BossWeld ST 141X User manual

DC INVERTER MANUAL

2

Thank you for choosing a BOSSWELD ST 141X / ST 181X Inverter DC MMA Welder

In this manual you will nd instructions on how to set up your welder along with general welding information

safety information and helpful tips. We encourage you to go online to our website for more tips and

troubleshooting as well as many welding resources.

The BOSSWELD ST 141X / ST 181X are the latest in IGBT MMA Stick Electrode Welder technology, this very

lightweight welding machine, is easy to use, generating a very smooth and stable output, ideal for welding jobs

around the home, farm, workshop or on site.

We truly hope you enjoy using your welder!

Every effort has been made to ensure that this manual has been prepared accurately, however errors and omissions are excepted.

BOSSWELD is a trademark of Dynaweld Industrial Supplies Pty Ltd.

MMIG

• Simple to learn

• MIG Wire is fed through the gun to create the weld pool

• Gas or flux prevents oxidisation in the weld

• Weld with or without gas

• Point and pull the trigger

• Great for maintenance, small projects

& automotive repairs

METAL TYPES

Mild steel, stainless steel & aluminium

SSTICK

• Easiest process to learn

• Best choice for quick repairs

• Slower than MIG welding

• Forgiving in dirty/rusty environments

• Not recommended for thin sheet metal welding

METAL TYPES

Mild steel, stainless steel & cast iron

TTIG

• Gives a better weld finish

• Accurate heat control

• Considered the most challenging process to learn

• Good way to weld thin material

• Argon gas is required

METAL TYPES

Mild steel, stainless steel & aluminium

PPLASMA CUTTING P

• Wide range of uses to cut conductive metals

• Uses an accelerated jet of hot plasma

• High speed/low cost cutting method

• Used extensively replacing gas cutting methods

• Air compressor is required

METAL TYPES

Mild steel, stainless steel & aluminium

3

CONTENTS PAGE

WARRANTY 4

BOX CONTENTS 5

WARNINGS 6

MACHINE CARE / SAFETY INSTRUCTIONS 7

WORK AREA SAFETY 8

MAINTENANCE & DISPOSAL 9

FRONT & REAR PANEL LAYOUT 10

STICK / MMA WELDING SETUP 11-12

GENERAL MMA WELDING 13-14

TIG WELDING SETUP 15-16

LIFT ARC START 17

TIG TORCH SPARES 18

GENERAL TIG WELDING 19-20

TROUBLE SHOOTING 21

4

DO NOT GRIND YOUR PLUG

This will void any warranty on your machine

WARRANTY

This warranty is in addition to the statutory warranty provided under Australian Consumer Law, but does not

include damage resulting from transport, misuse, neglect or if the product has been tampered with.

The product must be maintained as per this manual, and installed and used according to these instructions on

an appropriate power supply. The product must be used in accordance with industry standards and acceptable

practice.

Special n ote:

If this welders duty cycle is exceeded the welder will enter “thermal overload” which will

automatically stop the welding output in order to protect, both the user and the welder. You will know

the welder has gone into thermal overload when the overload error indicator light is illuminated.

The welder will then cool itself down, and once the overload error indicator light is no longer

illuminated, welding can then re-commence.

Please note. Exceeding the machine’s duty cycle, cannot be considered grounds for warranty or return.

This warranty covers the materials used to manufacture the machine and the workmanship used to produce the

item. This Warranty does not cover damage caused by:

1. Normal wear and tear due to usage

2. Misuse /abuse or Neglect of the item

3. Transport / handling breakages

4. Lack of maintenance, care and cleaning

5. Environmental factors, such as usage in temperatures exceeding 40 degrees, above 1000mt sea level, rain,

water, excessive damp, cold or humid conditions.

6. Improper setup or installation

7. Use on Incorrect voltage or non authorised electrical connections and plugs

8. Use of non standard parts

9. Repair, case opening, tampering with, modications to any part of the item by non authorised BOSSWELD

repairers.

This warranty covers the machine only and does not include Torches, Leads, Earth Clamps, Electrode holders,

Plasma Torches, Tig Torches and any of the parts on those items unless there is a manufacturing fault.

1. REGISTRATION

Purchasers are encouraged to register for warranty on our website. www.bossweld.com.au/warranty

2. TIME PERIOD - 3 Years (ST 141X) (ST 181X)

A warranty claim must be made within 3 years from the date of purchase of this product. Any claim must include

proof of purchase.

3. HOW TO MAKE A CLAIM - NEED SOME HELP?

• Visit our website www.bossweld.com.au/troubleshooting for many helpful tips and guides to assist with the

setup and usage of your new machine. Still stuck….?

• Call the BOSSWELD Helpdesk on 1300 899 710 for over the phone assistance.

• If the machine is not operational then return the item to the place of purchase.

BOSSWELD MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED. THIS WARRANTY IS EXCLUSIVE

AND IN LIEU OF ALL OTHERS, INCLUDING, BUT NOT LIMITED TO ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

Note: Warranty will be void if 15Amp plug is ground down (ST 181X)

5

BOSSWELD ST 141X / ST 181X Inverter DC MMA Arc Welder Box Contents

1. BOSSWELD ST 141X or ST 181X Inverter DC MMA Arc Welder

2. Electrode Holder Lead

3. Welding Earth Lead

4. Carry Strap

5. Owners Manual (not shown)

1

2

4

3

6

The device and packaging material are not toys! Children must not be allowed to play with the machine and its

accessories. Plastic parts and packaging are choking risks for children.

