Service Manual DS 350 Modular

© PAT Rev. - 12/18/00 // CSH. 190118_-.DOC

TABLE OF CONTENTS

1GENERAL INFORMATION................................................................................................1

2WARNINGS .......................................................................................................................1

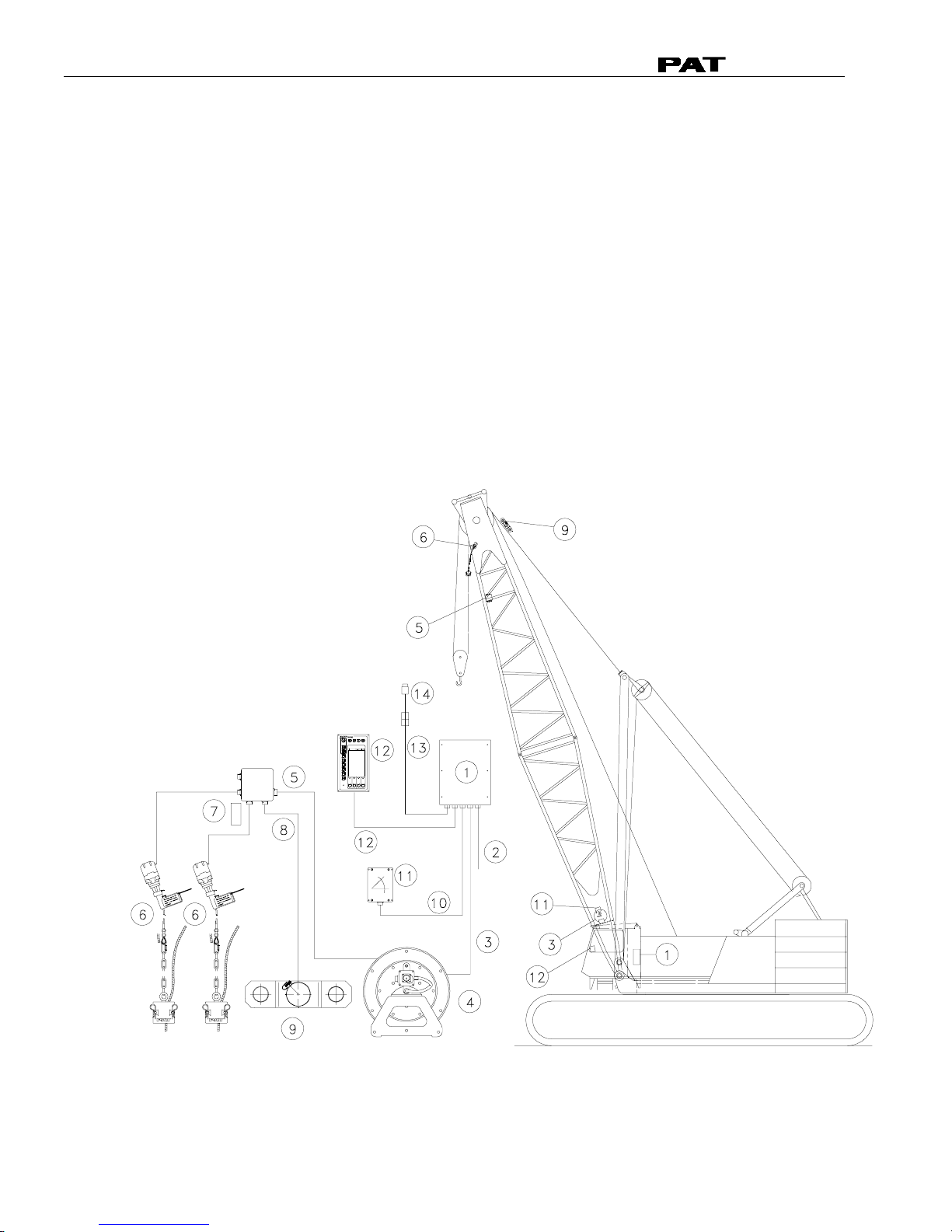

3SYSTEM DESCRIPTION...................................................................................................2

4GENERAL FLOW CHARTS...............................................................................................3

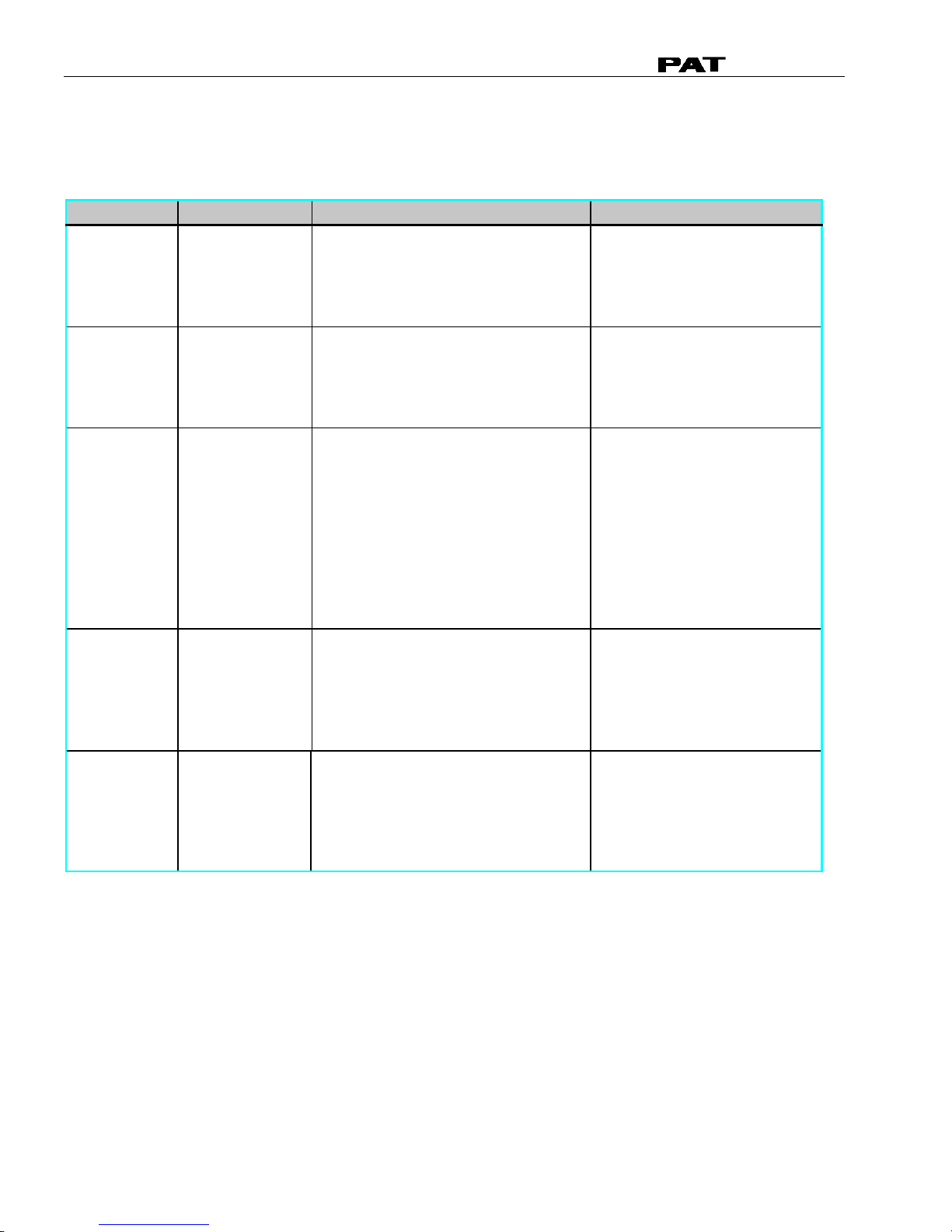

5ERROR CODES.................................................................................................................4

5.1 OPERATING ERRORS E01 THROUGH E06......................................................................................4

5.2 LOCKOUT FUNCTION ERRORS 07 AND 08......................................................................................5

5.3 ANALOG INPUT CHANNEL ERRORS................................................................................................5

5.4 ERRORS 31 AND UP.....................................................................................................................6

6FUNCTION LOCKOUT ....................................................................................................10

7NO DISPLAY....................................................................................................................11

8ANTI-TWO BLOCK PROBLEM........................................................................................13

9ANGLE SENSORS...........................................................................................................16

10LOAD READING..............................................................................................................18

11AREA DEFINITION INDICATION PROBLEM..................................................................20

12DATA TRANSFER CENTRAL UNIT <--> CONSOLE ......................................................21

