Booth DRY125 User manual

Booth Dispensers Ltd, Moor Park Avenue,

Blackpool, Lancashire

Tel +44 (0)1253 501800

www.booth-dispensers.co.uk

Installation Instructions

DRY125 Kitchen Cooler

Part Number 3B3967 Issue OR [18/06/09}

Booth Kitchen Cooler

Installation Instructions

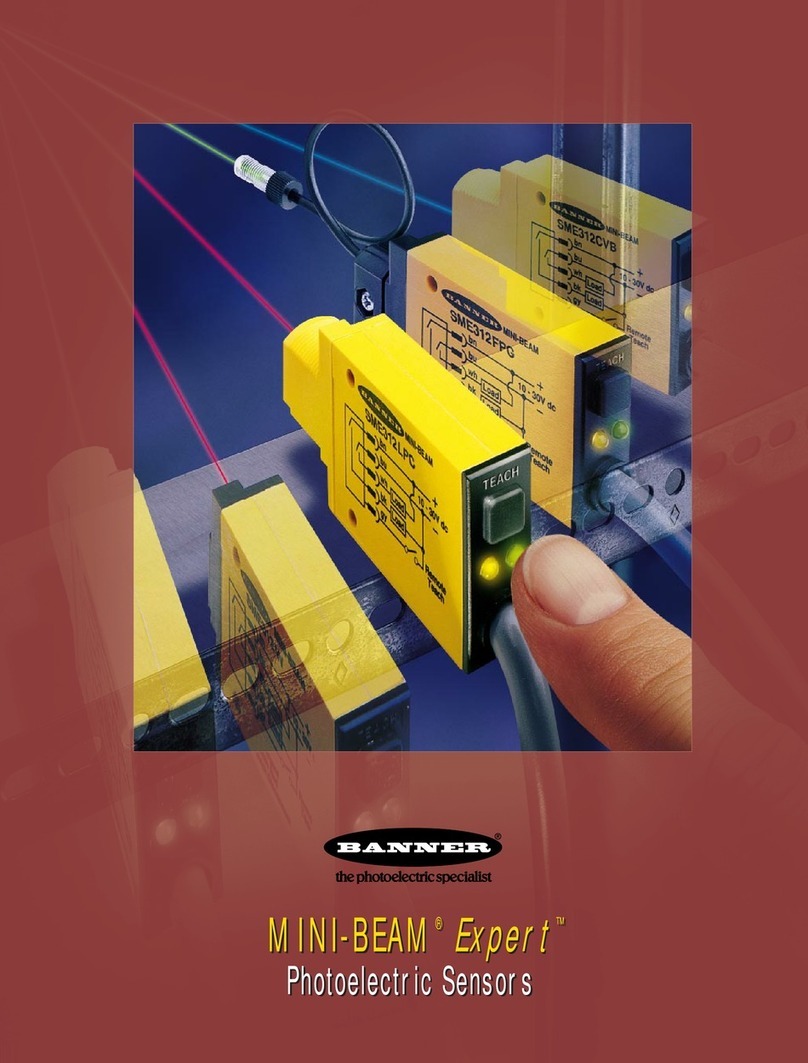

The Booth Kitchen Cooler is designed to be fitted into a kitchen cupboard, ideally below the sink,

in close proximity to both mains water and electrical supplies. If an electrical socket is not close to

the intended location of the cooler, one should be fitted by a qualified electrician. The cooler is

intended to be installed in conjunction with a water filter and dispense tap which are available as an

optional kit from Booth Dispensers. If

alternative parts are used, the instructions

for installing them should be followed to

make the connections to the mains water,

and the cooler should be connected

between the outlet of the filter and the

tap. These instructions cover the

installation of the cooler with the

optional kit from Booth Dispensers Ltd.

