The safety alert symbol (a triangle with an exclamation

point), which precedes the signal words danger, warning

and caution is used to alert the reader to personal injury

hazards.

_________________________________________________________________

In case of non-compliance with this safety instruction,

death or serious injury will occur.

_________________________________________________________________________________________________

_________________________________________________________________

In case of non-compliance with this safety instruction,

death or serious injury can occur.

_________________________________________________________________________________________________

_________________________________________________________________

In case of non-compliance with this safety instruction,

minor or moderate injury could occur.

_________________________________________________________________________________________________

_________________________________________________________________

In case of non-compliance with this safety instruction,

property damage could occur.

_________________________________________________________________________________________________

4 Intended Use

The cable strain relief bracket is for indoor use only, and

may only be used with parts indicated in this document.

Not explicitly mentioned parts may not be installed or

connected. Usage is only allowed in explicitly indicated

combinations of parts.

Do not install and use this cable strain relief bracket

before you have read all relevant documents. You must

read the safety instructions and all other directions for

use before you start any work or activity with this cable

strain relief bracket.

5 Accessories, Spare Parts and Wear Parts

The cable strain relief bracket does not contain any re-

placeable or wear parts. In case of failure, the entire cable

strain relief bracket must be replaced.

6 Ambient Conditions

7 Standards

7.1 CE marking

Declaration of Conformity

The cable strain relief bracket installed on the NY4150/10

module complies with the requirements and the target of

the following EU directive.

EMC Directive

•2014/30/EU

The cable strain relief bracket detached from the module

has no reference to a directive.

7.2 China RoHS 2 marking

The NYA04.1-STRAIN-RELIEF-4150-NY4901/40 complies

with the requirements of the Administrative Measures for

the Restriction of the Use of Hazardous Substances in

Electrical and Electronic Products, known as China RoHS

2.

