bonomi 85 Series User manual

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

NORTH AMERICA

NORTH AMERICA

TABLE OF CONTENTS

1. Warning

3

2. Transportation and Storage 3

3. Application 3

4. Valves Automation 3

5. Specications and Technical information 3

5.1 Technical Features 4

5.2 Power Requirements and Current Draw Information 4

6. Installation Instruction 4

6.1 Electrical Connection 5

6.2 Auxiliary Switches Wiring 6

6.3 Potentiometer Wirings (Optional) 6

6.4 Heating Resistors 6

6.5 Signal Lamp Unit 6-7

6.6 Setting Actuator Stop Positions 7

6.7 Actuator Cover Assembly 7

7. Manual Override 8

8. Fail-Safe Operation with Battery Backup (Optional) 8

9. Maintenance 8

10. Wiring Diagrams 9

11. Disposal of the Electric Actuators at the end of their Life Cycle 9

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

2

NORTH AMERICA

1. Warnings

• Please read the following instructions before making any instal-

lation of the actuator. The damages caused from the non-ob-

servance of these instructions are not covered in the warranty.

• This documentation must be kept in dry place and available for

use.

• The installation and maintenance of electric actuator must be

made only by qualied personnel.

• Before proceeding to the electrical connections, please make

sure the ground wiring system works correctly.

• Please always check that supply voltage is included between

the ones indicated on the label on the exterior of the actuator.

• Before making any maintenance on the actuator, always make

sure to shut off the power supply.

• Valbia s.r.l. reserves the right to change the data and the char-

acteristics of this manual at any time and with no notice in the

scope of a constant updating of technological improvement.

WARNING: The mechanical and electronic parts, according to

which the device is designed, are not eligible for modications.

2. Transportation and storage

Valbia electric actuators are supplied in paperboard boxes which are

of solid construction for a normal transport. Handle with care and

keep the cover until the moment of the installation of the actuator

The storage of the actuators requires a covered, dry and ventilated

environment, protected from temperature changes. The device must

be stored with the cover mounted. Prior to installation, visual

inspection is recommended to detect any anomalies caused by

transport or storage.

WARNING: Do not lift or move the actuator by the manual hand

wheel

3. Field application

VALBIAelectric actuators have been designed and tested to ball and

buttery valves and dampers for the industrial sector. Actuators are

available in standard version with rotation 0°-90°. On request we can

supply actuators with rotation 0°-180° or 0°-270°. For applications

other than that above are needed please contact VALBIA sales

department.

4. Valve automation

The mechanical assembling between the electric actuator and the

item to be automated (for example: the valve) can be done by

direct mounting or by a mounting kit. Both the cases you can verify

the right alignment and the correct dimensions of the part to

transmit the power in order to avoid axial stress which can damage

valve and actuator.

All Valbia electric actuators are in conformity of norm EN ISO 5211

DIN 3337.

In order to have a right automation of the valve, is necessary to use

a Valbia electric actuators whose range has a torque of at least

25% over the valve maximum torque.

Verify the actuator duty rating suitability with the application.

WARNING: Do not raise up or moved the motorized valve by using

the electric actuator as point of grip or hold.

5. Specications and technical information (Tab. 1-2)

Documentation Value

Object of Device Electric Actuator

Enclosure material Self-extinguish technopolymer

Enclosure rating IP67

Duty cycle 75%

Duty cycle 12V version 50%

Ambient temperature range -20°C ÷ 55°C -4°F ÷ +131°F

Axillary limit switches

1A @ 250VAC - 1A@ 30VDC (resistive load)

Fault auxiliary contact

1 A @ 250Vac - 1 A @ 30 Vdc (resistive

load)

Section of connections clamps’ connectors 0,5 - 1,5

Terminal block type Plug in connector

Section of terminal block 14 - 22 AWG 2.08 - 0.32 mm2

Minimum conductors temperature 85°C 185°F

Protection class against shock Class I

Restriction of continue operation time (timeout)

Standard

Power supply voltage tolerance ± 10

Multiple parallel actuators wiring Standard (*)

Cable entries PG11 electric connections

Standard stroke 90°

Position indicator Standard

Manual override Standard

(*) It is important to verify that the application and its components

are properly sized with the actuator characteristics and require-

ments.

Requested Features for UL508 Standard

UL listed le number NMTR.E303174

Enclosure type Type 4x Indoor Use Only

Connection conductor/wires

Listed exible cord (ZJCZ) min. S or SJ

Green terminal block screws (max tightening

capacity of model 100-240V AC.) 0.56 Nm 5 In. Lbs.

Black terminal block screws (max tightening

capacity of model 100-240V AC.) 0.50 Nm 4.50 In. Lbs.

Terminal block screws (max tightening

capacity of model 12-24V DC.) 0.50 Nm 4.50 In. Lbs.

Enclosure screws maximum tightening

capacity 2.5 Nm 22.15 In. Lbs.

External pollution degree 3

Internal pollution degree 2

Overvoltage category 2

Product in conformity with the European Community norms

LOW VOLTAGE 2014/35/UE (LVD)

ELECTROMAGNETIC COMPATIBILITY 2014/30/UE (EMC)

MACHINERY 2006/42/CE

ROHS 2011/65/UE

REGULATION No 1907/2006 (REACH)

Use copper (CU) conductor

3

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

NORTH AMERICA

5.1 Technical Features

Technical characteristics of Valbia electric actuators as below:

• Heater: all actuators are standard equipped with heater to avoid

condensation into the actuator (paragraph 6.4);

• A safety system detects when the actuator supplies a torque

higher than expected (torque limiter): the device makes three

triggering attempts. In case of negative results, it makes a short

rotation in the opposite direction to relieve the mechanical ten

sion to the gears. The torque limiter intervention is] indicated by

a red color LED (paragraph 6.5) and by the opening of the re

mote signal an auxiliary contact (paragraph 6.2).

• A safety system intervenes to shut off the actuator in case the

motor works past over the allowable operation time value (the

time value depends on the actuator models). The maximum

working time fault is indicated by a red color LED (paragraph

6.5) by the opening of the auxiliary contact of the remote signal

(paragraph 6.2).

• Duty rating: the electric actuator was designed to work with

a nominal duty rating of 75% (or 50% in the 12V ac/dc models),

referred to the working time, the maximum temperature and to

the nominal load. This parameter denes the rest time after an

operation. The use of the actuator with an higher duty rating

or with a temperature above 55°C (131°F) can cause the im

proper torque limiter intervention or the failure of electronic com

ponents.

5.2

Power requirements and current draw information (Tab. 3)

MOD. VB030 VB060 VB110

Nominal Torque (Nm) 30 60 110

Nominal Torque (In. Lbs.) 266 530 975

Nominal Tension (H Version) 100-240VAC

Current Absorbed (H Version) 0.4-0.2A 0.6-0.3A 0.4-0.2A

Absorbed Power (H Version) 40-48 VA 60-72 VA 40-48 VA

Nominal Tension (L Version)

12V

AC/DC 24V

AC/DC 12V

AC/DC 24V

AC/DC 12V

AC/DC 24V

AC/DC

Current Absorbed (L Version) 2.2-

1.8A 1-0.7A 3.8-

2.85A 1.8-

1.2A 2.2-

1.8A 1-0.7A

Absorbed Power (L Version) 26.5-22

VA 24-17

VA 46-34

VA 43-29

VA 26.5-22

VA 24-17

VA

Frequency 50/60 HZ

Rotation Time 0°-90° (sec.) 8 9 27

MOD. VB190 VB270 VB350

Nominal Torque (Nm) 190 270 350

Nominal Torque (In. Lbs.) 1680 2390 3100

Nominal Tension (H Version) 100-240VAC

Current Absorbed (H Version) 0.6-0.3A 0.6-0.3A 0.75-0.4A

Absorbed Power (H Version) 60-72 VA 60-72 VA 75-96 VA

Nominal Tension (L Version) 12V

AC/DC 24V

AC/DC 12V

AC/DC 24V

AC/DC 12V

AC/DC 24V

AC/DC

Current Absorbed (L Version) 3.8-

2.85A 1.8-

1.2A 3.8-

2.85A 1.8-

1.2A 4.75-

3.65A 1.95-

1.65A

Absorbed Power (L Version) 46-34

VA 43-29

VA 46-34

VA 43-29

VA 57-44

VA 47-40

VA

Frequency 50/60 HZ

Rotation Time 0°-90° (sec.) 27 50 50

6. Installation instruction

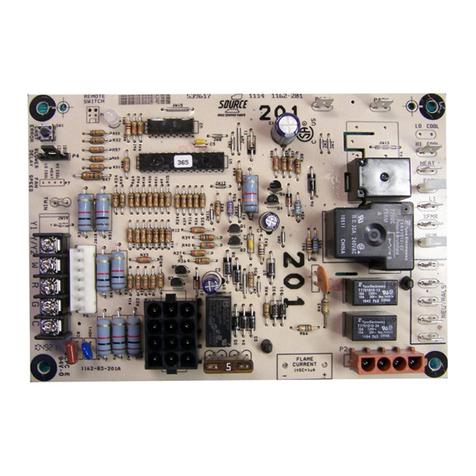

Fig.1 External view of the actuator

A

D

C

H

E

B

1. Remove position indicator “B” by loosening the screws “C”;

2. Screw the fasteners “D” to remove the upper cover “A”;

3. Raise up the cover “A” carefully to avoid to damage the internal

electric parts;

4. Turn in the electric supply cable (diameter 6 ÷ 9

mm / 0.24” ÷ 0.35”) by the properly bolds “E” (PG11);

5. Proceed to connect the cable in its proper terminal block “F” by

looking at the wiring diagram (Fig.2) according to the different

voltage (please also review the tag you nd inside the cover).

WARNING: the actuators should be properly grounded and wired in

accordance with local electrical code.

WARNING: before performing any maintenance on the actuator, al-

ways make sure to shut off the power supply rst.

WARNING: make sure that the power supply is set between the val-

ues indicated as indicated on the label on the side of the actuator.

WARNING: Valbia electric actuators may be mounted in many po-

sitions, however, we do not suggest using it with the cable glands

positioned upright, since it cannot guarantee a perfect wiring tight-

ness. We also recommend to avoid using it with the indicator facing

down. If the actuator assembly and the respective electrical con-

nection are provided in different moments, make sure that the cable

entries are hermetically sealed.

WARNING: please ensure suitably rated cable glands and protec-

tion plug are used, according to IP protection rating. Properly seal

the electrical connectors to prevent any liquid and dust inltration.

Warranty is voided if this warning is not respected.

The cables must be of the appropriate size to the type of electrical

connector selected. Verify the correct tightening of the electrical con-

nectors.

WARNING: if the device is used not respecting the manufacturer

specications, the provided protection may be impaired. For the wir-

ing, it is necessary to open the upper cover “A” in order to locate the

terminal block on the power supply board.

4

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

NORTH AMERICA

6. Installation instructions (continued)

WARNING: before opening the upper cover shut down the power

supply voltage.

To remove the upper cover “A” untighten the screws “D” and make

sure to avoid collisions with the internal electrical parts. Insert the

power supply cables inside the lower enclosure entries “E”, tighten

by the user. The terminal block “F” is composed by two parts, one of

which removable. To simplify the procedure, it is possible to remove

the removable part, wiring it and insert it once the wiring is done.

Proceed to the cable connections in the appropriate terminal block

“F” following the wiring diagram (paragraph 6.1).

WARNING: please pay attention during the wiring and setting

phases of the electromechanical limit switches, in order to avoid

uids or other substance from getting on or around any electronic

components. Moreover, before assembling the upper cover please

make sure that the o-ring is seated in the proper groove and there

are no impediments that could compromised the enclosure sealing.

6.1 Electrical connection

The wiring diagram, which should be followed for proper wiring of

the actuators, is shown in paragraph 10.0 and it can be found also

on the label inside the upper cover. Please follow the maximum

allowed electrical rating values. The terminal block “F” in the 100-

240Vac is shown in Fig. 3, 12Vac/dc and 24Vac/dc in Fig. 2. The

cables through the connector must be of the proper size.

• The signal cable of “closing (clockwise rotation)” (positive

supply +12Vdc / +24Vdc or phase 12Vac / 24Vac / 100-240Vac)

must be connected to the terminal “1” of the terminal-block “F”;

• The signal cable of “opening (counter-clockwise rotation)” (pos-

itive supply +12Vdc / +24Vdc or phase 12Vac / 24Vac/ 100-

240Vac) must be connected to the terminal “3” of the termi-

nal-block “F”;

• The signal cable “common” (0V / neutral) must be connected to

the terminal “2” of the terminal-block “F”;

• The grounding cable must be connected to the properly sig-

naled terminal.

