Boston gear ORC-S Series Installation instructions

Installation & Operation Instructions

Boston Gear®

ORC-S Series Trig-O-Matic

Overload Release Clutches

P-3003-BG

ORC-S Series

2Boston Gear • 800-825-6544 P-3003-BG

Contents

I. Introduction

A. Operating Principle .....................2

B. Resetting Instructions ...................3

C. Torque Adjustment .....................4

Il. Mounting Sprockets or Sheaves to Clutch

A. Type “T” Housing ....................5, 6

B. Type “B” Housing ....................5, 6

Ill. Locating and Mounting Clutch and

Couplings to Shaft

A. Location ............................7

B. Mounting Basic Clutch ..................7

C. Mounting Type “C” Flexible

Coupling.............................9

D. Mounting Type “N” Index and

Type “R” Rigid Couplings ................9

IV. Limit Switches .........................10

V. General Maintenance

A. Lubrication ..........................11

B. Annual Inspection .....................11

Vl. Repair Instructions

A. General Disassembly ..................11

B. Basic Unit Assembly...................12

C. Torque Verification ....................13

D. Limit Switch Actuating Plate

Assembly ...........................13

Exploded Parts View ...................16 - 18

Overload Release Clutches –

Standard Model S

Installation and Maintenance Instructions

I. Introduction

A. Operating Principle

The ORC Series, Model S Overload Release Clutch

consists of two basic components: the rotor and the

housing assembly. The clutch rotor is keyed and secured

to a shaft with a setscrew.

The housing assembly includes a drive pawl and a reset

pawl which are pivoted within the clutch housing. The

drive pawl is held engaged in the rotor notch by the

combined compression of the drive and reset springs as

shown in Figure 1. The combined compression of these

two springs determines the maximum torque which will

be transmitted without overload. With the clutch in the

engaged position shown in Figure 1, the rotor and the

housing are held together and the entire unit rotates with

the drive shaft at the same speed.

