Boonton CPS2000 User manual

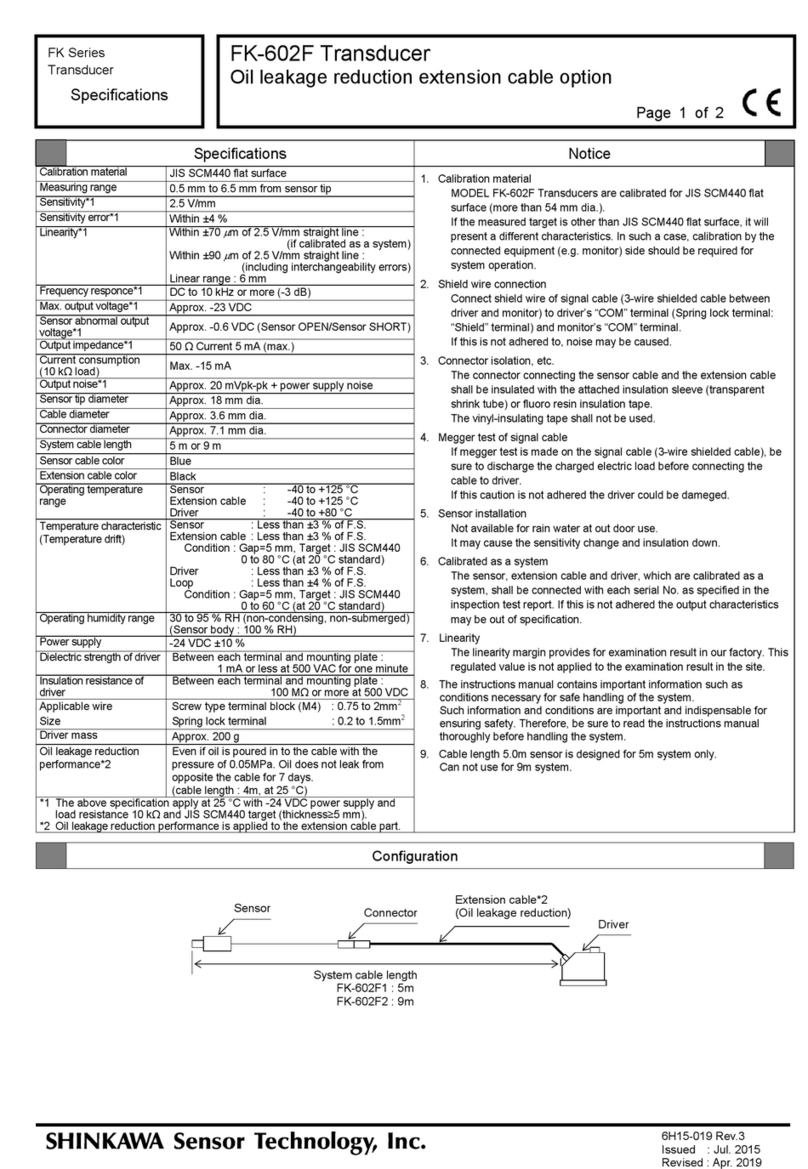

CPS2000

True-Average Connected Power Sensors

INSTRUCTION MANUAL

98408200A | Rev 0

CPS2000 Series Instruction Manual

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation and

maintenance of this instrument. Failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture, and intended use of the

instrument. Boonton Electronics assumes no liability for the customer’s failure to comply with these

requirements.

DO NOT OPERATE THE INSTRUMENT IN AN EXPLOSIVE ATMOSPHERE

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS

Operating personnel must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified maintenance personnel. Do not replace components with the

power cable connected. Under certain conditions dangerous voltages may exist even though the power

cable was removed, therefore; always disconnect power and discharge circuits before touching them.

DO NOT SERVICE OR ADJUST ALONE

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and

resuscitation, is present.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT

Do not install substitute parts or perform any unauthorized modifications on the instrument. Return the

instrument to Boonton Electronics for repair to ensure that the safety features aremaintained.

S-1 SAFETY SUMMARY Page 2

CPS2000 Series Instruction Manual

SAFETY SYMBOLS

This safety requirement symbol has been adopted by the International Electro-technical

Commission, Document 66 (Central Office) 3, Paragraph 5.3, which directs that an

instrument be so labeled if, for the correct use of the instrument, it is necessary to refer to

the instruction manual. In this case it is recommended that reference be made to the

instruction manual when connecting the instrument to the signal source and USB host.

The CAUTION symbol denotes a hazard. It calls attention to an operational procedure,

practice or instruction that, if not followed, could result in damage to or destruction of

part or all of the instrument and accessories. Do not proceed beyond a CAUTION symbol

until its conditions are fully understood and met.

The NOTE symbol is used to mark information which should be read. This information can

be very useful to the operator in dealing with the subjects covered in this section.

