Page

6.2 Connection Points of KCU.................................................................................................................... 72

6.2.1 Positions of the Connection Points.................................................................................................... 72

6.2.2 X1, Module Bus................................................................................................................................. 73

6.2.3 X20 TX, X21 RX (SERCOS interface)............................................................................................... 74

General Information........................................................................................................................ 74

S6, SERCOS Transmission Power................................................................................................ 75

6.2.4 X50, E-Stop Input.............................................................................................................................. 75

6.2.5 X51, Master Communication SERCOS............................................................................................. 76

6.2.6 X52, Status Messages....................................................................................................................... 76

6.2.7 X53, Control Voltage Output.............................................................................................................. 77

6.2.8 X54, DC Bus, Equipment Grounding Conductor Output KSM........................................................... 77

6.2.9 DC Bus Connection L+, L-................................................................................................................. 78

6.2.10 Control Voltage Supply +24V, 0V...................................................................................................... 80

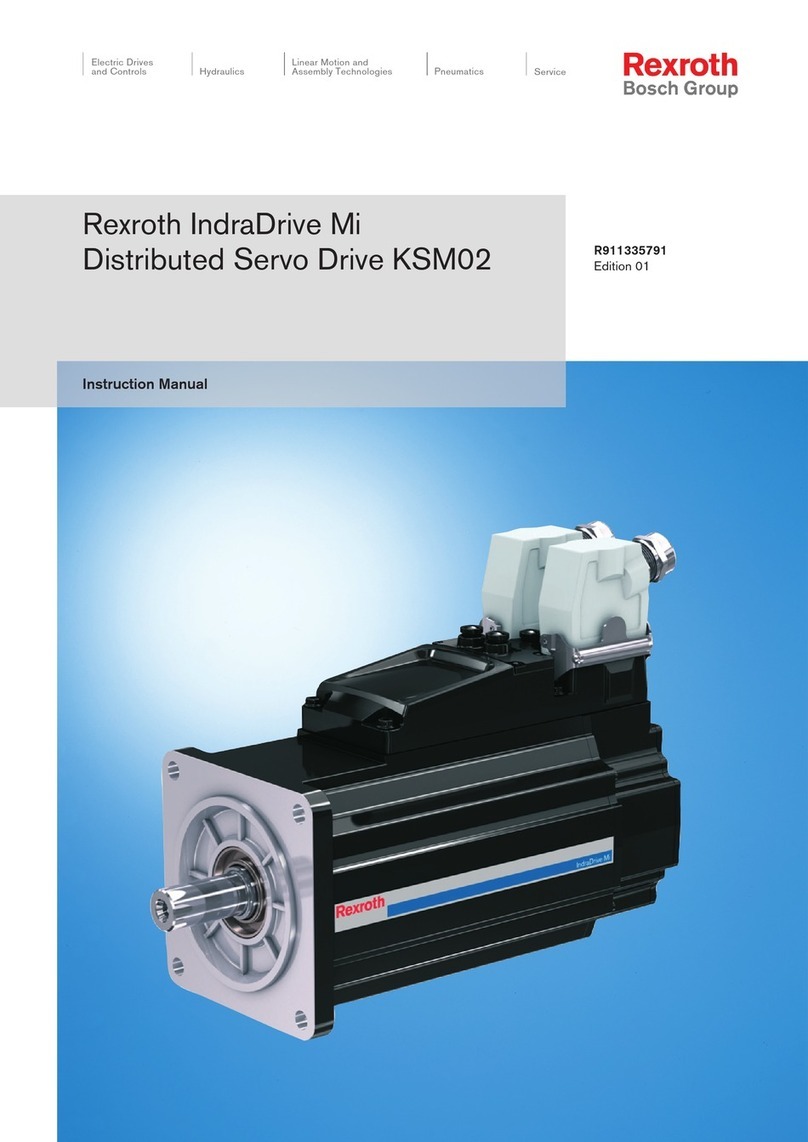

6.3 Connection Points of KSM.................................................................................................................... 81

6.3.1 Positions of the Connection Points.................................................................................................... 81

6.3.2 X2 Serial Interface, Service Input "Release Brake"........................................................................... 82

6.3.3 X3.1, X3.2 Connection Point Hybrid Cable........................................................................................ 84

6.3.4 X7 Connection Point MultiMediaCard ............................................................................................... 85

6.3.5 X37, X38 Digital Inputs/Output.......................................................................................................... 86

6.3.6 Second Connection Point of Equipment Grounding Conductor........................................................ 89

7 Notes on Project Planning........................................................................................... 91

7.1 Notes on Mechanical Project Planning................................................................................................. 91

7.1.1 Mounting Clearance.......................................................................................................................... 91

7.1.2 Output Shaft...................................................................................................................................... 91

Plain Shaft...................................................................................................................................... 91

Output Shaft With Key.................................................................................................................... 91

Output Shaft With Shaft Sealing Ring............................................................................................ 92

7.1.3 Bearings and Shaft Load................................................................................................................... 92

General Information........................................................................................................................ 92

Radial Load, Axial Load.................................................................................................................. 93

Bearing Service Life....................................................................................................................... 94

7.1.4 Holding Brakes.................................................................................................................................. 95

Brake Control and Supply............................................................................................................... 95

Safety Requirements...................................................................................................................... 95

Dimensioning Holding Brakes........................................................................................................ 97

7.1.5 Mechanical Attachment of Driving Elements..................................................................................... 97

General Information........................................................................................................................ 97

Redundant Bearings....................................................................................................................... 97

Gear Attachment............................................................................................................................ 98

Coupling Attachment...................................................................................................................... 98

Bevel Gear Pinions or Skew Bevel Driving Pinions........................................................................ 99

7.2 Notes on Electrical Project Planning..................................................................................................... 99

7.2.1 Power Supply.................................................................................................................................... 99

Supply Units................................................................................................................................... 99

7.2.2 Electronic Control System KCU....................................................................................................... 100

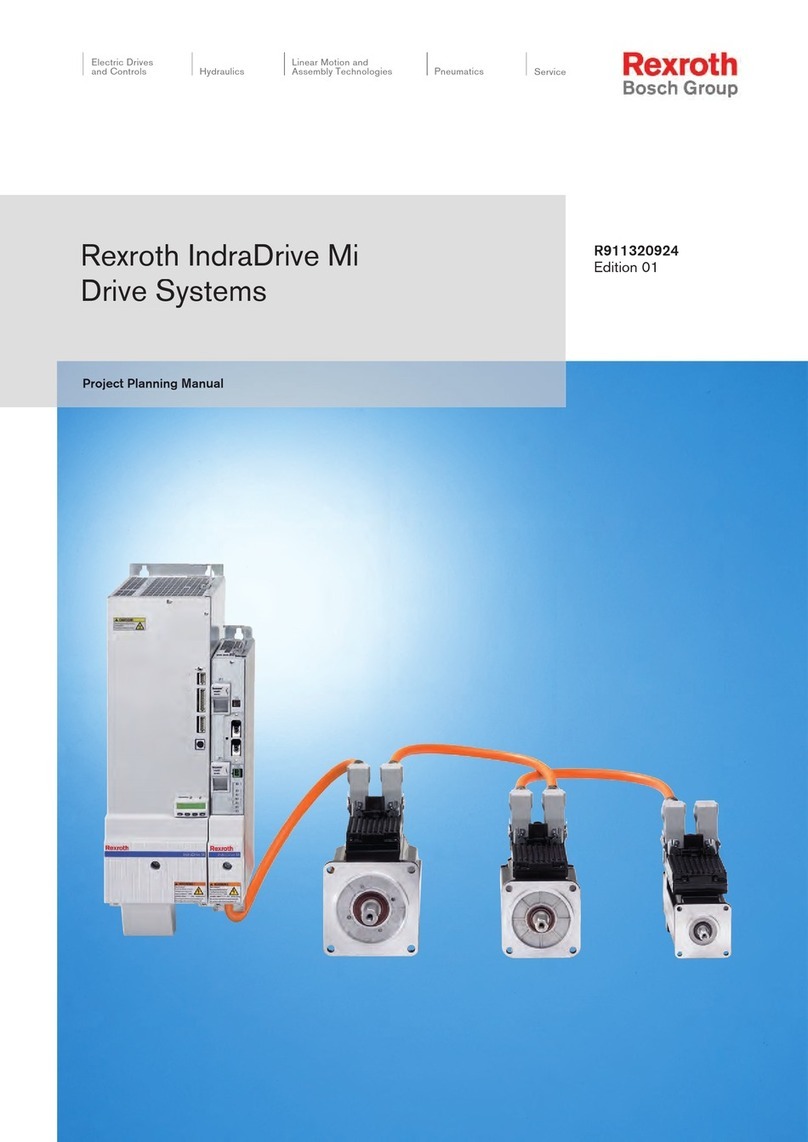

Project Planning Manual |Rexroth IndraDrive Mi Electric Drives

and Controls

|Bosch Rexroth AG III/VI

Table of Contents