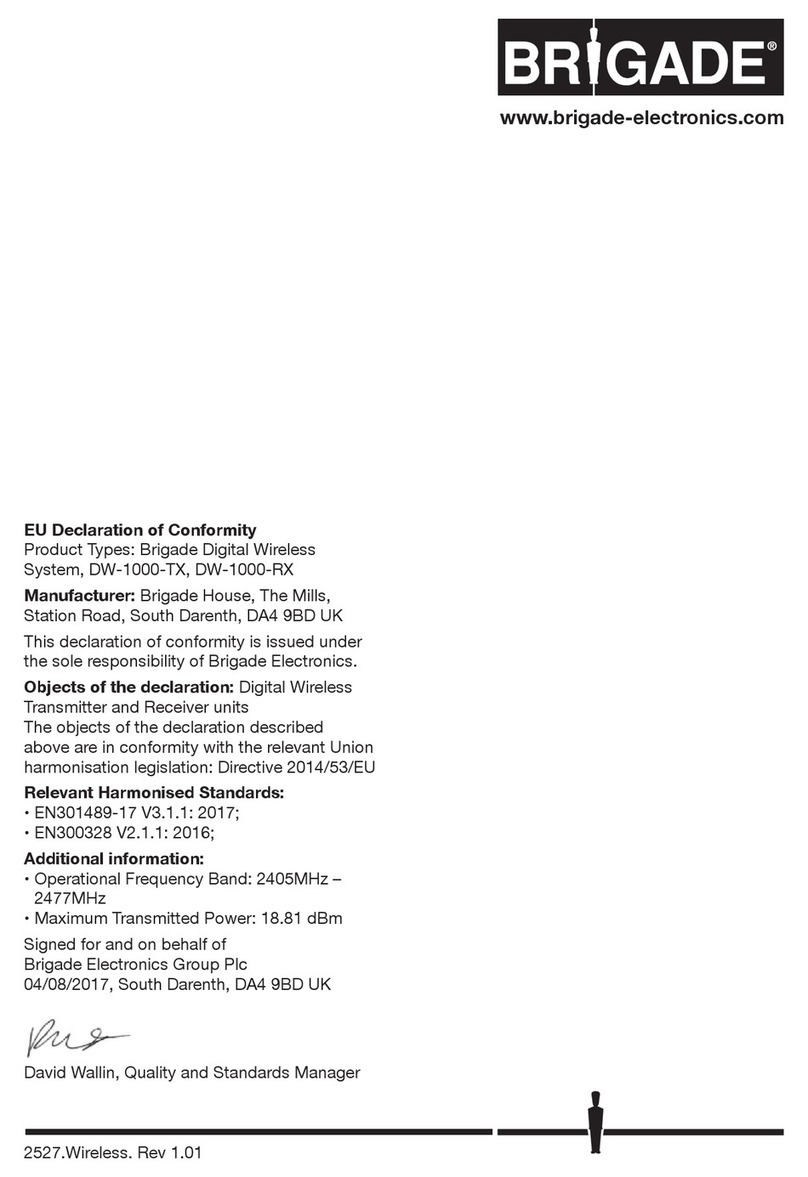

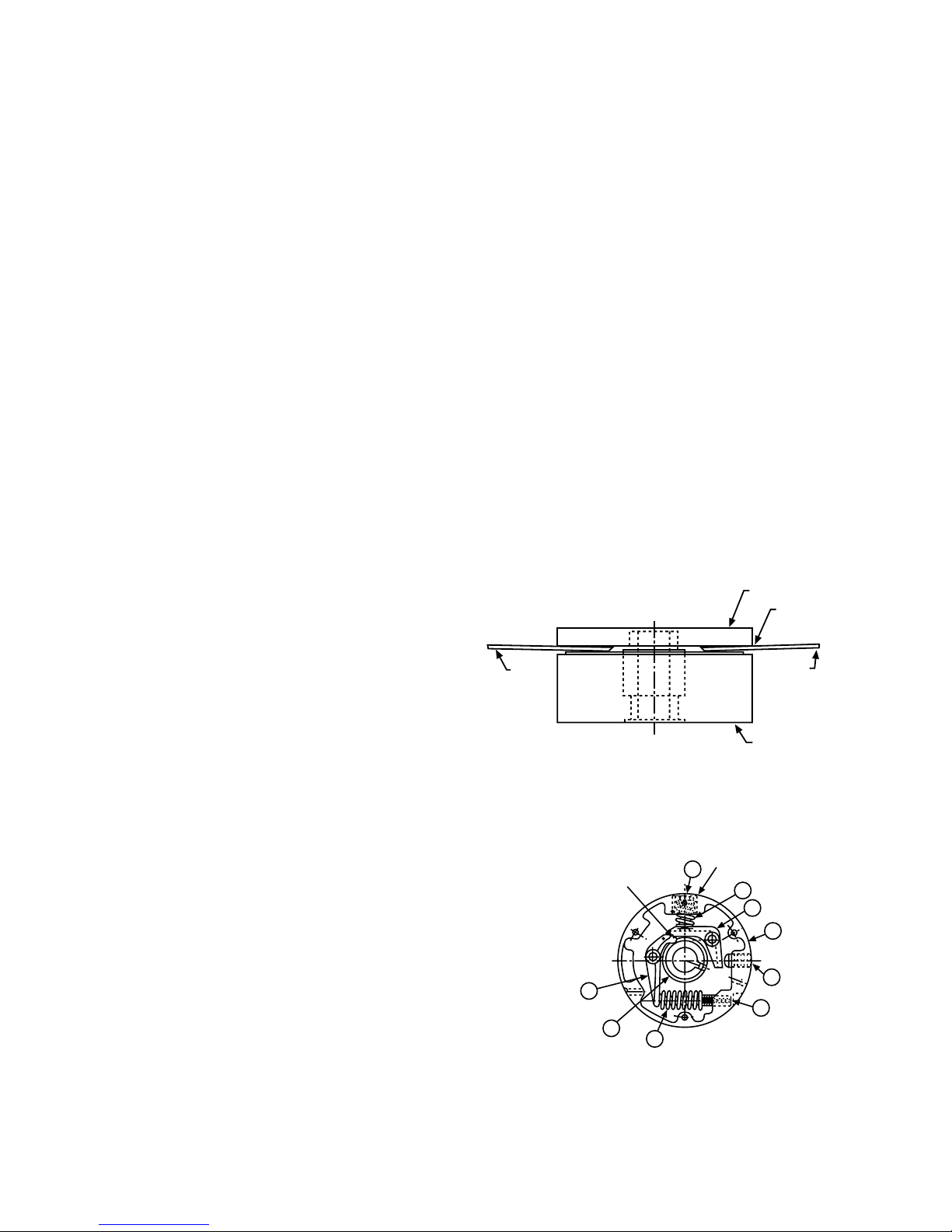

Figure 1

When an overload occurs, the rotor rotates from its

normal position within the housing. At this instant, the

combined compression of the drive and reset springs is

overcome. For a manual reset clutch, the drive pawl is

forced out of its engaged position from the rotor and as

it pivots up, the reset pawl lifts and locks the drive pawl

out of contact with the rotor as shown in Figure 2. The

clutch is then free to rotate until it is reset. For a clutch

with the automatic reset feature, the reset pawl applies

pressure to the top of the drive pawl, holding it in contact

with the rotor as shown in Figure 3.

Housing

Limit Switch Pin

Retracted

Reset Spring

Drive Pawl

Engaged With

Rotor

Rotor

Drive Spring

Boston Gear • 800-825-6544 P-3003-BG 3

Figure 2 - Manual Disengaged

Figure 3 - Automatic

B. Instructions

1. Manual Reset

Note: Be sure not to use a powered wrench as

it may cause damage to the reset pawl and/or

reset spring!

a. After the overload condition has been corrected,

rotate the drive until the rotor keyway is in

alignment with the hole stamped 22 located

on the outside diameter of the housing. (See

Figure4)

b. Reset the clutch by inserting a hex wrench into

the reset screw (Stamped 20) shown in Figure 4,

and turn the screw clockwise until the reset pawl

releases the drive pawl. Refer to Table 5 for the

proper wrench size.

c. After the drive pawl enters the rotor notch, turn

the wrench counterclockwise until the reset

screw has stopped at its original position, which

is approximately flush with the O.D. of the clutch

housing. This is essential to restore the

torque to its original setting.

d. Reducing the clutch torque setting may make

the reset procedure easier if the clutch is near

the maximum torque.

2. Automatic Reset

After one complete revolution the drive pawl will

automatically return to its original engaged position. After

the overload condition has been corrected, “jog” the

drive until the drive pawl engages with the rotor.

(Stamped 9)

Actuating

Pin

Drive Pawl

(Stamped 26)

Drive Spring

(Stamped 8)

Drive Spring Screw

Rotor Setscrew

Access Screw

(Stamped 22)

Reset Screw

(Stamped 20)

Rotor

Reset Pawl

Housing

Reset Spring

Reset Spring Screw

Limit Switch Pin

Extended

Reset Pawl Holds

Drive Pawl in Contact

With Rotor

Drive Pawl

Disengaged From

Rotor

Limit Switch Pin

Extended

Reset Pawl

Engages Notch

in Drive Pawl

Manual

Reset Scr

ew

Drive Pawl Locked

Out Of Contact

with Rotor

Figure 4 - Clutch Internal Components

(Stamped 20)

4Boston Gear • 800-825-6544 P-3003-BG

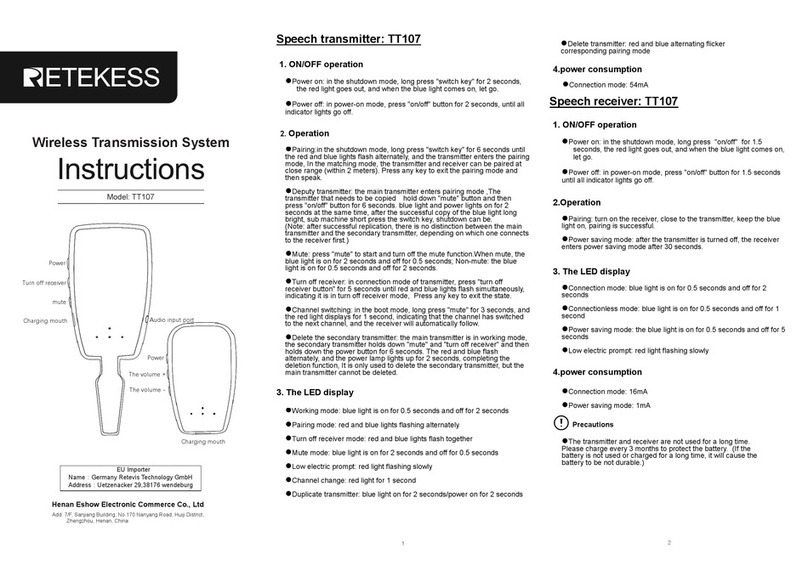

C. Torque Adjustment

The clutch is supplied with a torque selector dial. This

dial makes torque adjustments on the clutch possible.