13DRAWINGS .....................................................................................................................23

13.1 ELECTRICAL WIRING (DRAWING 1) PART 1................................................................................23

13.2 CENTRAL UNIT BREAKDOWN / PARTS LIST (DRAWING 2)............................................................25

13.3 CONSOLE DS350/1334 / PARTS LIST (DRAWING 3)...................................................................27

13.4 CENTRAL UNIT MAIN BOARD LAYOUT (DRAWING 4) ...................................................................28

13.5 CENTRAL UNIT ANALOG INPUT MODULE (DRAWING 5)................................................................29

13.6 CONSOLE CONNECTION BOARD (DRAWING 6) ...........................................................................30

13.7 FORCE TRANSDUCER (DRAWING 7)..........................................................................................31

13.8 AREA DEFINITION SWITCH (DRAWING 8) ...................................................................................31

13.9 BOOM JUNCTION BOX (DRAWING 9)..........................................................................................32

13.10 CABLE REEL (DRAWING 10)...................................................................................................33

14PROCEDURES................................................................................................................34

14.1 PROCEDURE 1: EPROM LOCATION AND INSTALLATION..............................................................34

14.2 PROCEDURE 2: MAIN BOARD REPLACEMENT.............................................................................35

14.3 PROCEDURE 3: ANGLE SENSOR ADJUSTMENT/REPLACEMENT....................................................36

14.4 TROUBLESHOOTING MOISTURE.................................................................................................37

14.5 THEORY 1: OPERATION OF ANGLE SENSOR...............................................................................39