Agri-Spread AS35 User manual

©Copyright Agrispread September 2014

830 Belt Spreader

LIME & FERTILISER SPREADER OPERATING MANUAL

AS35, AS55, AS85, AS100, AS120 & AS120-T MODELS

Original Instructions

©Copyright Agrispread September 2014

830 Belt Spreader

Contents

Product Details.................................................................................................................................................1

Setting Spinner Speeds and Rear Deflectors......................................................................................................4

Setting the Application Rate.............................................................................................................................5

Gear Box Parts.................................................................................................................................................7

General Maintenance......................................................................................................................................10

Belt Maintenance and Adjustment ..................................................................................................................10

Belt Care........................................................................................................................................................12

Maintenance of Bearings................................................................................................................................15

Maintenance of Land driven Gearbox.............................................................................................................18

Maintenance of Hydraulic Gearbox.................................................................................................................19

Wheel Tightening Sequence ...........................................................................................................................20

Wheel Tightening Torque...............................................................................................................................20

Servicing Axles..............................................................................................................................................21

Tighting Torques for Underslung Suspension..................................................................................................22

Replacing Filter Element................................................................................................................................23

Agri-Spread Density Metres ...........................................................................................................................25

Headland Control Valve.................................................................................................................................25

Mounting Spreader to Tractor.........................................................................................................................26

Dismounting Spreader from Tractor................................................................................................................27

Connecting Up Hydraulics to Your Trailer......................................................................................................28

Adjusting Height of Hitch...............................................................................................................................29

Maintenance of Hitch .....................................................................................................................................30

Operating Handbrake......................................................................................................................................31

Maximum Tyre Inflation Pressure...................................................................................................................32

Maximum Spreader Speed..............................................................................................................................32

Bout Width Testing Form...............................................................................................................................34

Appendix 1 - Setting your Spreading Rate.......................................................................................................36

How to use Rate Charts:.................................................................................................................................37

Recommended Spinner Speeds For Spreading.................................................................................................38

Rate Charts (Please Note Rate Charts Are Only Used) with landdriven gearbox ..............................................44

Disclaimer

While every effort has been made in the production of this manual to ensure that the information contained

herein is full and correct, Agrispread assumes no responsibility for errors or omissions. Agrispread reserves the

right to modify the machinery and the technical data contained within the manual without prior notice.

Further to this, Agrispread assumes no liability for any damages that may result from the use of the information

contained within this manual.

©Copyright Agrispread September 2014 1

830 Belt Spreader

Product Details

Agrispread Model No: ………………………….. Serial Number….2013/

Spinner motor size: ………………………………………………………….….

Hydraulic valve No: ……………………………………………………………

Wheel & tyre spec: ……………………………………………………..………

Recommended Pressure: …………………………. Max.: ……………………..

Figure 1: Location of Machine Serial Plate

Notes

2 ©Copyright Agrispread September 2014

830 Belt Spreader

Important Safety Precautions

Never exceed the spreader’s speed rating as this could lead to death or serious injury.

Never carry out adjustments or maintenance on machinery while it is in operation, as

this could lead to death or serious injury.

Never attempt to clear a blockage while the spreader is in operation as this could lead

to death or serious injury.

Never operate the machine without all safety guards in place and properly secured as

this can result in death or serious injury.

Always disconnect hydraulic connections before carrying out any of the maintenance

instructions. Failure to disconnect, the above, could lead to death or serious injury.

Do not ride on the spreader. The ladder is only provided for ease of access during

servicing or maintenance operations.

Do not overload the spreader. Exceeding the axle weight will cause irreparable

damage to the spreader.

Observe all current Health and Safety Regulations.

When carrying out maintenance tractor should be turned off and the key removed.

All persons except the operator should be kept away a minimum of 75 m from

spreading area

Never enter machine when the spreader is running

Loose fitting clothing should never be worn when while using the machine as these

could become entangled in moving parts and could result in death or serious injury.

Personal Protective equipment should be worn when handling fertiliser (check

MSDS).

General

1. Keep the machine as clean as possible

2. Check wheel nuts daily before use.

3. Check tyre pressures before use (see max inflation pressure table)

4. Grease all bearings weekly.

5. Always check the oil filter indicator on the filter (if fitted,) before use.

6. Always change tractor oil and filter in accordance with the manufacturer’s

instructions.

©Copyright Agrispread September 2014 3

830 Belt Spreader

All maintenance work must be carried out when the machine is turned off and the key

removed.

Failure to comply with the instructions given in this manual may lead to the following

dangers:

-Danger of entrapment due moving conveyer type floor

-

-Danger of entanglement with spinners

-Danger of getting entangled in the shaft transmission parts if the guards are

removed;

Danger of falls when climbing ladder

Users should become thoroughly familiar with the contents of this manual before using,

servicing and mounting the spreader to the tractor. Never wear loose clothing when operating

the machinery. Always wear approved garments complying with accident prevention

provisions such as non-slip shoes, hearing and eye protection. Wear a jacket with reflecting

stickers if the spreader is used near public roads.

Work Area

The operator must remain seated while working the machine. Always ensure the tractor has

been turned off and the parking brake applied before any maintenance or changes are carried

out to the spreader.

Caution

The driven floor should never be operated with the doors in closed position this could cause

irreparable damage. On some fertilisers it should not be operated with less than 20 mm of gap

as packing will occur and the belt will jam. When spreading Steel Works Slag, always

operate the machine in the low gear with the door open as wide as possible.

4 ©Copyright Agrispread September 2014

830 Belt Spreader

Setting Spinner Speeds and Rear Deflectors

Spinner Speed is the most important factor in achieving an accurate spread pattern. The

spinner speed is adjusted by altering the control on the valve at the front of the machine

(shown in Figure 1 below). Guideline spinner speeds for various different materials are given

in Table 1 : Recommended Spinner Speeds For Spreading on page 38.