There are mill marks on the housing near the hole

stamped 9 on the outside diameter of the housing.

The mill marks have stamped values indicating a

set, or minimum and maximum torque. (See Figure

5) If a drastic change in torque is desired, it may be

necessary to change springs. See Section Vl for spring

replacement.

Figure 5

1. Increasing the Torque.

a. Make sure the clutch is engaged.

b. Turn the torque adjustment screw clockwise

until it is flush with the milled depth of the

desired torque setting or until nuisance trips are

eliminated.

c. Check its operation.

2. Decreasing the Torque.

a. Make sure that the clutch is engaged.

b. Turn the torque adjustment screw

counterclockwise until it is flush with the milled

depth of the desired torque setting.

c. Check its operation.

3. See Figure 6 for Limit Switch Actuating

Mechanism adjustment.

Limit Switch Actuating Mechanism (LSAM)

In some cases, it may be necessary to adjust the

actuating mechanism. This is accomplished by first

setting the clutch at the minimum torque settings, and

second disengaging the clutch. Remove access plug

#5 (stamped #26) and insert an allen wrench into the

actuating adjusting screw #29. (Refer to Table 5 for

wrench sizes) Rotate adjusting screw #29 clockwise

until the spring pressure applied by the actuating spring

#28 against the actuating stud nut #39 is just sufficient

to release the actuating plate #31. The adjustment

should then be tested by resetting the clutch and

then disengaging it. If the adjustment is correct, the

actuating plate will release at the exact time of clutch

disengagement. Replace plug #5. If the trip plate does

not release, repeat the entire proess.