The cooler is supplied with an air inlet

duct that will need to be fitted as per the

illustration opposite. This allows cool air

to be drawn in from a vent in the kick-

board at the front of the cupboard, and

warm air is blown out through the rear

panel in the cupboard. The rear panel of

the cupboard should not be too close to

the wall, and a gap of 50mm will be

sufficient in most cases. In virtually all

installations, the warm air will then be

able to escape from this area easily, and

no additional ventilation will be

necessary. For example, a gap of 15mm

between the cupboard base and the top of

the kick-board will be sufficient.

However, if the back of the cupboard is

completely sealed to the wall, and there

is no way for warm air to escape, the

cooler will not work correctly, and

additional ventilation will be necessary to

allow the warm air to escape.

1. IMPORTANT: Before making any cuts into the cupboard or kick board, ensure the area

to be cut is free from water pipes or electrical cables. There is a risk of serious injury or

death if electrical cables are cut, and significant damage to property if a water pipe is cut.

2. Before installation, ensure there is an electrical socket in close proximity to the intended site of

the cooler. If not, it will be necessary to have one fitted by a qualified electrician.

Introduction

Installation Instructions

3. Also ensure that there is adequate space at the back of the cabinet and a way for warm exhaust

air to escape, a 50mm gap between the

panel and wall should be sufficient.

