Booth BAR2H User manual

Booth D

i

s

p

e

n

s

e

r

s

Ltd, Moor

Park Avenue, B

l

a

c

k

poo

l

,

L

a

nc

a

s

h

i

r

e

,

FY2 0LZ, U

K

+44 1253

501800

Product

M

a

nu

a

l

B

A

R

2

H

Shelf

M

oun

t

e

d

Beer

C

oo

l

e

r

s

3

B

6993

-

O

R

12

1

I

n

t

r

odu

c

t

i

on

C

on

t

e

n

t

s

S

ec

t

i

on

P

a

g

e

S

ec

t

i

on

P

a

g

e

I

n

tr

oduc

t

i

on

2

F

a

u

l

t

f

i

nd

i

ng

8

S

p

e

c

i

f

i

c

a

t

i

on

&

I

n

s

t

a

ll

a

t

i

on

3

Spare

p

a

rt

s

9

M

od

e

l

N

u

m

b

e

r

i

ng

C

on

v

e

n

t

i

on

4

R

e

m

o

v

a

l

,

Tr

a

n

s

po

rt

a

t

i

on

&D

i

s

po

s

a

l

10

S

ch

e

m

a

t

i

c

s

5

-

7

I

n

t

r

odu

c

t

i

on

The

BAR2H

i

s

an

i

c

e

bath coo

l

e

r

d

e

s

i

gn

e

d

to

p

r

o

v

i

d

e

ch

ill

e

d

product

f

o

r

under counter

a

pp

li

c

a

t

i

on

s

.

The system uses a bath water r

e

c

i

r

cu

l

a

t

i

on

system and

python to

generate and

m

a

i

n

t

a

i

n

op

t

i

m

u

m

d

r

i

n

k

temperature at the

po

i

n

t

o

f

d

i

s

p

e

n

s

e

.

The

BAR2H

coo

l

e

r

i

s

d

e

s

i

gn

e

d

f

o

r

e

ff

e

c

t

i

v

e

p

e

r

f

o

r

m

a

nc

e

and

i

m

p

r

o

v

e

d

energy

e

ff

i

c

i

e

nc

y

.

It

i

s

i

d

ea

l

f

o

r

a range

o

f

a

pp

li

c

a

t

i

on

s

,

i

t

s

compact

s

i

z

e

i

d

ea

ll

y

s

u

i

t

e

d

to

under counter

i

n

s

t

a

ll

a

t

i

on

s

.

S

a

f

e

t

y

The

BAR2H

Hydrocarbon

un

i

t

s

use

R290

(Care

40,

Propane). B

e

l

o

w

are some

s

a

f

e

ty

po

i

n

t

s

w

h

i

ch

t

h

e

end user must adopt

to

m

i

t

i

g

a

t

e

the r

i

s

k

o

f

un

s

a

f

e

cond

i

t

i

on

s

a

r

i

s

i

ng.

S

e

rv

i

c

e

must on

l

y

be

c

a

rr

i

e

d

out by

a

s

u

i

t

a

b

l

y

qu

a

li

f

i

e

d

r

e

f

r

i

g

e

r

a

t

i

on

e

ng

i

n

ee

r

.

The un

i

t

s

hou

l

d

be

i

s

o

l

a

t

e

d

f

r

o

m

the

e

l

e

c

tr

i

c

i

ty

s

upp

l

y

b

e

f

o

r

e

r

e

m

o

v

a

l

o

f

the

co

v

e

r

s

.

Do not

damage the r

e

f

r

i

g

e

r

a

t

i

on

c

i

r

cu

i

t

.

V

e

n

t

il

a

t

i

on

op

e

n

i

ng

s

must be

c

l

ea

r

o

f

ob

s

tr

uc

t

i

on

s

.

There must be a gap

o

f

at

l

ea

s

t 100mm

between the

a

pp

li

a

nc

e

and

a w

a

ll

or other r

e

s

tr

i

c

t

i

on.

Where

e

l

e

c

tr

i

c

a

l

componentsare r

e

p

l

a

c

e

d,

the new component must be o

f

the same ty

p

e

.

Operate

un

i

t w

i

t

h

i

n

(

a

m

b

i

e

n

t)

op

e

r

a

t

i

ng

temperatures;

10°C to

32

°

C

.

2

11

Introduction

Specificationand

I

n

s

t

a

ll

a

t

i

on

Removal,Transportation and

Di

s

po

s

a

l

I

m

po

rt

a

n

t:

Before removal

from

the installation, ensure all electrical, product

and

g

a

s

c

onn

ec

t

i

on

s

are d

i

s

c

onn

ec

t

e

d

.