Figure 6

5Adjustment Access Plug

28 Actuating Spring

29 Actuating Adjusting Screw

30 Spring Mounting Screw

31 Actuating Plate

32 Trip Pin

35 Release Ring

38 Return Spring

39 Actuating Stud Nut

43 Spring Terminal

To

rque Adjusting Screw

Squar

e Wrench Socket

Milled Depth

For Max. Torque

Milled Depth For

Set or Min. Torque

Reset Spring

Disc

Lock Screw

Maximum Torque

Limit Stop Pin

43

32 35

31

38

30 39 28 29

5

Boston Gear • 800-825-6544 P-3003-BG 5

Table 1

Sprocket Mounting Screw Seating Torques

Size Screw

Size Qty Dowel

Size Qty Seating

Torque

Ream

Size

1 1/4-20 3 1/4 1 150 in.lb. .2495

2 5/16-18 3 5/16 1 305 in.lb. .3120

3 3/8-16 4 3/8 1 545 in.lb. .3745

4 1/2-13 4 1/2 1 1,300 in.lb. .4995

5 5/8-11 6 5/8 1 2,530 in.lb. .6245

6 5/8-11 6 5/8 1 2,530 in.lb. .6245

II. Mounting Sprockets or Sheaves to

Clutch

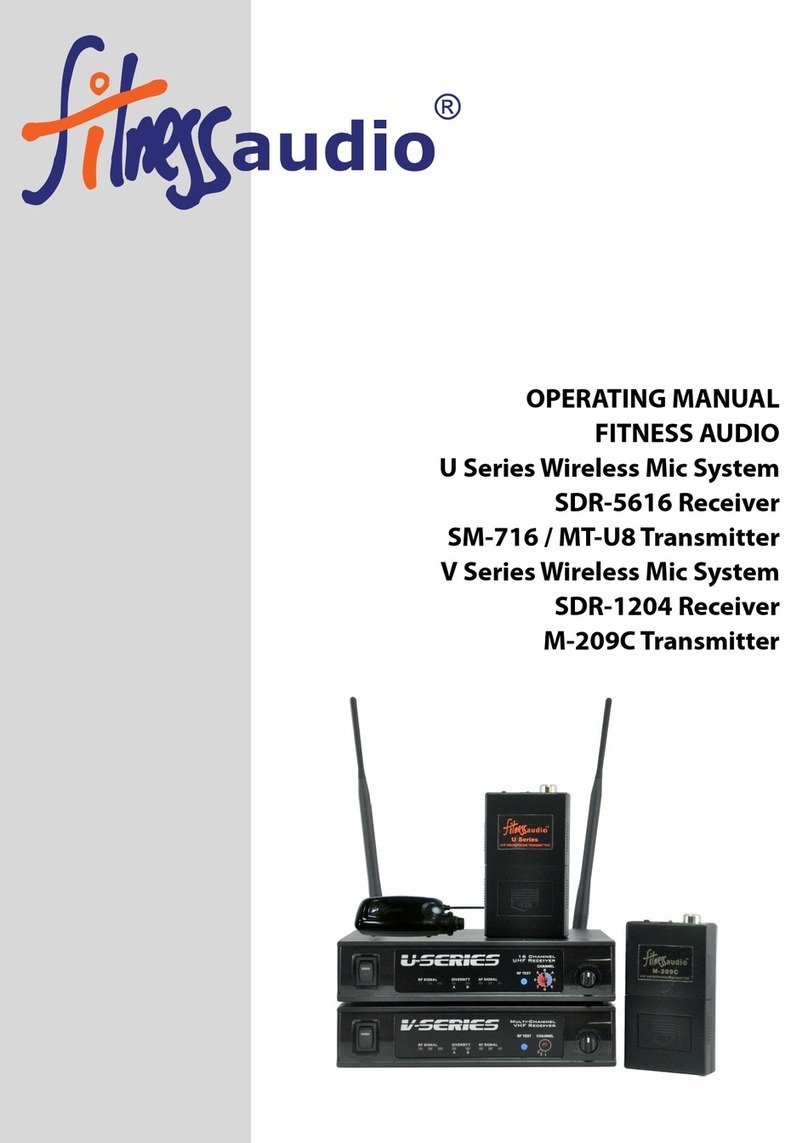

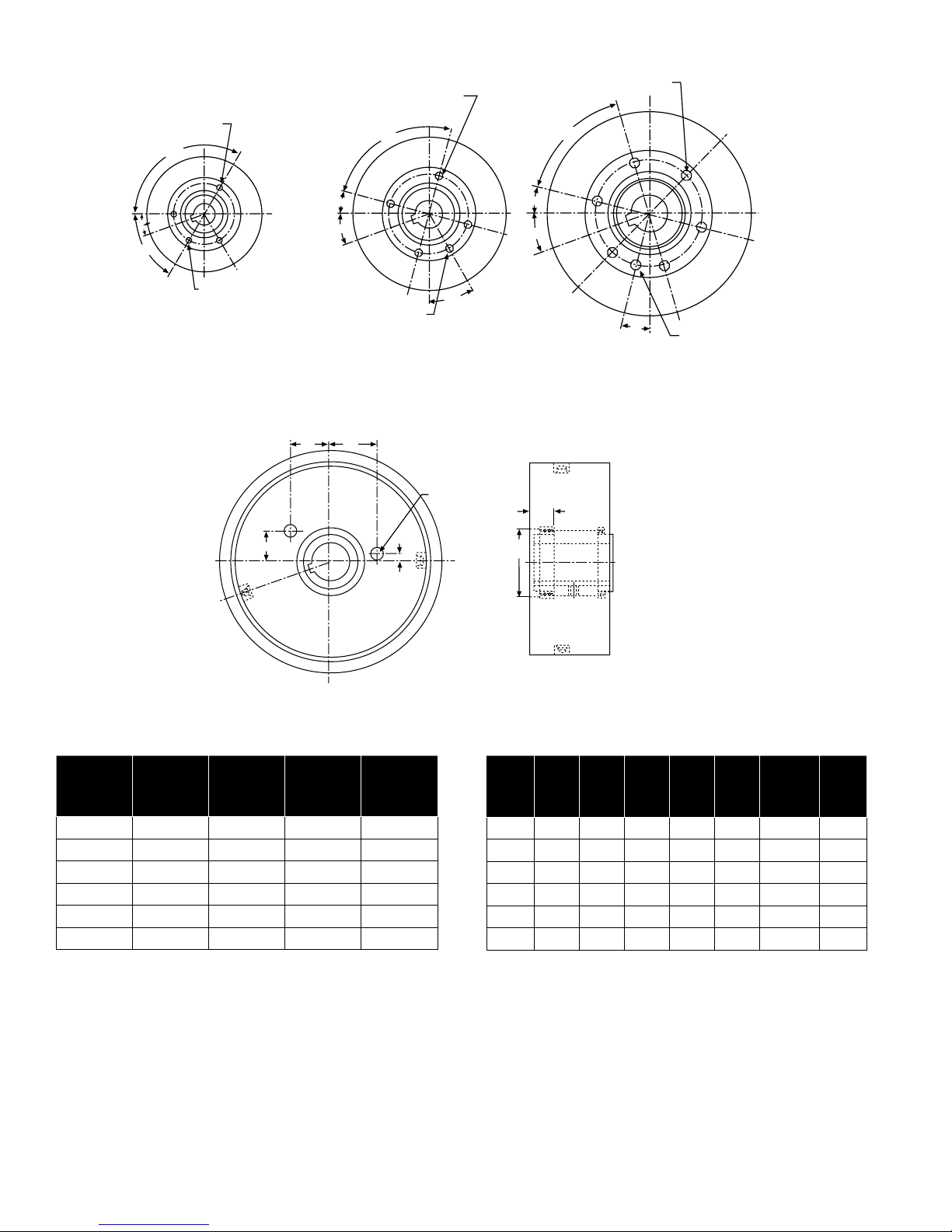

A. Type “T” Housing (Refer to Figure 7)

1. Inspect mating pilots on clutch and sprocket or

sheave for nicks or burrs and remove as required.

2. Position sprocket or sheave on housing and align

dowel pin holes.

3. Attach sprocket or sheave to housing with mounting

bolts and high collar lock washers. Refer to Table 1

for recommended seating torques.

4. Finish ream sprocket or sheave for dowel pin. Refer

to Table 1 for dowel pin and recommended ream

sizes.

5. Install dowel pins to a point where they bottom in

housing.

B. Type “B” Housing

A Type “B” is a basic unit and is sold without any

mounting hole arrangement. It is modified by the

customer for special applications. Refer to Figure 8.

Table 2

Minimum Number of Teeth of Standard Plate Sprockets Adaptable to Type “T” Clutch

Clutch

Size

Chain Size and Pitch

#25

1/4 in.

Pitch

#35

3/8 in.

Pitch

#40

1/2 in.

Pitch

#41

1/2 in.

Pitch

#50

5/8 in.

Pitch

#60

3/4 in.

Pitch

#80

1 in.

Pitch

#100

1-1/4 in.

Pitch

#120

1-1/2 in.

Pitch

#140

1-3/4 in.

Pitch

#180

2 in.

Pitch

1 40 28 22 22 18 — —————

2 54 36 28 28 22 19 — — — — —

3 X 45 34 36 28 25 19 — — — —

4 X X 42 45 36 30 23 19 — — —

5 X X X X 42 36 30 22 19 17 —

6 — — X X X 48 36 30 24 21 19

Notes:

1. X - On Application Only.

2. For smaller sprockets consult factory. As in most cases, a design modification can be made.

6Boston Gear • 800-825-6544 P-3003-BG

Table 3 - Type “T” Mounting Hole Patterns

Size Thread Depth Bolt Circle

Pilot Dia.

+.000

-.002

1 1/4-20 .50 2.375 1.875

2 5/16-18 .50 3.000 2.250

3 3/8-16 .62 4.125 3.250

4 1/2-13 .87 5.000 3.203

5 5/8-11 1.00 6.250 4.125

6 5/8-11 1.00 8.750 6.000

Notes:

1. Mounting bolts must be minimum 160,000 PSI tensile, Rc 36-43.

2. Dowel pins must be minimum 150,000 PSI shear, Rc 50-58 core

hardness.

Table 4 - Type “B” Housing Dimensions

Size A B C D E

F

+.000

-.002

G

1 .81 .81 1.06 .11 .31 1.500 .69

2 .90 1.25 1.37 .18 .37 1.875 .81

3 1.25 1.62 1.94 .29 .50 2.750 .94

4 1.56 2.12 2.37 .43 .56 2.828 1.48

5 1.94 2.62 3.00 .58 .69 4.000 1.62

6 2.62 3.50 3.87 .90 .87 5.500 2.00

Notes:

1. The “E” Dimension on Table shows pawl trunnion holes. These holes

are not through holes and they should be avoided when mounting a

coupling, sprocket, etc. to the clutch.

3 Tapped Holes at 120°

120° Typ.

20°

60°

1 Dowel Hole at 60°

Sizes 1 and 2 Mountin

g

Hole Pattern

4 Tapped Holes at 90°

90° Typ.

15°

20°

30°

1 Dowel Hole at 30°

6 Tapped Holes at 60°

60° Typ.

