Page

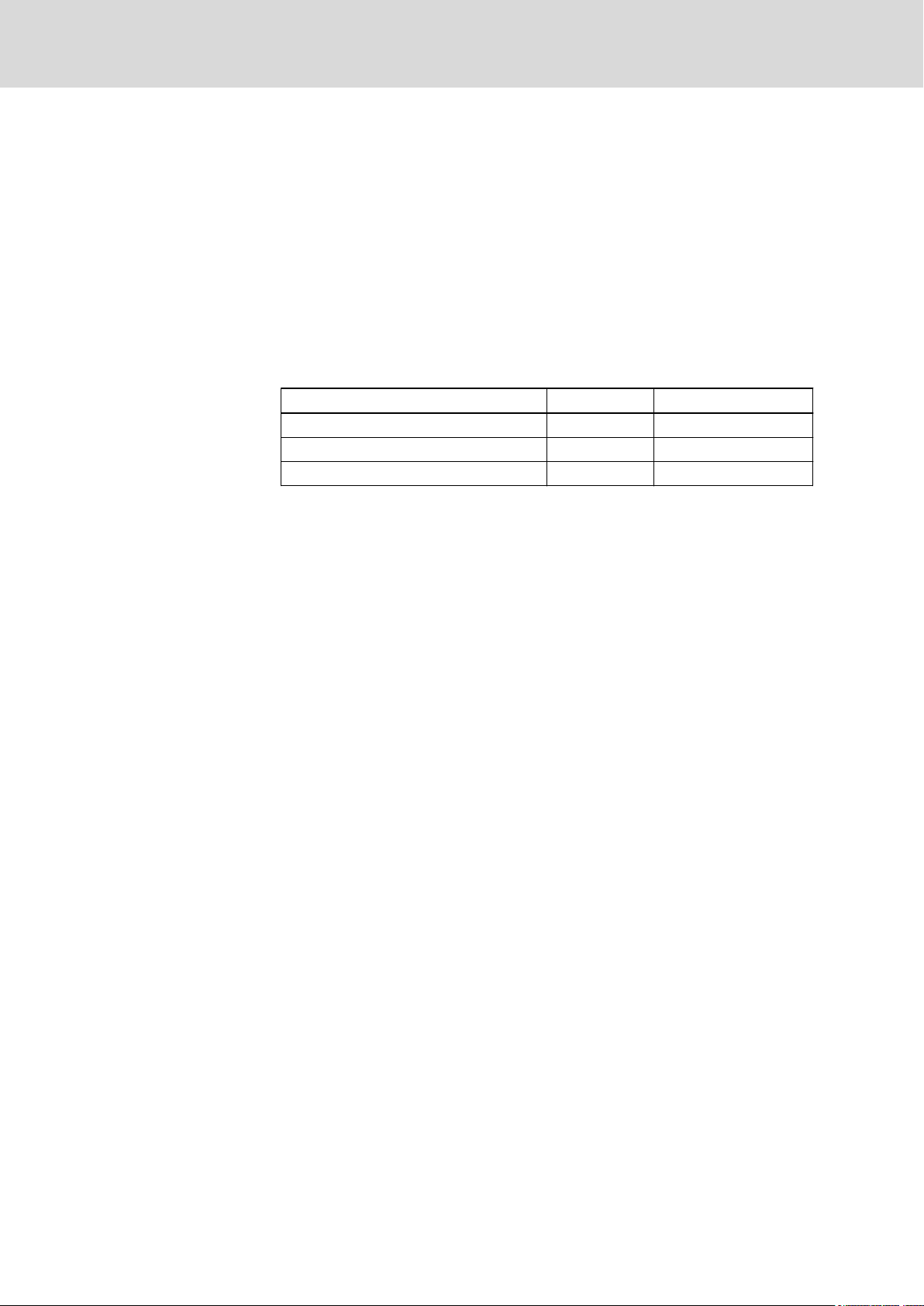

4.6 Compatibility Test................................................................................................................................. 24

5 Dimensions, Mounting and Dismounting..................................................................... 25

5.1 Task...................................................................................................................................................... 25

5.2 Housing Dimensions............................................................................................................................. 25

5.3 Mounting and Dismounting................................................................................................................... 25

5.3.1 Mounting Notes................................................................................................................................. 25

5.3.2 Mounting............................................................................................................................................ 26

5.3.3 Dismounting....................................................................................................................................... 27