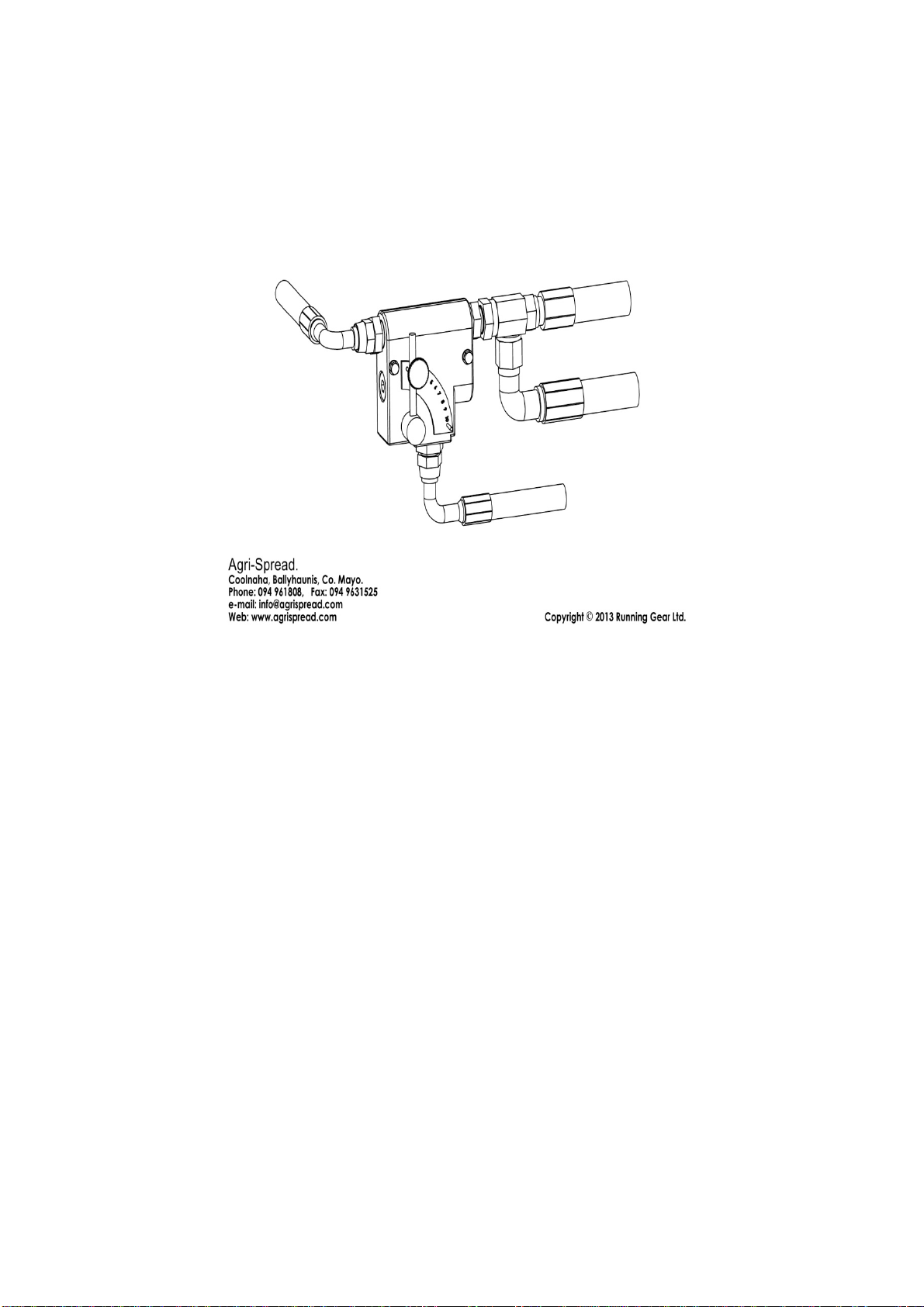

Figure 2: Spinner Flow Control Valve

When setting spinner speeds ensure the engine of the tractor is running at the same R.P.M. as

it will normally be operating in the field and make sure that the oil is warmed up to its normal

operating temperature. Always monitor the spinner speed by watching the tachometer when

operating the spreader as an error of 50 R.P.M. on spinner speed will result in a deterioration

of the spread pattern. If the spinner speed is too high there will be too much material behind

the spreader. If the spinner speed is too slow there will be too little material behind the

spreader.

