Installation

This manual is used for installation on the VBX and

Forge spreaders. Illustrations may vary .

Determine the left and right sides of the machine from

the normal operating position.

Note: Use pipe tape on all threaded connections.

Installing the Frame Rails

and T ank

1. Park your vehicle on a level surface, engage the

parking brake, shut of f the engine, and remove

the keys.

2. Disconnect the spreader power/ground cable

from the wire harness.

3. Use a 500 kg (1/2 ton) minimum lifting device to

raise the spreader and place it on jack stands;

refer to your spreader Owner ’ s Manual for the

location of the lift points.

4. Remove the spinner assembly; refer to your

spreader Owner ’ s Manual .

5. Remove the rear cover according to your

spreader:

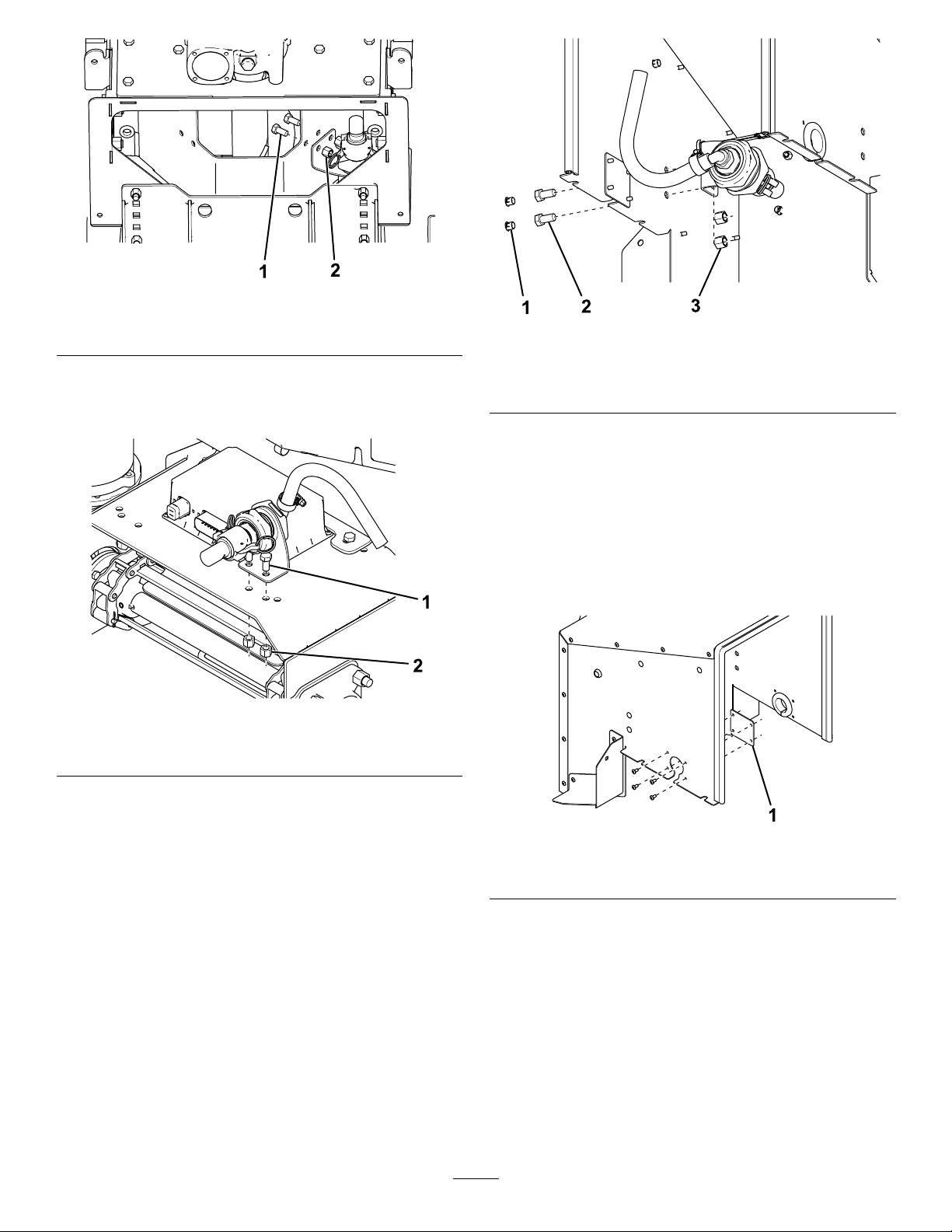

•For VBX spreaders, remove the plastic clips

securing the rear cover to the hopper ( Figure

1).