• Open the packaging and remove the welder carefully.

• Check that the delivery is complete.

• If possible, store the packaging until the warranty period has expired.

PERSONAL PROTECTIVE EQUIPMENT (PPE)

GLOVES AND PROTECTIVE CLOTHING

Use protective gloves and re resistant protective clothing when welding.

Avoid exposing skin to ultraviolet rays produced by the arc.

WELDING HELMET

Under no circumstances should the welder be operated unless the operator is wearing a

welding helmet to protect the eyes and face. There is serious risk of eye damage if a helmet is

not used. The sparks and metal projectiles can cause serious damage to the eyes and face.

The light radiation produced by the arc can cause damage to eyesight, and burns to skin.

Never remove the welding helmet whilst welding.

SAFETY GLASSES

After welding use appropriate safety glasses when brushing, chipping or grinding the slag from

the weld.

OTHER PERSONS

Ensure that other persons are screened from the welding arc and are at least 15 metres away

from the work piece. Always ensure that the welding arc is screened from onlookers, or people

just passing by. Use screens if necessary, or non-reecting welding curtain. Do not let children

or animals have access to the welding equipment or to the work area.

SWITCHING OFF

When the operator has nished welding they must switch the welder off.

DO NOT put the electrode holder down with the welder switched ON.

When leaving the welder unattended, move the ON/OFF switch to the OFF position and

disconnect the welder from the electrical mains supply.

Do not leave hot material unattended after welding.

FUMES &GASES ARE DANGEROUS

Smoke and gas generated whilst welding or cutting can be harmful to people’s health. Welding

produces fumes and gases. Breathing these fumes and gases can be hazardous to your health.

• Do not breathe the smoke and gas generated whilst welding or cutting, keep your head out of

the fumes

• Keep the working area well ventilated, use fume extraction or ventilation to remove welding

fumes and gases.

• In conned or heavy fume environments always wear an approved air-supplied respirator.

Welding fumes and gases can displace air and lower the oxygen level causing injury or

death. Be sure the breathing air is safe.

• Do not weld in locations near de-greasing, cleaning, or spraying operations.

The heat and rays of the arc can react with vapours to form highly toxic and irritating gases.

• Materials such as galvanized, lead, or cadmium plated steel, containing elements that can

give off toxic fumes when welded. Do not weld these materials unless the area is very well

ventilated, and or wearing an air supplied respirator.

WARNING

7

Keep the welding cables, earth clamp and electrode holder in good condition. Failure to do this can result in

poor welding quality, which could be dangerous in structural situations.

Prior to use, check for breakage of parts and any other conditions that may affect operation of the welder.

Any part of the welder that is damaged should be carefully checked to determine whether it will perform its

intended function whilst being safe for the operator. Any part that is damaged should be properly repaired, or

replaced by an authorised service centre.

IMPROPER USE

It is hazardous to use the welding machine for any work other than that for which it was designed e.g. do not

use welder for thawing pipes.

HANDLING

Ensure the handle is correctly tted. As welding machines can be heavy, always use safe lifting practices when

lifting.

POSITION AND HANDLING

To reduce risk of the machine being unstable / danger of overturning, position the welding machine on a

horizontal surface that is able to support the machine weight. Operators MUST NOT BE ALLOWED to weld in

raised positions unless safety platforms are used.

WARNING

The user of this welder is responsible for their own safety and the safety of others. It is important to read,

understand and respect the contents of this user guide. When using this welder, basic safety precautions,

including those in the following sections must be followed to reduce the risk of re, electric shock and personal

injury. Ensure that you have read and understood all of these instructions before using this welder.

Persons who are not familiar with this user guide should not use this welder. Keep this booklet in a safe place

for future reference.

TRAINING

The operator should be properly trained to use the welding machine safely and should be informed about the

risks relating to arc welding procedures. This user guide does not attempt to cover welding technique. Training

should be sought from qualied / experienced personnel on this aspect, especially for any welds requiring a high

level of integrity for safety.

SERIOUS FIRE RISK

The welding process produces sparks, droplets of fused metal, metal projectiles and fumes.

This constitutes a serious re risk. Ensure that the area in which welding will be undertaken is clear of all

Inammable materials. It is also advisable to have a re extinguisher, and a welding blanket on hand to protect

work surfaces.

MACHINE CARE / SAFETY

SAFETY INSTRUCTIONS

8

Ensure a clear, well lit work area with unrestricted movement for the operator.

The work area should be well ventilated, as welding emits fumes which can be dangerous.

Always maintain easy access to the ON/OFF switch of the welder, and the electrical mains supply.

Do not expose the welder to rain and do not operate in damp or wet locations

WORK AREA

Where welding must be undertaken in environments with increased risk of electric shock, conned spaces or in

the presence of ammable or explosive materials, it is important that the environment be evaluated in advance

by an “expert supervisor”. It is also recommended that welding in these circumstances be carried out in the

presence of persons trained to intervene in emergencies.

AVOID ELECTRICAL CONTACT

Use adequate electrical insulation with regard to the electrode, the work piece and any accessible earthed metal

parts in the vicinity. Avoid direct contact with the welding circuit. The no load voltage between the earth clamp

and the electrode can be dangerous under certain circumstances.

Note: For additional protection from electric shock. It is recommended that this welder be used in conjunction

with a residual current device (RCD) with rated residual current of 30MA or less.