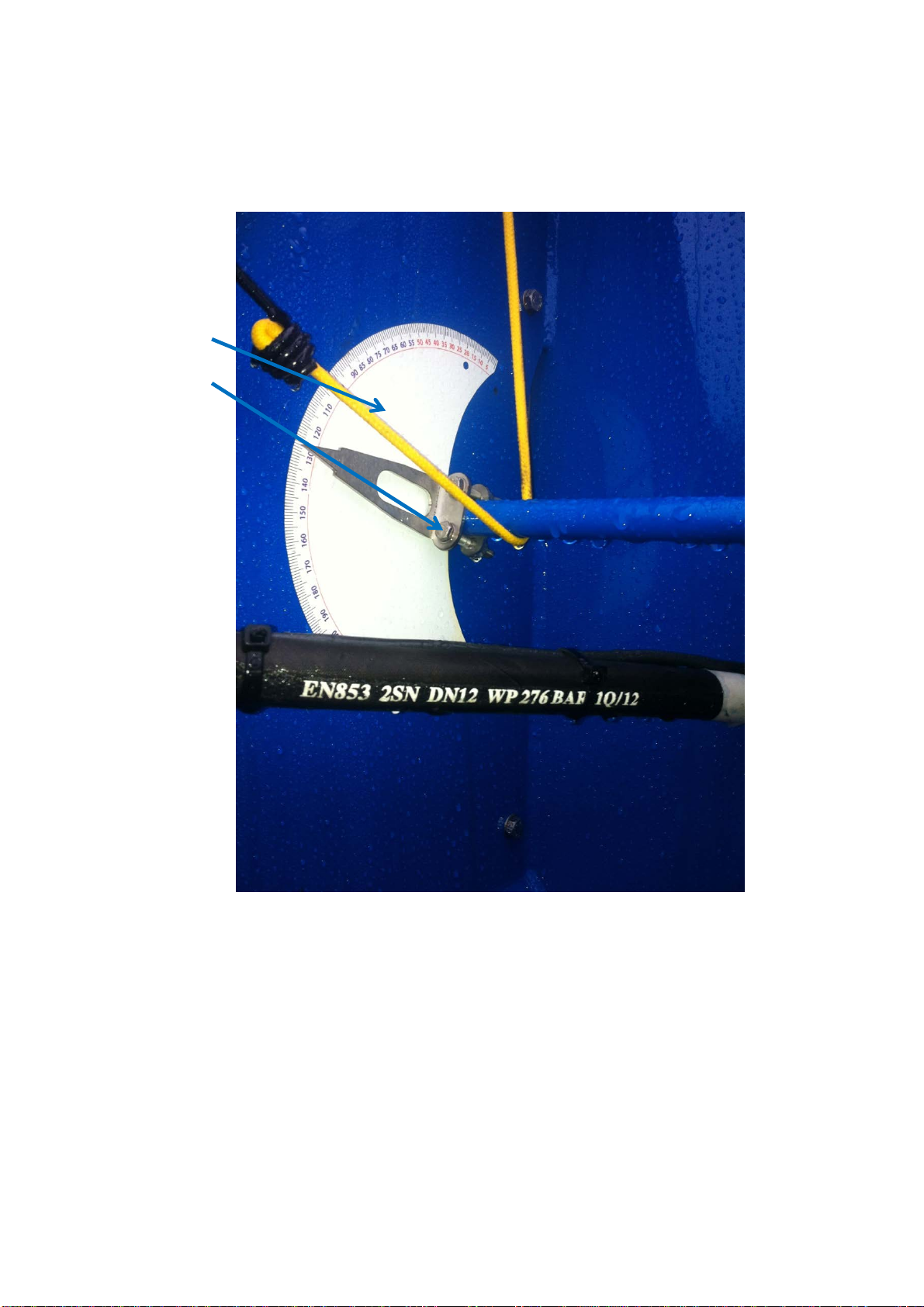

It is sometimes necessary to alter the angle of the rear deflectors to lighten the spread behind

the machine and throw the material more into the centre of the pattern. This is shown in the

table on the following page along with the spinner speeds for sample materials and is

expressed in the following manner.

WARNING: NEVER ADJUST THE DEFLECTORS WHILE THE

SPINNERS ROTATING.

©Copyright Agrispread September 2014 5

830 Belt Spreader

Setting the Application Rate

The application rate of material is controlled by the back door settings and gear selection.

Refer to the rate charts in Appendix 1 - Setting your Spreading Rate. At the back of this

manual for guideline settings of the door opening in millimetres and which gear should be

selected. Once you have selected your rate from the charts, remove the retaining pins in the

door handles and adjust the door so that the top of the door indicator lines up with your

selected figure on the chart. Replace the retaining pins and check that both doors are level

with each other. The rate is now set. With the huge variation of prills and compounds it is

impossible to be 100% accurate without checking the batch of material you are spreading.

