Booth BAR3 User manual

Product Manual

BAR3

Shelf Mounted Beer Coolers

Part Number 3B6694 Issue C

Contents

Introduction

The BAR3 is an ice bath cooler designed to provide chilled product in a dispense application. The

system uses a bath water recirculation system and python to generate and maintain optimum drink

temperature at the point of dispense.

The BAR3 cooler is designed for effective performance and improved energy efficiency. It is ideal for a

range of applications, its compact size ideally suited to under counter installations.

Safety

The BAR3 units use different refrigerants dependant on the model selected. BAR300 models use R134a

refrigerant, whereas BAR3H Hydrocarbon units use R290 (Care 40, Propane). Below are some safety

points which the end user must adopt to mitigate the risk of unsafe conditions arising.

Service must only be carried out by a suitably qualified refrigeration engineer.

The unit should be isolated from the electricity supply before removal of the covers.

Do not damage the refrigeration circuit.

Ventilation openings must be clear of obstructions.

There must be a gap of at least 100mmbetween the appliance and a wall or other restriction.

Where electrical components are replaced, the new component must be of the same type.

Operate unit within (ambient) operating temperatures; 10°C to 32°C.

Section

Page

Section

Page

Introduction & Safety

2

Fault finding

9

Specification & Installation

3-4

Spare parts

10

Model Numbering Convention

5

Removal, Transportation

& Disposal

12

Schematics

6-8

Introduction

Specification

BAR300

Dimensions

570mm(W)

450mm(D)

280mm(H)

Compressor

Tecumseh

THB4422Y

Dry Weight

24kg

This product contains R134a Refrigerant gas with

a GWP of 1430 in an hermetically sealed system

Wet Weight

39kg

Supply

230Vac/50Hz

Refrigerant

R134a 145g

Rated Input

400W

Climatic Class

N

Rated Current

5A

Fuse Rating

5A

IP Rating

N/A

BAR3H

Dimensions

570mm(W)

450mm(D)

280mm(H)

Compressor

Cubigel

NLY60RAa

Dry Weight

28kg

This product contains R290 Propane Refrigerant

gas with a GWP of 3 in an hermetically sealed

system

Wet Weight

39kg

Supply

230Vac/50Hz

Refrigerant

R290a 70g

Rated Input

500W

Climatic Class

N

Rated Current

5A

Fuse Rating

5A

IP Rating

N/A

Installation

The unit must be installed by a competent person, on a firm level surface capable of supporting the

weight of the machine when the bath is filled, and all connections made.

Ensure that the ventilation openings are not blocked to allow free movement of air through

the unit. Failure to do this will seriously affect the reliability of the fridge, invalidate

the warranty and shorten the life of the fridge system.

The water bath requires filling prior to switch on. Fill the bath using cold water through the

opening on the top of the machine until water is displaced from the overflow. Discontinue

filling and replace the overflow cap.

Specification and Installation

Connect the dispense python to the ‘Recirculation’ Flow and Return.

Connect the product to the stainless steel product coil.

BAR3H - For details on how to install Tube in Tube/Scope dispense, please contact Brandels at

http://www.brandels.co.uk/. Alternatively, please phone on 01253 501800 to speak to one of our

advisors.

Connect the unit to mains power.

Turn on the mains voltage supply. After a short delay the compressor fans will activate. The unit

will now begin to reduce the bath water temperature.

Continue to monitor the bath level as the python fills with water. Top up if necessary.

Once the water is at the correct temperature an ice bank will begin to form. As the ice begins to

form, a small amount of water will be displaced.

Once a full ice bank is produced, the fans and compressor will switch off and the machine is ready

for use.

Specification and Installation

Unit number BAR3(Z) ( Y ) ( X ) ( W )

Key:

(Z) Refrigerant Type

(Y) Pump Type

(X) Module Type

(W) Deck

(V) Number of coils

- - - Coil type and number of coils repeated as necessary

Reference

Part #

Description

(Z)

REFRIGERANT

0

1S0409

R134a Refrigerant

H

1S0615

R290 (Hydrocarbon)

Refrigerant

(Y)

PUMP

2

1A5176

SPC8/2 pump

4

1A5177

SPC12/4

6

1A6273

Saber Pump Assy (BAR3H)

1A6292

Saber Pump Assy (BAR30)

(X)

MODULE

M

1A5361

Mechanical Control

E

1A5362

Eliwell Control

D

1A6310

DFX Control

(W)