Disposal

of

Scrap Un

i

t

s

It

i

s

ill

e

g

a

l

to

s

i

m

p

l

y

scrap a r

e

f

r

i

g

e

r

a

t

i

on

un

i

t

.

B

e

f

o

r

e

a

un

i

t

can be scrapped

it

must

f

i

r

s

t

have

t

h

e

gas removed

by

a

s

p

e

c

i

a

li

s

t

u

s

i

ng

s

p

e

c

i

a

li

s

t

e

qu

i

p

m

e

n

t

.

P

l

ea

s

e

contact

Booth D

i

s

p

e

n

s

e

r

s

Ltd.,

who

will

be happy

to

p

r

o

v

i

d

e

a

quo

t

a

t

i

on

f

o

r

d

i

s

po

s

a

l

.

T

r

a

n

s

po

r

t

a

t

i

on

I

m

po

r

t

an

t

: T

h

i

s

un

i

t

must be transported

i

n

an

up

r

i

gh

t

po

s

i

t

i

on

As w

i

t

h

a

ll

r

e

f

r

i

g

e

r

a

t

i

on

systems,

i

rr

e

p

a

r

a

b

l

e

damage can be caused

by

l

a

y

i

ng

the

un

i

t on

i

t

s

s

i

d

e

o

r

even tr

a

n

s

po

rt

i

ng

up

s

i

d

e

down.

Where the un

i

t

i

s

transported

by

a

c

a

rr

i

e

r

,

the carton

s

hou

l

d

a

l

w

a

y

s

be marked

i

n

a

con

s

p

i

cuou

s

manner, the correct up

r

i

gh

t

po

s

i

t

i

on

i

n

w

h

i

ch

it

must be

h

a

nd

l

e

d.

If

a

un

i

t

has been transported

i

nco

rr

e

c

t

l

y

it

s

hou

l

d

be

p

l

a

c

e

d

i

n

the correct up

r

i

gh

t

po

s

i

t

i

on

and

l

e

f

t

f

o

r 24

hours b

e

f

o

r

e

a

tt

e

m

p

t

i

ng

to run

the

s

y

s

t

e

m

.

F

a

il

u

r

e

to

observe the above

p

r

e

c

a

u

t

i

on

s

cou

l

d

s

e

r

i

ou

s

l

y

damage the system, and w

ou

l

d

v

o

i

d

a

n

y w

a

rr

a

n

ty

.

10

S

p

ec

ifi

ca

t

i

on

Di

m

en

s

i

on

s

453

mm

(W)

425mm(D) + 40mm

f

o

r

Product

C

o

il

s

282

mm

(H)

C

o

m

p

r

e

ss

o

r

H

u

y

a

i

C

ub

i

g

e

l

N

LY

45

R

A

Dry W

e

i

gh

t

25

k

g

T

h

i

s

product

con

t

a

i

n

s

P

r

opane

Refrigerantgas

with

a

GWP of 3 in

a

hermetically

s

ea

l

ed

s

y

s

t

e

m

S

upp

l

y

230

V

a

c

/

50

H

z

R

e

f

r

i

ge

r

an

t

R290

80g

Rated

I

npu

t

300

W

Climatic

C

l

a

ss

N

Rated

C

u

rr

en

t

1.25

A

Fuse

R

a

t

i

ng

5

A

I

n

s

t

a

ll

a

t

i

on

The un

i

t

must be

i

n

s

t

a

ll

e

d

by

a competentperson,

on

a

firm

l

e

v

e

l

s

u

r

f

a

c

e

c

a

p

a

b

l

e

o

f

s

uppo

rt

i

ng

t

h

e

w

e

i

gh

t

o

f

the

m

a

ch

i

n

e

when the bath

i

s

f

ill

e

d.

It

i

s

i

m

po

rt

a

n

t

that the v

e

n

t

il

a

t

i

on

op

e

n

i

ng

s

i

n

t

h

e

m

a

ch

i

n

e

are

not

b

l

oc

k

e

d

to

a

ll

o

w

the

f

r

ee

movement o

f

a

i

r

.

I

n

a

d

e

qu

a

t

e

v

e

n

t

il

a

t

i

on

will

shorten the

li

f

e

o

f

the

f

r

i

dg

e

s

y

s

t

e

m

.

Note:

At

t

h

i

s

stage

do not

connect the

unit to

the electrical

s

upp

l

y

Ensure that the v

e

n

t

il

a

t

i

on

op

e

n

i

ng

s

are

not

b

l

oc

k

e

d,

to

a

ll

o

w

f

r

ee

movement o

f

a

i

r

through

the

un

i

t

.

