BOSSCO X-SERIES User manual

X-SERIES

The ultimate push around scissor lifts

USER GUIDE

EN 280 IP24

BoSS_XSeries_Userguide_Rev C 0519_English.indd 1 08/05/2019 12:19

1BoSS X-Series User guide

1.1 Introduction

1.2 Characteristics and description

1.3 Intended use

1.4 Selection and minimum attributes of operators

1.5 Modications

1.6 Terminology

Contents

Section 1 - Description

2

3

5

5

7

8

Page

Section 2 – Specification

9

10

10

10

10

11

11

11

2.1 Technical data

2.2 Operating site

2.2.1 Ground conditions

2.2.2 Ground atness

2.2.3 Overhead obstructions

2.2.4 Segregation from other site vehicle movements

2.3 Noise and vibration

2.4 Limitations

Section 3 – Safety rules

Section 4 – Operating instructions

4.1 Daily checks

4.2 Manoeuvring the platform

4.3 Engaging the brakes

4.4 Battery isolation switch

4.5 Entering and leaving the work platform

4.6 Handset controller

4.7 Emergency stop

4.8 Emergency lowering

4.9 Battery charging

Section 5 – Transport, handling and storage

5.1 Storage

5.2 Loading and unloading

5.3 Lifting

5.4 Preparation for transport

6.1 Machine labelling

6.2 Maintenance record

6.3 Repairs record

6.4 Examination / tests record

6.5 Daily checks – operator checklist

Section 6 – Maintenance and repair record

7.1 Conned Space Guardrail

7.2 Bumpers - Front and side impact protection

7.3 Heavy-Duty All-Weather Covers

Section 7 – BoSS X-Series accessories

12

14

15

16

16

17

18

18

19

19

21

21

23

23

25

27

27

27

29

31

32

32

Section 8 – Variations on earlier BoSS X-Series

machines

33

BoSS_XSeries_Userguide_Rev C 0519_English.indd 1 08/05/2019 12:19

2

bosspoweredaccess.com

BoSS X-Series User guide

1.1 Introduction

This user guide provides information on the safe operation of the

BoSS X-Series single person push around scissor lifts namely the

BoSS X2 (now discontinued), BoSS X3 and BoSS X3X. This user

guide does not apply to BoSS X3 machines with serial numbers

between YMG11001 and 11300. Operators should read and

understand all the information contained within this user guide before

operating a BoSS X-Series machine.

Additional copies of this user guide may also be obtained from the

manufacturer; please see the contact details on the back cover. The

instructions are also available to download from the manufacturer’s

website at www.bosspoweredaccess.com.

The information contained in this user guide is based on the latest

product information at the time of publication. The manufacturer

operates a policy of continuous product improvement. We reserve

the right to make product changes at any time without notice.

Section 1 - Description

BoSS_XSeries_Userguide_Rev C 0519_English.indd 2 08/05/2019 12:19

3BoSS X-Series User guide

1.2 Characteristics and description

The BoSS X-Series is a range of manually propelled scissor lifts.

Each machine includes the following features as standard:

Automaticbrakingonxedcastors

Foot operated click-on brakes on swivel castors

Tilt sensor

Platform overload sensor with LED indicator on handset controller

Pressure loss valve

Safety cut-out on descent (preprogrammed to 3 seconds)

Audible alarm on descent

Self-closing gate with locking latch and transit gate lock

Gate incorporates end toeboard removing trip hazard

Slip-resistant deck incorporating lanyard point

Safety and usage instructions mounted on the guardrail

Platform mounted handset controller with emergency stop

Secondary emergency stop button mounted on the chassis

Battery charge level indicator

Battery charger with charging indicator

Non-powered emergency platform lowering mechanism

Fail-safe props for deployment during maintenance

Anti-static strip

Rigid,robustboxsectionscissors

Machinestthroughstandarddoorwaysandintosmallpassenger

lifts

Winching eye

Heavy duty power pack, battery charger and battery

Serviceable components in slide out drawer

BoSS_XSeries_Userguide_Rev C 0519_English.indd 3 08/05/2019 12:19

4

bosspoweredaccess.com

BoSS X-Series User guide

1.2 Characteristics and description

Guardrailmountedtoolbox(withtooltray)forstorageofcharging

cables and guardrail tools

Wide forklift pockets for lifting, hoisting and strapping during

transit

Heavy-duty castors with cast aluminium hubs and non-marking

tyres

Maintenance Manual

EC Declaration of Conformity

6monthsLOLERcertication(UKonly)