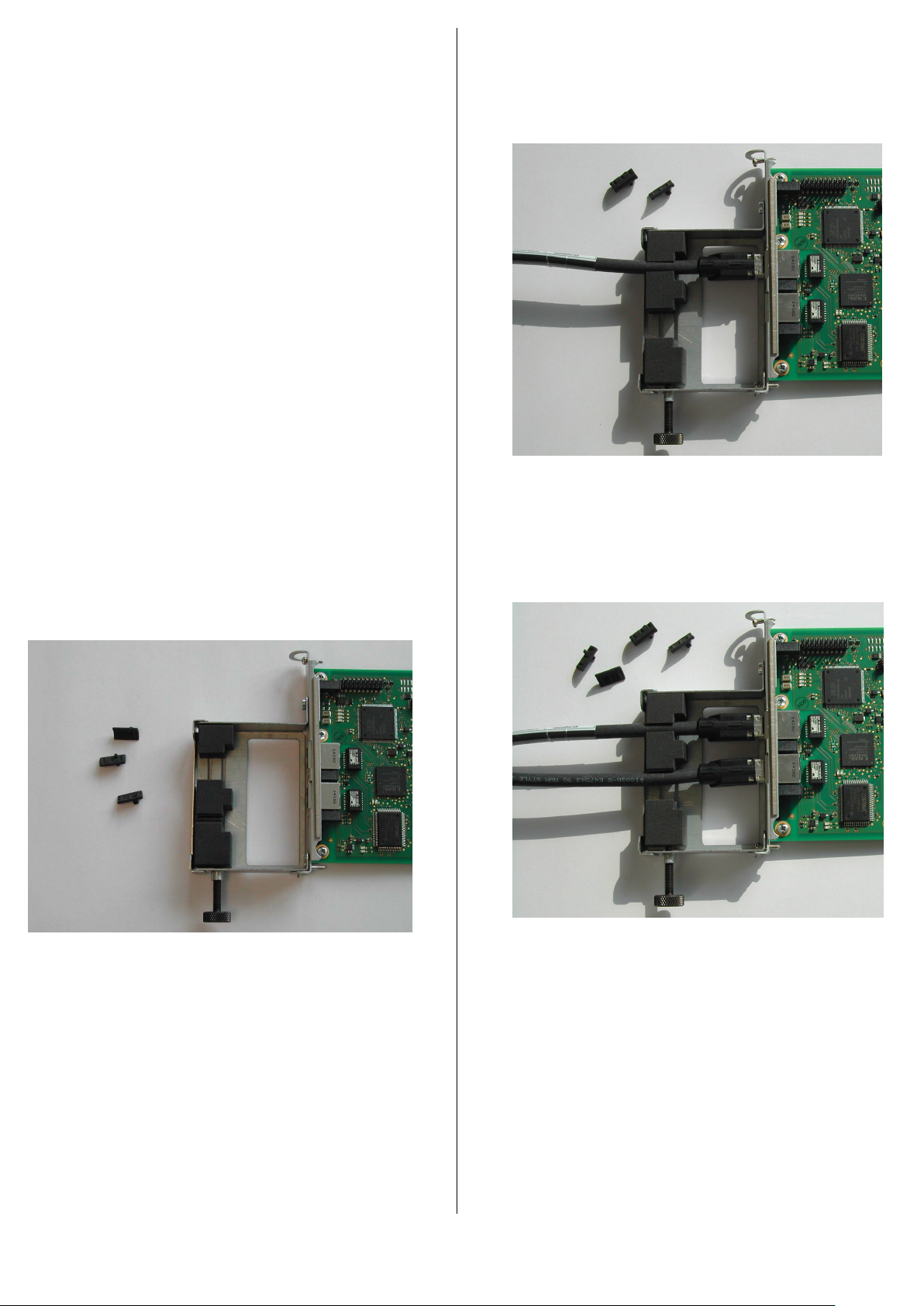

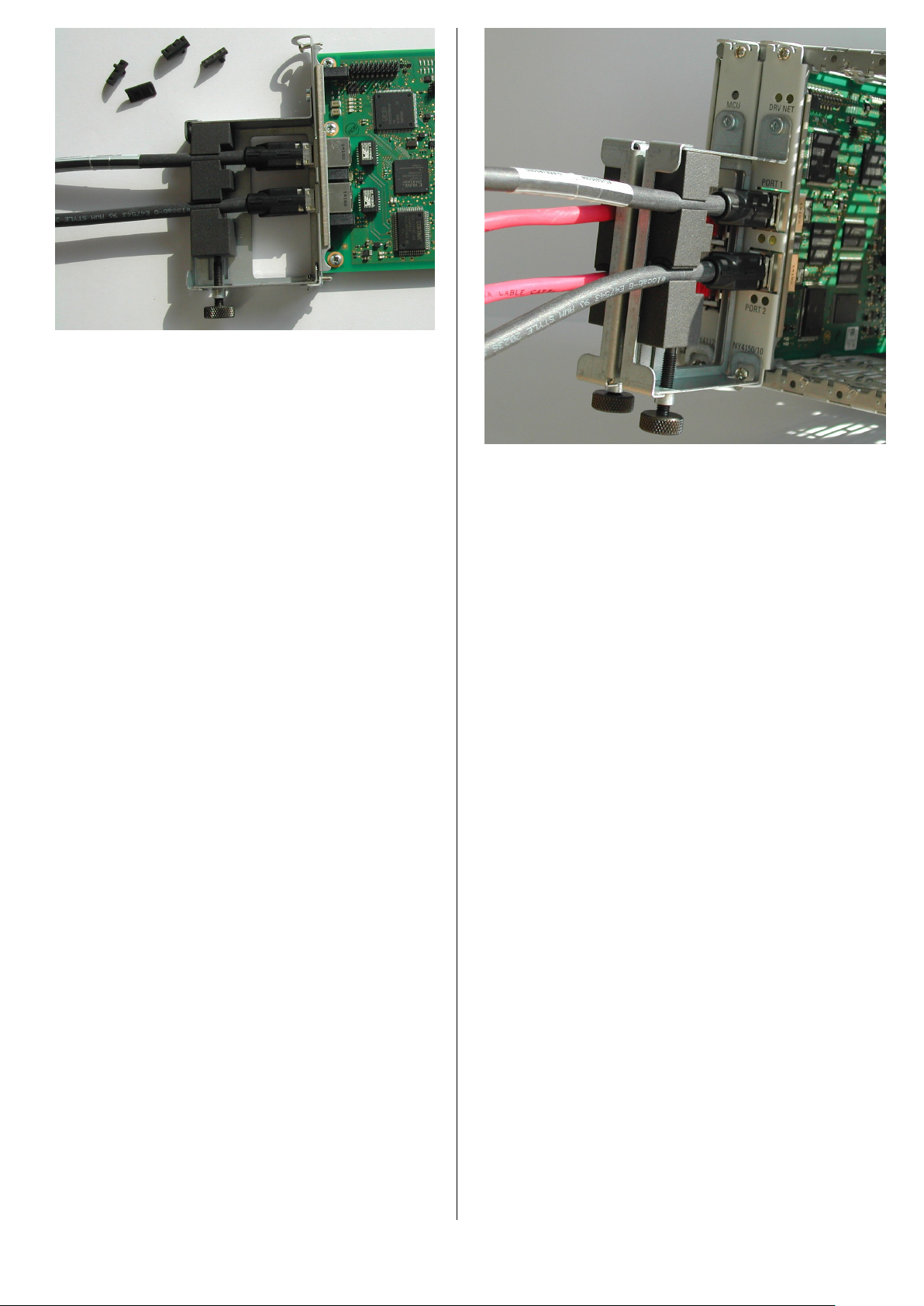

8 Installation and Removal

_________________________________________________________________

Damage to the NY4150/10 may occur

due to electrostatic discharges.

Comply with all ESD protective measures while working

with modules and components. Avoid electrostatic dis-

charges.

_________________________________________________________________

Power supplies must be switched off with the disconnect-

ing device installed in the cabinet.

8.1 Mechanical dimensions

The dimensions of the cable strain relief bracket are the

following.

You can see the dimensions of the cable strain relief

bracket in the following views.

Operating Storage and transport

Maximum environment

temperature

+5 ... +55 °C -40 °C … +85 °C

Relative Humidity

10 % … 90 %

(non-condensing)

5 % … 95 %

(non-condensing)

Mechanical Strength

IEC 60068-2-6:2007

Vibration, broadband:

Shock:

IEC 60068-2-27:2008

Maximum altitude 4000 m

NYA04.1-STRAIN-RELIEF-4150-NY4901/40