14°

20°

14°

1 Dowel Hole at 14°

Sizes 5 and 6 Mountin

g

Hole PatternSizes 3 and 4 Mountin

g

Hole Pattern

"B" "C"

"A"

"D"

"E" Dia. Typ.

"G"

"F"

Dia.

Figure 7 - Type “T” Standard Mounting Hole Patterns

Figure 8 - Type “B” Housing Conguration

Boston Gear • 800-825-6544 P-3003-BG 7

III. Locating and Mounting Clutch and

Couplings to Shaft

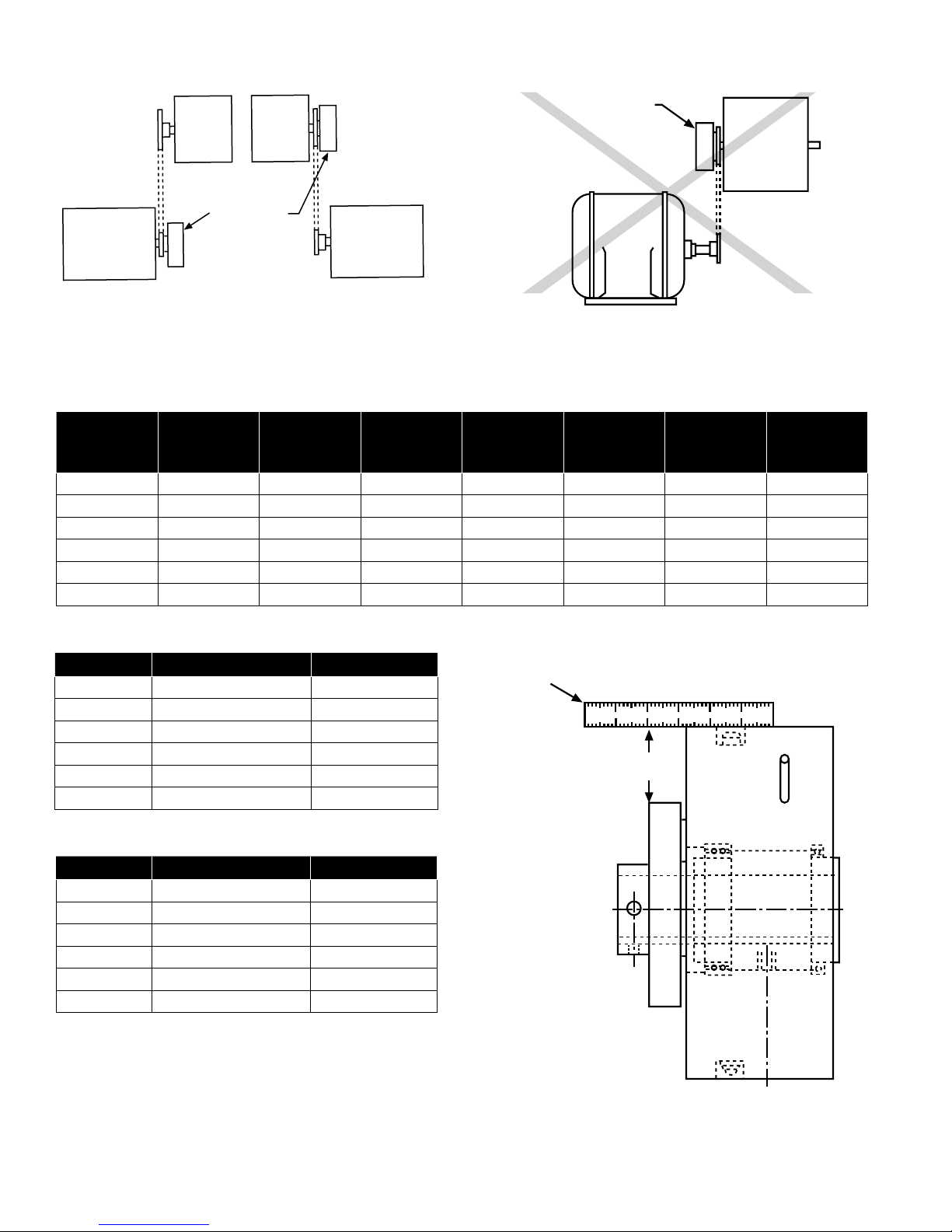

A. Location

The clutch should always be located as close as

possible to the source of an overload condition. Figures

9 through 12 indicate both preferred and not preferred

locations for mounting an ORC Series, Model S Overload

Release Clutch.

Note: Clutch mounted sprockets, etc. and couplings

should be positioned as close to a supporting

bearing as possible to minimize overhung loads.

A minimum shaft engagement of 1-1/2 times the

shaft diameter is recommended for clutch and

coupling flange installation.

1. Direct Drives

a. Figure 9 shows the preferred location for

mounting in a direct drive application. The

clutch is mounted on the low speed side of the

reducer, and transmits power from its housing,

through its rotor to the driven shaft.

b. Locating the clutch as shown in Figure 10 is

not preferred. Here the clutch is mounted on

the high-speed side of the reducer. Generally,

mounting in this manner requires the clutch to

be hypersensitive to perform satisfactorily.

2. Indirect Drives

a. Either location of the clutch shown in Figure 11

is preferred in indirect drive applications.

b. The mounting location in Figure 12 is not

preferred for the same reasons as those for

Figure 10. Always consult the factory when a

mounting of this type is necessary.

B. Mounting Basic Clutch

1. Inspect shaft and key for any nicks or burrs and

remove any that may be present.

2. Remove the access screw from the hole stamped

22 outside of the clutch housing. Make sure that the

clutch is engaged where the rotor keyway is in line

with the hole stamped 22.

3. Position shaft key and slide clutch onto shaft.

4. Align sprocket or sheave mounted to clutch with

mating sprocket or sheave in drive train. Refer to

installation and alignment instructions furnished with

sprocket or sheave.

5. Select the correct hex wrench from Table 5 and

insert it through the hole stamped 22 in the housing.

Tighten the rotor setscrew securing the clutch to the

shaft.

Note: Turn wrench clockwise only! Do not remove

setscrew from rotor!

Refer to Table 6 for recommended setscrew

seating torques.

6. Remove the hex wrench and replace access screw

in the housing.