DECK

0

1A5746

No Coils

1

1A5747

1 Coil

2

1A5748

2 Coils

3

1A5749

3 Coils

4

1A5750

4 Coils

5

1A6201

Tube in Tube / Scope

Model Numbering Convention

BAR3H & BAR300 Eliwell Wiring Schematic

Schematic

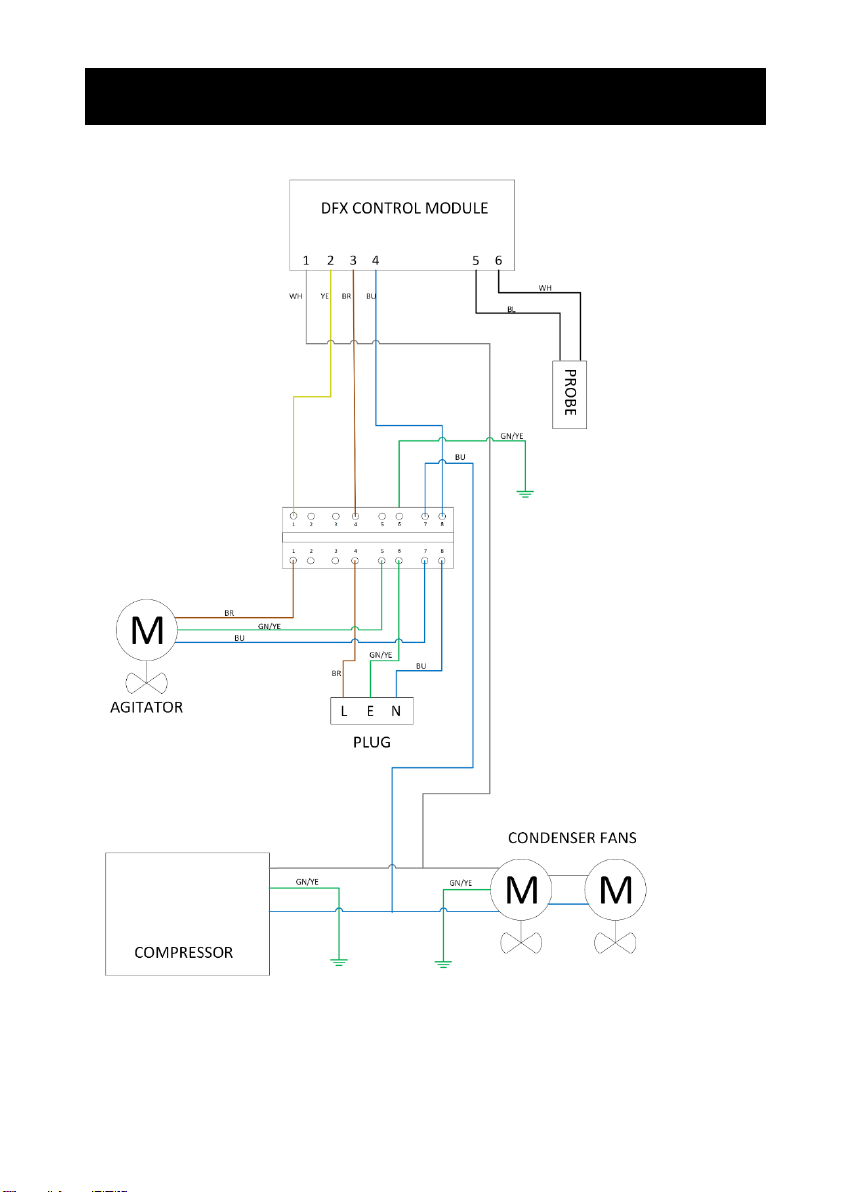

BAR3H & BAR300 DFX Wiring Schematic

Schematic

BAR3H & BAR300 Mechanical Wiring Schematic

Schematic

Prior to any fault finding, please ensure all connections to the chiller are sound and that the incoming supply

is turned on. Also ensure that all electrical connections to the chiller and in the chiller are secure and in

good condition, the power is on and that the chiller has had adequate time to reach operating temperature

NOTE: Isolate from mains before removing any panels

No

Drinks

Water supply

Check connections to water supply.

Check water supply is turned on.

Check system for blockages.

Frozen product

coil

Check thermostat/temperature probe is

correctly located into the bath probe well.

Check the agitator is running. If supply

voltage is present renew agitator

assembly.

If agitator is running with no water

agitation check agitation blades.

Warm

Drinks

Insufficient air flow

through the fridge.

Check that the condenser is not blocked.

Check for blockages and obstructions to

ventilation grills.

Cooling Fans Not

running

Check supply to cooling fans.

If supply present replace fans.

If supply not present check connections,

thermostat, high side protection (digital

thermostat only) and fuse.

Compressor not

running

Check supply to Compressor.

If supply present return for repair.

If supply not present check connections,

thermostat, high side protection (digital

thermostat only) and fuse.

Fridge failure

If compressor & fan are running and there

is no cooling, return for repair.