In general the use of extension leads should be avoided. If used however, ensure that the extension lead is

used with the welder is of a suitable current rating and heavy duty in nature that MUST have an earth

connection. If using the welder outdoors, ensure that the extension lead is suitable for outdoor use. Always keep

extension leads away from the welding zone, moisture and any hot materials.

WELDING SURFACES

Do not weld containers or pipes that hold, or have held, ammable liquids or combustible gases or pressure.

Do not weld on coated, painted or varnished surfaces as the coatings may ignite, or can give off dangerous

fumes.

WORK PIECE

When welding, the work piece will remain at high temperature for a relatively long period. The operator must not

touch the weld or the work piece unless wearing welding gloves. Always use pliers or tongs. Never touch the

welded material with bare hands until it has completely cooled.

VOLTAGE BETWEEN ELECTRODE HOLDERS OR TORCHES

Working with more than one welding machine on a single work piece, or on work pieces that are connected,

may generate a dangerous accumulation of no-load voltage between two different electrode holders or torches,

the value of which may reach double the allowed limit.

9

WARNING

Before starting any cleaning, or maintenance procedures on the welding machine, make sure that it is switched

OFF and disconnected from the mains supply.

There are no user serviceable parts inside the welder. Refer to a qualied service personnel if any internal

maintenance is required. After use, wipe the welder down with a clean soft dry cloth.

Regular inspection of the supply cord is required and if damaged is suspected, it must be immediately replaced

by the manufacturer, its service agent or similarly qualied persons in order to avoid a hazard

STORAGE/ TRANSPORT

Store the welder and accessories out of children’s reach in a dry place. If possible store the welder in the

original packaging. The appliance must unconditionally be secured against falling or rolling over during

transport.

DISPOSING OF THE PACKAGING

Recycling packaging reduces the need for landll and raw materials. Reuse of the recycled material

decreases pollution in the environment. Please recycle packaging where facilities exist. Check with your local

council authority for recycling advice.

DISPOSING OF THE WELDER

Welders that are no longer usable should not be disposed of with household waste but in an environmentally

friendly way. Please recycle where facilities exist. Check with your local council authority for recycling advice.