3-year parts warranty

The following BoSS X-Series machine accessories are also

available:

ConnedSpaceGuardrail

Bumpers - Front and side impact protection

Heavy-Duty All-Weather Covers

BoSS_XSeries_Userguide_Rev C 0519_English.indd 4 08/05/2019 12:19

5BoSS X-Series User guide

BoSS X-Series machines have been designed to comply with the

safety requirements of the European Machinery, Low Voltage and

Electromagnetic Compatibility Directives and in accordance with

the European Standard EN 280 Mobile Elevating Work Platforms

– Design calculations – Stability criteria – Construction – Safety –

Examinationsandtests.

BoSS X-Series machines are intended to lift one person (plus

essential tools and materials) to enable work to be undertaken at

height. BoSS X-Series machines are designed for indoor use only

and must be used on level ground which is able to support the

weightofthemachineanditsmaximumsafeworkingload.Typical

applicationsincludebuildingandconstruction,particularlytandstrip

out,shoptting,paintinganddecorating,generalmaintenanceand

cleaning at varying heights above ground level.

WARNING

The user must obtain the guidance and written approval of the

manufacturer in the event of any special working methods or

conditionswhichareoutsidethosespeciedinthissection.

1.4 Selection and minimum attributes of

operators

Personnel operating a BoSS X-Series machine should have either

been selected, trained and authorised to do so, or be undergoing

formal training under supervision. ISO 18878 gives details of the

requirements for the training of MEWP operators. Records of training

andexperienceofpersonnelshouldbeconsultedtoassistinthe

selection of suitable personnel.

Personnelshouldbeinstructednottoworkundertheinuenceof

alcohol,drugsorotherimpairmenttoefciency.Personnelshould

also be assessed as to their physical ability to undertake the

appointed tasks. The BoSS X-Series machine operator should:

1.3 Intended use

a. be physically t.

b. appear to be comfortable working at height when taken up in

the work platform of a MEWP.

c. have a responsible attitude.

d. demonstrate an ability to learn.

e. be able to communicate clearly with other personnel on site.

BoSS_XSeries_Userguide_Rev C 0519_English.indd 5 08/05/2019 12:19

6

bosspoweredaccess.com

BoSS X-Series User guide

f. be able to demonstrate understanding of relevant health and

safety regulations.

g. be able to demonstrate understanding of accident prevention

and control.

h. be able to demonstrate that they can work safely at height.

i. be able to demonstrate understanding of the need for

plus correct use and maintenance of personal protective

equipment.

j. operate the BoSS X-Series machine safely and manoeuvre the

machine as required, to correctly position and carry out the

tasks in a correct and proper manner.

k. be able to identify and avoid foreseeable hazards plus

recognise unsafe practices and developing situations.

l. carry out daily pre-use checks.

WARNING

Operation of the BoSS X-Series machine by untrained or inadequately

trained operators may result in serious injury or death.

A course for the category Push Around Vertical (PAV) is offered by

IPAF-approvedtrainingcentresintheUK.

BoSS_XSeries_Userguide_Rev C 0519_English.indd 6 08/05/2019 12:19

7 BoSS X-Series User guide

1.4 Continued

In addition to the Operator of the BoSS X-Series machine the Site

Surveyor and Planner plus the machine Demonstrator should be

competenttofulltheserolesasspeciedintheSafeUseofMEWP’s

– Code of Practice sections 7.2.6 and 7.2.7 respectively.