Flexible Coupling Coupling

Half

Overload Clutch

Motor Reducer Machine

Coupling Half Overload Clutch Flexible Coupling

Motor Reducer Machine

Figure 9

Figure 10

8Boston Gear • 800-825-6544 P-3003-BG

Table 5 - Wrench Size Chart

Clutch Size

Drive Spring

Screw Hex

Wrench

Reset Spring

Screw Square

Wrench

Manual Reset

Screw Hex

Wrench

Rotor

Setscrew Hex

Wrench

Access

Screws Hex

Wrench

Locking

Screw Hex

Wrench

Adjustment

Screw Hex

Wrench

1 3/16 3/8 3/16 3/32 1/8 3/32 1/16

2 1/4 3/8 1/4 1/8 5/32 3/32 5/64

3 5/16 1/2 5/16 3/16 3/16 1/8 1/8

4 5/16 1/2 3/8 1/4 5/16 1/8 1/8

5 3/8 1/2 1/2 5/16 5/16 1/8 1/8

6 3/4 3/4 1/2 5/16 5/16 1/8 1/8

Table 6 - Rotor Setscrew Seating Torques

Size Screw Size Seating Torque

1 10-32 36 in. lb.

2 1/4-28 87 in. lb.

3 3/8-24 290 in. lb.

4 1/2-20 620 in. lb.

5 5/8-18 1,325 in.lb.

6 5/8-18 1,325 in.lb.

Table 7 - Coupling Setscrew Seating Torques

Size Screw Size Seating Torque

1 5/16-18 165 in. lb.

2 3/8-16 290 in. lb.

3 3/8-16 290 in. lb.

4 1/2-13 620 in. lb.

5 1/2-13 620 in.lb.

6 1/2-13 620 in.lb.

Driving

Member

Driven Machinery

Overload Clutch

Location

Driving

Member

Overload Clutch

Motor

Reducer

Straightedge

Coupling Parallel Alignment

Offset

12 345

Figure 12

Figure 13

Figure 11

Boston Gear • 800-825-6544 P-3003-BG 9

C. Mounting Type “C” Flexible Coupling

1. After the clutch has been mounted on its shaft as

explained in Section lll, inspect the coupling shaft

and key for any nicks or burrs and remove any that

are present.

2. Make sure that the coupling shaft keyway is in

alignment with the clutch shaft keyway. Position

shaft key and slide coupling onto the appropriate

shaft.

3. Slide the coupling flange onto the coupling studs.

The coupling flange and adapter should be

separated by a gap of 1/8”.

4. Secure the coupling to drive shaft by tightening the

two setscrews located in the hub of the flange. Refer

to Table 7 for recommended coupling setscrew

seating torques.

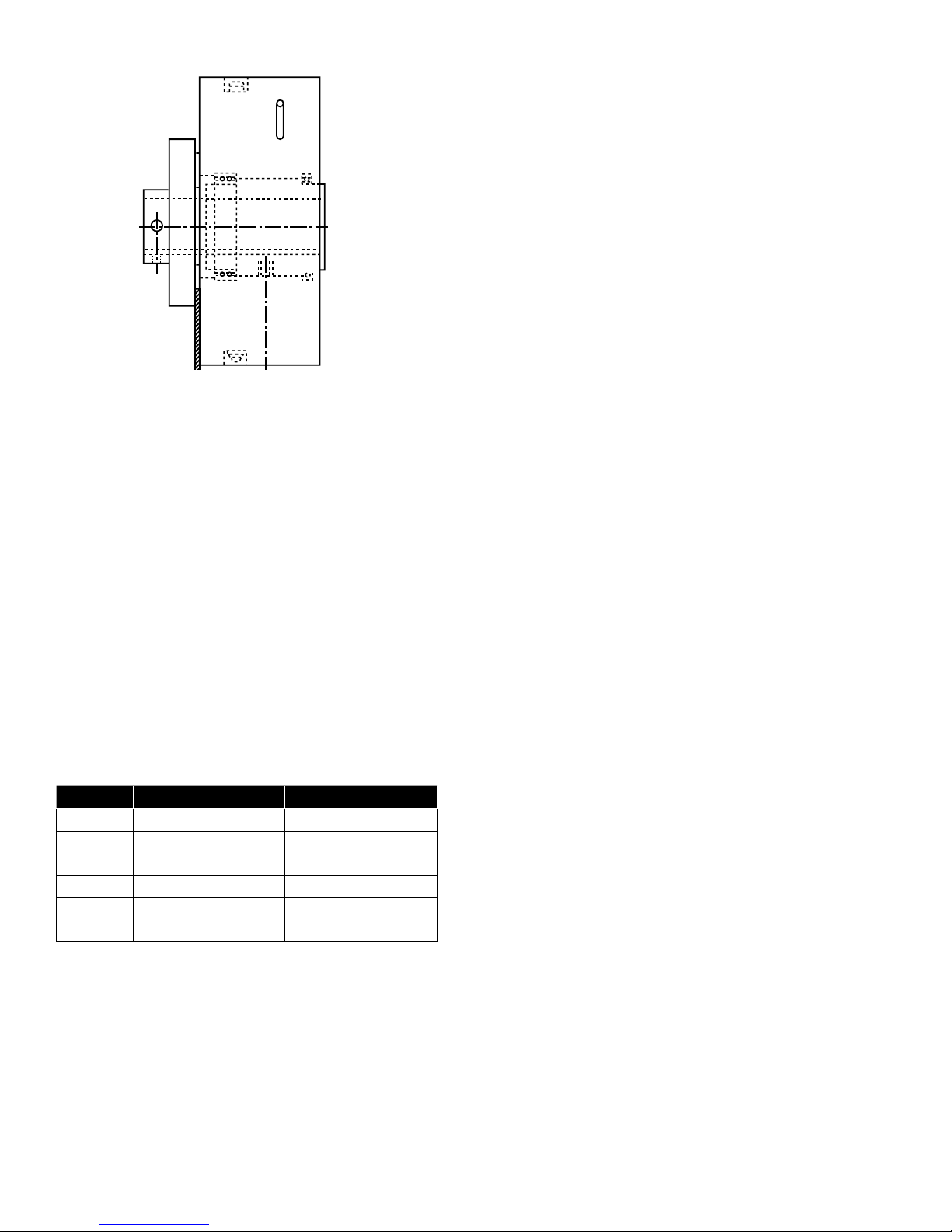

5. Parallel Alignment

a. Place a straightedge across the clutch housing

and coupling flange as shown in Figure 13.

b. Measure the offset around the periphery of these

two components without rotating the shafts.

c. If the difference in offset from any two points

180 degrees apart exceeds the maximum value

shown in Table 8, the shafts must be realigned.