MAINTENANCE

DISPOSAL

10

FRONT PANEL

1. Power Indicator Light

2. Overload Error Indicator

3. Digital Display

4. MMA / TIG switch

5. Current Adjustment Knob

6. Positive Output Connection Socket

7. Negative Output Connection Socket

REAR PANEL

8. Mains Power Switch 10Amp

- ST 141X

Mains Power Switch 15Amp

- ST 181X

9. Cooling Fan

10. 240V AC Mains Power Cord

2

3

4

5

1

6

7

8

10

9

Note: Warranty will be void if

15Amp plug is ground down

11

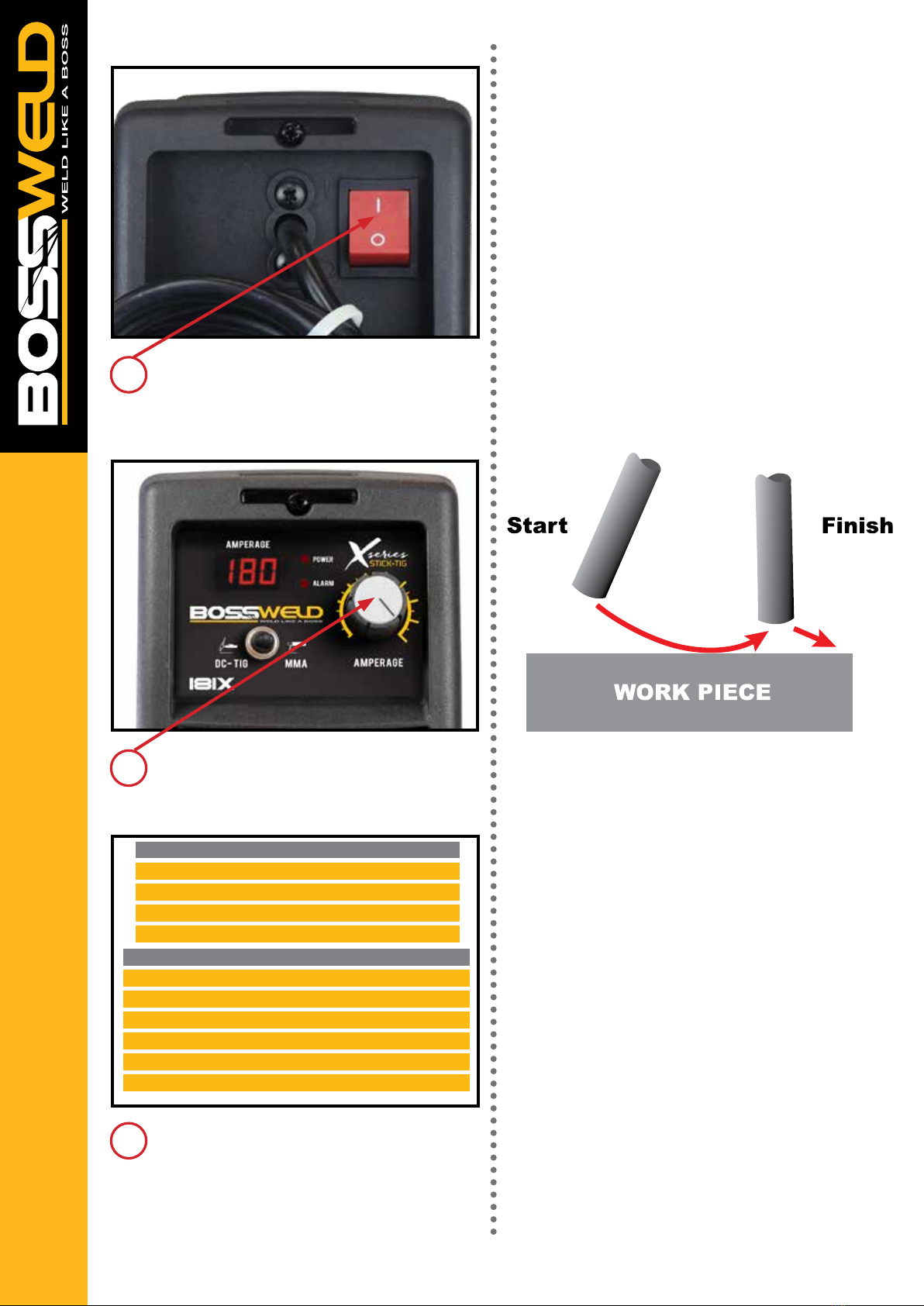

MACHINE SET UP STICK / MMA

2. Connect earth Clamp

to the terminal

2. Connect Electrode holder

to the terminal

Note: The below image shows setup for DCEP / Negative Polarity

(Most Common application)

Note: Pictures may vary from your machine model

Plug the machine 10Amp (EVO 141) or 15Amp

(ST 181X) input power lead into the wall socket,

e

nsuring that the power switch on the machine

is in the OFF position.

Connect earth clamp rmly to work-piece

ensuring that the clamp makes good contact

with bare metal.

Assemble Arc and Earth leads into the

welding terminals depending on requirements

of electrodes. Refer to your electrode packet

for polarity and current requirements.

• DCEP/ Negative Polarity (most common application)

- Earth clamp connector into the negative terminal.

- Electrode holder connector into the positive terminal.

•DCEN/Straight Polarity

- Earth clamp connector into the Positive terminal.

- Electrode holder connector into the Negative terminal.

Take electrode holder and insert bare metal

rod end of electrode and twist red handle to

clamp electrode.

1 3

2 4

12

Select your required current by turning the

Welding Parameter Adjustment Knob.

Ensure the electrode/electrode holder is not

near the work-piece or can earth out, turn the

machine on using the mains power switch.

The front displays will light up and the cooling

fan will start.

5

6

Please see table on page 13 as a guide to

Welding Parameters.

7

Amperage Selection Guide

Rod Size/ Gauge Welding Current

1.6mm 40-50 Amps

2.0mm 50-75 Amps

2.5mm 75-105 Amps

3.2mm 105-140 Amps

4.0mm 140-160 Amps

Average Metal Thickness Electrode Size

1.0 - 2.0mm 2.0mm

2.0 - 5.0mm 2.6mm

5.0 - 8mm 3.2mm

8.0mm + 4.0mm

Note: Pictures may vary from your machine model

STARTING THE ARC (SCRATCH)

The welding arc is obtained when the welding current is

forced across a gap between the electrode tip and the

workpiece. A welder must be able to strike and establish

the correct arc easily and quickly.

The scratching method is easier for beginners. The elec-

trode is moved across the plate inclined at an angle, as

you would strike a match. As the electrode scratches the

plate an arc is struck. When the arc has formed,

withdraw the electrode momentarily to form an

excessively long arc, then return to optimal arc length.

The optimal arc length, or distance between electrode

and puddle, is the same as the diameter of the

electrode (the actual metal part within the ux covering).

Holding the electrode too closely to the joint

decreases welding voltage, which creates an erratic arc

that may extinguish itself.

13

Amperage Selection Guide

Rod Size/ Gauge Welding Current

1.6mm 40-50 Amps

2.0mm 50-75 Amps

2.5mm 75-105 Amps

3.2mm 105-140 Amps

4.0mm 140-160 Amps

WELDING CURRENT

Welding current level is determined by the size of electrode - the normal operating range and current are

recommended by manufacturers. Typical operating ranges for a selection of electrode sizes are illustrated in

the table. As a rule of thumb when selecting a suitable current level, an electrode will require about 40 Amps

per millimetre (diameter). Therefore, the preferred current level for a 4mm diameter electrode would be 160

Amps, but the acceptable operating range is 140 to 180 Amps. It is important to match the machine to the job

Average Metal Thickness Electrode Size

1.0 - 2.0mm 2.0mm

2.0 - 5.0mm 2.6mm

5.0 - 8mm 3.2mm

8.0mm + 4.0mm

ELECTRODE SIZE SELECTION

Electrode size selection will be determined by the thickness of the section being welded. A thicker section will

need a larger diameter electrode. The table below shows the maximum size of electrodes for average

thicknesses of section (based on General Purpose 6013 Electrode).

TIPS

• Keep the welding current as low as possible for the job at hand to maintain the best duty cycle from your

welding machine, prevent the ux from burning and make slag removal easier.

• To break the circuit withdraw the electrode from the work piece. Be careful with the end of the electrode,

as it will be HOT. Provided the current setting is correct, the surface of the work piece will also melt by the

intensity of the electric arc. A degree of “penetration” is thereby obtained, and a complete “fusion” of the

work piece and the deposited electrode is met.

• If the transformer overheats, the overload cut-out protector will activate and cut off. The light will illuminate

to show that the cut out has operated.

• After cooling, the protector will reconnect the supply circuit and the welder will be ready for further use.

Note: If the duty cycle of the machine is exceeded, the thermostatic protection will activate and the

machine will cut out, to cool down.