The HINT symbol is used to identify additional comments which are outside of the normal

format of the manual, however can give the user additional information about the

subject.

S-2 SAFETY SUMMARY Page 3

CPS2000 Series Instruction Manual

Table of Contents

1 Introduction............................................................................................................................................6

1.1 Overview..........................................................................................................................................6

1.2 Definitions........................................................................................................................................6

2 Setup & Installation................................................................................................................................7

2.1 System Requirements & Dependencies...........................................................................................7

2.1.1 CPS2000 GUI System Requirements ..................................................................................... 7

2.1.2 CPS2000 GUI Software Requirements .................................................................................. 7

2.1.2.1 IVI Shared Components Availability.......................................................................8

2.1.2.2 VISA Implementations and Availability..................................................................8

2.2 Installation .......................................................................................................................................9

3 General Use & Configuration ...............................................................................................................10

3.1 Connecting to a Power Sensor.......................................................................................................10

3.1.1 USB......................................................................................................................................11

3.1.1.1 Required Equipment............................................................................................11

3.1.1.2 Setup Steps ..........................................................................................................11

3.1.2 Ethernet ..............................................................................................................................12

3.1.2.1 Required Equipment............................................................................................12

3.1.2.2 Setup Steps ..........................................................................................................12

3.1.2.3 Configuring the TCP/IP Settings of a Power Sensor.............................................13

3.2 Configuring a Power Sensor...........................................................................................................15

3.3 Connecting to Multiple Power Sensors .........................................................................................16

3.4 Upgrading the Firmware on a Power Sensor.................................................................................17

3.5 Other Features...............................................................................................................................19

3.5.1 Set Display Refresh..............................................................................................................19

3.5.2 Show Low Power Readings .................................................................................................19

4 Troubleshooting ...................................................................................................................................20

4.1 Recovery After a Failed Firmware Upgrade................................................................................... 20

5 Boonton Resources on RF Power Measurements................................................................................20

Appendix A –Software License...................................................................................................................22

END-USER LICENSE AGREEMENT..........................................................................................................22

Appendix B –Warranty & Repair................................................................................................................24

B.1 Repair Policy...................................................................................................................................24

B.2 Contacting Boonton .......................................................................................................................24

B.3 Limited Warranty ...........................................................................................................................24

TABLE OF CONTENTS Page 4

CPS2000 Series Instruction Manual

List of Figures

Figure 1 - USB Device Selection ..................................................................................................................11

Figure 2 - TCPIP Search Success ..................................................................................................................13

Figure 3 - Software Overview......................................................................................................................15

Figure 4 - Multiple Device View ..................................................................................................................16

Figure 5 - Firmware Upgrade Menu............................................................................................................18

Figure 6 - Firmware Upgrade Process.........................................................................................................18

List of Tables

Table 1 - Minimum System Requirements.................................................................................................... 7

Table 2 - IVI-C Driver Prerequisites...............................................................................................................7

Table 3 - IVI.NET Driver Prerequisites........................................................................................................... 7

Table 4 –VISA Implementations & Availability.............................................................................................8

LIST OF FIGURES

LIST OF TABLES AND FIGURES Page 5

CPS2000 Series Instruction Manual

1Introduction

1.1 Overview

This document describes the setup and usage of the CPS2000-Series True-Average Connected Power

Sensors, CPS2000 GUI application software, Boonton CPS2000 IVI.NET driver software, and Boonton

CPS2000 IVI-C driver software.

1.2 Definitions

Term/Abbreviation

Definition

VISA

Virtual Instrument Software Architecture. A test & measurement

device I/O specification.

IVI

Interchangeable Virtual Instruments. A test & measurement device I/O

specification layered above VISA.

PoE

Power over Ethernet. A system or method by which power is passed

along with data via Ethernet cabling.

LAN

Local Area Network

I-1 INTRODUCTION Page 6

CPS2000 Series Instruction Manual

2Setup & Installation

2.1 System Requirements & Dependencies

2.1.1 CPS2000 GUI System Requirements

The CPS2000 GUI software application’s minimum system requirements are as follows:

Operating System

Windows 7 SP1 or newer (32- and 64-bit)

Processor

1 GHz CPU

RAM

1 GB RAM

Disk Space

512 MB of Available Disk Space

Graphics

DirectX 9 Compatible Integrated or Dedicated Graphics Card

Other

.NET Framework 4.0 or later –Included with the CPS2000 GUI application installer

Table 1 - Minimum System Requirements

2.1.2 CPS2000 GUI Software Requirements

To communicate with power sensors, the Boonton Power Viewer software application makes use of the

Boonton CPS2000 IVI.NET driver.

The Boonton CPS2000 IVI.NET driver is an IVI-Compliant driver included as part of the CPS2000 GUI

application installer. Also included with the CPS2000 GUI application installer is the Boonton CPS2000

IVI-C driver.