Failure

to do

t

h

i

s

will

s

e

r

i

ou

s

l

y

affect the reliability

of

the f

r

i

dge

,

invalidate the warranty and shorten the life

of

the fridge

s

y

s

t

e

m

.

L

oc

a

t

e

a

con

t

a

i

n

e

r

beneath the bath

o

v

e

r

f

l

o

w to

prevent any water

s

p

ill

a

g

e

as the bath

i

s

f

ill

e

d

and when

i

c

e

i

s

f

o

r

m

e

d

i

n

the

b

a

t

h.

Fill

the bath u

s

i

ng

co

l

d

water

through

the

‘

B

a

t

h

F

ill

’

op

e

n

i

ng

on

the

top

o

f

the

m

a

ch

i

n

e

un

t

il

water

i

s

d

i

s

p

l

a

c

e

d

f

r

o

m

the

o

v

e

r

f

l

o

w

.

Connect the d

i

s

p

e

n

s

e

python to

the

‘

R

e

c

i

r

cu

l

a

t

i

on

’

F

l

o

w

and

R

e

t

u

r

n.

Connect the

product to

the

s

t

a

i

n

l

e

ss

s

t

ee

l

product

co

il

s

.

Connect the un

i

t to

the

e

l

e

c

tr

i

c

a

l

s

upp

l

y

and

turn

on.

A

f

t

e

r

a short

d

e

l

a

y

the compressor and

f

a

n

s

will

s

t

a

rt

.

The un

i

t

will

now

b

e

g

i

n

to

reduce the bath water temperature. Once the water

i

s

at

t

h

e

correct temperature, an

i

c

e

bank

will

b

e

g

i

n

to

f

o

r

m

.

As the

i

c

e

b

e

g

i

n

s

to

f

o

r

m

,

a

s

m

a

ll

amount o

f

water

will

be

d

i

s

p

l

a

c

e

d.

Oncea

full

i

c

e

bank

i

s

produced, the

f

a

n

and compressor

will

s

w

i

t

ch

off

and the

m

a

ch

i

n

e

i

s

ready

f

o

r

u

s

e

.

Note: The t

i

m

e

taken

f

o

r

the

un

i

t to

reach

op

e

r

a

t

i

ng

temperature

will

vary

d

e

p

e

nd

i

ng

on

a

m

b

i

e

n

t

temperature, hu

m

i

d

i

ty

and the temperature

o

f

the

i

nco

m

i

ng

water

s

upp

l

y

.

3

Specification and Installation

Removal, Transportation & Disposal

Model

N

u

m

b

e

r

i

ng

Spare P

a

r

t

s

SPC8/2

Pump –

1

A

5176

SPC12/4

Pump –

1

A

5177

E

li

w

e

ll

C

on

tr

o

ll

e

r –

1

A

5362

DFX

C

on

tr

o

ll

e

r –

1

A

6310

4 9

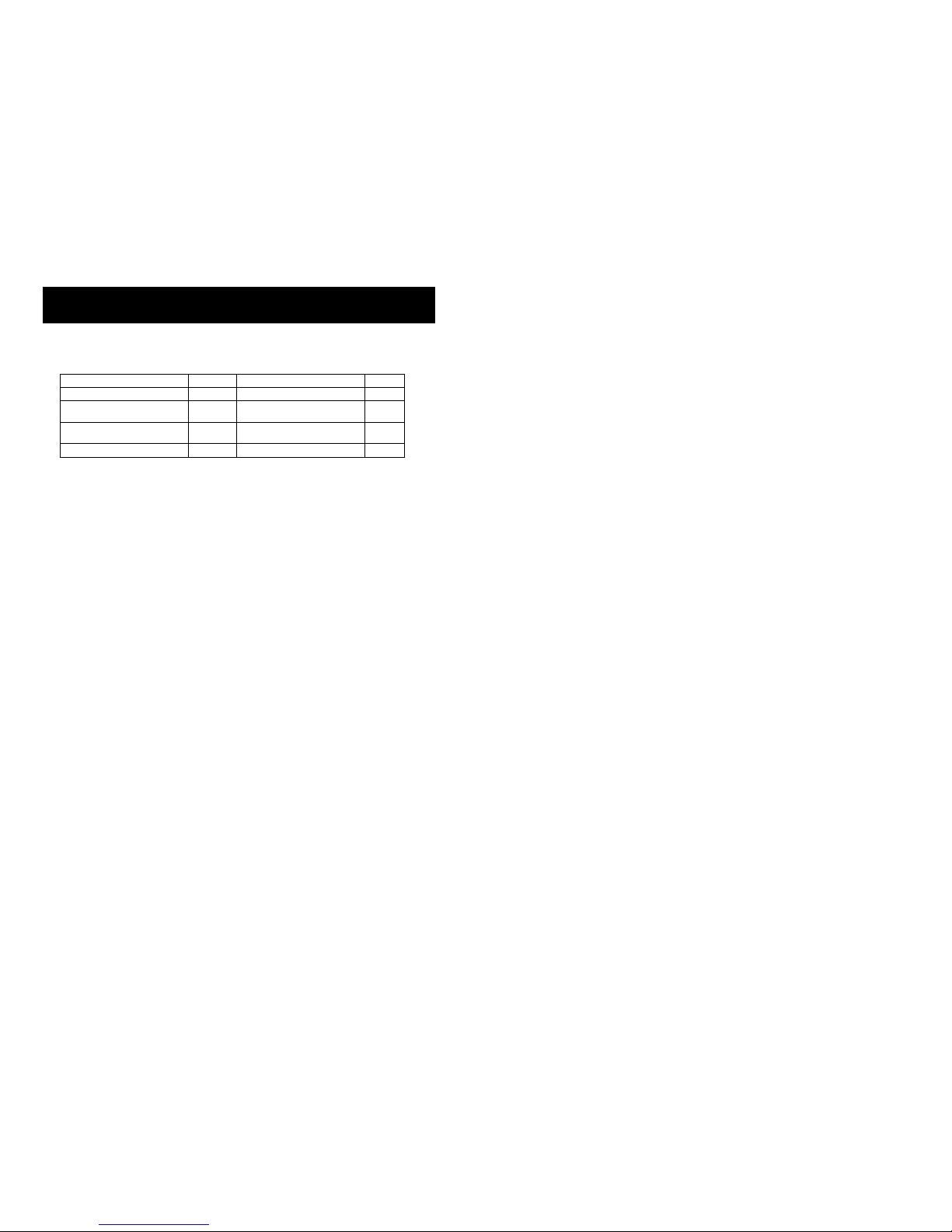

UNIT NUMBER (BAR2H) (X) (Y) (Z)

KEY:

BAR2H

BASE TYPE

(X)

PUMP

(Y)

CONTROL OPTION

(Z)

NO OF COILS/DECK OPTION

REFERENCE

PART #

DESCRIPTION

(X)

PUMP

2

1A5176

SPC8/2 PUMP

4

1A5177

SPC12/4

(Y)

CONTROL

M

1A5361

MECHANICAL

E

1A5362

ELIWELL

D

1A6310

DFX CONTROL

(Z)