14

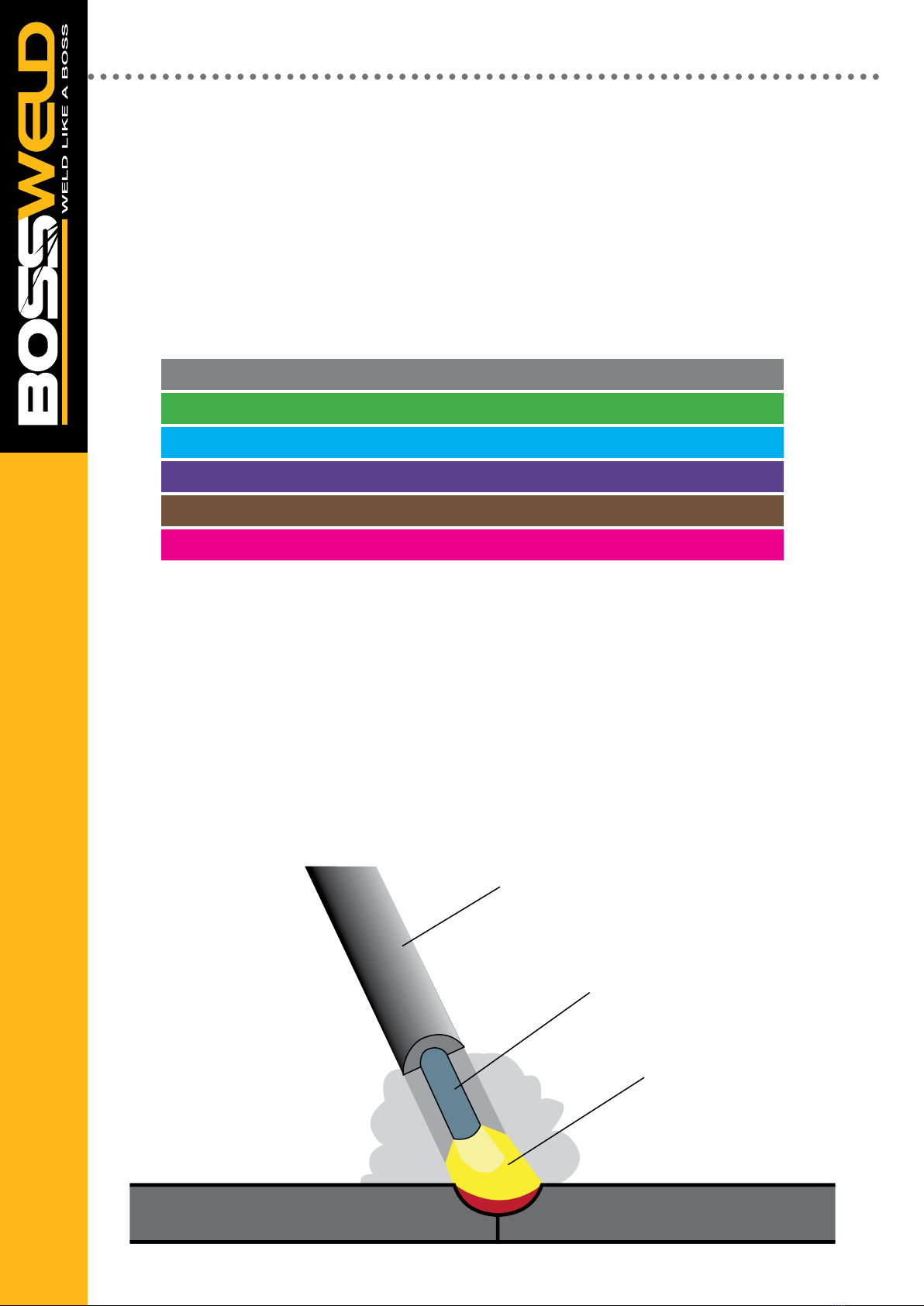

MANUAL METAL ARC PROCESS (MMA WELDING)

When an arc is struck between the metal rod (electrode) and the workpiece, both the rod and workpiece

surface melt to form a weld pool. Simultaneous melting of the ux coating on the rod will form gas and slag

which protects the weld pool from the surrounding atmosphere. The slag will solidify and cool and must be

chipped off the weld bead once the weld run is complete (or before the next weld pass is deposited).

The process allows only short lengths of weld to be produced before a new electrode needs to be inserted in

the holder. Weld penetration is low and the quality of the weld deposit is highly dependent on the

skill of the welder.

TYPES OF ELECTRODES

Arc stability, depth of penetration, metal deposition rate and positional capability are greatly inuenced by the

chemical composition of the ux coating on the electrode. There are many types of Electrodes, and these

are generally matched to the base metal. For example if welding Mild Steel then select a Mild Steel (General

Purpose Electrode). Electrodes are identied by a universal numbering system (AWS Type code).

Electrodes are often packed in sealed packaging to keep moisture out. However, if a pack has been opened

or damaged, it is essential that the electrodes are redried according to the manufacturer’s instructions.

ARC FORCE

Also called Dig and Arc Control. Gives a power source variable additional amperage during low voltage

(short arc length) conditions while welding. Helps avoid “sticking” stick electrodes when a short arc

length is used.