The Boonton CPS2000 IVI-C driver has the following software prerequisites:

Software

Minimum Version

VISA Shared Components

5.6.0

IVI Shared Components

2.4.2

Table 2 - IVI-C Driver Prerequisites

The Boonton CPS2000 IVI.NET driver has the following software prerequisites:

Software

Minimum Version

VISA.NET Shared Components

5.6.0

IVI.NET Shared Components

1.4.0

Table 3 - IVI.NET Driver Prerequisites

2-1 SETUP & INSTALLATION Page 7

CPS2000 Series Instruction Manual

2.1.2.1 IVI Shared Components Availability

The IVI and IVI.NET Shared Components required by the CPS2000 GUI software application and IVI

drivers are included with the CPS2000 GUI application installer.

Alternatively, the shared components are available from the official IVI foundation website:

http://www.ivifoundation.org

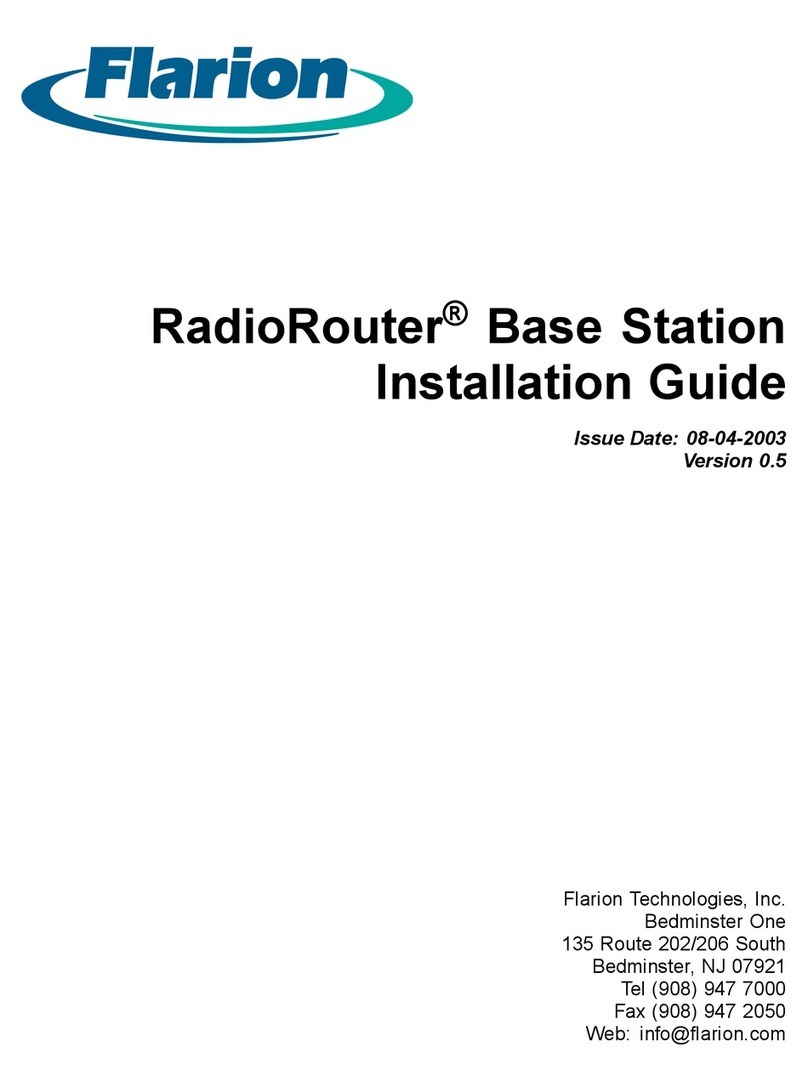

2.1.2.2 VISA Implementations and Availability

The VISA and VISA.NET Shared Components are not included with the CPS2000 GUI application installer.

Known compatible VISA implementations, and their required minimum version, are listed below:

Vendor

Software

Minimum

Version

Recommended

Version

Download Location

National

Instruments

NI-VISA

15.0.1

17.0

http://www.ni.com/download/ni-visa-

17.0/6646/en/

Keysight

IO

Libraries

Suite

17.2.20407.1

18.1.22713.0

https://www.keysight.com/find/iosuite

Table 4 –VISA Implementations & Availability

The recommended VISA implementation is NI-VISA 17.0 provided by National Instruments.

2-2 SETUP & INSTALLATION Page 8

CPS2000 Series Instruction Manual

2.2 Installation

Note!

Installation and operation of the CPS2000 GUI requires installation of the IVI.NET, IVI,

VISA.NET, and VISA shared components. The IVI.NET and IVI shared components are

included with the CPS2000 GUI software installer, but the VISA shared components are

only obtainable from a 3rd party vendor. These components must be installed before using

the CPS2000 GUI software. See section 2.1.2.

Installation of the CPS2000 GUI software application Boonton CPS2000 IVI drivers can be performed

using the CPS2000 GUI software application installer available on Boonton’s website.

The setup installer includes the CPS2000 GUI software application, the required IVI Shared Components,

and Boonton CPS2000 IVI drivers.

2-3 SETUP & INSTALLATION Page 9

CPS2000 Series Instruction Manual

3General Use & Configuration

3.1 Connecting to a Power Sensor

The CPS2000 series of devices supports connection via USB and Ethernet (TCP/IP). Specifically, the

supported modalities are as follows:

Connected to PC via USB.

Powered by the USB connection to the PC.

Connected to PC via Ethernet LAN (TCP/IP).

Powered by PoE (Power over Ethernet).

Connected to PC via Ethernet LAN (TCP/IP).

Powered by USB Power Adapter.

Connected to PC via Ethernet LAN (TCP/IP).

Powered by USB connection to the PC.

3-1 GENERAL USE & CONFIGURATION Page 10

CPS2000 Series Instruction Manual

3.1.1 USB

All CPS2000 power sensors support connection to a PC using USB.

3.1.1.1 Required Equipment

a) CPS2000 Power Sensor

b) USB 2.0 Type A Male to Type B Male cable

c) PC with the CPS2000 GUI application installed

3.1.1.2 Setup Steps

To setup and take measurements with a CPS2000 power sensor connected by USB, follow these steps:

1. Connect the CPS2000 power sensor to the PC using a standard USB 2.0 Type A Male to

Type B Male cable.

2. Start up the CPS2000 GUI application.

3. The CPS2000 power sensor will appear in the device list. Select the device and click OK to

open the device.

Figure 1 - USB Device Selection

4. The application will immediately begin taking power measurements.

Start Simulated Device

When a CPS2000 power sensor is not available, users may still access the CPS2000 GUI by

selecting the Start Simulated Device button.

3-2 GENERAL USE & CONFIGURATION Page 11

CPS2000 Series Instruction Manual

3.1.2 Ethernet

The CPS2000 power sensors also support connection to a LAN network via standard Ethernet cabling.

3.1.2.1 Required Equipment

a) CPS2000 Power Sensor

b) CAT5 or CAT6 Ethernet Cable

c) Local network with router setup and configured

d) PoE (“Power over Ethernet”) Ethernet switch or USB wall power source

e) PC with the CPS2000 GUI application installed

Note!

When using the device via an Ethernet connection, the device must be powered using PoE

or with a USB power adapter. The device does not support connection to a PC via both

Ethernet and USB at the same time.

3.1.2.2 Setup Steps

To setup and take measurements with a CPS2000 power sensor connected by Ethernet, follow these

steps:

1. Connect the CPS2000 power sensor to your LAN using a standard Ethernet cable.

a. If not using Power over Ethernet, connect the CPS2000 power sensor to a power using

a USB power adapter.

2. Start up the CPS2000 GUI application.

3. Select Manually Enter IP Address button.

4. Enter the IP address of the device.

Note!

To determine the IP address of a CPS2000 power sensor, users need to connect to the

sensor via USB. Then go to the File -> Configure Network Settings… menu and select the

sensor in question. A Network Configuration window will appear with the information.

Please see section 3.1.2.3 for additional information.

3-3 GENERAL USE & CONFIGURATION Page 12

CPS2000 Series Instruction Manual

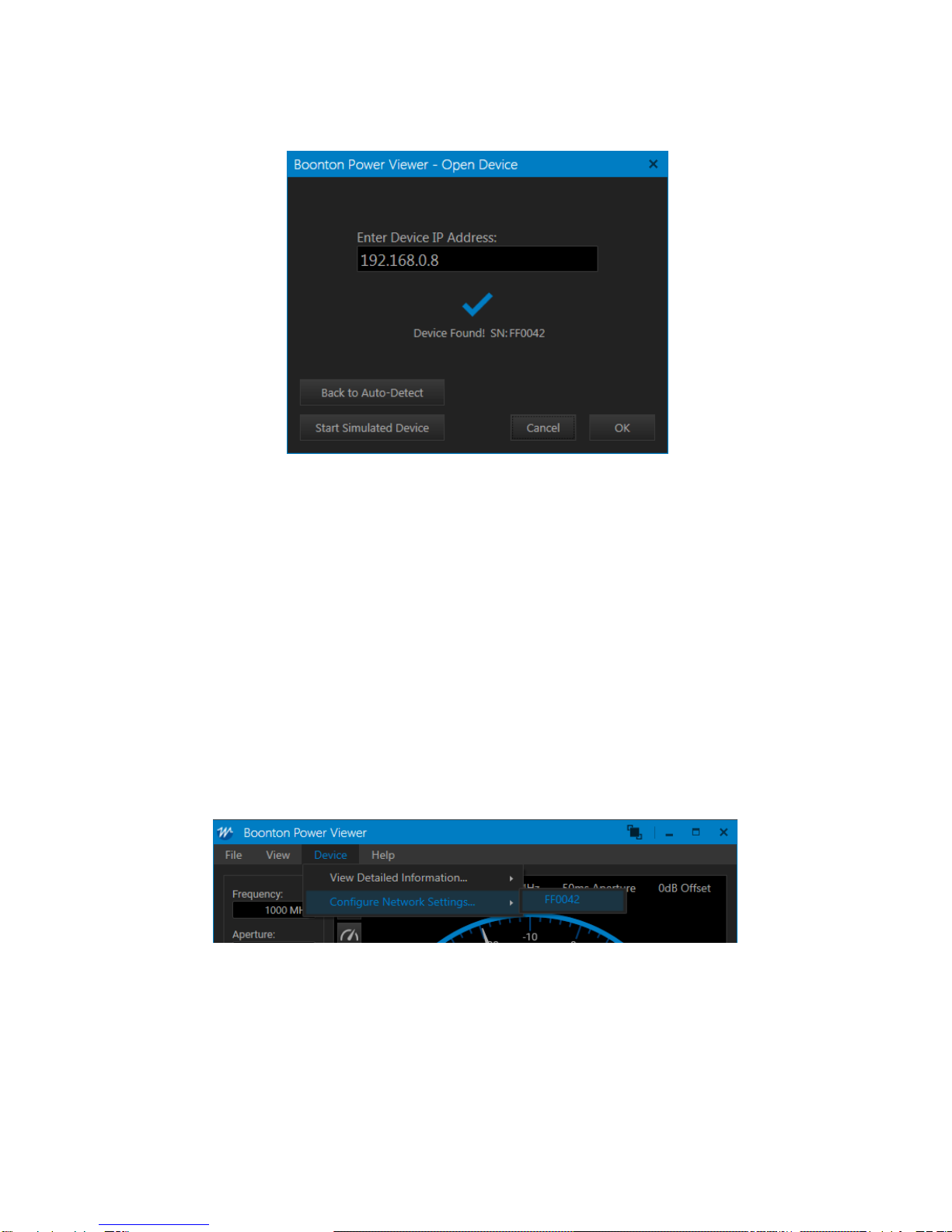

5. The software will then verify the IP.

Figure 2 - TCPIP Search Success

6. Click OK to open the device.

7. The application will immediately begin taking power measurements.

Auto-detect

If the Cancel button is selected, the user will be returned to the Open Device window with

Auto-Detect of USB devices disabled. To return to the Open Device window with Auto-Detect

with Auto-Detect enabled, select the Back to Auto-Detect button.

3.1.2.3 Configuring the TCP/IP Settings of a Power Sensor

To configure the TCP/IP settings of a Power Sensor, select the device you want to configure under the

File -> Configure Network Settings…menu:

Configure the settings as required using the input boxes within the New Settings section of the window.

When finished, click the Store New Settings…button to apply the changes.