When planning the job the Site Surveyor and Planner should work

through the following stages

a. Identify the task to be undertaken.

b. Select an appropriate MEWP.

c. Identify the hazards associated with the task.

d. Carry out a risk assessment.

e. Identify control measures.

f. Develop the method to be used.

g. Record the planning in a Method Statement (including any

contingency activities for personnel rescue).

h. Communicate the plan to all persons involved.

i. Review the plan before the job starts and incorporate any

changing circumstances.

1.5 Modifications

NomodicationsshallbemadetoanyBoSSX-Seriesmachine

unless the manufacturer has given full written approval. If in doubt,

please contact the manufacturer for advice:

WernerUKSales&DistributionLtd.

Blackwater Trading Estate

The Causeway

Maldon

Essex

CM9 4LJ

UnitedKingdom

t +44 (0) 1621 745900

f +44 (0) 1621 859845

BoSS_XSeries_Userguide_Rev C 0519_English.indd 7 08/05/2019 12:19

8

1.6 Terminology

346 7

8

910

1

2

5

11

12

13

14

15

16

17

18

19

20

2122

23

24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Guardrail mounted tool box (with tool tray)

Forklift pockets for lifting, hoisting and

strapping during transit

Battery charging cable connection point

Battery charging indicator

Battery charge level indicator

Chassis mounted emergency stop

Heavy-duty castors with cast aluminium

hubs and non-marking tyres

Step up to platform

Fixed castors with automatic braking

applied on platform ascent

Swivel castors with click on brakes

Emergency lowering release valve (stage

1 of 2 of emergency descent procedure)

Guardrails

Work platform

Scissor assembly

Hydraulic cylinder

Pressure loss valve

Fail-safe props

Chassis

Winching eye

Handset controller

User guide storage tube

Self-closing gate with locking latch and

transit gate lock

Slip-resistant deck incorporating lanyard

point

Anti-static strip

Emergency lowering pull handle (stage 2

of 2 of emergency descent procedure)

25

25

BoSS_XSeries_Userguide_Rev C 0519_English.indd 8 08/05/2019 12:20

9BoSS X-Series User guide

Section 2 - Specification

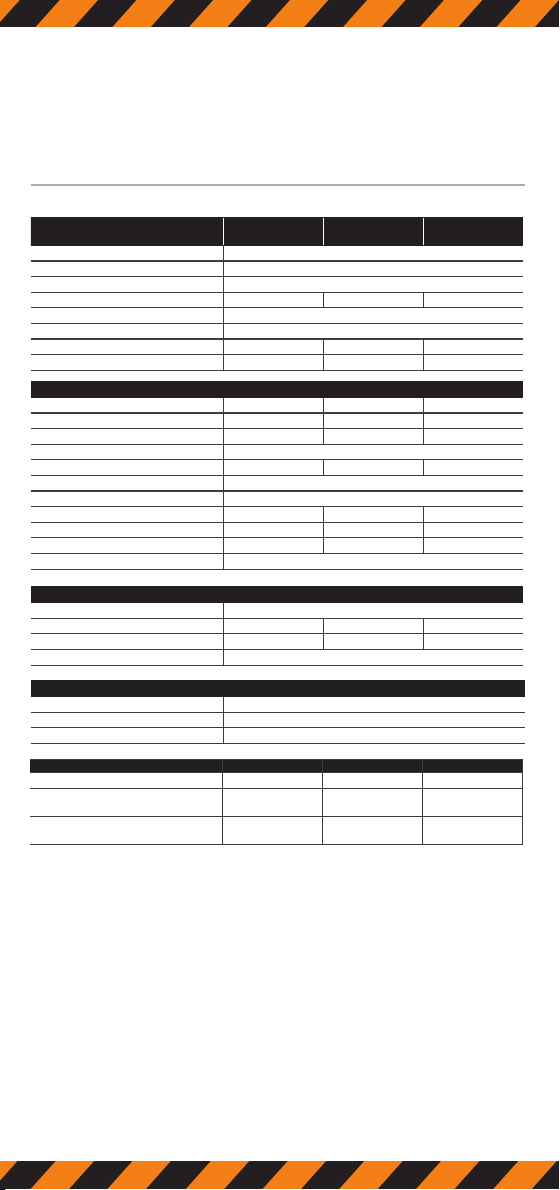

Rated load, manual forces and weight: BoSS X3X BoSS X3 BoSS X2

(Discontinued)

Safe working load 240kg

Equivalent to 1person(80kg)plus160kgtools&materials

Maximumallowablemanualforce 200N (interior use only)

Maximumallowablechassisinclination 1.25˚ 1.5˚ 1.5˚

Maximumallowablewindspeed 0m/s

Maximumloadperwheel 450kg

Machine weight 370kg 349kg 313kg

Maximumpointloading(fullyloaded) 17.43kg/cm216.83kg/cm215.8kg/cm2

Dimensions:

Maximumplatformheight 3.2m 2.55m 2.01m

Minimum platform height 0.695m 0.695m 0.6m

Maximumsafeworkingheight 5.2m 4.55m 4.01m

Platform width 0.57m

Platform length 1.25m 1.05m 1.05m

Platform guardrail height 1.1m

Toeboard height 0.15m

Overall width 0.76m 0.7m 0.7m

Stowed height 1.8m 1.8m 1.7m

Stowed length 1.41m 1.21m 1.21m

Ground clearance 0.05m

Electrical:

Voltage 12V DC

Power pack motor 1.2kW DC 1.2kW DC 0.8kW DC

Battery 12V/100Ah 12V/100Ah 12V/80Ah

Battery charger Automaticmultivoltage(110&240V)

Hydraulics:

Maximumhydraulicpressure 225 bar

Working pressure 150 bar

Hydraulicuidreservoir 2 litres

2.1 Technical data

Performance:

Maximumlifts/descentsononecharge >215 (240kg load) >225 (240kg load) >250 (240kg load)

Ascent time 18 seconds

(240kg load)

15 seconds

(240kg load)

12 seconds

(240kg load)

Descent time (including 3 second delay) 21 seconds

(240kg load)

18 seconds

(240kg load)

15 seconds

(240kg load)

BoSS_XSeries_Userguide_Rev C 0519_English.indd 9 08/05/2019 12:20

10

bosspoweredaccess.com

BoSS X-Series User guide

2.2 Operating site

When a BoSS X-Series machine is delivered to site ensure that

the machine will be able to reach the work area; these are not

rough terrain machines and should not be pushed across unstable

orunevengroundasthiscouldcausesignicantdamagetothe

machines. It is good practice to walk the route from the machine

parking place to the workplace.

A visual inspection of the operating area should be made before

setting up the machine paying particular attention to the following

issues:

2.2.1 Ground conditions

Ensure that the ground on which the BoSS X-Series machine is to

operate is capable of supporting the weight of the machine (including

themaximumratedloadof240kg).Beawareofspecicoorareas

such as manhole covers which may not be designed to withstand the

followingmaximumpointloadingexertedbythecastorwheels:

BoSS X3X – 17.43kg/cm2

BoSS X3 – 16.83kg/cm2

BoSS X2 – 15.8kg/cm2

2.2.2 Ground flatness

IdeallytheBoSSX-Seriesmachineshouldbeoperatedonaat

surface resulting in a 0 degree chassis inclination. However, the

BoSS X-Series machine can be safely operated where the ground

isslightlyunevenresultinginthefollowingmaximumlateraland

longitudinal inclinations:

BoSS X3X – 1.250

BoSS X3 – 1.50

BoSS X2 – 1.50

TheBoSSX-Seriesmachinesarettedwithatiltsensorandwill

notraiseifthisangleisexceeded.Allfourcastorwheelsmustbein

contact with the ground at all times.

2.2.3 Overheard obstructions

Ensure that adequate clearance is available above and around the

platform before deployment and elevation. Pay particular attention to

the presence of live electrical cables.