POWER SOURCE

Electrodes can be operated with AC and DC power supplies. Not all DC electrodes can be operated on AC

power sources; however AC electrodes may be used on either AC or DC

Base Metal Electrode Type Type

Mild Steel Mild Steel General Purpose 6013

Stainless Steel Stainless Steel 316L 316L

Dissimilar Metals Dissimilar 680 312

Cast Iron Nickel Arc 98 Ni99

High Strength Steel Low Hydrogen TC16

TRIGGER

WELDING WIRE

FLUX COATING

ROD

ARC

CONTACT TIP

DROPLETS

SHIELDING GAS

ARC

MOLTEN WELD METAL

SHROUD

WORK PIECE WORK PIECE

WORK PIECE WORK PIECEWORK PIECE WORK PIECE

WORK PIECE WORK PIECE

STRAIGHT GROUND

CORRECT PREPERATION - STABLE ARC INCORRECT PREPERATION - STABLE ARC

RADIAL GROUND

ARC WANDER

TUNGSTEN ELECTRODE

GAS LENS

STABLE ARC

FLAT TIP POINTED TIP

GRINDING WHEELGRINDING WHEEL

FILLER WIRE

Note: Do not use wheel for other jobs or tugsten can become contaminated and cause lower weld quality

15

MACHINE SET UP TIG WELD

7.Select TIG

2. Connect TIG Torch

to the terminal

5. Connect earth Clamp

to the terminal

4. Connect the Argon Gas Regulator

to the Gas bottle and connect the Gas Hose

from the torch to the Input socket on the

Regulator. Ensure the Gas regulator is in the

off position.

Plug the machine 10Amp (EVO 141) or 15Amp

(ST 181X) input power lead into the wall socket,

e

nsuring that the power switch on the machine

is in the OFF position.

1

Connect the Argon Gas Regulator to the Gas

bottle and connect the Gas Hose to the Gas

Input socket from the torch to the Regulator.

Ensure the Gas regulator is in the off position.

4

Install the TIG Torch to the machine

by connecting the Dinse Connector to the

Negative Output Connection Socket , the Gas

hose to the regulator and the TIG Torch

Control Socket and screw the nut up rmly.

2

Set up the TIG torch. Place the Tungsten

Electrode into the torch head and ensure back

cap and collet body are screwed in rmly.

3

NOTE: TIG Torch option and regulator shown are not supplied with the machine.

Note: Pictures may vary from your machine model

16

Select DC-TIG, Select your required current

by turning the Welding Parameter Adjustment

Knob.

Turn the machine on using the mains power

switch. The front displays will light up and the

cooling fan will start.

6

7

Connect earth clampto the positive terminal

and rmly to work-piece ensuring that the

clamp makes good contact with bare metal.

5

MACHINE SET UP TIG WELD - CONTINUED

Note: Pictures may vary from your machine model

Turn on regulator and set gas ow to between

10-15 L/min depending on your welding

environment.

Turn the valve on the torch head to start the

ow of gas, Remember to turn it off when

nished welding.

8

9

IMPORTANT! -

We strongly recommend that you check for gas

leakage prior to operation of your machine. We

recommend that you close the cylinder valve when

the machine is not in use. BOSSWELD authorised

representatives or agents of BOSSWELD will not be

liable or responsible for the loss of any gas.

Note: It is advisable to run a few test welds using

scrap or offcut materials, in order to tune the

machine to the correct settings prior to welding

the job.

17

Note: Pictures may vary from your machine model

LIFT ARC START

With a small movement rotate the Gas Cup

forward so that the Tungsten Electrode touch-

es the work piece.

Press the button on the TIG torch Now rotate the Gas Cup in the reverse

direction to lift the Tungsten electrode from the

work piece to create the arc.

3

24

Lay the outside edge of the Gas Cup on the

work piece with the Tungsten Electrode

1- 2mm from the work piece.

1

18

BACK CAP

INSULATOR

COLLET

COLLET BODY

GAS LENS ALUMINA CUP

ALUMINA CUP

TORCH BODY

GAS LENS COLLET BODY

PART NO. DESCRIPTION

95.17FV.4.1.DA50 Tig Torch 17 Valve, 4mt, 1 pc, Dinse 50

BOSSWELD 17 SERIES 150AMP TIG TORCH COMPLETE

PART NO. DESCRIPTION

9957Y04 Back Cap Short

9557Y05 Back Cap Medium

955Y02 Back Cap Long

PART NO. DESCRIPTION

9518CG Torch Body Front Insulator

9554N01 Torch Body Front Insulator Lens Cup

PART NO. DESCRIPTION

9510N21 Collet 0.5mm

9510N22 Collet 1.0mm

9510N23 Collet 1.6mm

9510N24 Collet 2.4mm

9510N25 Collet 3.2mm

9510N20 Collet 4.0mm

PART NO. DESCRIPTION

9510N29 Collet Body 0.5mm

9510N30 Collet Body 1.0mm

9510N31 Collet Body 1.6mm

9510N32 Collet Body 2.4mm

9510N28 Collet Body 3.2mm

95406488 Collet Body 4.0mm

PART NO. DESCRIPTION

9510N50 Alumin Cup Size 4

9510N49 Alumin Cup Size 5

9510N48 Alumin Cup Size 6

9510N47 Alumin Cup Size 7

9510N46 Alumin Cup Size 8

9510N45 Alumin Cup Size 10

9510N44 Alumin Cup Size 12

PART NO. DESCRIPTION

9545V24 Gas Lens Collet 1.0mm

9545V25 Gas Lens Collet 1.6mm

9545V26 Gas Lens Collet 2.4mm

9545V27 Gas Lens Collet 3.2mm

9545V28 Gas Lens Collet 4.0mm

PART NO. DESCRIPTION

9554N18 Gas Len Alumin Cup Size 4 - 6.0mm

9554N17 Gas Len Alumin Cup Size 5 - 8.0mm

9554N16 Gas Len Alumin Cup Size 6 - 9.5mm

9554N15 Gas Len Alumin Cup Size 7 - 11.0mm

9554N14 Gas Len Alumin Cup Size 8 - 12.7mm

9554N19 Gas Len Alumin Cup Size 11 - 17.5mm

PART NO. DESCRIPTION

954WP26V Torch Head with Valve

95WP26FV Flex Torch Head with Valve

19

TIG WELDING

Tungsten inert gas (TIG) welding became an overnight success in the 1940s for joining magnesium and

