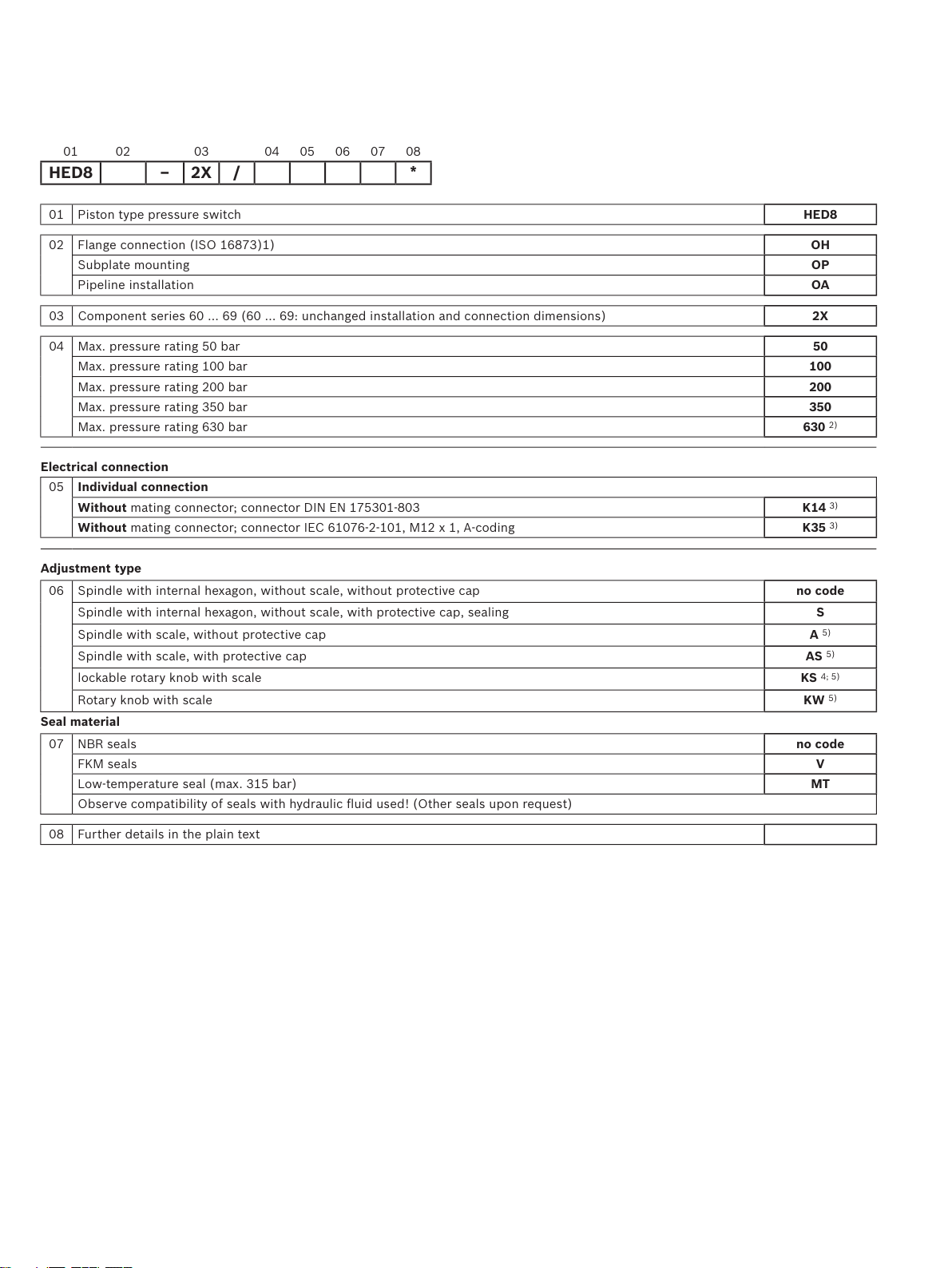

4/16 HED 8 | Pressure Switch

Bosch Rexroth AG, RE 50061, edition: 2016-09

Technical data

(For applications outside these parameters, please consult us!)

Hydraulic

Pressure rating bar 50 100 200 350 630

Max. operating pressure

Conformity ▶ NBR/FKM seals bar 350 350 350 400 630

▶ MT version bar 315 315 315 315 –

Pressure adjustment range (decreasing) bar 5...50 10...100 15...200 25...350 40...630

Pressure differential per rotation 1) bar ≈19 ≈35 ≈77 ≈120 ≈214

Hydraulic fluid 1) see table below

Hydraulic fluid temperature range

(at the valve operating ports)

°C -25 ... +80 (NBR seals)

-20 ... +80 (FKM seals)

-40 … +80 (low-temperature seals)

Viscosity range mm2/s 10 … 800

Maximum permissible degree of contamination of the hy-

draulic fluid, cleanliness class according to ISO 4406 (c)

Class 20/18/15 2)

Load cycles ≥ 5 million

General

Mass kg 0.8

Installation position any

Ambient temperature range °C -25 to +50 (NBR seals)

-20 to +50 (FKM seals)

-40 to +50 (low-temperature seals)

Sine test according to DIN EN 60068-2-6:1996-05 5...2000 Hz, max. 10 g, 10 double cycles

Transport shock according to DIN EN 60068-2-27:1995-03 15 g / 11 ms

Bump test according to DIN EN 60068-2-29:1995-03 25 g / 6 ms

Noise test according to DIN EN 60068-2-64:1996-05 20...2000 Hz 10...30 min

Conformity ▶ CE DIN EN 61058-1: 2002 / A2: 2008

DIN EN 60947-1: 2007 / A1: 2011

DIN EN 60947-5-1: 2004 / A1: 2009

DIN EN 60529: 1991 / A2: 2013

▶ UL UL 508 17th edition File No E223220 (up to 350 bar)

▶ CCC GB 14048.5-2008

Hydraulic fluid Classification Suitable

sealing materials

Standards Data sheet

Mineral base oils HL, HLP, HLPD, HVLP, HVLPD NBR, FKM low-temperature

seals

DIN 51524 90220

Bio-degradable ▶ Insoluble in water HETG NBR, FKM ISO15380 90221

HEES FKM

▶ Soluble in water HEPG FKM ISO15380

Flame-resistant ▶ Water-free HFDU, HFDR FKM ISO 12922 90222

▶ Containing water HFC (Fuchs Hydrotherm 46M,

Petrofer Ultra Safe 620)

NBR ISO 12922 90223

Important information on hydraulic fluids:

▶ For more information and data about the use of other hydraulic

fluids, refer to data sheets above or contact us!

▶ There may be limitations regarding the technical data (tempera-

ture, pressure range, life cycle, maintenance intervals, etc.).

▶ Flame-resistant – contains water:

– Maximum pressure differential per control edge 50bar

– Pressure pre-loading at the tank port > 20% of the pressure

differential, otherwise increased cavitation

– Life cycle as compared to operation with mineral oil HL,

HLP 50 to 100%

▶ Bio-degradable and flame-resistant: When using these hydraulic

fluids that are simultaneously zinc-solving, zinc may accumulate

(700mg zinc per pole tube).