3-4 GENERAL USE & CONFIGURATION Page 13

CPS2000 Series Instruction Manual

3-5 GENERAL USE & CONFIGURATION Page 14

CPS2000 Series Instruction Manual

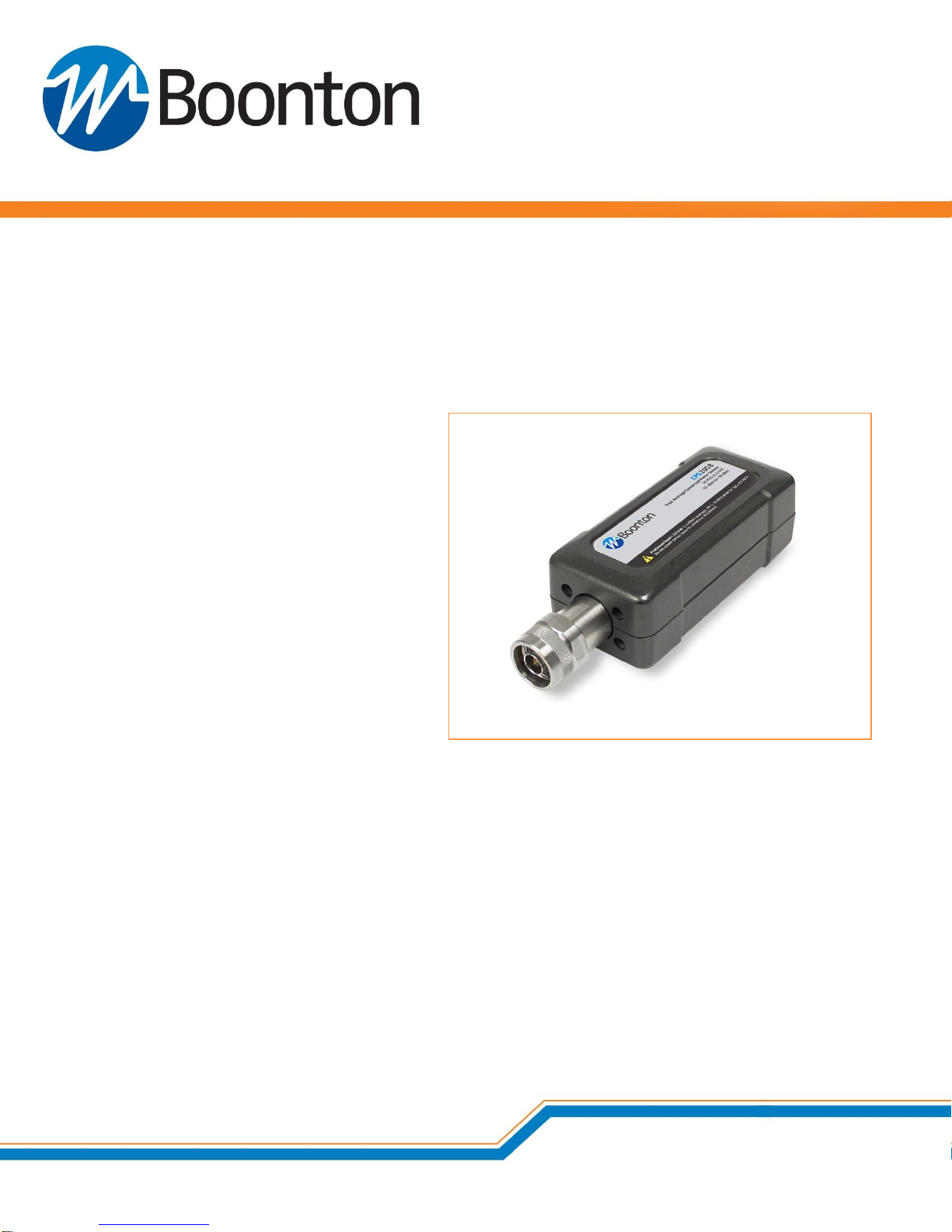

3.2 Configuring a Power Sensor

The CPS2000 GUI application provides a simple device configuration UI.

Figure 3 - Software Overview

1

Settings panel, including Frequency,

Aperture, and Offset settings.

3

Units selection

Aperture

1 ms - 2 s

The aperture time is the total time the

sensor observes the input signal to

make one power measurement.

4

Visualization selected. Options

include Text-Only, Gauge-Only, and

Text + Gauge.

Offset

+/-200 dB

This feature provides the ability to

apply corrections to measurements

when RF devices are between the

sensor and DUT.

5

6

Power Measurement

Add Device…button for adding

additional devices

2

Live Power vs. Time graph

(units are dBm only)

7

Applied settings

1

2

3

6

4

7

5

Always-on-Top

Feature

Show/Hide

Global

Settings

Panel

Show/Hide

Y-Axis

Configuration

Undock & resize

Live Power graph

with Always-on-

Top feature

3-6 GENERAL USE & CONFIGURATION Page 15

CPS2000 Series Instruction Manual

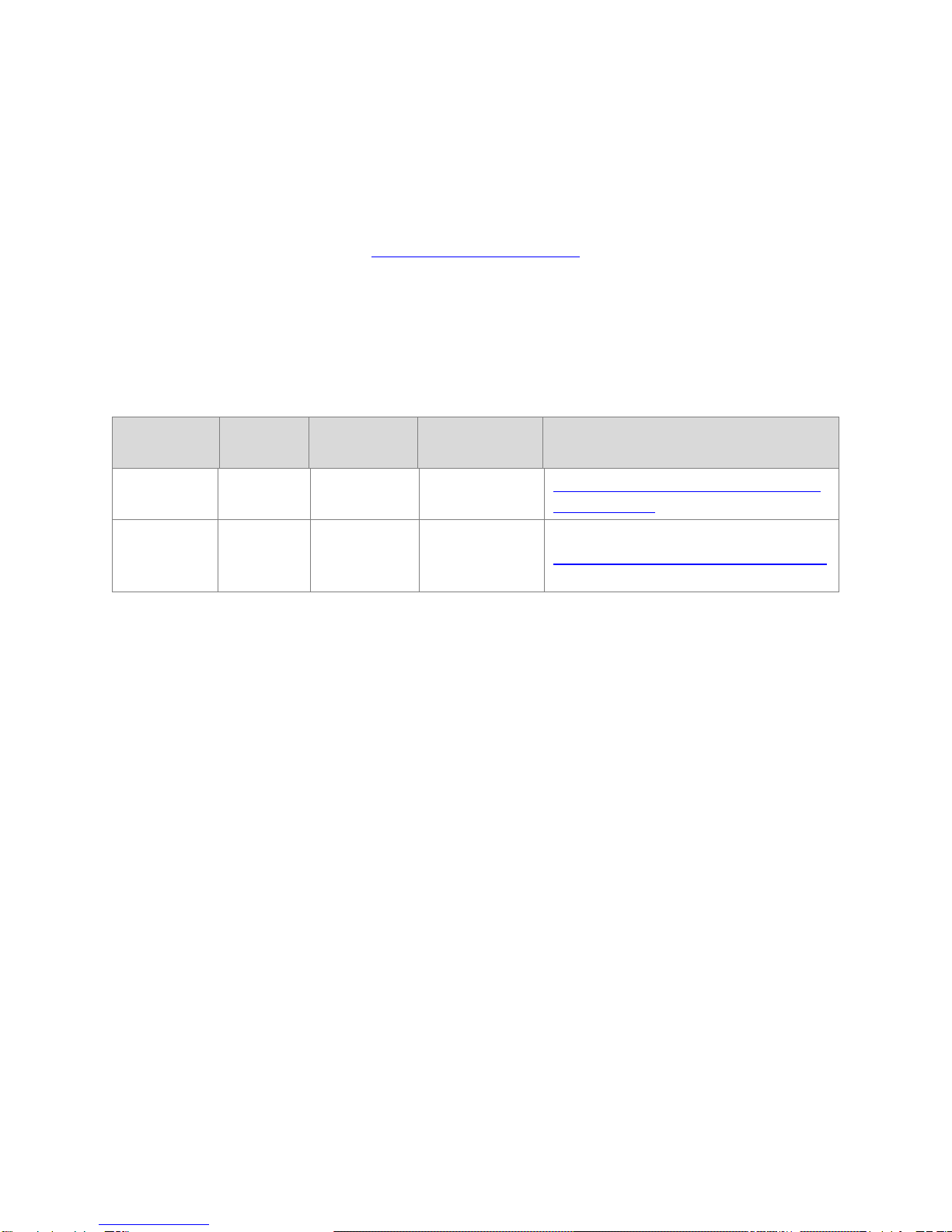

3.3 Connecting to Multiple Power Sensors

The CPS2000 GUI application supports connecting multiple devices. To connect to additional devices,

click the Add Device… button.

To toggle the view between single and multiple sensor readings, navigate to View -> Graph -> All

Channels or No Channels.

Figure 4 - Multiple Device View

3-7 GENERAL USE & CONFIGURATION Page 16

CPS2000 Series Instruction Manual

1

Global settings panel, affects all devices

that are linked to the global settings

5

Applied device settings for each device

2

Device label –A user configurable label

for a Power Sensor or Ratio

6

Toggle buttons to configure or remove a

specific Power Sensor or Ratio

3

Color selector

7

Adds a ratio between two power

measurements

4

Graph toggle checkbox

3.4 Upgrading the Firmware on a Power Sensor

To determine the current firmware version on a CPS power sensor, navigate to Device -> View Detailed

Information -> and select the sensor of interest.

3-8 GENERAL USE & CONFIGURATION Page 17

CPS2000 Series Instruction Manual

To upgrade firmware, the CPS2000 GUI application includes a utility for loading firmware onto a

CPS2000 power sensor. The utility is accessible using the File -> Upgrade Device Firmware… menu:

Figure 5 - Firmware Upgrade Menu

To load new firmware onto a power sensor, select it from the list of devices, select an upgrade file, and

then click the Start Upgrade button.

Figure 6 - Firmware Upgrade Process

When the firmware loading process has completed, the power sensor will automatically be reconnected

and power measurements will automatically startup again.

3-9 GENERAL USE & CONFIGURATION Page 18

CPS2000 Series Instruction Manual

3.5 Other Features

The CPS2000 GUI includes additional features described below.