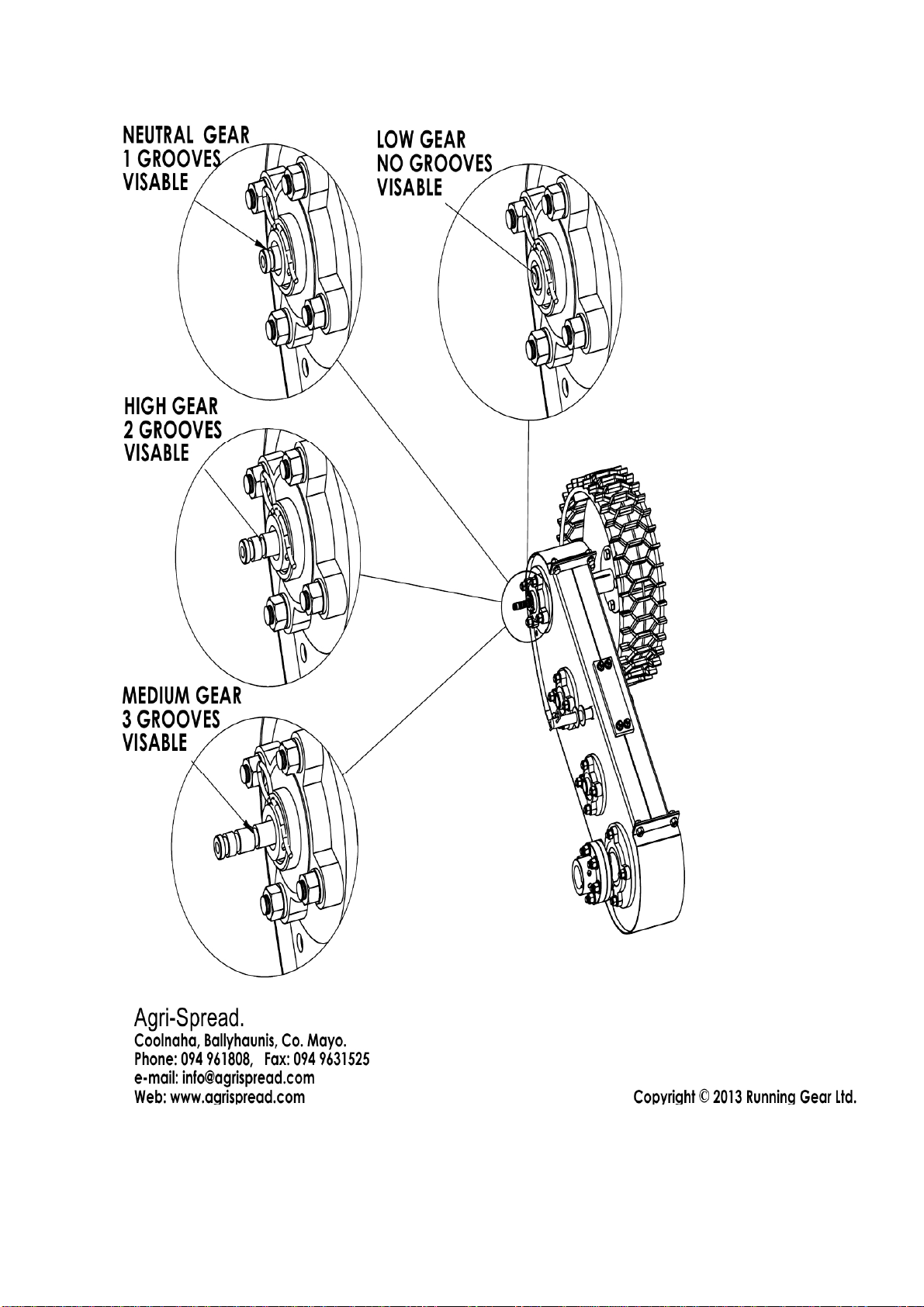

GEAR SETTINGS

Med..High..Low gear denoted on the table refers to the gear box selector on the inside of the

jockey wheel drive arm. Gear is selection is indicated on the decal on the gear box. Neutral is

between each gear. Always remember to replace the retaining pin after changing gear. Details

of changing gear are explained on page 8.

Use will dictate accurate settings.

To Start Spreading

Single Spool Tractors... Start by opening the tractor spool valve.

Twin Spool Tractors... Start the spinners by opening the tractor spool valve. Engage

the gearbox by lowering the gearbox ram until the gearbox jockey wheel is in full contact

with the trailer wheel. Do not run at high speed while engaging wheel.

Both... Ensure engine RPM is within the range as when the spinner speed was set and check

the spinner speed on the tachometer. Drive off maintaining engine RPM and using the tractor

gearbox to keep the engine from labouring. This will ensure the hydraulic flow will be

sufficient to maintain constant spinner speed.

To Stop Spreading

Single Spool Tractors... To raise jockey wheel clear of main wheel return the hydraulic

selector for the spinner to off through neutral to reverse flow until wheel is lifted and then

return to neutral.

Twin Spool Tractors... Lift the gearbox clear of the main trailer wheel by operating the

gearbox ram spool valve on the tractor, only stop spinners if required. Stop spinners by

operating the spinner spool valve on the tractor when required.

6 ©Copyright Agrispread September 2014

830 Belt Spreader

Feed Plate

Adjustments

Vane Settings

When starting testing, have the rear cross bar pivoted up into the neutral position. If after

carrying out a test there is still an unacceptable amount of material behind the spreader, pivot

the rear cross bar to the active position with the centre deflectors set at centre. Repeat test.

Spread width m

odifiers

Extend this end ofplate B

to reduce the amount of

material falling behind

thespreader.

Align ends of Contact

plates A and B

Centre V Insert

Centre deflectors

Extend this end ofplate A

to reduce the amount of

material directly behind

the spreader

Contact Plate A

To spread less material

behind the spreader,

increase the angle of the

centre deflectors.

Contact

Plate B

Rear Cross Bar

©Copyright Agrispread September 2014 7

830 Belt Spreader

Gear Box Parts

Gear Selection Details

Gear Change:

To change gear, remove “R” Clip from gear selector. Complete gear change by moving gear

selector to gear required. (See Figure 3 below)

When selecting gear it is necessary to rotate the Jockey wheel manually in order to select

required gear.

After selecting required gear, reinsert “R” Clip as shown above.

8 ©Copyright Agrispread September 2014

830 Belt Spreader

Figure 3: Gearbox Settings

©Copyright Agrispread September 2014 9

830 Belt Spreader

Removing Belt for Replacement

Should it be necessary to remove the belt, the following procedure should be adopted.

1. Slacken the both front adjuster’s worm drives right off.

2. Separate the bearing block carriers from the front adjuster’s on both sides of the

trailer.

3. Undo the grub screws on the inside of the front roller;

4. Remove bearing blocks on both sides.

5. Pull the bearing block with the loosened grub screws from the front roller shaft.

6. Slide Front Roller out from spreader

7. Remove all belt rollers by a tap up and out.

8. Loosen grub screws on rear belt roller

9. Loosen bolts which mount bearings to spreader

10. Remove bearings from rear roller

11. Slide the rear belt roller out from spreader

12. Remove the belt.

To install a new belt repeat the process in reverse order but ensure the belt is in correctly

Direction of rotation is marked and that the belt is on top side of pinch roller.

10 ©Copyright Agrispread September 2014

830 Belt Spreader

General Maintenance

All maintenance work must be carried out when the machine is turned off and the key

removed.

Belt Maintenance and Adjustment

The belt has been aligned in the factory before delivery of the spreader with no load. After

several initial loads, the belt will stretch and may need to be re-tensioned. This is described

below.