BoSS_XSeries_Userguide_Rev C 0519_English.indd 10 08/05/2019 12:20

11 BoSS X-Series User guide

2.2.4 Segregation from other site vehicle movements

Every worksite should be subject to a risk assessment and where

vehicle movements are likely to occur close to the BoSS X-Series

machine, measures should be taken to segregate the machine from

other vehicles. This might include the use of cones, barriers, signage

and rerouting measures.

2.3 Noise and vibration

ThemaximumnoiselevelemittedbyaBoSSX-Seriesmachineis

75.8dB(A).HandandarmvibrationexperiencedonaBoSSX-Series

machinedoesnotexceed2.31m/s2.

2.4 Limitations

The BoSS X-Series machine is limited to indoor operation and

must not be used outdoors. Please consult the manufacturer if you

are unsure about any application for which the machine is being

considered.

The machine has been tested for Electromagnetic Compatibility

(EMC). However, operation near to high powered radio transmission

apparatus (e.g. radar, antennae) or within strong electrical and/or

magneticeldsmayaffectsomeofthefeaturesofthismachine.

WARNING

This machine has not been designed for operation in a hazardous

environmentwhereammableorexplosivegasesorparticulates

are present. Advice should be sought from the person in charge of

the site regarding the need to select MEWP’s that are designed for

use in the hazardous environment and the use of suitable personal

protectiveequipment.Expertadvicemayneedtobesought.

This machine is not electrically insulated and must never be used for

live line working. Death or serious injury can result from contact with

(or inadequate clearance from) electrical conductors.

The risk assessment carried out as part of the planning process when

considering the use of a BoSS X-Series machine should take account

of the particular hazards of lone working. Of particular concern is

the rescue of the occupant from the platform in the case of machine

malfunction, work platform entanglement or a medical emergency.

GuidanceonloneworkingisgivenintheHSEleaetINDG73.

BoSS_XSeries_Userguide_Rev C 0519_English.indd 11 08/05/2019 12:20

12

bosspoweredaccess.com

BoSS X-Series User guide

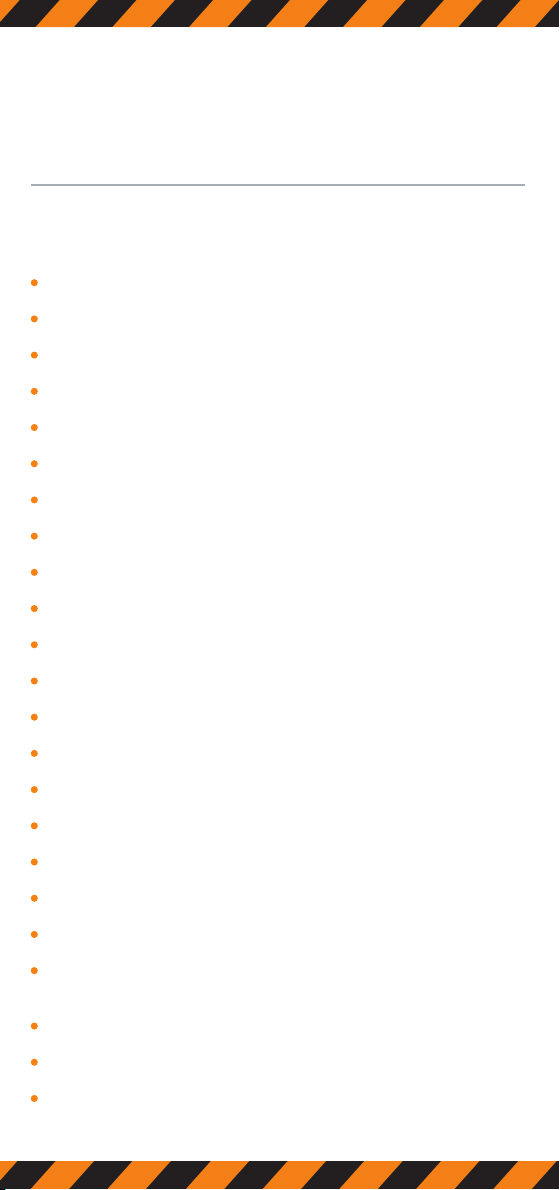

Section 3 - Safety rules

These safety rules should be adhered to in every way.

NEVER exceedthe240kgSafeWorkingLoadoftheplatform.

NEVER use the BoSS X-Series machine as a crane.

NEVER attempt to increase the reach or working height of the BoSS

X-Series machine by use of additional equipment eg. ladders.

NEVER usetheBoSSX-Seriesmachineintemperaturesexceeding45ºCor

below-15ºC.

NEVER manoeuvre the BoSS X-Series machine on an inclined surface

otherwise it may become uncontrollable.

NEVER release the brakes or manoeuvre the BoSS X-Series machine whilst

in an elevated position, as this may cause instability.

NEVER manoeuvre the BoSS X-Series machine with a person or materials

on the platform.

NEVER attempt to get on or off the work platform of the BoSS X-Series

machine when elevated.

NEVER applyexternalsideloadstotheplatformorscissorstructure.

NEVER allow persons at ground level to operate the controls whilst the

platform is occupied (unless in an emergency situation).

NEVER operate the BoSS X-Series machine outdoors.

NEVER use the BoSS X-Series machine as a jack, prop or tie to support

other structures or machines etc.

NEVER interfere with, wedge or attempt to override hydraulic, electrical or

mechanical safety devices.

NEVER open the drawer in the chassis. The drawer must only be opened by

an authorised, trained and competent maintenance engineer.

NEVER allow works overhead of the BoSS X-Series machine to be carried

out which are outside the control of the operator.

NEVER use the BoSS X-Series machine as an electrical earth when welding

structures alongside it.

NEVER use the guardrails to carry materials.

NEVER attempt to overreach.

NEVER stand in front of, or behind the BoSS X-Series machine whilst it is

being winched.

BoSS_XSeries_Userguide_Rev C 0519_English.indd 12 08/05/2019 12:20

13 BoSS X-Series User guide

Section 3 - Safety rules

ALWAYS ensure that there are no obstructions/persons that may be struck by

the platform before and during raising and lowering of the platform.

ALWAYS carrytoolsandmaterialswithintheconnesoftheguardrailsofthe

work platform.

ALWAYS undertake the daily checks recommended in this user guide prior to

the operation of the machine.

ALWAYS ensure that all instructions, warning and safe working load labelling

and plates are clean and legible.

ALWAYS ensure the BoSS X-Series machine is positioned on adequate

ground to support the weight of the machine and its rated load.

ALWAYS keep the BoSS X-Series machine clear of live electric conductors.

ALWAYS keeptheBoSSX-Seriesmachineawayfromcontactwithxed

objects (e.g. ceilings etc.) or moving objects (e.g. vehicles, cranes

etc.)

ALWAYS ensurehandsarewithintheconnesoftheguardrailswhenelevating

the work platform.

ALWAYS ensure the access gate is closed and latched once the operator has

entered the work platform.

ALWAYS ensure that another responsible person on site knows how to use the

emergency controls (i.e. the chassis mounted emergency stop and

the two stage emergency lowering procedure).

ALWAYS ensure the weight is evenly distributed within the platform.

ALWAYS ensure the safety of persons that may enter the area around the

platform and keep other vehicles clear of the work area (cordon off to

prevent persons and other vehicles entering the danger area).

ALWAYS lock the swivel castors when the machine is stationary whether or not

it is in use.

ALWAYS ensure the tilt sensor alarm sounds when the power is switched on.

ALWAYS ensure that the battery is charged before use.

ALWAYS read and understand this user guide before using the machine.

ALWAYS deploy both fail-safe props if working under the work platform.

ALWAYS thread the hoisting straps inside the guardrails when hoisting the

machine.

ALWAYS checkthattheLOLERcerticationofthemachineisindatebefore

use(UKONLY).

BoSS_XSeries_Userguide_Rev C 0519_English.indd 13 08/05/2019 12:20

14

bosspoweredaccess.com

BoSS X-Series User guide

4.1 Daily checks

It is essential to carry out daily checks on the BoSS X-Series machine

to ensure its safe condition of use including the following as a

minimum:

Hydraulicoilleaksbyvisualinspectionoftheooraroundthe

chassis and by feeling underneath the chassis drawer outer casing.