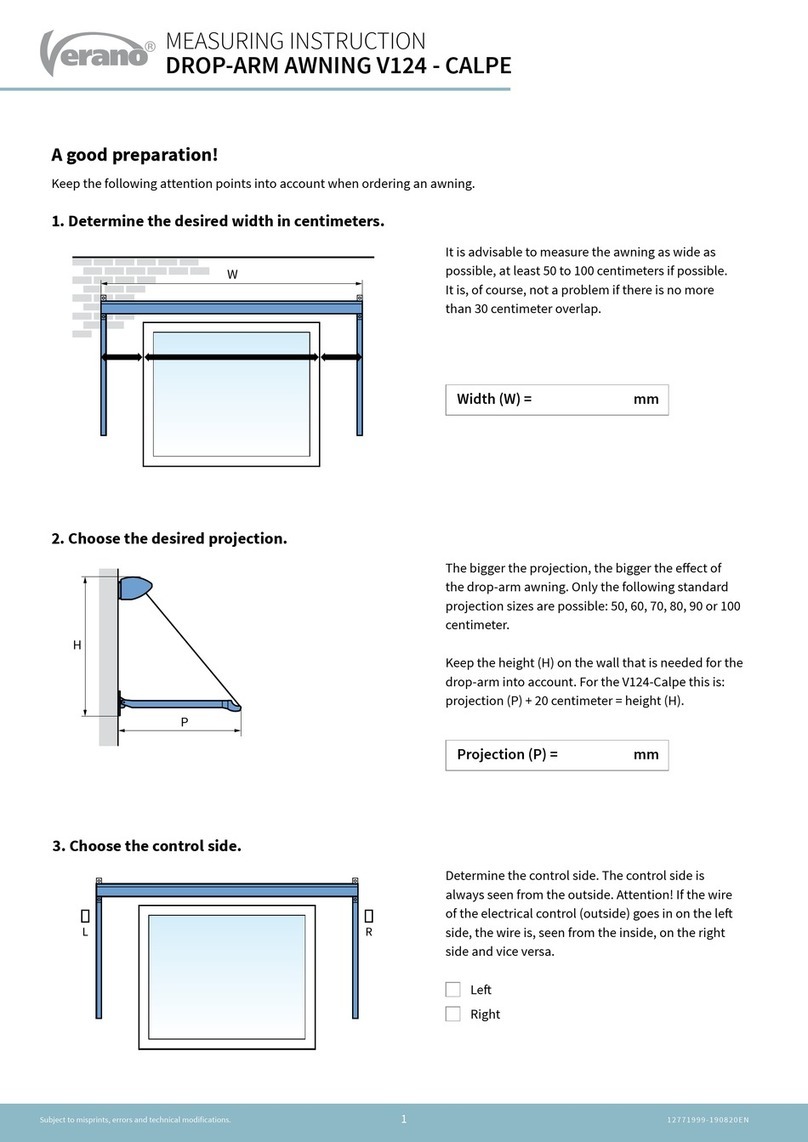

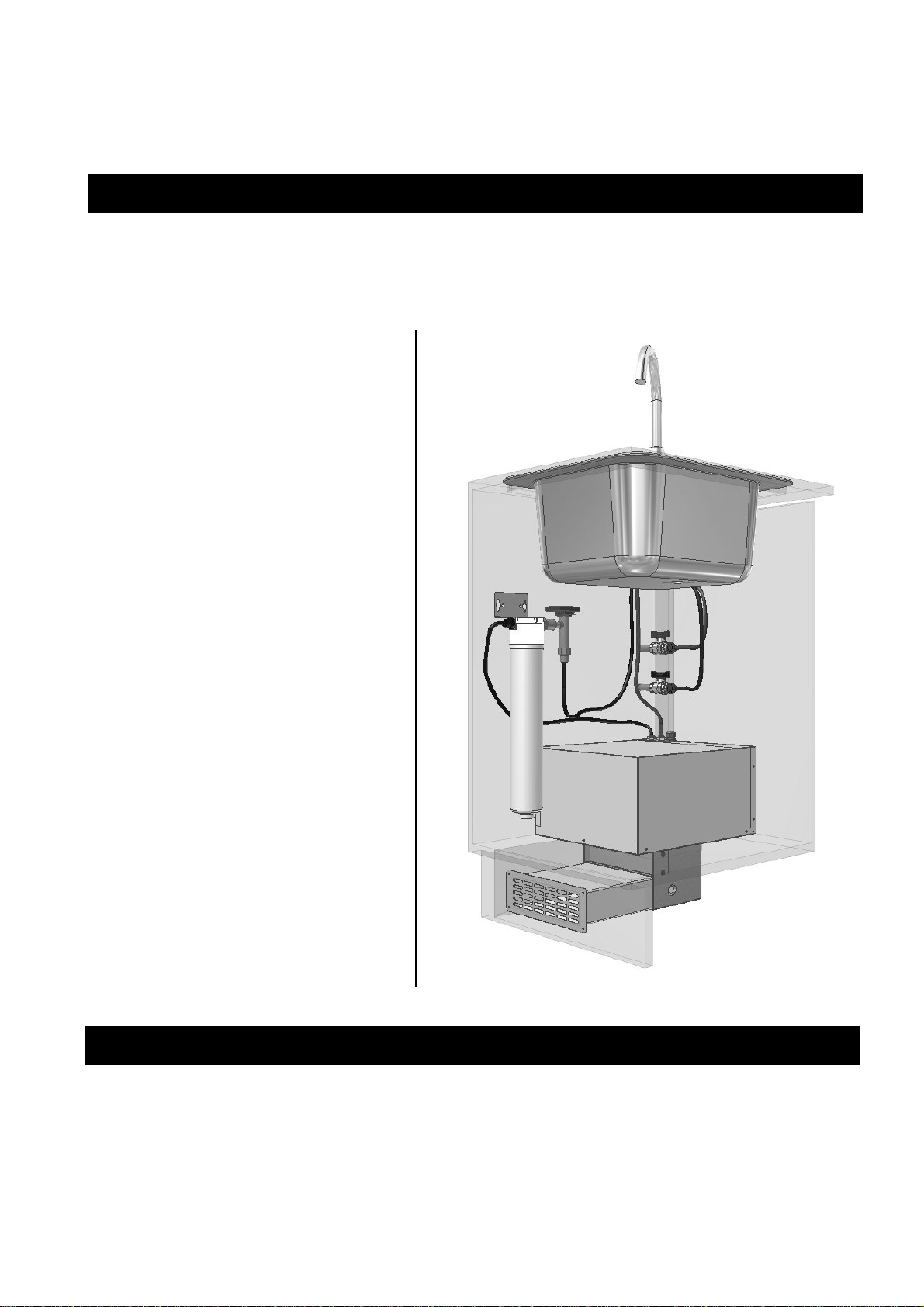

4. Identify the best location for the cooler,

tap and filter by reference to the

illustration above, the water circuit

diagram opposite, the tap and filter

instructions and the parts themselves.

Take care now in planning the

connection to the water mains, routing

of flexible tubes and location of

components to ensure the installation is

as unobtrusive as possible.

5. It is also necessary to ensure that the air

inlet duct will not clash with any legs

or other obstacles in the cupboard kick

space, and that the cooler and filter will

not clash with any other fixtures within

the cupboard such as drainage

components.

6. Using the Cooler template A, mark the

position of the cooler sides on the base

of the cupboard, and the position of the

opening for the air inlet. Using

template B, mark the opening for the

exhaust air in the back of the cabinet.

Remove the templates and cut out the

two openings.

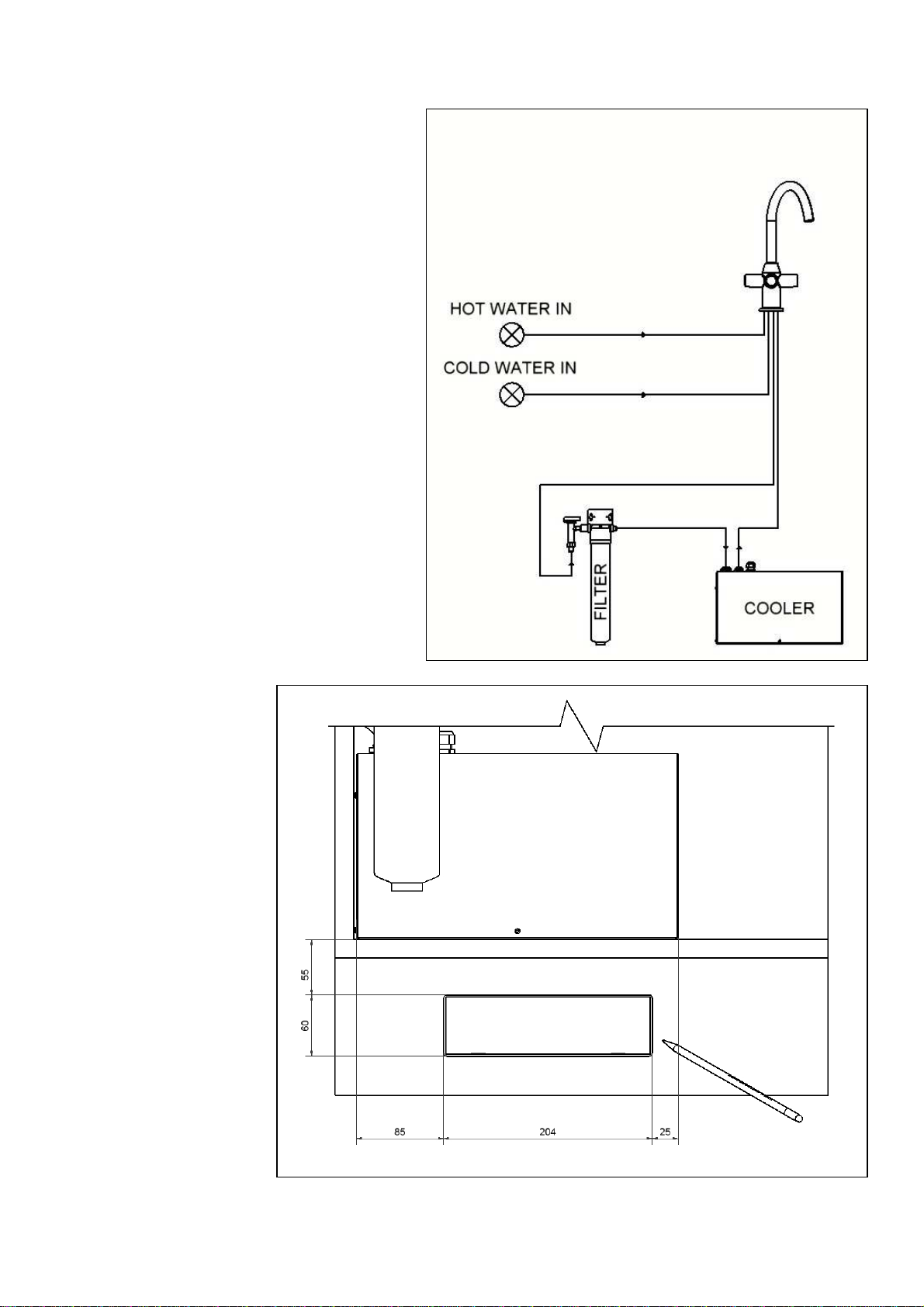

7. Referring to the

drawing opposite,

mark out the

position of the

opening in the

kick-board, and

cut out the air inlet

hole in the kick

board. Note:

Dimensions are

measured from

the left side and

bottom of the

cooler. The left

side of the cooler

should have been

marked onto the

base in item 5

above.

8. Insert the right-

angled spigot into

the hole in the

base of the cabinet.

9. Fit the length of rectangular duct through the cut-out in the kick board and into the spigot.

Ensure it is fully engaged into the socket and mark the ducting where it protrudes from the kick

board. Remove the duct and cut to length.

10. Refit the rectangular duct, and attach the outlet grill to the kick-board using 4 screws, this will

retain the duct in position.

11. Now place the cooler in position over the air inlet opening, ensuring the outlet grille on the back

of the machine aligns with the back of the cabinet, and that the cooler is in the correct position

as marked in point 4. Note: It is advisable to place a sheet of cardboard or towel beneath the

cooler to help slide it into position, and protect the base of the cupboard. This must be

removed once the cooler is in position.

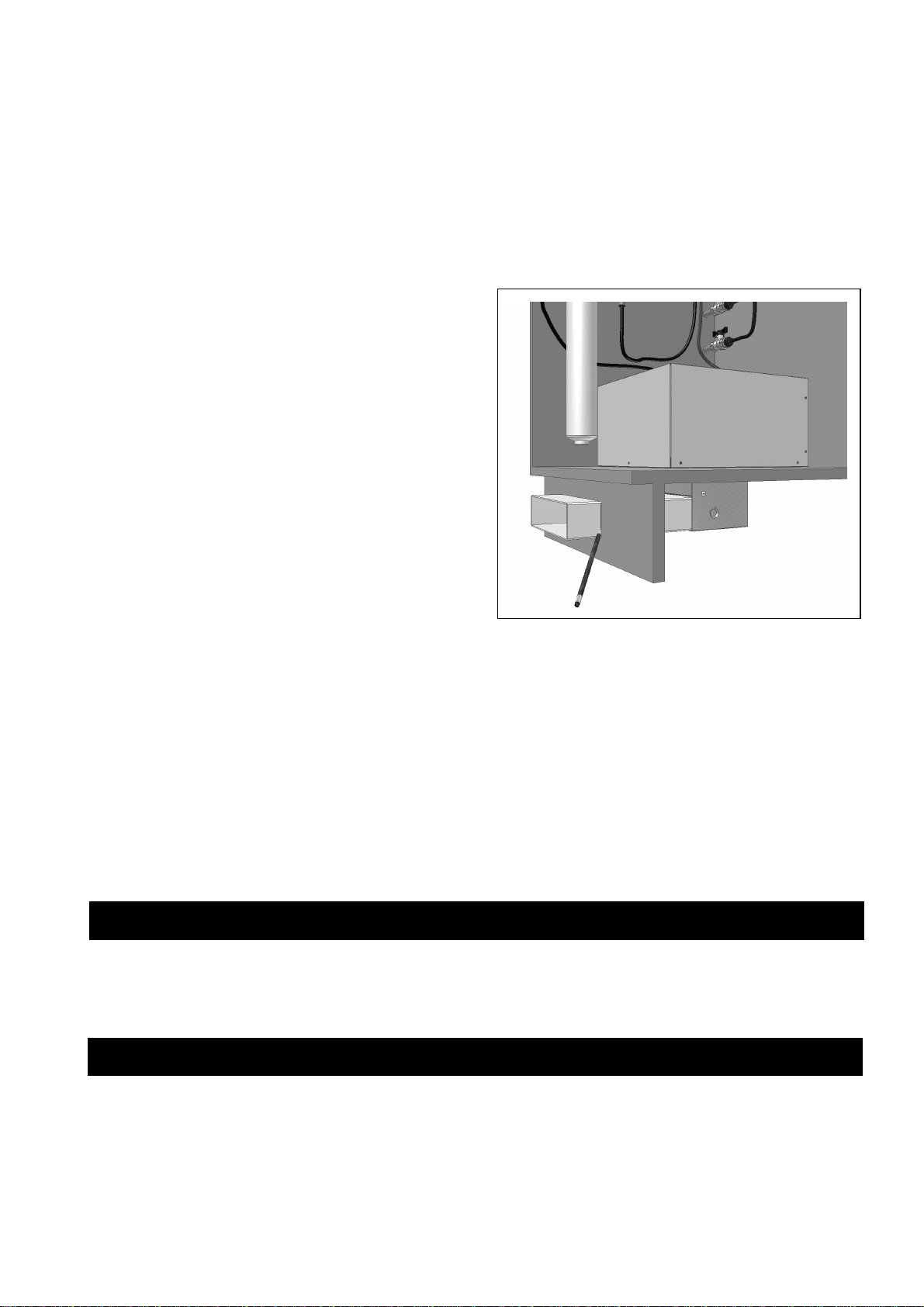

12. Secure the cooler in position using one of the

fixing brackets supplied. Loosen the cooler

screw at the front centre, near the base, insert the

bracket and replace screw. Then secure the

bracket by driving the self tapping screw to the

cabinet base.

Important Note: The ventilation openings must

align with the cut-outs in the cabinet to ensure

reliable operation of the cooler, and the cooler

should be fixed in position to prevent the cooler

being moved inadvertently.

13. Fit the tap and filter by following the

instructions contained in the kit, but do not make

the final water connections between the filter

outlet and tap.

14. Connect the outlet of the filter to the cooler inlet (left connection) by simply pushing the blue

water tube fully home into the fitting. Fit insulation to the tube between the tap and cooler, and

connect the tube to the cooler outlet. Note: If cutting the tube to length, it is important that

the cut is perpendicular to the tube, otherwise difficulties may be experienced with the

push-fit fittings sealing.

15. Turn on the water supply and ensure all connections are sound. Open the filtered water tap and

flush approximately 10 litres through the system.

16. Connect the power lead from the chiller to an electrical socket, and turn the power on. The

compressor and fan will start indicating the fridge is working correctly. After a few minutes, the

fan and compressor will turn off indicating the fridge has reached its normal operating

temperature and is ready for use.

It is illegal to simply scrap a refrigeration unit. Before a unit can be scrapped it must first have the

gas removed by a specialist using specialist equipment. Please contact Booth Dispensers ltd who

will be happy to provide a quotation for disposal.

Important: This unit must be transported in an upright position

As with all refrigeration systems, irreparable damage can be caused by laying the unit on its side

or even transporting upside down. Where the unit is transported by a carrier, the carton should

always be marked in a conspicuous manner, the correct upright position in which it must be

handled. If a unit has been transported incorrectly it should be placed in the correct upright

position and left for 24 hours before attempting to run the system. Failure to observe the above

precautions could seriously damage the system.

Disposal of Scrap Unit

Transportation of refrigeration equipment

Table of contents

Other Booth Accessories manuals