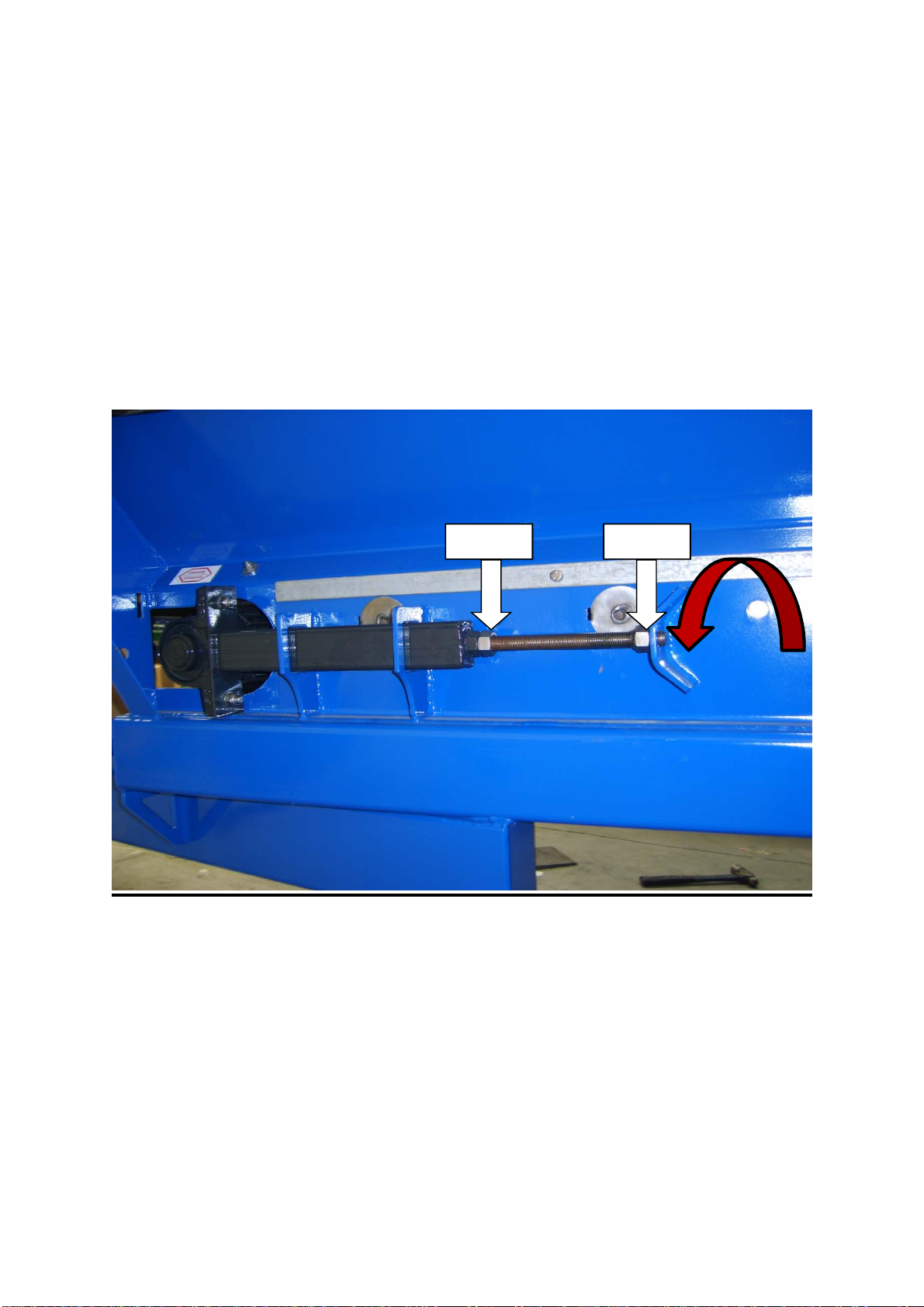

Left Hand Front Adjuster:

Using a 30 mm spanner, unlock nut “A”. Turn Nut “B” in the downward direction as shown

by the red arrow. See above illustration for details. (Note: positioning of front roller may

differ for different models) Turn the worm drive for only one revolution then repeat the

process on other belt adjuster(Note: for right hand adjuster nut B should be tightened in

upward direction . Repeat this process until belt is sufficiently tight. Location of Front

adjuster is shown in Figure 4: Location of Front Adjuster .

Nut “A”

Nut “B”

©Copyright Agrispread September 2014 11

830 Belt Spreader

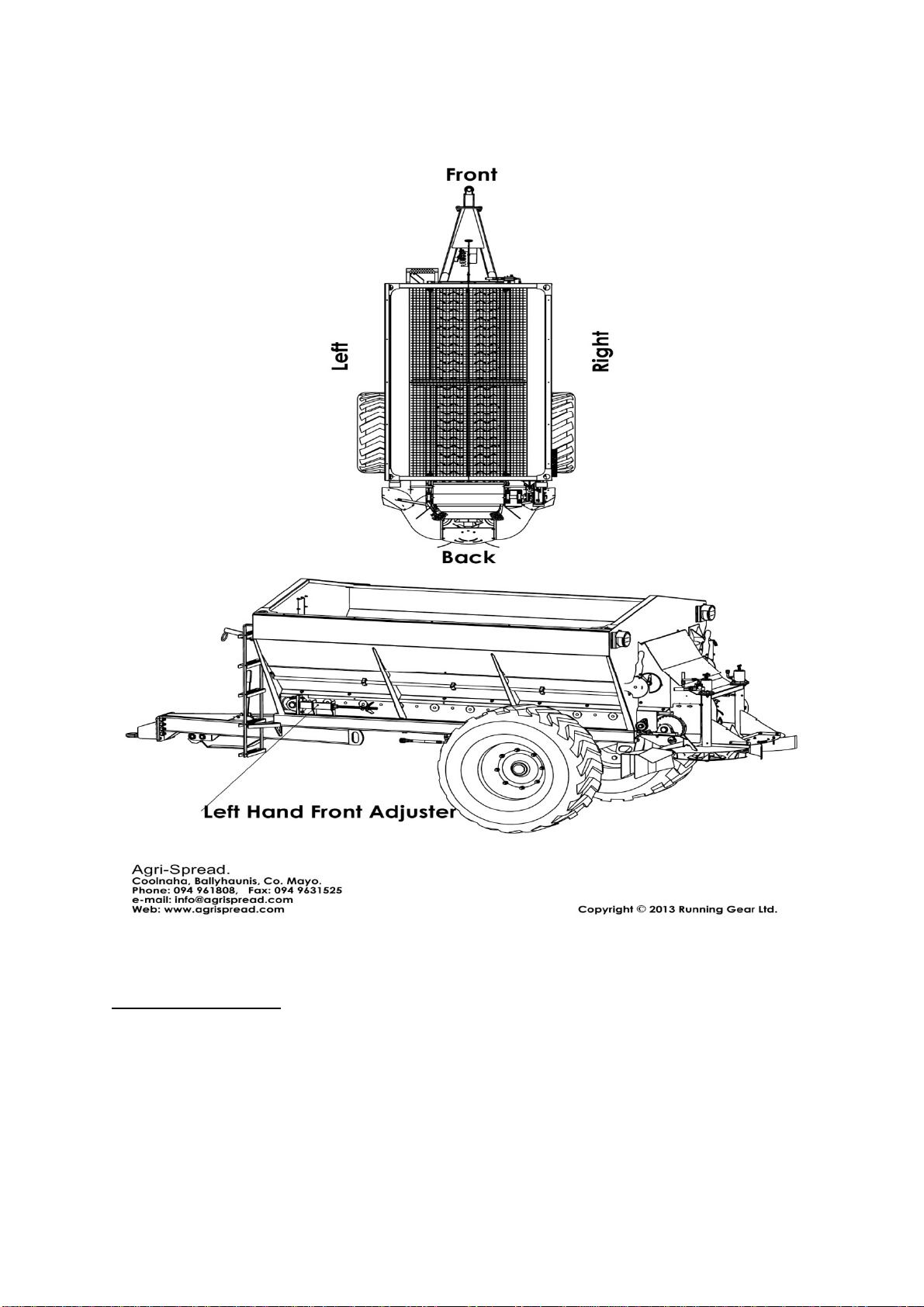

Figure 4: Location of Front Adjuster

Belt Alignment:

If the belt drifts to this side of the spreader (left hand side), the left hand adjuster only should

be tensioned 1/8 of a turn at a time. After each turn run the belt for 3 minutes. If the belt

continues to drift to this side repeat the process. Adjust evenly so that the belt does not slip

under full loads

Repeat the process for the right hand adjuster.

12 ©Copyright Agrispread September 2014

830 Belt Spreader

Belt Care

Keep the rear stripper bar clean to prevent build up as this will cause premature belt wear and

alter the spread pattern. Remove material build up from behind and under skirting for the

same reason.

End of Season

Slacken the belt before storage. Free up bed rollers before commencing new season

operation.

Check all nylon nuts (item 1) and roller end bushings(item 2) to ensure they are tight

©Copyright Agrispread September 2014 13

830 Belt Spreader

Check couplings (item 4) and coupling insert (item 5) to ensure it is in good

condition.

Ensure both side skirts (item 6) are in good condition, free of holes and damage, if

side skirts are damaged replace immediately as failure to do so is likely cause further

damage.

14 ©Copyright Agrispread September 2014

830 Belt Spreader

Check calibration sticker is legible and still functioning correctly (e.g. when door is

fully closed door pointer should be at zero, when at 50mm it should be opened 50mm

etc. ).To recalibrate close door fully loosen door pointer nuts ,set pointer to zero and

retighten door pointer nuts.

Calibration sticker

Door pointer nuts

©Copyright Agrispread September 2014 15

830 Belt Spreader

Maintenance of Bearings

All bearings should be greased regularly. Each bearing has a grease nipple attached. The

locations of bearings are shown in Figure 5 below. (Warning Machine should not be

operating while maintenance is being carried out).All bearings are marked with “grease

“Label.

Figure 5: Belt Bearing Locations

16 ©Copyright Agrispread September 2014

830 Belt Spreader

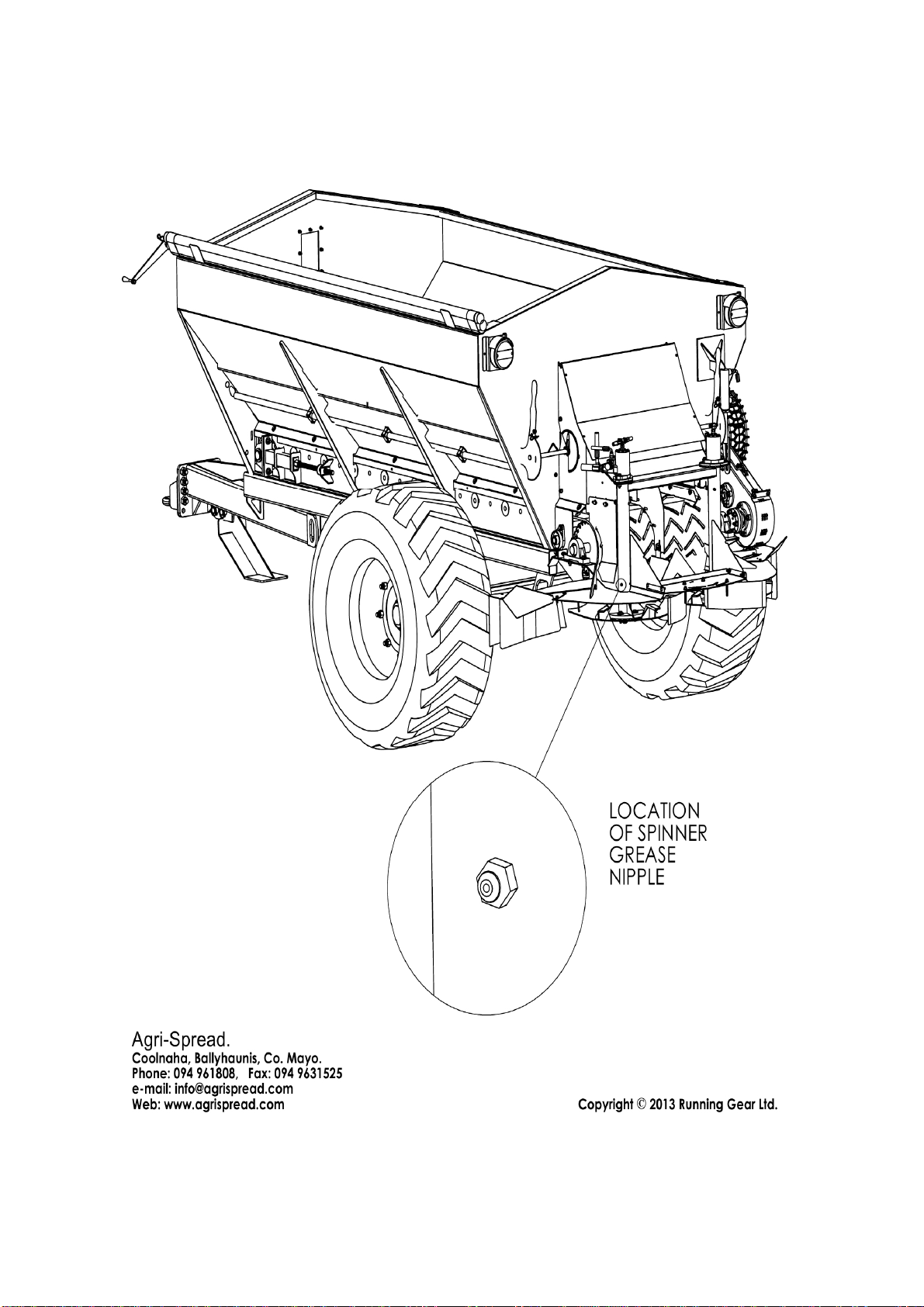

Each Spinner has a grease nipple for the purpose of lubrication. Spinners should be greased

before each use.