Visiblelooseelectricalttingsandswitchesbyvisualinspection.

Visible chafed hydraulic hose or electrical cables by visual

inspection.

Condition of castors, tyres and brakes by visual inspection.

Structure – guardrails, platform, scissors and chassis (e.g. cracks,

corrosion,abrasions,crackedwelds,loosexings,generaldamage

etc).

Visual inspection of castellated scissor nuts and locking pins.

Obscured, dirty or damaged instruction labelling and plates.

Emergency stop function activated on the handset.

Emergency stop function activated on the chassis.

Emergency lowering of the platform (see page 19).

Raise and lower functions including the 3 second descent delay

(the raise and lower functions can be tested by removing the

handset controller from its mount on the work platform and using

the controls whilst at ground level).

Without the swivel castor brakes applied and on a level surface,

raisetheplatformuntiltheautoxedcastorbrakesareengaged.

Then push the machine from the left and right side of the gate end

of the machine to ensure the brakes are functioning.

Switch on the power and ensure that the tilt sensor alarm sounds

toconrmoperation.Alsocheckthatthebatteryisfullycharged.

If the above daily pre-use checks reveal malfunctions or damage on the

machine,thenitmustnotbeuseduntiltheproblemisrectiedbyan

accredited maintenance engineer. If in doubt, seek further assistance by

contacting the manufacturer. If instruction labels or plates are no longer

legible or missing, contact the manufacturer for replacements. The Daily

Checks page in Section 6.5 of this user guide may be photocopied or are

available to download from our website at bosspoweredaccess.com to

provide an aide memoire for operators when undertaking these essential

checks.

WARNING

Before operating the BoSS X-Series machine, you must ensure that

you have been adequately trained in its use and have read and fully

understood this user guide, paying particular attention to the Safety Rules

in Section 3.

Section 4 – Operating instructions

BoSS_XSeries_Userguide_Rev C 0519_English.indd 14 08/05/2019 12:20

15 BoSS X-Series User guide

4.2 Manoeuvring the platform

Manoeuvre the platform into position using both hands on the

platform guardrail uprights as shown below. Take care to avoid

trapping hands or feet whilst manoeuvring the platform.

WARNING

Never manoeuvre the BoSS X-Series machine whilst it is elevated or

with a person, tools or materials on the platform.

Moving the machine up or down a slight gradient:

ALWAYS ensure that no person or obstacle is in front of the

machine going down a slight gradient or behind the machine going

up a slight gradient

DO NOT attempt to move the machine up or down a steep gradient

ALWAYS undertake a risk assessment

BoSS_XSeries_Userguide_Rev C 0519_English.indd 15 08/05/2019 12:20

16

bosspoweredaccess.com

BoSS X-Series User guide

4.3 Engaging the brakes

TheBoSSX-Seriesmachineisttedwithtwobrakingsystems:

Onthetwoxedcastors–thesebrakesareappliedautomatically

as the platform rises.

On the two swivel castors – these brakes are engaged by the use

of a foot pushing down on the lever as shown in the picture below.

Torelease,pushthefootundertheleverandickupwards.

The swivel castors MUST be locked whenever the machine is

stationary whether or not it is in use.

4.4 Battery isolation switch

The BoSS X-Series machine

isttedwithakeyoperated

switch on the handset

controller. This switch is used

to isolate the battery, and

therefore the electrical system,

preventing unauthorised

use. To enable the electrical

system, insert the key and turn

clockwise, as shown in the

image on the right, ensuring

the red emergency stop button

is fully released.

Ensure that when the machine

is not in use, the emergency

stop button is depressed and

the key removed.

New image using current BoSS X3X

at photo shoot

BoSS_XSeries_Userguide_Rev C 0519_English.indd 16 08/05/2019 12:20

17 BoSS X-Series User guide

4.5 Entering and leaving the work platform

Alwaysusethreepointsofcontactwhenenteringandexitingthe

platform (e.g. the use of two hands and one foot as shown in the

pictures below). Always use the step up to the platform on the chassis

of the machine.

On entering the platform, ensure that the gate is closed behind you,

as shown below.

BoSS_XSeries_Userguide_Rev C 0519_English.indd 17 08/05/2019 12:20

18

bosspoweredaccess.com

BoSS X-Series User guide

4.6 Handset controller

The handset controller includes the platform

raise and lower controls.

Pressingthe‘UP’buttonraisestheplatform.

Pressing the ‘DOWN’ button lowers the

platform.

Part way through the descent of the platform, a 3-second stop is

triggered to alert the operator to look down and around all 4 sides

of the platform to ensure that there are no people or obstacles

preventing the continued descent of the platform, thus averting any

risk of crushing or shearing.

Once the operator is sure that it is safe to continue the descent, the

‘DOWN’ button can be depressed a second time to continue the

lowering of the platform.

BoSSX-Seriesmachinesarettedwithaplatformoverloadsensor.

Iftheplatformloadisexceededtheplatformwillnotascendandthe

red LED indicator on top of the handset will illuminate.

4.7 Emergency stop

An emergency stop button is provided on the handset controller.

Once depressed this isolates the power to the raise and lower

functions.

To restore the power, twist the emergency stop button key clockwise

to release the button as shown below.

There is also an

emergency stop

button on the

chassis. Push in

to activate and

twist clockwise to

release.

BoSS_XSeries_Userguide_Rev C 0519_English.indd 18 08/05/2019 12:20

19 BoSS X-Series User guide

In the unlikely event of a power failure of the BoSS X-Series machine

the platform can be lowered manually by use of the following

procedure:

STEP 1 Turnthengerscrewontheemergencydescentvalve

anticlockwise until it will not turn any further, as shown in Figure 1 below.

STEP 2 Pull the red handle under the step up to the platform towards

you until the platform has fully lowered, as shown in Figure 2 below.

If for any reason, you need to stop the emergency descent at any

time, release the handle and the platform will stop descending.

To continue the descent pull the red handle again.

Figure 1 Figure 2

WARNING

Always ensure that someone at ground level i.e. other than the

operator, is trained to perform this procedure.

In the unlikely event that the motor will not stop running, even after

both emergency stop buttons have been depressed, open the drawer

in the chassis and using the red strap remove the 100A fuse and close

the drawer before undertaking the emergency lowering procedure

above. DO NOT reuse the machine until it has been inspected, and if

necessary repaired, by a competent engineer.

4.8 Emergency lowering

AbatterychargelevelindicatoristtedtotheBoSSX-Seriesmachine.

When the machine is fully charged all segments on the indicator will

beilluminatedred,asshowninFigure1below.Whenonlytherst

segment,ontheleftoftheindicatorisilluminatedredandashing,as

shown in Figure 2 below, it is time to put the machine on charge.

4.9 Battery charging

Figure 1 Figure 2

BoSS_XSeries_Userguide_Rev C 0519_English.indd 19 08/05/2019 12:20

This manual suits for next models

3

Table of contents

Popular Scissor Lift manuals by other brands

RUDETRANS

RUDETRANS RLS-G Series USER, OPERATING & INSTALLATION MANUAL

Mec

Mec 69 Series Operator's manual

Magni

Magni W 8 Use and maintenance manual

jcb

jcb Access Series quick start guide

QUALITY LIFTS

QUALITY LIFTS MID-RISE LIFT Installation, operation and maintenance manual

Sinoboom

Sinoboom GTJZ0408M Operation manual

DINGLI

DINGLI JCPT0808 operators manual with maintenance information

DINGLI

DINGLI JCPT1523DC operators manual with maintenance information

Bike-Lift

Bike-Lift CUSTOM 500 Use and maintenance manual

Bend-Pak

Bend-Pak Quatra XR-12000L Installation and operation manual

Haulotte

Haulotte H12 SD Operating and maintenance instructions

Mec

Mec Micro 26 Operator's manual