aluminium. Using an inert gas shield instead of a slag to protect the weldpool, the process was a highly

attractive replacement for gas and manual metal arc welding. TIG has played a major role in the acceptance

of aluminium for high quality welding and structural applications.

PROCESS CHARACTERISTICS

In the TIG process the arc is formed between a pointed tungsten electrode and the workpiece in an inert

atmosphere of argon or helium. The small intense arc provided by the pointed electrode is ideal for high

quality and precision welding. Because the electrode is not consumed during welding, the welder does not

have to balance the heat input from the arc as the metal is deposited from the melting electrode. When ller

metal is required, it must be added separately to the weldpool.

POWER SOURCE

TIG must be operated with a constant current power source - either DC or AC. A constant current power

source is essential to avoid excessively high currents being drawn when the electrode is short-circuited onto

the workpiece surface. This could happen either deliberately during arc starting or inadvertently during

welding. If, as in MIG welding, a at characteristic power source is used, any contact with the workpiece

surface would damage the electrode tip or fuse the electrode to the workpiece surface. In DC, because arc

heat is distributed approximately one- third at the cathode (negative) and two-thirds at the anode (positive),

the electrode is always negative polarity to prevent overheating and melting. However, the alternative power

source connection of DC electrode positive polarity has the advantage in that when the cathode is on the

workpiece, the surface is cleaned of oxide contamination. For this reason, AC is used when welding

materials with a tenacious surface oxide lm, such as aluminium.

ARC STARTING

The welding arc can be started by scratching the surface, forming a short-circuit. It is only when the

short-circuit is broken that the main welding current will ow. However, there is a risk that the electrode may

stick to the surface and cause a tungsten inclusion in the weld.

TUNGSTEN SELECTION / PREPARATION & GRINDING

ELECTRODES

Electrodes for DC welding are normally pure tungsten with 1 to 4% thoria to improve arc ignition. Alternative

additives are lanthanum oxide and cerium oxide which are claimed to give superior performance (arc starting

and lower electrode consumption). It is important to select the correct electrode diameter and tip angle for

the level of welding current. As a rule, the lower the current the smaller the electrode diameter and tip angle.

In AC welding, as the electrode will be operating at a much higher temperature, tungsten with a zirconia

addition is used to reduce electrode erosion. It should be noted that because of the large amount of heat

generated at the electrode, it is difcult to maintain a pointed tip and the end of the electrode assumes a

spherical or ‘ball’ prole.

Grinding creates the greatest hazard as the exposed tungsten/thoria area is greatly increased and ne

particles of potentially radioactive dust are released into the atmosphere. It is recommended that a dedicated

grindstone with local dust extraction is used, and a simple lter mask is worn. If the grinding wheel is not

tted with a protective viewing screen, eye protection must be worn.

TRIGGER

WELDING WIRE

FLUX COATING

ROD

ARC

CONTACT TIP

DROPLETS

SHIELDING GAS

ARC

MOLTEN WELD METAL

SHROUD

WORK PIECE WORK PIECE

WORK PIECE WORK PIECEWORK PIECE WORK PIECE

WORK PIECE WORK PIECE

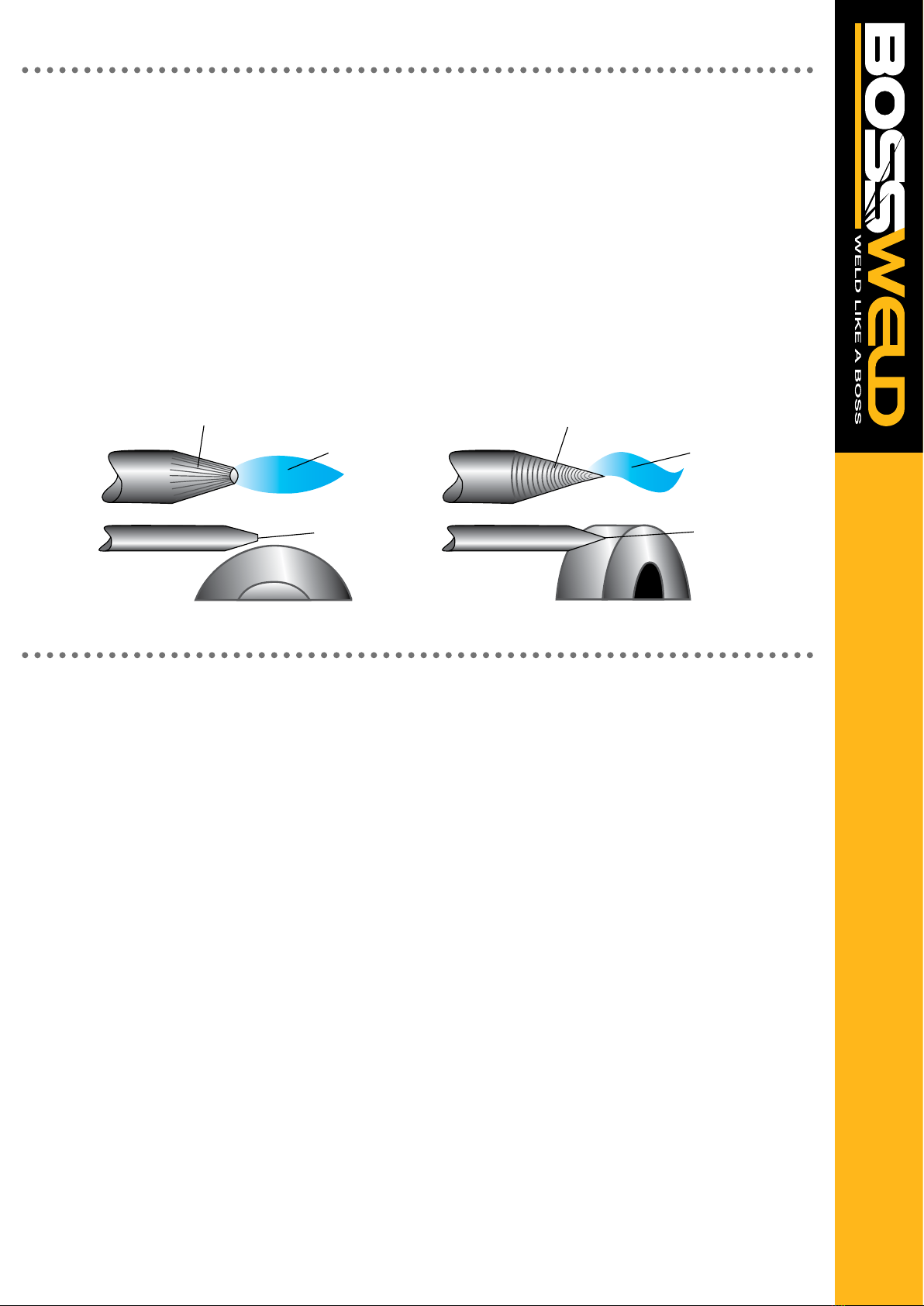

STRAIGHT GROUND

CORRECT PREPERATION - STABLE ARC INCORRECT PREPERATION - STABLE ARC

RADIAL GROUND

ARC WANDER

TUNGSTEN ELECTRODE

GAS LENS

STABLE ARC

FLAT TIP POINTED TIP

GRINDING WHEELGRINDING WHEEL

FILLER WIRE

Note: Do not use wheel for other jobs or tugsten can become contaminated and cause lower weld quality

20

TIG WELDING - CONTINUED

This risk can be minimised using the ‘lift arc’ technique where the short-circuit is formed at a very low

current level. The most common way of starting the TIG arc is to use HF (High Frequency). HF consists of

high voltage sparks of several thousand volts which last for a few microseconds. The HF sparks will cause

the electrode - workpiece gap to break down or ionise. Once an electron/ion cloud is formed, current can ow

from the power source.

Note: As HF generates abnormally high electromagnetic emission (EM), welders should be aware that its

use can cause interference especially in electronic equipment. As EM emission can be airborne, like radio

waves, or transmitted along power cables, care must be taken to avoid interference with control systems and

instruments in the vicinity of welding.

HF is also important in stabilising the AC arc; in AC, electrode polarity is reversed at a frequency of about 50

times per second, causing the arc to be extinguished at each polarity change. To ensure that the arc is

reignited at each reversal of polarity, HF sparks are generated across the electrode/workpiece gap to

coincide with the beginning of each half-cycle.

APPLICATIONS

TIG is applied in all industrial sectors but is especially suitable for high quality welding. In manual welding,

the relatively small arc is ideal for thin sheet material or controlled penetration (in the root run of pipe welds).

Because deposition rate can be quite low (using a separate ller rod) MMA or MIG may be preferable for

thicker material and for ll passes in thick-wall pipe welds.

TIG is also widely applied in mechanised systems either autogenously or with ller wire. However, several

‘off the shelf’ systems are available for orbital welding of pipes, used in the manufacture of chemical plant or

boilers. The systems require no manipulative skill, but the operator must be well trained. Because the welder

has less control over arc and weldpool behaviour, careful attention must be paid to edge preparation

(machined rather than hand-prepared), joint t-up and control of welding parameters.

T

TIG

X

X

X

X

√

√

√

√

TIG WELDING

MILD STEEL

STAINLESS STEEL

LOW ALLOY STEEL

ALUMINIUM

ARGON Ar-CO2-O2

WELDING GAS SELECTION CHART GUIDE

TRIGGER

WELDING WIRE

FLUX COATING

ROD

ARC

CONTACT TIP

DROPLETS

SHIELDING GAS

ARC

MOLTEN WELD METAL

SHROUD

WORK PIECE WORK PIECE

WORK PIECE WORK PIECEWORK PIECE WORK PIECE

WORK PIECE WORK PIECE

STRAIGHT GROUND

CORRECT PREPERATION - STABLE ARC INCORRECT PREPERATION - STABLE ARC

RADIAL GROUND

ARC WANDER

TUNGSTEN ELECTRODE

GAS LENS

STABLE ARC

FLAT TIP POINTED TIP

GRINDING WHEELGRINDING WHEEL

FILLER WIRE

Note: Do not use wheel for other jobs or tugsten can become contaminated and cause lower weld quality

This manual suits for next models

2

Table of contents

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual