug.