Bonjear BJ-S825 User manual

Truck Tire Spreader

Instruction Manual

‘

WARNINGS

◆Please read the instruction booklet and all the directionslisted on the

sticker attached on the machine carefully andfully understand the contents

before use, which is necessary for protecting the users from harms and the

machine from damages.

◆This machine is used for spreading tires or repairing protective casing of

tires only. It can’t be used for other applications. Our company will not

accept any responsibilities for all the consequences due to improper use.

◆Keep the spreading hooks and claws clean in the process of spreading, to

avoid sliding due to grease or some other foreign objects, which will bring

danger to the maintenance work.

◆Please don’t use the machine when it obviously appears too old or when it

is clearly twisted out of shape or when it’s damaged, and make treatment in

accordance with the local laws and regulations of waste management.

◆The professionals that operate the machine should wear suitable

protective ocular coverings in a correct way throughout, to protect the eyes

from harms caused by the sundries in the process of repairing.

Product Illumination

Horizontal pneumatic car tire spreader special design for fixed the tires and

spreading the tires during repairing cars and small trucks, microbus, in order

to work for the tire polishing, cleaning and films affixed etc, equipped with

work light and tools rack to improve work efficiency, enable the tire repairing

work to be more convenient and faster. Manifest personalized design.

Technical Parameter

Be propitious to:

tire type:8.25-20/14.00-20(9R-16.5R);R22.5

Work Voltage:

Input voltage:220V 50/60HZ

Work light voltage:12V

Air pressure:: 8-10 KG/CM²

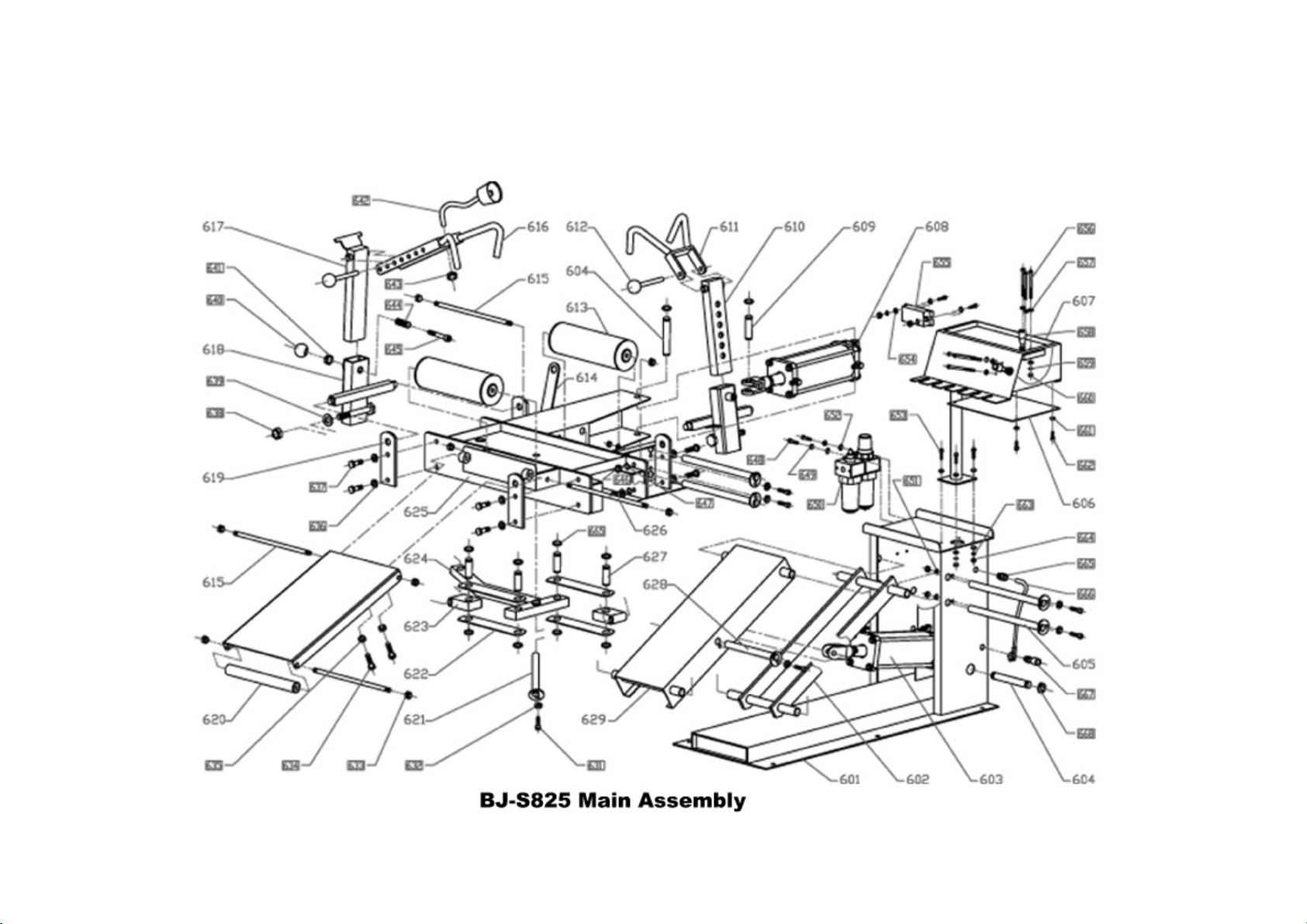

Product structure Illumination

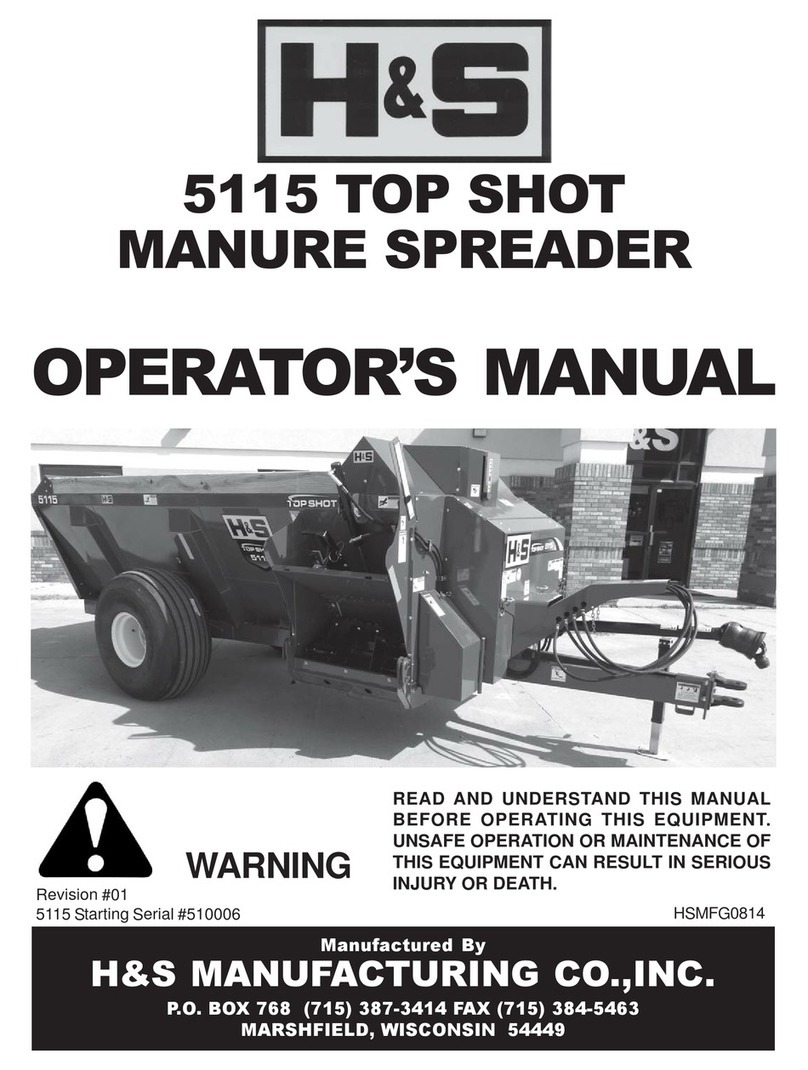

(1) Tools Tray (2) pneumatic control box (3) tools racks

(4) Air Regulator Device (5) main body Power

(6) Pneumatic union (7) up &down pneumatic cylinder

(8) Short spread hook (9) Long spread hook

(10) Tire platform (11) Work light

(12) up &down platform (13) Adjusting valve

(14)Spread pneumatic cylinder (15) Tire lever

(16) Pneumatic tools union

(17)Spread pneumatic cylinder control valve

(18) Up &down pneumatic cylinder control valve

INSTALLATION

1. Place this product on solid ground and keep its flat

2. Remove the backboard of pneumatic control box from the inclined support

board

3. Take the fixed pin from the pneumatic control box

4. Put the pneumatic control box on the top of body box and adjust well the

position

5. Connect the tools tray with pneumatic control box well

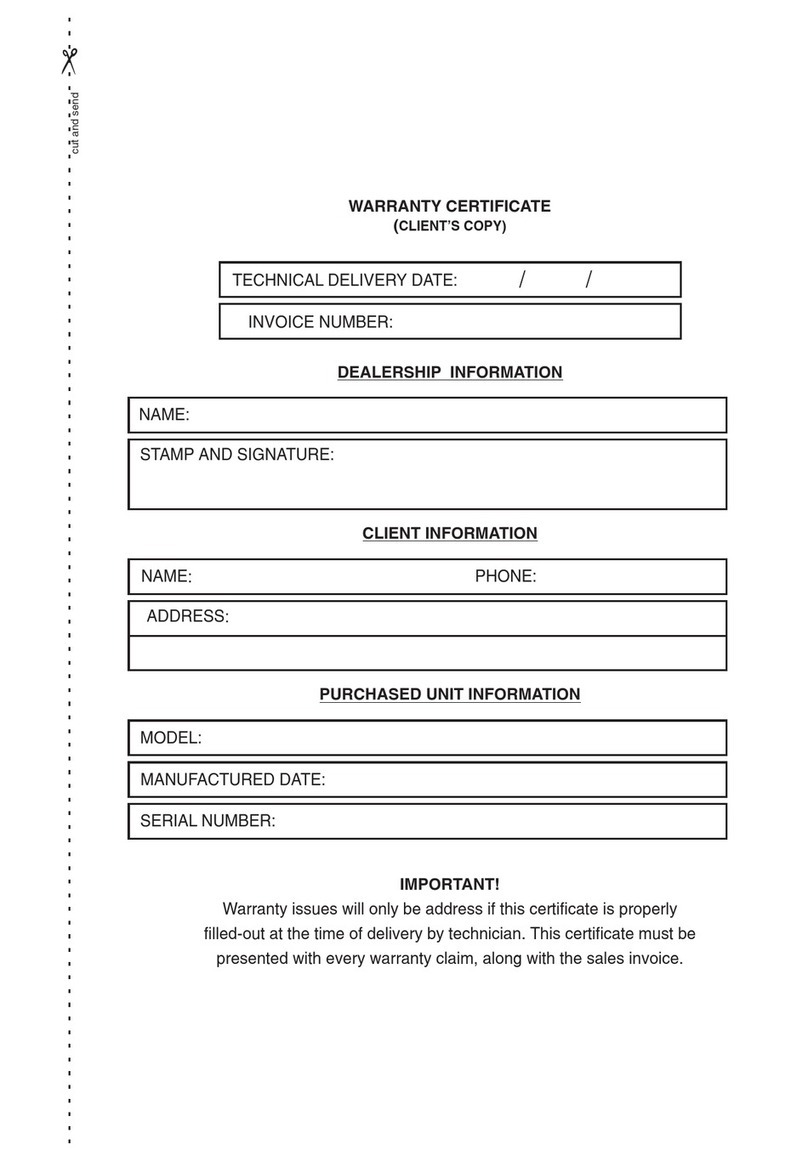

6. Connect the tire sloping board with equipments well

7. Connect the spread hook which equipped with work light with equipments

well

8. Connect the short spread hook with equipments

9. Connect a fast joint top at 1/4 normal temperature and moderate air

pressure onto the fast joint top of the machine’s air inlet. The minimum

standard is to use 1/4 inch’s wind pipe every 100 square inches.

10. Fixed it on the flatly ground with screws and keep the screw firmness

Operation

1. Before start the machine, check carefully whether the fasteners on the

machine are loose or not because of transportation. If yesterday, must be

re-tightened.

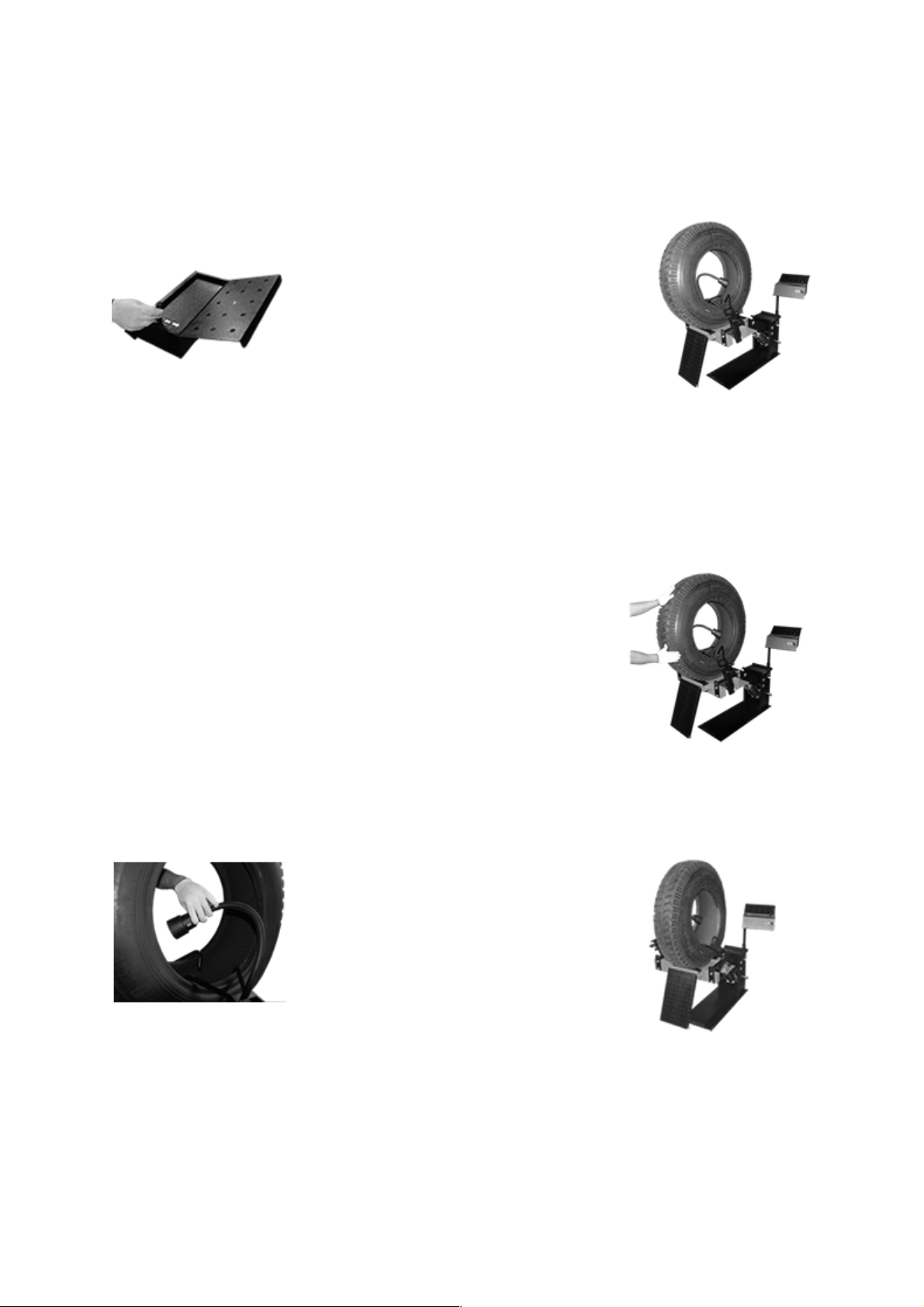

2. Fix the tire on the tire spreader with claw by hand

3. According to the size of tire which need be repaired to adjust the

spreading claw to be the appropriate height. Place the spreading hook to be

link pin of the hanging device. Adjust the spreading hook, move the link pin

and spreading hook up and town in order to insert into one of adjusting holes

which totally have seven groups. Put the short spread hook inside the tire

and try to place the tire in the middle of tire lever if possible

4. Pull the spreading control

valve to the direction of spreading, and spread the tire to the width needed.

The tire will probably disengage from the spreader if the spreading hook arm

is too high. Operate after it is lowered and the height is properly adjusted.

5. Pull the up&down control valve to the direction of up&down needed,

raise the tire to a proper height.

6. If it’s needed to revolve the tire to a new position, please pull the

spreading control valve to the direction of contraction, revolve the tire to a

proper position on the machine after the spreading hooks are loosened, then

operate the machine.

7. The working light fixed on the machine needed to be adjusted to a proper

position, to illuminate the inside sufficiently and make the repair work easy.

8. After finished maintenance work, please firstly move the up&down control

valve to the downward direction, let the tire fall to the lowest, then move the

up&down control valve to the direction of contraction, loosen the spreading

hook and remove it from the tire core, then discharge the tire along the

sloping board.

Maintenance

◆Add the lubrication oil to the oil cup in time, always guarantee that the oil

quantity in the cup to be occupy 1/3-2/3 of the total volume. Adjust drip oil

speed, piston reciprocating run every 5 ~ 6 times for drip one blob oil for

standard. ensure the oil pathway lubricate fully.

◆clear away the dust and sundries always, check whether the fastener is

loose or not.

◆Drip oil to the piston rod and the various parts of pin regularly. Reducing

friction, extending machine life.

NO

CODE

description

quantity

601

110000

body

1

602

130000

swinging frame

1

603

140000

up pneumatic cylinder

1

604

200004

pneumatic cylinder shaft

2

605

150001

shaft 1

4

606

160007

Motherboard of pneumatic control box

1

607

160000

pneumatic control box

1

608

170000

spreading pneumatic cylinder

1

609

200010

connecting union

1

610

240001

Adjustive pipe 1

1

611

250000

short spread hook

1

612

200007

Alignment unite element

2

613

290000

lever unite element

2

614

200005

Power line bracket

1

615

200008

Staff shaft

3

616

260000

Long spread hook

1

617

240000-2

Adjustive pipe 2

1

618

230000

swing frame

2

619

200002

branch union

4

620

222000

lever unite element

1

621

150000-3

Shaft 3

1

622

200001

connection board

4

623

280000

short pulling pole

2

624

270000

pulling pole

1

625

210000

Up & down bracket

1

626

200009

Shaft 2

1

627

200003

Connecting-rod shaft

4

628

150000-2

Shaft 2

1

629

120000

swing cover

1

630

160008

tools tray

1

631

Column hexangular bolt M8X10

6

632

washer 8

6

633

ceasing nut M12

8

634

Hexangular bolt M8X30

2

635

Hexangular nut M8

7

636

washer 12

12

637

Hexangular bolt M12X40

8

638

ceasing nut M16

2

639

washer 16

2

640

handle ball B-M10X32

2

641

Coarse thread Hexangular flat bolt M10

2

642

work light

1

643

Hexangular flat bolt M10

1

644

compressing spring

2

645

Column hexangular bolt M10X50

2

646

Hexangular nut M12

8

647

spring washer 12

2

NO

CODE

description

quantity

648

Column hexangular bolt M6X12

4

649

spring washer 6

2

650

air regulator

1

651

spring washer 8

5

652

big flat washer 6

2

653

Column hexangular bolt M5X16

2

654

big flat washer 5

2

655

electron transformer

1

656

crossed set bolt M4X40

6

657

washer 4

12

658

handle valve

2

659

spring washer 4

6

660

Hexangular nut M4

6

661

washer 5

12

662

Column hexangular bolt M5X10

4

663

spring washer 5

2

664

Hexangular nut M5

2

665

loop

1

666

power thread

1

667

metal quick connector

1

668

shaft spring loop 20