• In addition to the 3-points control mode, the 2-points control

mode is also available.

WARNING: the ground wiring system is mandatory.

6.1 Electrical connection (continued)

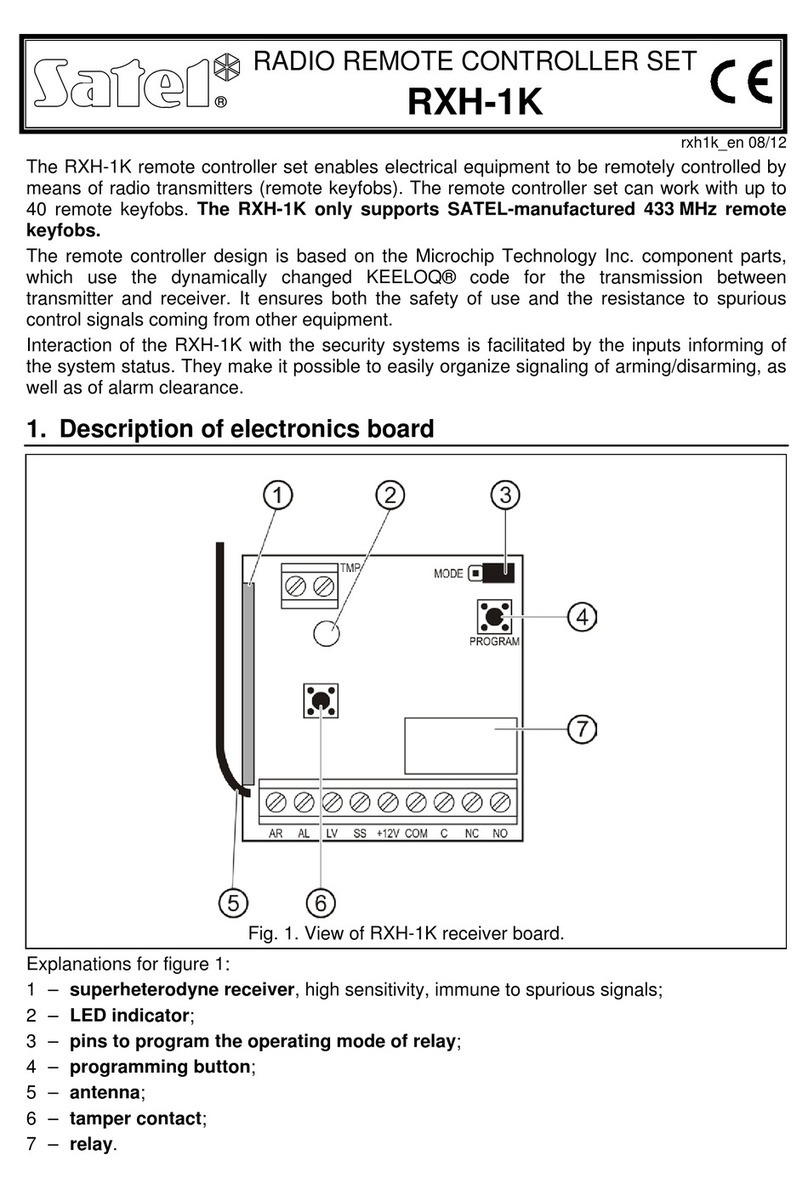

Fig.2 Board for the low voltage supply and particular of terminal block “F”

Fig.3 Board for the high voltage supply and particular of terminal block “F”

TERMINAL BLOCK “F”

TERMINAL BLOCK “F”

TERMINAL BLOCK “F”

5

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

NORTH AMERICA

6.2 Auxiliary switches wiring

The “G” terminal block is connected to two auxiliary and independent

limit switches (SPDT free contacts), FCU1 and FCU2, which indicate

the position of the actuator to the nal user. The terminal block “G” is

composed by two parts, one of which removable for easier wiring. To

simplify the procedure, it is possible to remove the removable part,

wiring it and insert it once the wiring is done.

Connect to the terminal block “G” between the following terminals:

• “B” and “C” to obtain the signal of closing position.

• “E” and “H” to obtain the signal of opening position.

The opening or closing signal comes when the blue cams push the

auxiliary electromechanical limit switch on the logic board. The cams

adjustment procedure is described on paragraph 6.6.

WARNING: during the installation it is recommended to verify the

alignment of the auxiliary limit switches by using a multimeter/tester.

The terminal block “R” is connected to a free contact NO which clos-

es in case of powered actuator and no detected anomaly. In case of

anomalies or not powered actuator the contact is open. The terminal

block “R” is composed by two parts, one of which removable for

easier wiring. To simplify the procedure, it is possible to remove the

removable part, wiring it and insert it once the wiring is done.

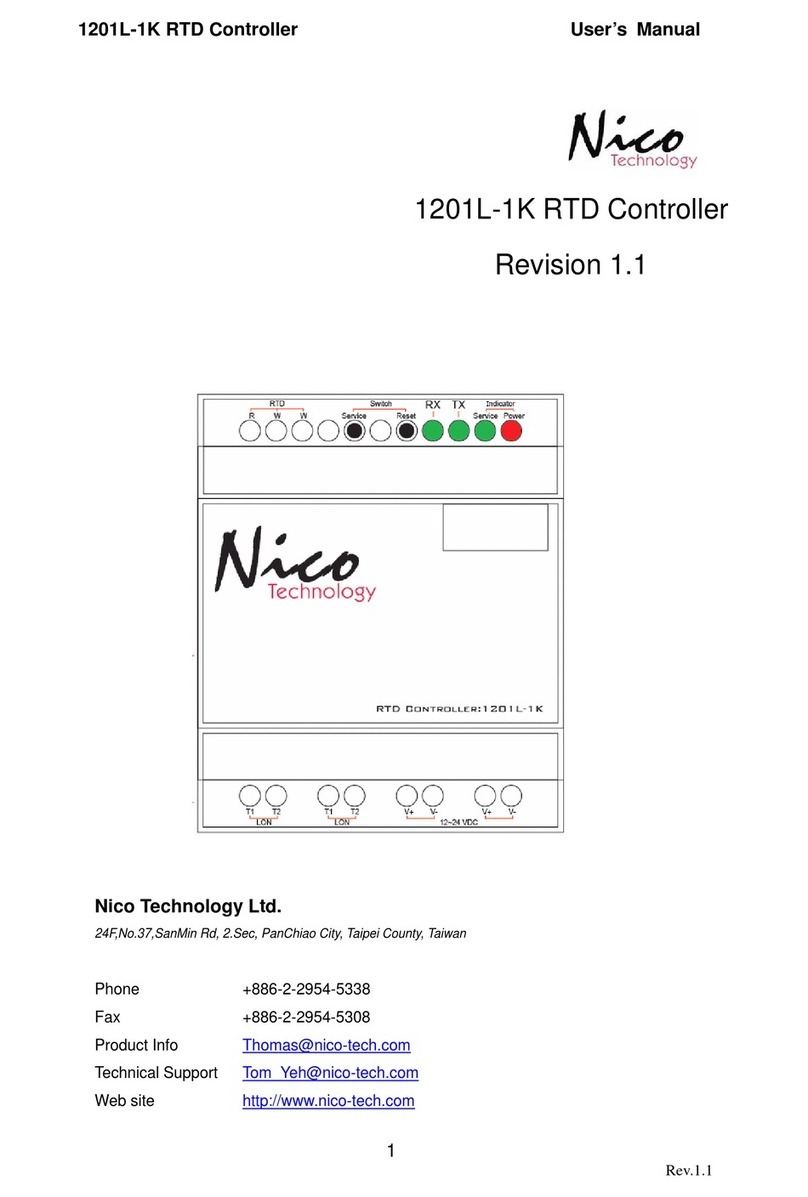

Fig.4 Control/logic board and particular of terminal blocks “G” and “R”

TERMINAL BLOCK "G" TERMINAL BLOCK “R”

6.3 Potentiometer wirings (optional) (Fig.5)

The actuator with potentiometer includes an extra terminal

block “POT” (Fig.5) which grants the possibility to use the re-

sistive infomation concerning the actuator position. Wiring in-

struction presented at Paragraph 10.0. When the actuator

is at 45°, the resistance value of the potentiometer is 2.5KΩ

Fig.5 Electric actuator particular of the terminal block “POT”

TERMINAL BLOCK “POT”

6.4 Heating resistors (Fig. 6)

All the actuators are equipped with “RIS” heating resistor which

works only if the actuator is connected to the power supply, when

the motor is not rotating and the temperature inside the actuator

goes down to 25°C / 77°F. It protects the actuator from the forma-

tion of condensation due to temperature changes.

The resistor is part of the electronics, it does not require additional

wiring and it is disabled when the internal temperature exceed 25°C

/ 77° F.

WARNING: to guarantee the normal operation of the resistor, it is

necessary to keep the actuator connected to the power supply

even in the open/close positions.

Fig.6 Electric actuator particular of the heating resistors “RIS”

RESISTORS “RIS”

6.5 Signal lamp unit

On the power supply board there is a green LED indicating that the

power is on

On the logic board there is a multicolor LED which indicates the fol-

lowing actuator modes.

Working State LED

Color Flashing Duration

(sec) Pause Between

Flashes (sec)

FC Powered Actuator Green 0.1 0.9

Rotating powered actuator Green 0.6 0.4

Power supply shut-off in FC Yellow 0.1 0.9

Power supply shut-off in rotation Yellow 0.6 0.4

6

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

NORTH AMERICA

6.5 Signal lamp unit (continued)

Every anomaly has a different number of ashes of the RED led on

the logic board.

Working State Effect

No.

of

Flashes

Flashing

Duration

(sec)

Pause

Between

Flashes

(sec)

Pause

Between

Flashing

Cycles

(sec)

Torque limit alert Actuator Block 1

0.1 0.3 1

Max torque alert Actuator Block 2

Below min. Threshold

Voltage Alert Re-enable 3

Time-out operation

intervention alert Actuator Block 4

Fault driver alert Actuator Block 5

WARNING: to reset the anomalies it is recommended to shut off the

power supply for more than 10 seconds to ensure the full discharge

of the capacitors on the electronic boards.

6.6 Setting actuator stop positions (Fig.7)

The opening or closing operation of the electric actuator is reached

when the black cams push the electromechanical limit switches on

the logic board (POS1 for closing position and POS2 for opening

position). The signal of opening and closing operation is obtained

when the blue cams push the electromechanical limit switches on

the logic board.

The procedure necessary to adjust the actuator stroke is the follow-

ing:

1. Make sure that the power supply is off;

2. Remove the upper cover of the actuator (paragraph 6.0);

3. To simplify the operation it is recommended to remove the re

movable parts of the terminal block “G” and “R”;

4. Make sure that the automated device (for instance the valve)

is in the “OPEN” position. For a more accurate and precise

adjustment, use the manual override “H” (paragraph 7.0);

5. Loosen the set screw in the cam 1 (black color), and rotate the

cam until it pushes the limit switch POS2 and until the “click”

of the electromechanical micro switch. Then tighten the set

cam screws;

6. Loosen the set screw in the cam 3 (blue color), and rotate the

cam until it pushes the limit switch FCU2 and until the “click

of the electromechanical micro switch). Then tighten the set

cam screws;

7. Power on the actuator and carry out the closing operation;

8. Wait for the completion of the operation, then shut off the

power supply;

9. Make sure that the automated device (for instance the valve)is

in the “CLOSED” position. For a more accurate and precise

adjustment, use the manual override “H” (paragraph 7.0);

10. Loosen the set screw in the cam 2 (black color) and rotate the

cam until it pushes the limit switch POS1 and until the “click” of

the electromechanical micro switch. Then tighten the set

cam screws;

11. Loosen the set screw in the cam 4 (blue color) and rotate the

cam until it pushes the limit switch FCU1 and until the “click”

of the electromechanical micro switch. Then tighten the set

cam screws.

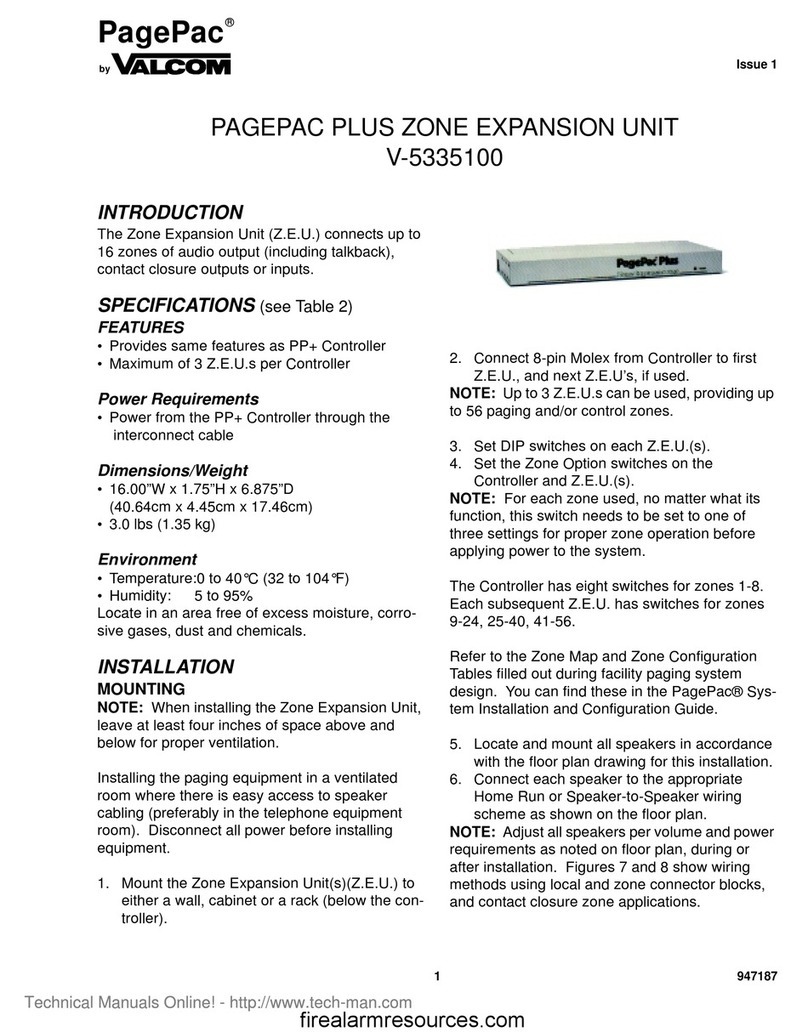

Fig.7 Particular of the cams of limit switches

CAM 4

CAM 3

CAM 2

CAM 1

6.7 Closure of electric actuator enclosure (Fig. 1)

1. After making the proper connection, please proceed to the as-

sembling of cover “A”, by paying close attention not to hit any

electronic parts;

2. Re-assemble the position indicator “B” on “OPEN ” blocking it

by screw “C”;

3. Make sure that the tightening of cables is secure, by screwing

the gland “E”;

4. Finish the closing of cover “A” by screwing in the fasteners “D”.

Fig.1 External view of the actuator

A

D

C

H

E

B

7

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

NORTH AMERICA

7.0 Emergency operation

All the VALBIA electric actuators have an external handwheel “H”

(Fig.1), which can manually operate the closing and opening posi-

tions.The manual operation operates by put in a pressure on the top

of handwheel and by making a small rotation in order to engage the

stem to the handwheel. After engaging the manual operation you

can make desired the position you wish by keeping pressure on, and

turning the handwheel.

WARNING: the handwheel for the manual override can be used with

actuator NOT power supplied. Do not use tools to action the hand-

wheel.

WARNING: do not operate the manual override when the actuator

is turning.

WARNING: if the actuator, exceeds the stroke range by the manual

override, to reset it is necessary to power the actuator until it returns

to the limit switch position.

8.0 Fail-Safe Operation with battery backup (optional)

The versions with battery of Valbia electric actuator use battery

packs with series of cells in NiMh technology and nominal voltage

on terminals at 24Vdc.

For the actuators with battery back-up, VALBIAcan set up the actua-

tor to automatically carry out one of the following actions in the event

of power outage:

• Opening: the in-progress/current operation is interrupted.

• Closing: the in-progress/current operation is interrupted.

• Completes the in-progress operation: the motor continues the

in progress action until it touches the travel stops/limit switches.

Battery operation is enabled after a delay of about 1 sec, it is instan-

taneous only if the emergency operation is consistent with the

operation in progress (for example, when the actuator is closing, the

supply voltage is lost and the battery set to NC intervenes).

The action in progress with the battery power supply is interrupted by

a possible mains voltage recovery.

A yellow light (LED) mounted on the power supply board indicates

that the board is charging the battery in TRICKLE mode.

When the battery is fully charged the LED light turn off.

The LED signal is reliable if the battery back-up has not been dam-

aged.

The battery is a component that guarantees a limited number of

charge / discharge cycles (over 500), therefore its life is inversely

proportional to the number of interventions.

WARNING: to guarantee the emergency battery intervention, it is

necessary that the actuator remains powered for more than 3 hours.

WARNING: for the version with battery it is recommended to power

the actuator within 3 months from the purchase date.

The actuator can also be used in “solenoid” mode (wiring with two

wires).To usethismode it ismandatory to followthewarnings above.

9.0 Maintenance

The electric actuator does not need any kind of maintenance. The

internal lubrication of the gears is sufcient for the device life. For

enclosure cleaning, use a light non-aggressive detergent. In case

of damages or operation issues, we suggest sending the actuators

back to Valbia for inspection.

Valbia s.r.l. declines responsibility and warranty on our actuators re-

paired from any third party.

8

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

NORTH AMERICA

9

IOM | 85 SERIES ON/OFF ELECTRIC ACTUATORS

11.0 Disposal of the electrical actuators at the end of their

life cycle

According to the provisions of the European directives 2011/65/UE

and 2012/19/UE, concerning the restriction of the use of hazardous

substances in electrical and electronic equipment as well as waste

management, all the VALBIAelectric actuators are designed in order

to be completely disassembled when they arrive at the end of their

life cycle, separating the different materials for the proper disposal

and/or recovery.

The crossed-out rubbish bin symbol indicates that the prod-

uct, at the end of its life cycle, becomes WEEE (Waste

Electrical and Electronic Equipment) and must be collected

separately from the other waste.

The device must not be disposed as a mixed urban waste, it must be

recycled through the proper collection system for disposal and for its

subsequent correct recycling.

The collection system of the equipment at the end of its life is guar-

anteed on the national territory through the national consortia for

the eco-sustainable management of WEEE. For all the information

contact VALBIA s.r.l.

At the end of the life cycle of the device, for its removal, a series of

precaution must be followed:

• The structure and the various components, if not usable, must

be demolished and divided up according to the type of product.

All this helps collection, disposal and recycling centers and

minimizes the environmental impact that this operation requires;

• Appropriate separate waste collection for subsequent sending

of the disused equipment for recycling, treatment and compati

ble environmental disposal contributes to preventing possible

negative effects on the environment and favors recycling of the

materials of which the equipment is composed;

• The illegal disposal of the product by the user involves the appli

cation of the penalties provided by the current regulations re

garding such subject.

The product at the end of its life, if properly disposed, is not po-

tentially dangerous for human health and the environment, on the

contrary, if unproperly abandoned, it could have a negative impact

on the ecosystem.

L(+) N(-)

L(+) N(-)

L (+)

N (-)

Fuse

COM

Opening

Closing

Ground

1 2 3 A B C D E H

" F "

Optional

Terminal block

24V dc battery

(not available

for 12V versions)

Power supply

voltage board

FCU1

FCU2

Open

Closed

NC

NO

NC

NO

Auxillary contacts

CONTROL/LOGIC BOARD

MAX 2A 250Vac / 30Vdc

AUXILLARY CONTACT

" R "

K

MAX 1A 120Vac / 2A 24Vdc

J

TERMINAL BLOCK " G "

Optional with

5kΩ 1W

potentiometer

456

12/24V DC Motor

123

Opening

2 POINTS CONTROL MODE

Ground (PE)

Term

3 points control mode

Closing

opening

123

MORS.

Term

“F”

“F”

Ground (PE)

ELECTRIC ACTUATOR

ELECTRIC ACTUATOR

TERMINAL BLOCK

ON/OFF ELECTRIC ACTUATOR

10.0 Wiring Diagram

NORTH AMERICA

CORPORATE OFFICE

750 IMPERIAL CT.

CHARLOTTE, NC 28273

PH: (704) 412-9031

FAX: (704) 412-9032

This manual suits for next models

6

Table of contents