Table 8 - Type “C” Misalignment

Size Maximum Allowable Misalignment

Parallel Angular

1 .012” .074”

2 .015” .091”

3 .016” .102”

4 .027” .159”

5 .031” .183”

6 .045” .231”

6. Angular Alignment

a. Measure the gap around the periphery between

the coupling flange and the clutch housing

without rotating the shafts. (See Figure 14).

b. If the difference between any two points 180

degrees apart exceeds the maximum angular

misalignment shown in Table 8, the shafts must

be realigned.

c. If a correction is required to satisfy angular

alignment requirements, then recheck the

parallel alignment.

D. Mounting the “N” Index Coupling and Type

“R” Rigid Coupling

1. After the clutch has been mounted on its shaft

as explained in Section lll, inspect mating pilots

of clutch and coupling for any nicks or burrs and

remove any that are present.

2. Inspect coupling shaft and key for any nicks or burrs

and remove any that are present.

3. In the case of a Type “R” make sure that the

coupling shaft keyway is in alignment with the clutch

shaft keyway. Position the shaft key and slide the

coupling flange onto the shaft.

4. Slide the coupling onto the clutch housing making

sure that the coupling pilot fits into the housing pilot

and that the mounting holes are aligned. In the case

of a Type “N” index coupling, make sure that the

desired mounting slots are aligned with the clutch

housing mounting holes.

5. Secure the coupling to the drive shaft by tightening

the two setscrews located in the hub of the flange.

Refer to Table 7 for recommended setscrew seating

torques.

6. Parallel Alignment

a. Place a straightedge across the clutch housing

and coupling flange as shown in Figure 13.

b. Measure the offset around the periphery of these

two components without rotating the shafts.

c. The shafts must be aligned until no offset exists

or is equal at all points around the periphery.

10 Boston Gear • 800-825-6544 P-3003-BG

Figure 14

7. Angular Alignment

a. Measure the gap around the periphery between

the coupling flange and clutch housing without

rotating the shafts. (See Figure 14)

b. The shafts must be aligned until no gap exists or

is equal at all points around the periphery.

c. If a correction is required to satisfy angular

alignment requirements, then recheck the

parallel alignment.

Note: The Type “N” and “R” coupling connection

is rigid and does not allow for forgiveness of

parallel or angular misalignment. To eliminate

unnecessary bearing loads, both shafts must be

in near perfect alignment.

Table 9 - Coupling Mounting Bolt Seating Torques

Size Bolt Size Seating Torque

1 5/16-18 160 in.lb.

2 3/8-16 280 in.lb.

3 1/2-13 700 in.lb.

4 5/8-11 1,200 in.lb.

5 5/8-11 1,200 in.lb.

6 5/8-11 1,200 in.lb.

8. Loosen the coupling setscrews and attach coupling

to clutch with hex head bolts and flat washers. Refer

to Table 9 for recommended bolt seating torques.

Secure coupling to drive shaft by tightening the

setscrews to the recommended seating torques in

Table 7.

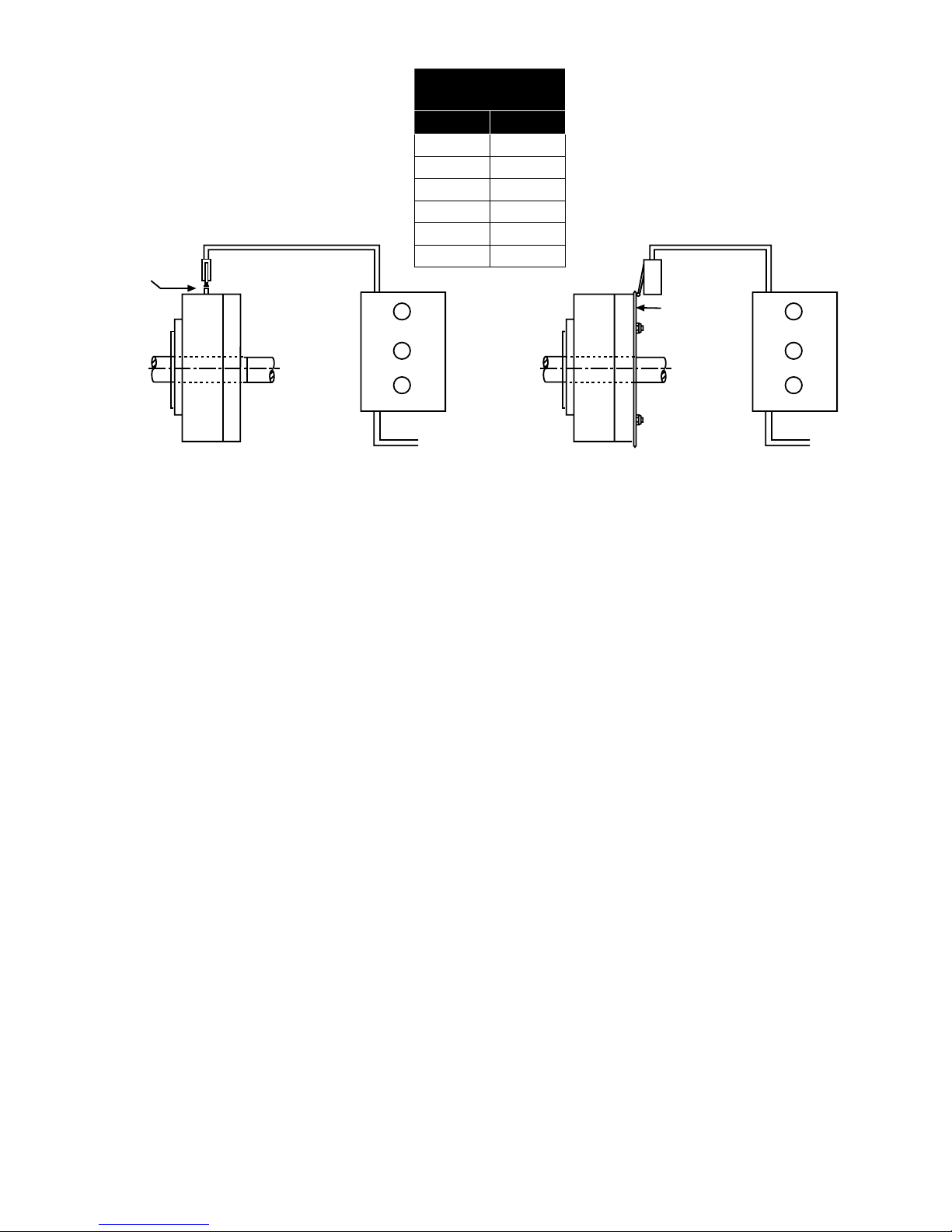

IV. Limit Switches

The ORC Series, Model S Overload Release Clutch

is available with two types of limit switch actuators,

a limit switch pin (LSAP) and a limit switch actuating

mechanism (LSAM).