Fault Finding

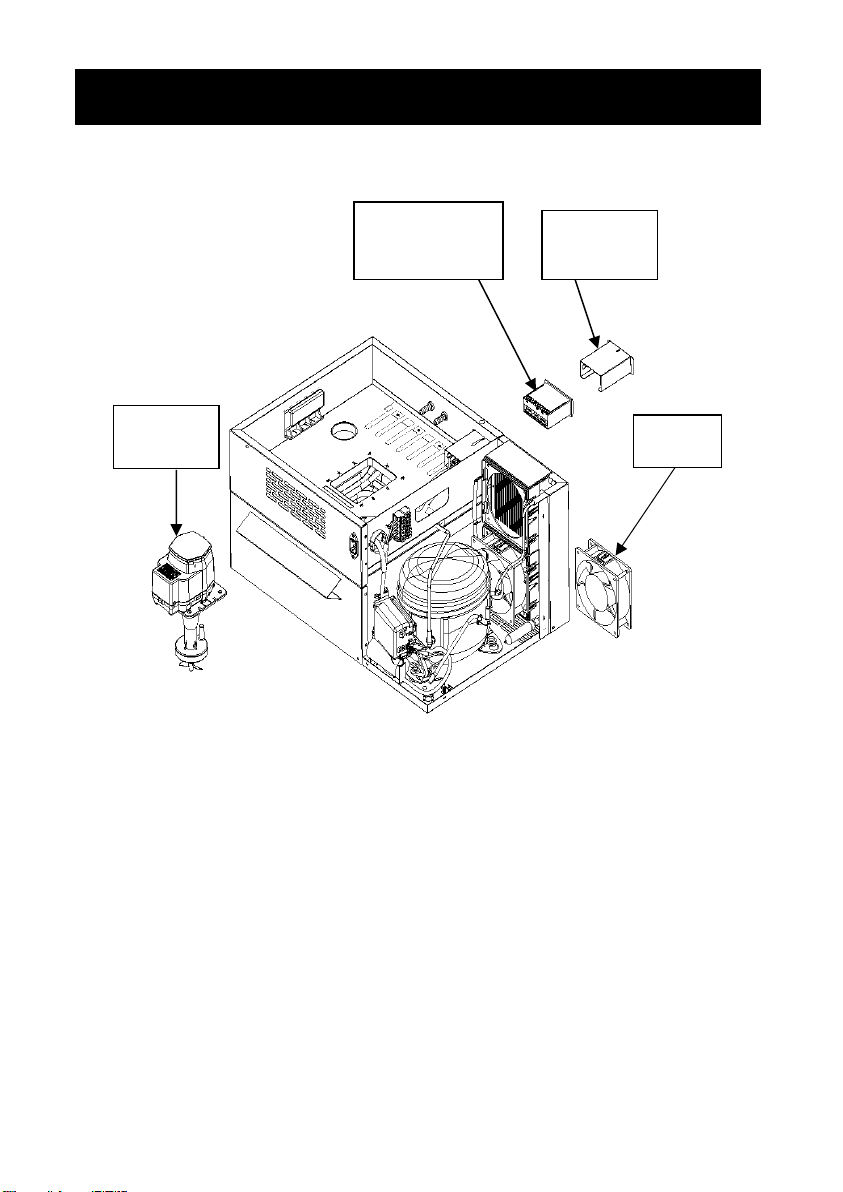

BAR300 Spares

1B5514

Cooling Fan

1A5362

Eliwell Control Module

1A6310

DFX Control Module

Pump

Refer to table

on Page 5

1A5361

Mechanical

Control Module

Spare Parts

BAR3H Spares

Spare Parts

3B6090

Coaxial Elbow

1B5514

Cooling Fan

1A5362

Eliwell Control Module

1A6310

DFX Control Module

1A5361

Mechanical

Control Module

INSU77

Polar Clean

Elbow

Pump

Refer to table

on Page 5

Important: Before removal from the installation, ensure all electrical, product and gas connections are

disconnected.

Disposal of Scrap Units

It is illegal to simply scrap a refrigeration unit. Before a unit can be scrapped it must first have the gas removed

by a specialist using specialist equipment. Please contact Booth Dispensers Ltd., who will be happy to provide a

quotation for disposal.

Transportation

Important: This unit must be transported in an upright position

As with all refrigeration systems, irreparable damage can be caused by laying the unit on its side or even

transporting upside down. Where the unit is transported by a carrier, the carton should always be marked in a

conspicuous manner, the correct upright position in which it must be handled.

If a unit has been transported incorrectly it should be placed in the correct upright position and left for 24 hours

before attempting to run the system.

Failure to observe the above precautions could seriously damage the system, and would void any warranty.

Removal, Transportation and Disposal

Booth Dispensers Ltd, Moor Park Avenue, Blackpool,

Lancashire, FY2 0LZ, UK

+44 1253 501800

Table of contents

Other Booth Accessories manuals