g029502

Figure 1

1. Plastic clip 2. Rear cover

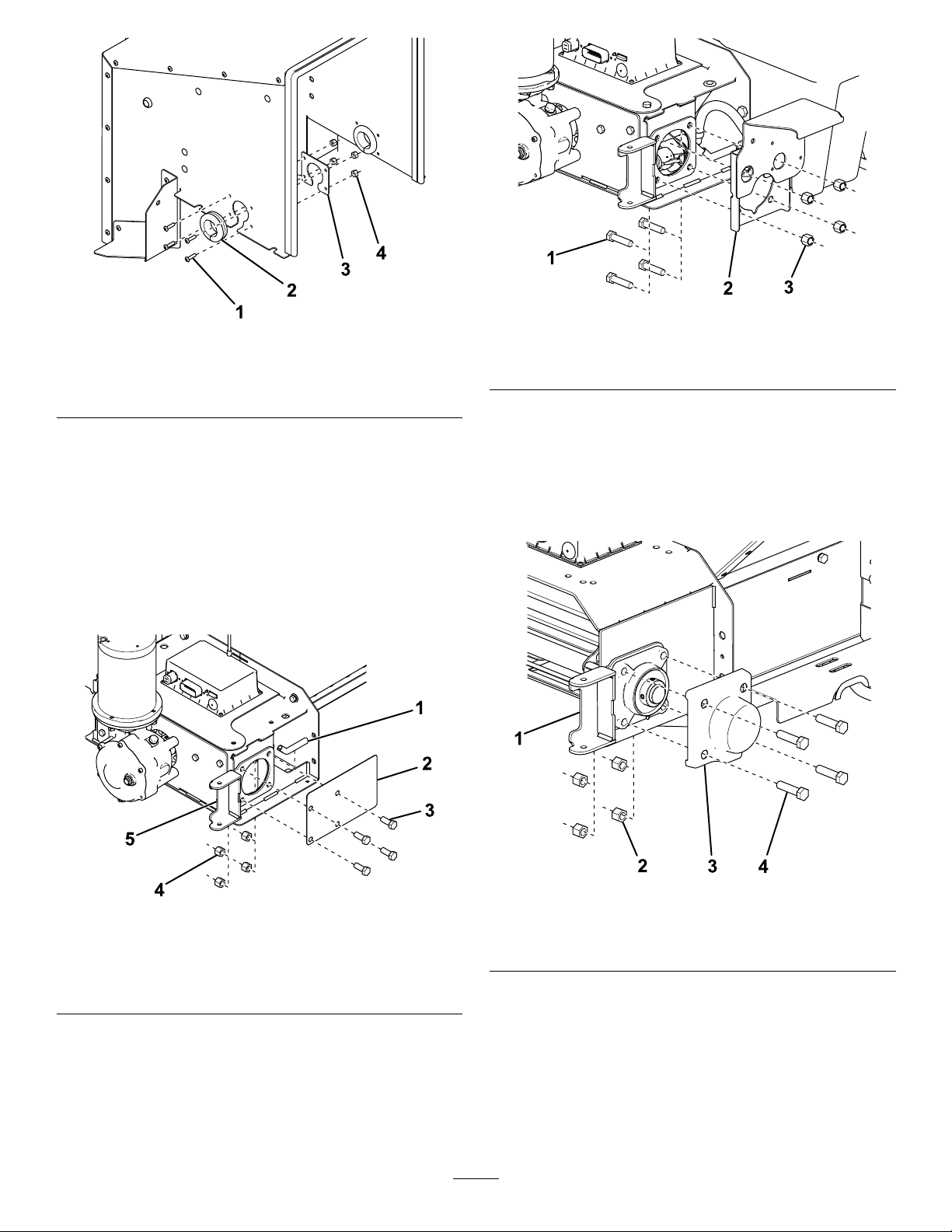

•For Forge spreaders, remove the bolts

securing the rear cover to the hopper ( Figure

2).

g223387

Figure 2

1. Bolt 2. Rear cover

6. Carefully pull away the rear cover and unplug

the cover harness from the control module.

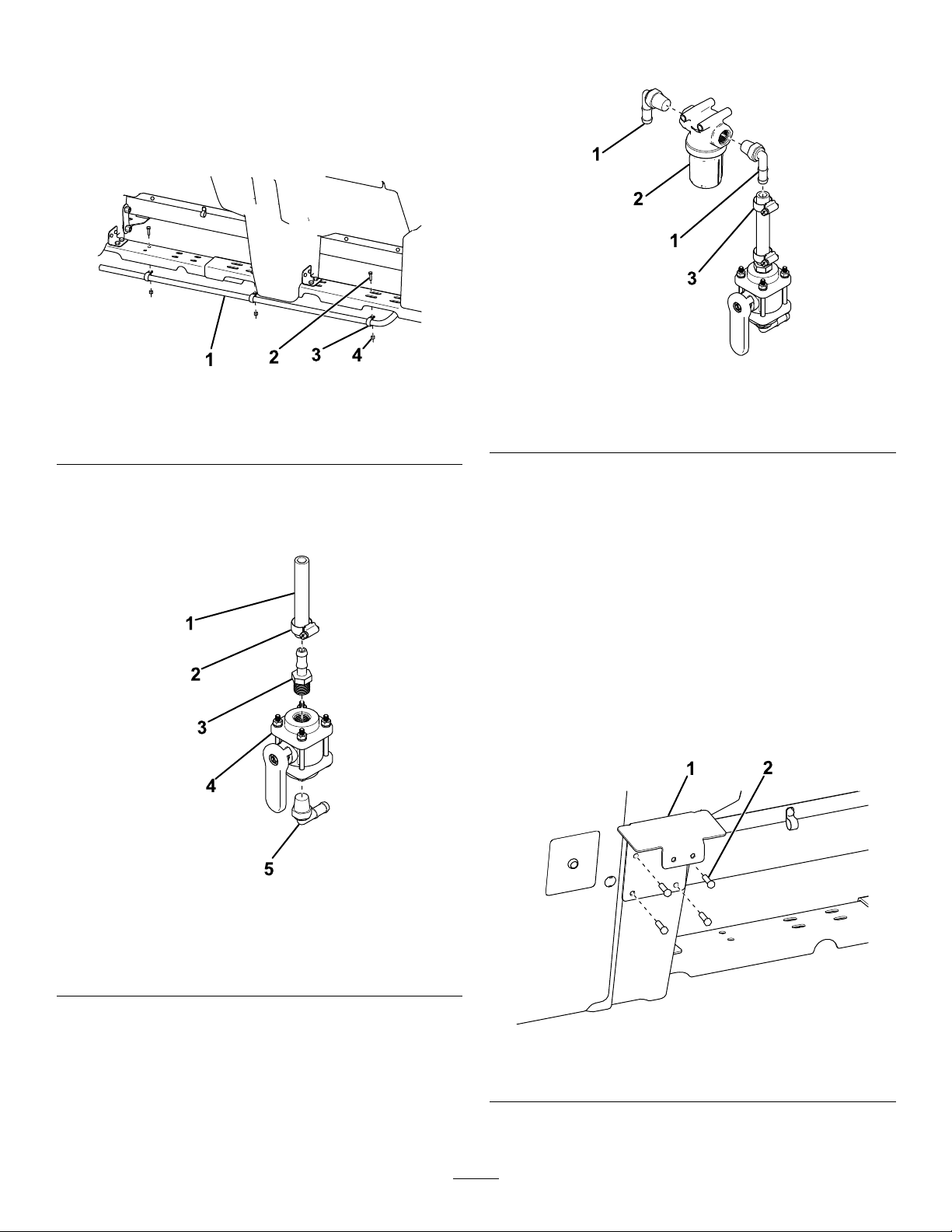

7. Slide both the long and short frame rails under

the legs of the spreader ( Figure 3 ). If you are

installing the kit onto a VBX 6500 or Forge 1.0

spreader , you do not need the short frame rails.

If installing the kit onto a VBX spreader , use the

wide L-brackets for the hopper legs closest to

the pre-wet tank.

g436603

Figure 3

1. Short frame rail 4. Bolt (3/8 inch)

2. T ap plate

5. Long frame rail

3. L-bracket

6. L-bracket (wide)

2