14

669

washer 6

4

670

Hexangular nut M6

2

671

Column hexangular bolt M8X12

1

672

Lathedog

2

673

bellows

1

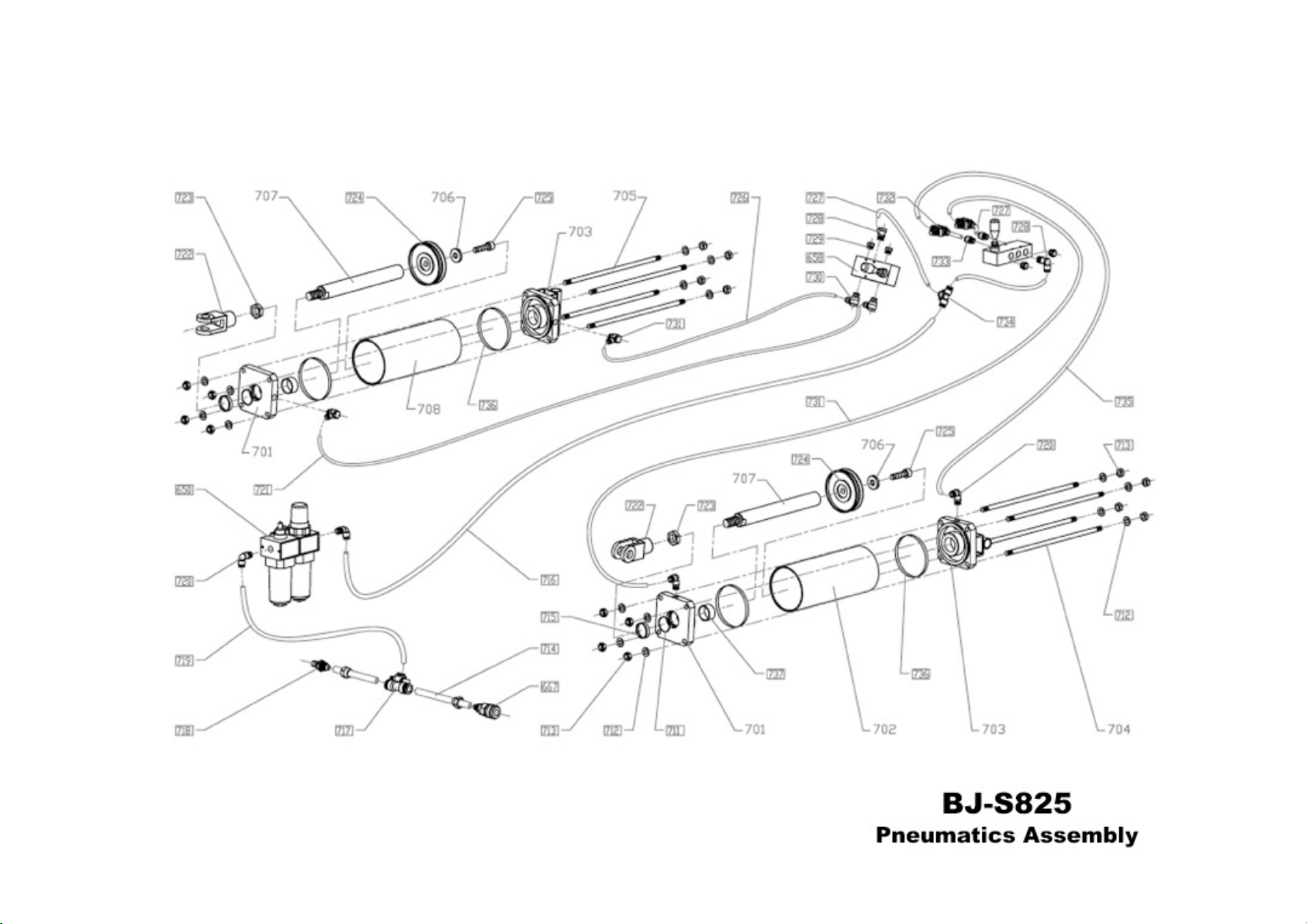

NO

CODE

description

quantity

667

metal quick connector

1

701

140005

pneumatic cylinder cover

2

702

140003

pneumatic cylinder canister

1

703

141000

cylinder bottom

2

704

140007

connecting staff

4

705

170002

connecting staff

4

706

140006

washer

2

707

140002

piston staff

2

708

170001

pneumatic cylinder canister

1

711

0-ring 31.5X3.55

2

712

washer 10

16

713

ceasing nut M10

16

714

PU pipe Φ12X138

2

715

Dustproof seal 32X40

2

716

PU pipe Φ8X1450

1

717

quick insert union 12-8

1

718

metal quick connector

1

719

PU pipe Φ8X400

1

720

Quick insert right-angle connector 8-02

4

721

PU pipe Φ6X2300

1

722

union

2

723

Hexangular flat nut M20X1.5

2

724

piston Φ100

2

725

Column hexangular bolt M12X45

2

726

PU pipe Φ6X2700

1

727

PU pipe Φ8X180

4

728

quick insert middle union 8-02

1

729

subminiature silencer

4

730

quick insert middle union 6-02

4

731

PU pipe Φ8X300

1

732

speed adjusting union 8-8

2

733

quick insert straight union 8-02

2

734

quick insert upright union Φ8

1

735

PU pipe Φ8X1300

1

736

O rubber ring 95X2.65

4

737

oil-free piston Φ32XΦ36X18

2

Table of contents

Popular Spreader manuals by other brands

Amazone

Amazone ZG-B 5500 Ultra Hydro operating manual

Fisher

Fisher QUICK-CASTER 300W Owner's manual and installation instructions

Kellfri

Kellfri 33-JMATV manual

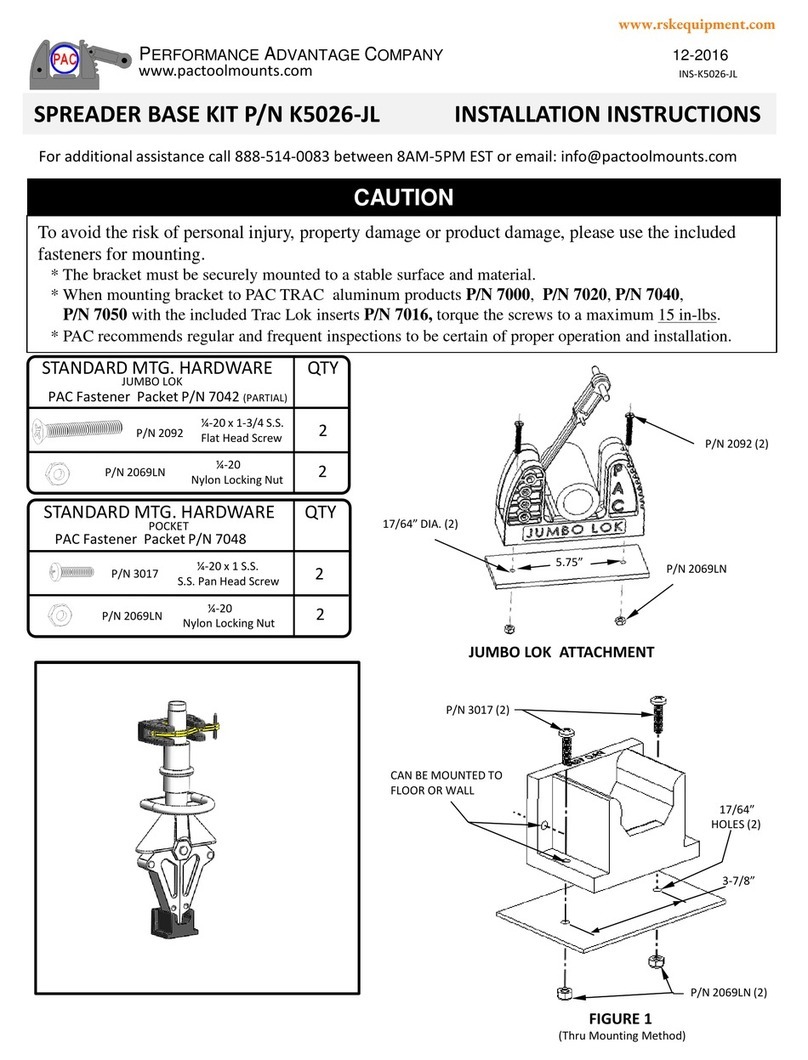

PERFORMANCE ADVANTAGE COMPANY

PERFORMANCE ADVANTAGE COMPANY K5026-JL installation instructions

Agri-Spread

Agri-Spread AS35 operating manual

Kubota

Kubota VS220-330 Technical & service manual