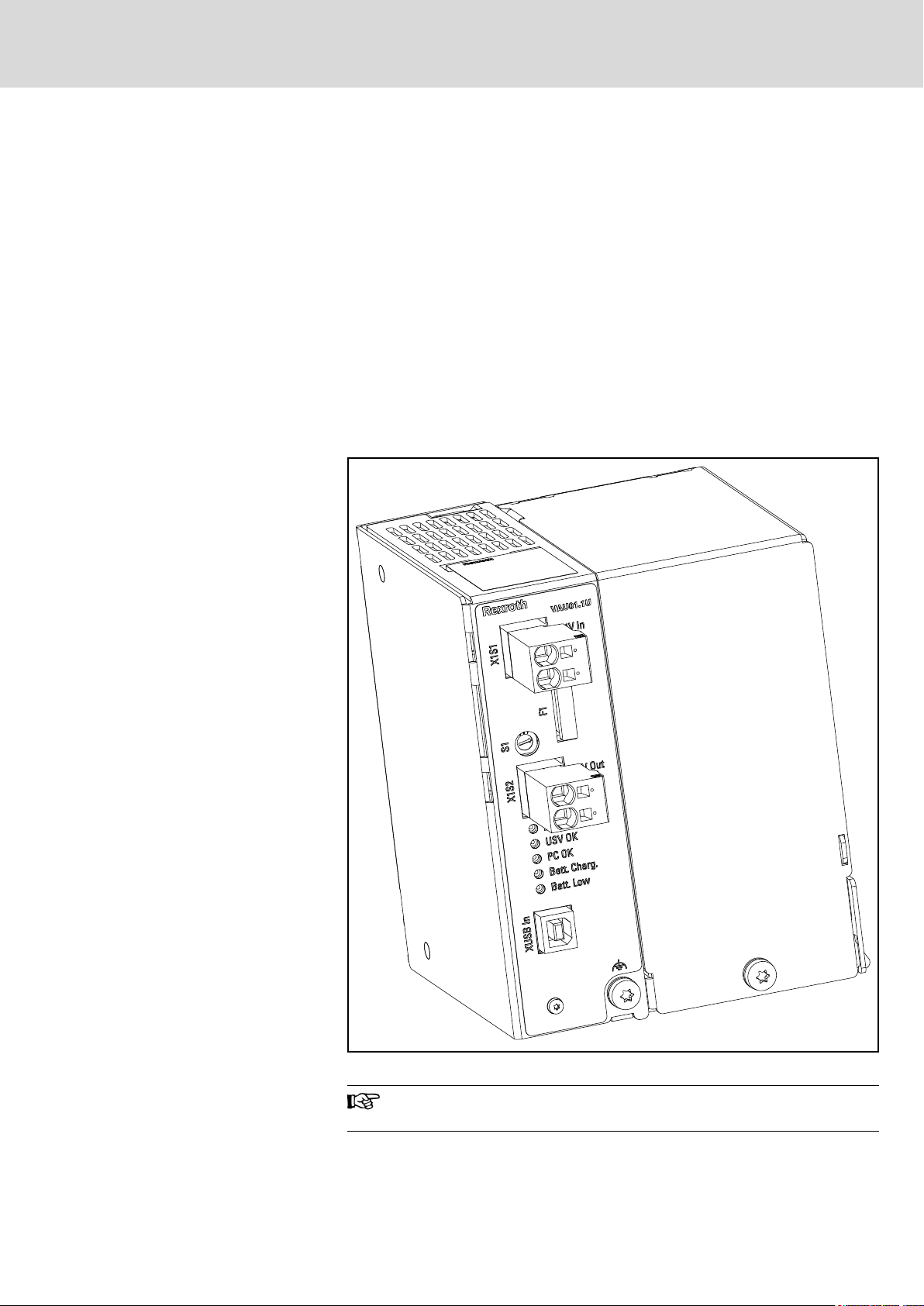

6 Operating and Display Components............................................................................ 29

6.1 Task...................................................................................................................................................... 29

6.2 Connector Panel................................................................................................................................... 29

6.2.1 General Information........................................................................................................................... 29

6.2.2 Overview of the LEDs for Operating and Error Display..................................................................... 30

6.3 Fuse F1................................................................................................................................................. 31

6.4 Rotary Switch S1.................................................................................................................................. 32

6.4.1 Position of S1 Rotary Switch............................................................................................................. 32

6.4.2 General Information........................................................................................................................... 32

6.4.3 Timing Depending on the Position of S1 Rotary Switch.................................................................... 32

6.4.4 Timing Depending on the Position of Rotary Switch S1 and Settings in the UPS-NT Control Software

........................................................................................................................................................... 33

7 Interfaces and Wiring .................................................................................................. 39

7.1 Task...................................................................................................................................................... 39

7.2 Connector Panel................................................................................................................................... 39

7.2.1 General Information........................................................................................................................... 39

7.2.2 Overview of the Connections............................................................................................................. 40

7.3 Voltage Connection.............................................................................................................................. 41

7.3.1 General Information........................................................................................................................... 41

7.3.2 Wiring the Power Connection............................................................................................................ 41

7.3.3 Wiring of the VAU 01.1U, Cable Lengths and Cable Cross-Sections............................................... 44

7.4 Interface XUSB In................................................................................................................................. 44

7.4.1 General Information........................................................................................................................... 44

8 Maintenance, Storage and Transport.......................................................................... 47

8.1 Task...................................................................................................................................................... 47

8.2 General Information.............................................................................................................................. 47

8.3 Replacing Batteries............................................................................................................................... 48

8.4 Storing the VAU 01.1U......................................................................................................................... 51

8.5 Transporting the VAU 01.1U................................................................................................................. 51

9 Ordering Information.................................................................................................... 53

9.1 Type Designation Code........................................................................................................................ 53

Bosch Rexroth AG DOK-SUPPL*-VAU*01.1U**-PR03-EN-P

Rexroth IndraControl VAU 01.1U UPS with USB interface

II/63

Table of Contents