DECK

0

1A6305

NO COILS

1

1A6306

1 COIL

2

1A6307

2 COILS

3

1A6308

3 COILS

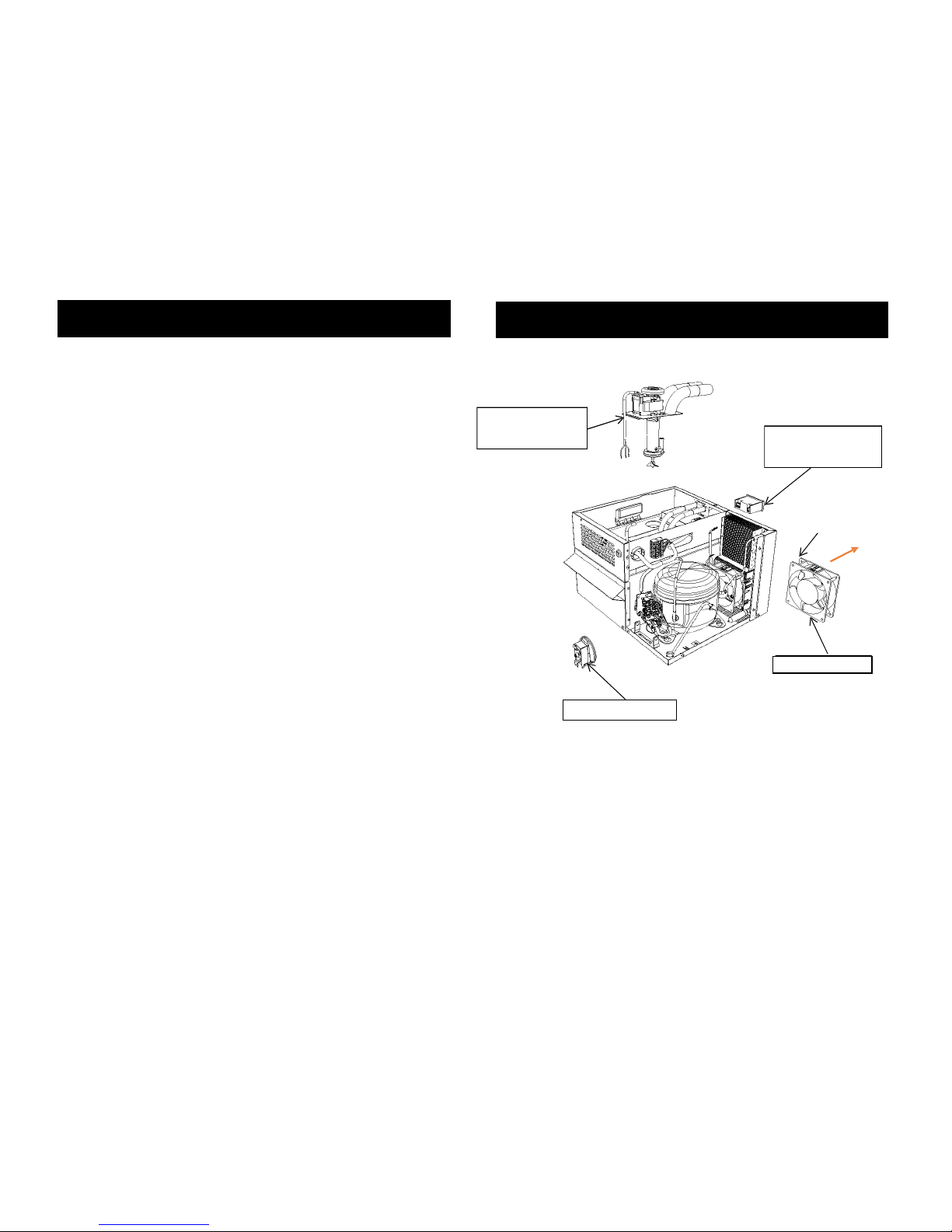

Mechanical Stat –1A5361

1B5514 –Cooling Fan

Model Numbering Convention

Spare Parts

Electrical Connections

this side

D

i

r

e

c

t

i

on

o

f

a

i

r

fl

o

w

Fault

F

i

nd

i

ng

S

c

h

e

m

a

t

i

c

P

r

i

o

r to

any

f

a

u

l

t

f

i

nd

i

ng,

p

l

ea

s

e

ensure

a

ll

conn

e

c

t

i

on

s

to

the

ch

ill

e

r

are sound and t

h

a

t t

h

e

i

nco

m

i

ng

s

upp

ly

i

s

turned

on.

A

l

s

o,

ensure t

h

a

t

a

ll

e

l

e

ct

r

i

cal

l

conn

e

c

t

i

on

s

to

the

ch

ill

e

r

and

i

n

the

ch

ill

e

r

are secure and

i

n

good

cond

i

t

i

on,

the power

i

s

on

and that the ch

ill

e

r

has had

a

d

e

qu

a

t

e

t

i

m

e

to

reach

op

e

r

a

t

i

ng

t

e

m

p

e

r

a

t

u

r

e

.

NOTE:

I

s

o

l

a

t

e

from

m

a

i

n

s

before removing any

p

a

n

e

l

s

No Drinks

Water supply

Check connections to water supply.

Check water supply is turned on.

Check water supply is turned on.

Check system for blockages.

Check system for blockages.

Frozen product coil

Check thermostat/temperature probe is correctly

located into the bath probe well.

Check the agitator is running. If supply voltage is

present renew agitator assembly.

If agitator is running with no water agitation check

agitation blades.

Warm Drinks

Insufficient air flow through the

fridge.

Check that the condenser is not blocked.

Check for blockages and obstructions to

ventilation grills.

Cooling Fans Not running

Check supply to cooling fans.

If supply present replace fans.

If supply not present check connections,

thermostat, high side protection (digital thermostat

only) and fuse.

Compressor not running

Check supply to Compressor.

If supply present return for repair.

If supply not present check connections,

thermostat, high side protection (digital thermostat

only) and fuse.

Fridge failure

If compressor & fan are running and there is no

cooling, return for repair.

8

Eliwell

Wiring

S

c

h

e

m

a

t

i

c

Schematic

Fault Finding

5

S

c

h

e

m

a

t

i

c

S

c

h

e

m

a

t

i

c

DFX Wiring

S

c

h

e

m

a

t

i

c

6

M

ec

h

a

n

i

ca

l

Wiring

S

c

h

e

m

a

t

i

c

7

Schematic

Schematic

Table of contents

Other Booth Accessories manuals