Figure 6 : Location of spinner grease nipples

©Copyright Agrispread September 2014 17

830 Belt Spreader

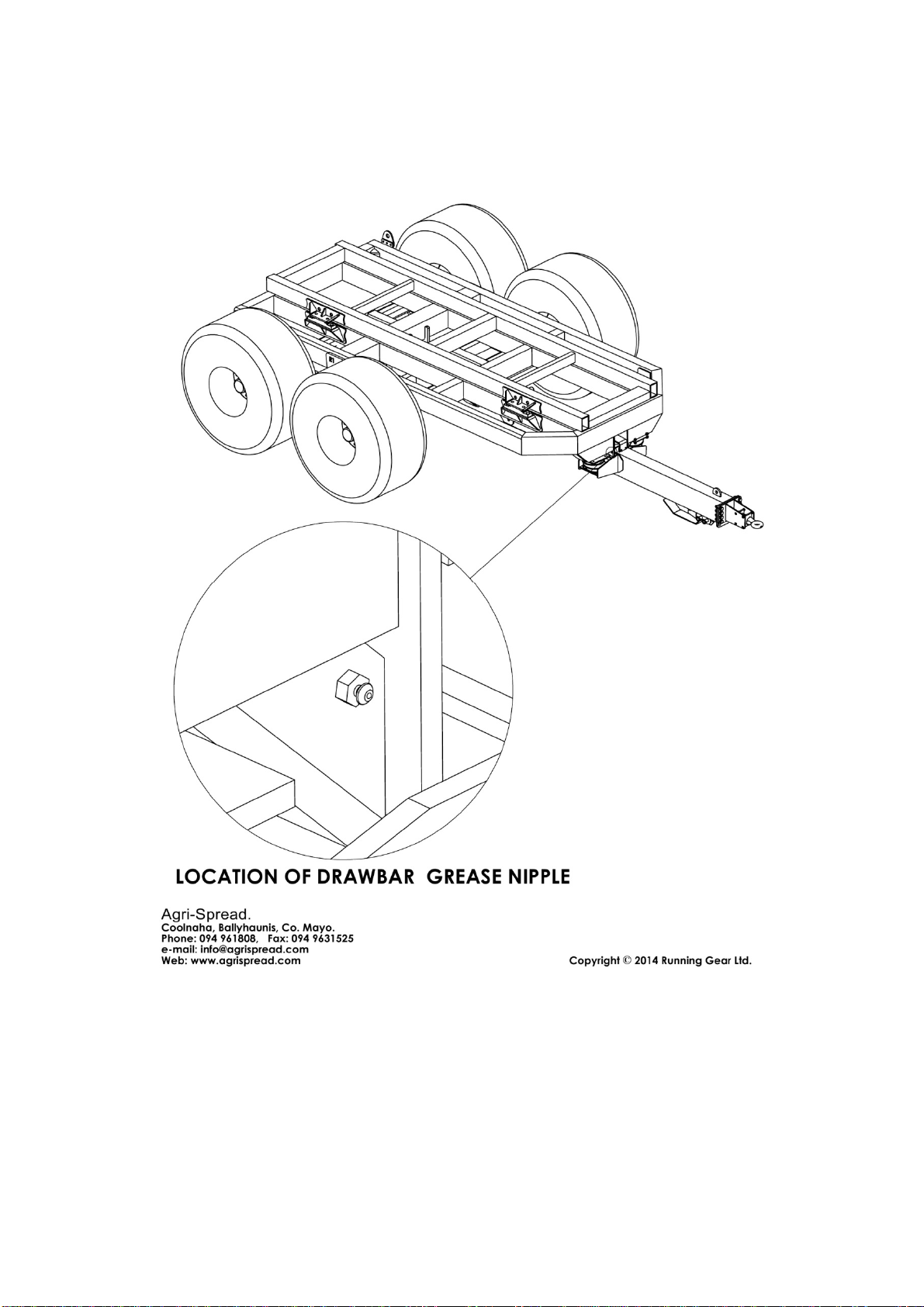

The drawbar should be checked to ensure that chassis is free from corrosion and cracks. The

drawbar should be greased after every use via the grease nipple shown in diagram below.

18 ©Copyright Agrispread September 2014

830 Belt Spreader

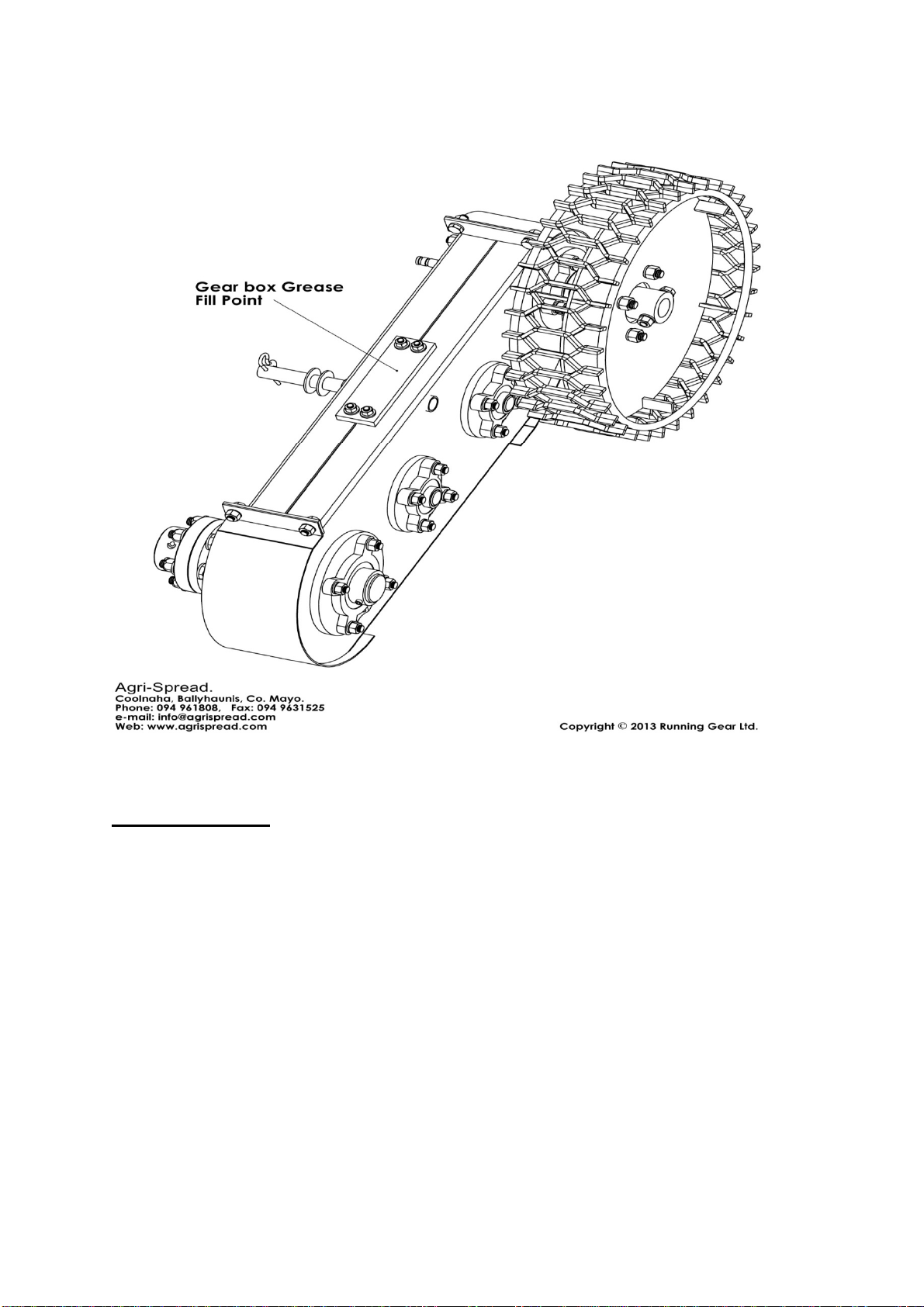

Maintenance of Land driven Gearbox

Grease details:

Recommended Oil: 80 W 90, 1 part oil

Recommended Grease: Lithium Complex Grease. 6 part Grease

Gearbox should be checked for grease regularly. Gearbox does not need to be emptied out,

just top up when necessary

There are 8 grease nipples on the gear box these should be greased regularly

This manual suits for next models

5

Table of contents

Other Agri-Spread Spreader manuals