2

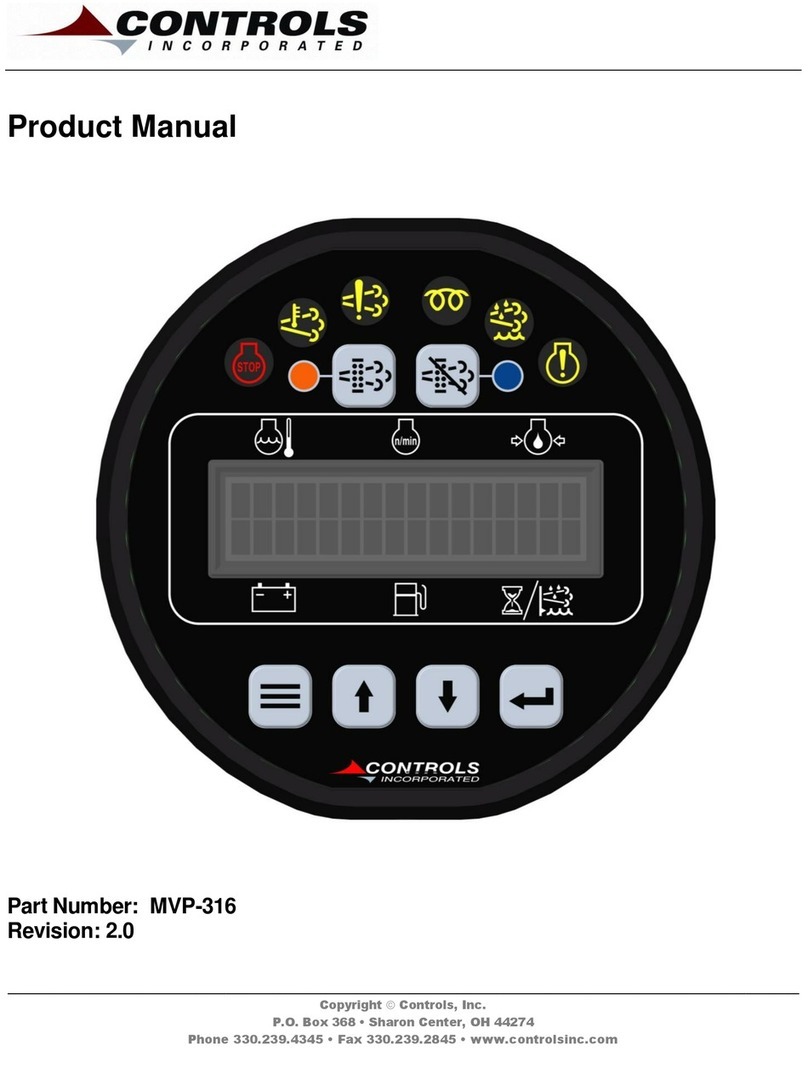

PANEL OPERATION

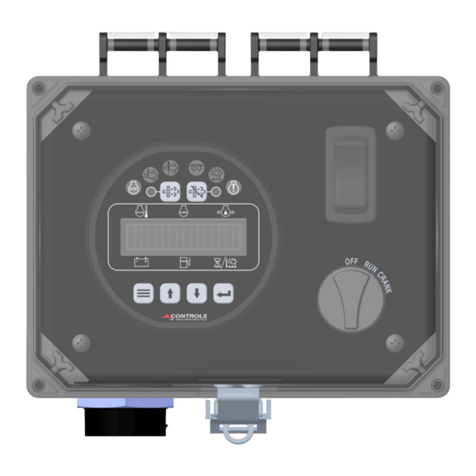

MANUAL OPERATION

1) Engine Start - Turn key to CRANK position

2) Engine Stop - Turn key to OFF position

AUTO START/STOP OPERATION

1) Engine Start - Turn key to AUTO position

Engine start/stop based on auto start/stop settings. Panel display shows “Auto Start ARMED”

message. The engine starts when the remote start input wire is grounded. The engine stops

with the remote start wire is not grounded.

SLEEP MODE

To minimize current draw, the panel goes into a sleep mode two minutes after being set in auto

mode. In sleep mode, the display goes blank and the red lamp blinks once every ten seconds. The

engine ECU is also turned off.

Upon receiving a signal from a float or transducer the panel wakes up, the display turns back on and

normal operation commences.

Pushing any of the four buttons wakes up the panel and turns the display on. It will return to sleep

mode after a two minute period.

For service purposes, to keep engine ECU powered, access the menu system. The engine ECU remains

on when the menu system is active.