Cresco 25SW User manual

Thank you for purchasing our

Cresco 25SW Fertilizer and

Salt Spreader | Assembled

Scan for video assembly:

We’re delighted to have you as a customer

and are here to help! First off, let’s get your

product assembled!

https://crescospreaders.com/spreaders/spreads-professional/

Table of Contents:

1: Spare Parts

2: Slide System Explanation

3-5: Assembling your Cresco 25SW

6-8: Slide System Explanation

9-12: How to Use the Cresco 25SW

13: Application guide for fertilisers

14: Warranty

3 YEAR

WARRANTY!

1

Spare Parts

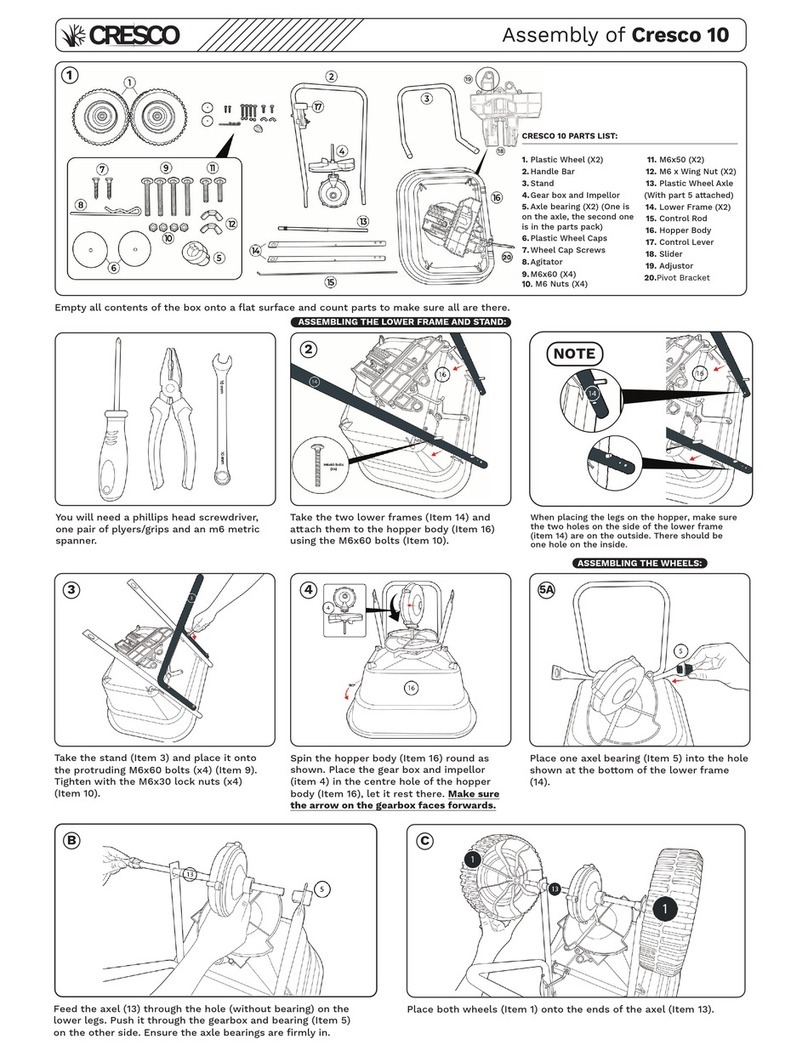

Empty all contents of the box onto a flat surface and count parts to make sure all are there.

1. Hopper Body & Frame

2. Pneumatic Wheels

3. Control Rod

4. Handle Bar

5. Back Stand

6. 4 x M6 x 45 Bolts

7. 8 x M6 Lock Nuts

8. Small Cotter Pin

9. Large Cotter Pin

10. Privot Bracket

11. 4 x M6 x 65 Bolts

12. Large Agitator

13. Small Agitator

CR25 PARTS LIST:

2

Slide System Explanation *** VERY IMPORTANT ***

Your Cresco spreader comes with two different application sliders.

One is for winter and the other is for summer!

Please locate and choose your slider.

Summer SliderWinter Slider

DO NOT SPREAD FERTILIZER

WITH THE WINTER SLIDER

3

Assembling your Cresco 25

Place the Hopper body (1) on the table so that the

gearbox is pointing upwards. Take the bolts out of

the main frame (1) - you will use these to attach

the backstand to the hopper body and main frame

(1). Remove the nuts from the bolt ends.

1

Take the backstand (5) and align it with the

holes on the main frame (1). Place the four bolts

through the holes available.

2

Take the pneumatic wheels (2) and slide them

over the axles on each side of the main frame

(1). You will also need the two cotter pins (8 & 9)

that sit inside the parts bag.

4

Use a spanner to tighten the lock nuts. The

backstand (5) should now be securely attached

to the hopper body and frame. (1).

3

Align the hole on the inside of the pneumatic

wheel (2) with the hole on the axle. Take the

large cotterpin (9) and thread it through the two

holes.

5

After threading the cotter pin (9) through the two

holes, use a pair of plyers to pull apart the two

ends of the cotter pin (9). The wheel will then be

secured in place.

6

4

Thread the four remaining bolts (6) through the

holes on the handle bar (4) and the back stand

(5).

11

Align the holes on the handle bar and on the

back stand (5).

10

Turn the hopper body and main frame (1) over

so that the spreader sits on its wheels and

backstand. Take the handle bar and slide it down

the two ends of the backstand.

9

Once in position, use the same plyers to split the

ends of the cotter pin (8) to hold the wheel in

place.

8

Take the small cotterpin (8) and place it through

the hole on the outside of the other wheel.

7

Take the bent end of the control rod (3) and

thread it through the hole at the back of the

pivot bracket. It should lock into place.

12

Assembling your Cresco 25

5

If the application hole is fully open and the lever

is set at 20, tighten the screw so that the control

rod (3) is secure.

Take the other end of the control rod (3) and

align it with the hole on the on/o mechanism of

the handle bar (4). Push the on/o lever all the

way to 20 and then hand tighten the screw.

15

13

Make sure the slider at the bottom of the hopper is

fully open. You should see the entirety of the holes

or hole on the slide system. Insert both agitators,

with the smaller one going under the larger.

14

Assembling your Cresco 25

6

Ice Melts

Winter

For spread width 6 meters. Pavement setting (2 meters).

Slide System Explanation

7

Border Control

To protect your borders simply slide the border control into position to cut o

the left hand side of the spread pattern.

Summer

The summer slide system comes with 20 dierent settings and a border

control. This slider provides control over the accuracy of your spreading.

Large/Heavy Materials Small/Light Materials

Slide System Explanation Guide Only

88

Slide System Explanation

9

How to Apply Fertilizer to your lawn like a pro in four steps!

Step 1: Understanding the application rate and settings

Step 2: Preparing the Spreader

Step 3: Walking Patterns for the optimum application

Step 4: Cleaning & Maintenance

Step 1: Understand the application rate and

settings

Application Rate Settings

Check the back of the fertilizer bag

to nd out the recommended G/m²

and spreader application setting.

If the spreader setting is not on the back

of the bag, please get in touch with your

fertilizer bag provider.

Set the handle to the correct setting.

If you are unable to nd the required Cresco volume setting, please visit,

www.crescospreaders.com

How to use the Cresco 25

10

Spread Pattern Settings

Once you have the correct application rate, you will need to check that the

spread of material is even on both sides of the spread pattern.

To balance the spread pattern for your material, check online or with your

fertilizer or seed provider.

For a quick reference, please refer to our guide on the previous page.

Step 2: Preparing the Spreader

Check the material to be applied is dry and free owing to ensure it will ow

freely through the hopper. Make sure your application rate and spread pattern

settings are correct, close the application hole fully and then pour in your

material.

How to use the Cresco 25

11

WARNING **Do not pour material in the hopper when the application holes are

open as it can lead to spillages or leaks that can damage the area. Do not open

the gauge until you are over the area you want to spread and are moving at a

brisk walk***

Step 3: Walking Patterns for the optimum

application (For Fertilizer Only)

There are two methods of eective spreading, longitudinal fertilizer spreading

and cross sectional fertilizer spreading.

When applying fertilizer please make sure you walk at 3mph and keep the

hopper in a stable, upright position.

Your outlet hole should look like this

before you pour in any material.

How to use the Cresco 25

12

Single Pass Fertilizer Spreading

Use ½ the application rate suggested

on the back of your fertilizer bag

Cover the area as shown by passing

over it in an up and down track

as shown, taking into account the

spread width of the material being

applied.

Cross Sectional Fertilizer Spreading

Use ½ the application rate suggested

on the back of your fertilizer bag

Cover the area as shown. Repeating

by a second pass in the same

manner going across the area as

shown in the diagram.

Step 4: Cleaning and Maintenance

How to use the Cresco 25

13

Application Guide for Fertilisers

Speed

Calibration Setting Guide

Mph 3

Kph 4.828

Metres p/

Sec 1.34

Product 05mm - 1mm 1mm - 2mm 3mm - 5mm

Width Metres 3.5 3.5 3.5 4.0 4.0 4.0 4.5 4.5 4.5

Application

Rate Grams /Sq

M20 35 50 20 35 50 20 35 50

Run Time Secs 10 10 10 10 10 10 10 10 10

Distance metres 13.4 13.4 13.4 13.4 13.4 13.4 13.4 13.4 13.4

Area Sq Metres 47 47 47 54 54 54 60 60 60

Target

Weight Grams 938 1,876 3,015 938 1,876 3,015 938 1,876 3,015

Setting 8.5 11 14 11 13.5 19.5 13 18 16 (X2)

Slider Position ------7 Clicks

LHS 7 Clicks

LHS 7 Clicks

LHS

LHS (Left hand slider adjuster)

is recommended to be engaged

when spreading large sized

granular materials to provide a

more uniform distribution on the

left and right side of the spread

pattern. Conversely with very

light materials (e.g. grass seed)

engaging the RHS (Right hand

slider adjuster) will be similarly

benecial.

Left hand

slider

adjuster

The manufacturer cannot

be held responsible for

any variations in sq. metre

application volumes, or spread

width dierences, due to

possible variations in materials,

application conditions at the

time and dierent operator

application techniques.

*Do not spread Fertiliser or seed materials with the winter slider*

This chart should be used as a guide only.

Right hand

slider

adjuster

14

DMMP Ltd. warrants this product free of defects in original workmanship and

materials for a period of 3 Years to the end user with the original dated purchase

receipt.

If a manufacturing non-conformance is found, DMMP Ltd. will repair or replace

the part(s) or product at it’s discretion at no charge provided the failure is not

the result of incorrect installation, mishandling, misuse, tampering, or normal

wear and tear as determined by DMMP ltd.

DMMP Ltd. at its discretion may require that the part(s) or product be returned

along with the original purchase receipt at owners’ expense for examination and

compliance with the terms of this warranty.

Do not return any product without rst receiving authorization

from DMMP Ltd. To seek remedy under this warranty, contact

DMMP Ltd. at +44 (0)1455 825 400 or email us at info@

dmmp.co.uk and describe the nature of the manufacturing

defect.

SPECIFIC LIMITATIONS:

This warranty covers only the

part(s) or product; any labour

charges associated with repair or

replacement of nonconformances

are specically excluded.

Due to the corrosive nature of most fertilizers

and ice melt products, DMMP Ltd makes no warranty

against and specically excludes part(s) or product

degradation or failure due to corrosion or its eects.

To negate the eects of corrosive materials on

your product, clean and dry your spreader or seeder

thoroughly after each use. As a further preventative

measure, coat all metal parts with a light oil or silicon

spray.

3-Year Limited Warranty

Other Cresco Products

Cresco 10SW

Code: CR10SW

Cresco 20SW

Code: CR20SW

Cresco SRS

Code: CRSRS

Heavy Duty Snow

Shovel

Code: H464P

Cresco 1

Code: CR001

Cresco 5

Code: CR005

Wide Snow Clearer

Code: H611

3 in 1 Foldable

Snow Shovel

Code: HZS212

Cresco Snow

Blaster

Code: H595

Polar Tough

Snow Plough

Code: YH74900

Helps manage snow

accumulation

Reduces labour

costs compared to

a shovel

Two grip design

makes snow

removal easy and

minimises

lifting and stooping

Wave ribbed design

reinforces blade

strength

Ergonomic

arm-rest handle for

easy holding

New heavy duty

gearbox

Cushioned on/o

lever with solid rod

linkage

A lightweight and ip

back- stand allows

it to be shipped fully

assembled

Cushioned on/o

lever with solid rod

linkage

Pneumatic Wheels

Large moulded

wheels

Pneumatic wheels

allow a consistent

impellor speed and

a smooth drive

Easy to use on/o

system

Large 2Kg Hopper

Seed Plate Bag

Included with 11

Seed Plates

Strong row marker

mounting

Powder coated

steel tubed handle

Large comfortable

ergonomic grip

Steel blade Steel edge to

increase cutting

power and longevity

Anodised

aluminimum head

Teloscopic

anodised

aluminimum handle

Product / Season Unique Selling Points

Cresco 15SW

Code: CR15SW

Large 46Kg Warranty

Fertilizer Hopper

Capacity

Strong, durable

frame

Cresco 25SW

Code: CR25SW

This manual suits for next models

1

Table of contents

Other Cresco Spreader manuals