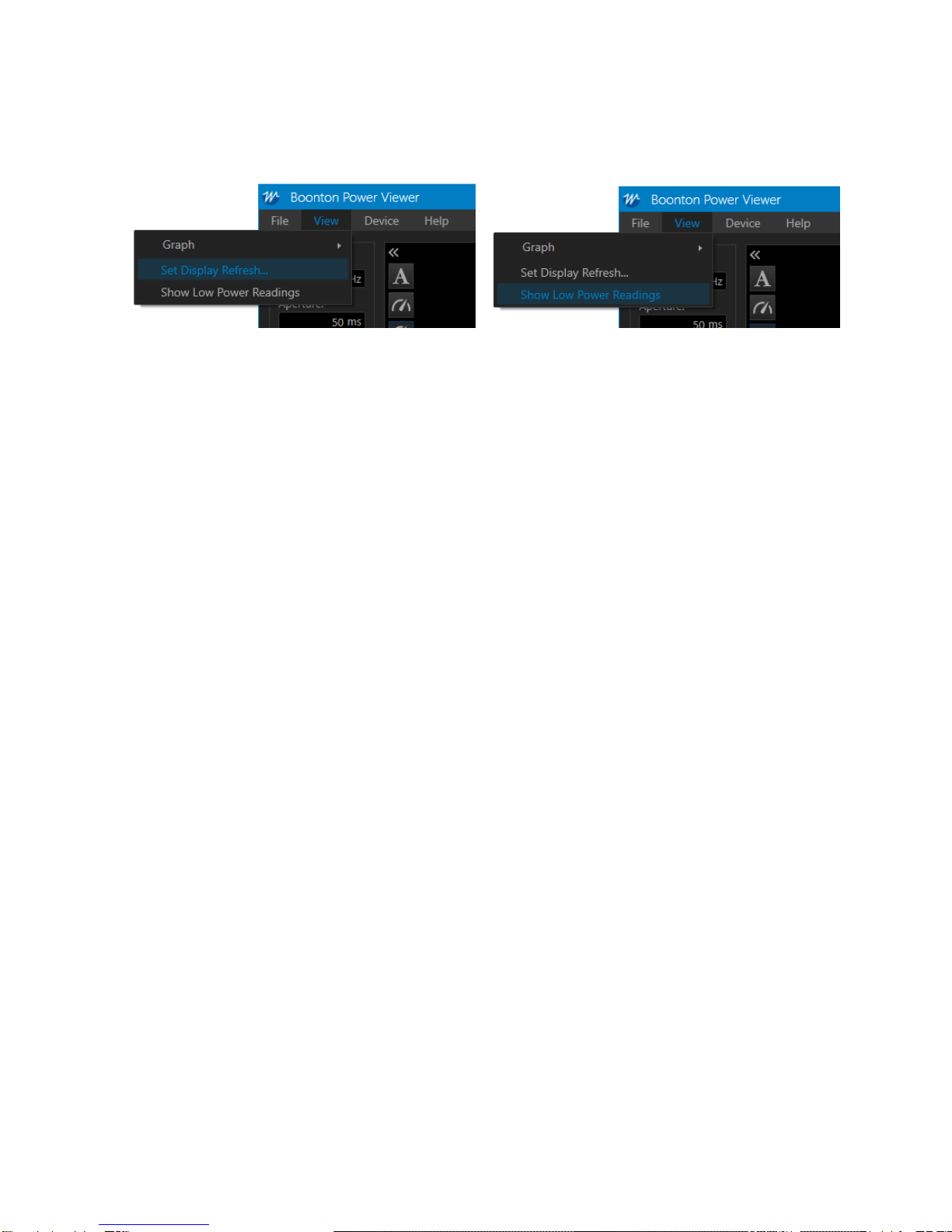

3.5.1 Set Display Refresh

Users can select the display refresh rate from x to y.

3.5.2 Show Low Power Readings

The CPS2000 power sensor can detect power levels below the specified measurement range. Users can

elect to display these readings by selecting Show Low Power Readings. Otherwise, the when power

levels are below the specified range, the display will read “Too Low” (default setting).

3-10 GENERAL USE & CONFIGURATION Page 19

CPS2000 Series Instruction Manual

4Troubleshooting

4.1 Recovery After a Failed Firmware Upgrade

If a failure is encountered when attempting to upgrade a device, such as if the cable is disconnected

during an upgrade, the device may be left in a state that prevents operation of the normal upgrade

procedure.

If this occurs, the device can still be recovered. To recover the device, follow these steps:

1. Open a Windows Command Prompt window

2. Within the command prompt, navigate to the CPS2000 GUI application’s directory:

> cd C:\Program Files(x86)\Boonton\CPS2000

Note: This location depends on the location where the application was installed. If

you installed the application to a different location, you will need to use a different

path.

3. Execute the following command, replacing <path> with the path to your firmware upgrade

.sb file.

> blhost.exe --usb 0x1cb5,0x2000 receive-sb-file <path>

4. Allow the upgrade to complete.

5. When finished, execute the following command:

> blhost.exe --usb 0x1cb5,0x2000 reset

6. The device will reset and will then be available for use in the CPS2000 GUI application.

5Boonton Resources on RF Power Measurements

Information regarding power measurement and Boonton Power Sensor products is available free of

charge from the Resource Library section of the Boonton website. All Boonton power sensor instruction

manuals cover the details of RF power measurement techniques. The following links highlight a few of

the available application notes, articles, webinars and white papers related to RF Power measurements

and techniques:

•Principles of RF Power Measurements:

http://www.boonton.com/resource-library/power-measurement-reference-guide

•Videos:

http://boonton.com/resource-library?brand=Boonton&go=videos

•Application Notes:

http://www.boonton.com/resource-library?brand=Boonton&go=application_notes

4-1 TROUBLESHOOTING AND RESOURCES Page 20

Other manuals for CPS2000

1

Table of contents

Other Boonton Accessories manuals