A. Limit Switch Pin

A Limit Switch Pin is furnished as a standard item to

activate a limit switch that triggers the electrical controls.

The Limit Switch Pin protrudes radially from the clutch

housing and its travel is controlled by the drive pawl

motion upon disengagement. The Limit Switch Pin can

be used if the housing continues to rotate when an

overload occurs and the rotor stops, i.e, the housing

is the driver and the rotor is the driven. Housing RPM

has to be considered to determine the time for the Limit

Switch Pin to revolve around before contacting the limit

switch, see Figure 15, for Limit Switch Pin Travel.

The standard Limit Switch Pin extension is 1 inch from

the outside diameter of the clutch housing. It can also

be made flush with the surface of the housing in an

engaged position.

B. Limit Switch Actuating Mechanism

A Limit Switch Actuating Mechanism provides instant

operation of a limit switch to immediately shut down the

drive or actuate an alarm should an overload occur.

The mechanism is entirely contained in the clutch cover

and is actuated by the motion of the drive pawl. When

an overload occurs, the drive pawl motion releases the

actuating plate and it trips a limit switch. The total travel

of the plate is 5/16 of an inch. (See Figure 15)

The actuating plate must be reset by manually pushing

it back into position. The clutch must be engaged when

resetting the plate or the plate will not reset when the

clutch is disengaged.

Feeler Gage

Boston Gear • 800-825-6544 P-3003-BG 11

A limit switch should be able to operate within the plate

travel of 5/16 of an inch. The switch should be wired in

parallel with a jog circuit so that the drive can then be

indexed to the start/run circuit.

V. General Maintenance

A. Lubrication

The Overload Release Clutch is prelubricated at the

factory and is also equipped with a grease pack fitting.

For optimum performance and wear resistance it is

suggested that the clutch be lubricated with a Bentone

type, NLGI grade 0 grease. The lubrication schedule

should be in accordance with good operating practices

for the equipment on which the clutch is mounted. The

clutch is also supplied with a grease relief fitting. When

there is enough grease in the clutch any excess grease

will be extruded through the relief fitting.

B. Annual Inspection

The Overload Release Clutch is constructed of heavy

duty materials. Under reasonably clean conditions

the unit will operate with a minimum of maintenance.

A scheduled annual inspection of bearings, pawls,

rotor, springs, tripping mechanism, and other internal

components is suggested. However, the actual

frequency should be in accordance with good operating

practices for the equipment on which the clutch is

installed.

VI. Repair Instructions

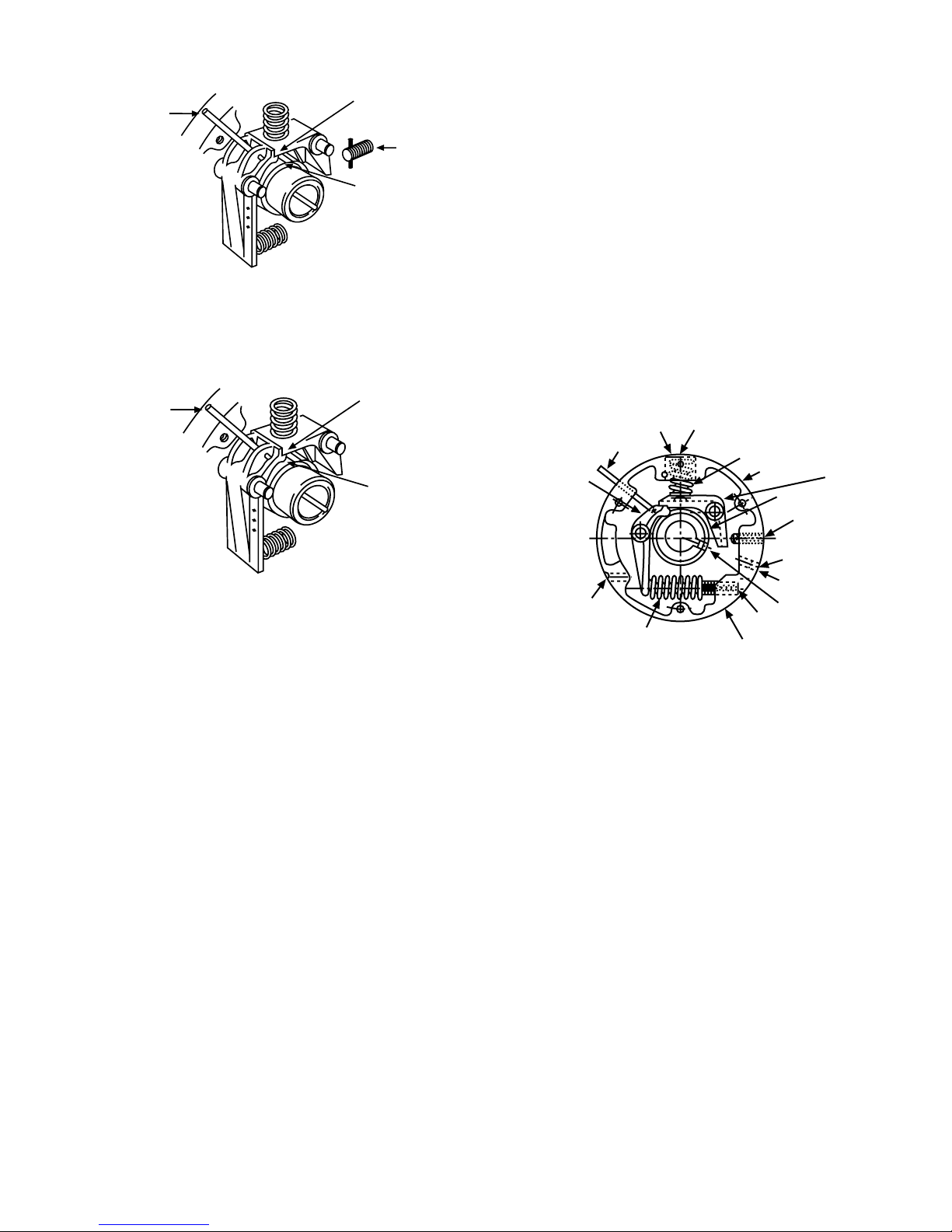

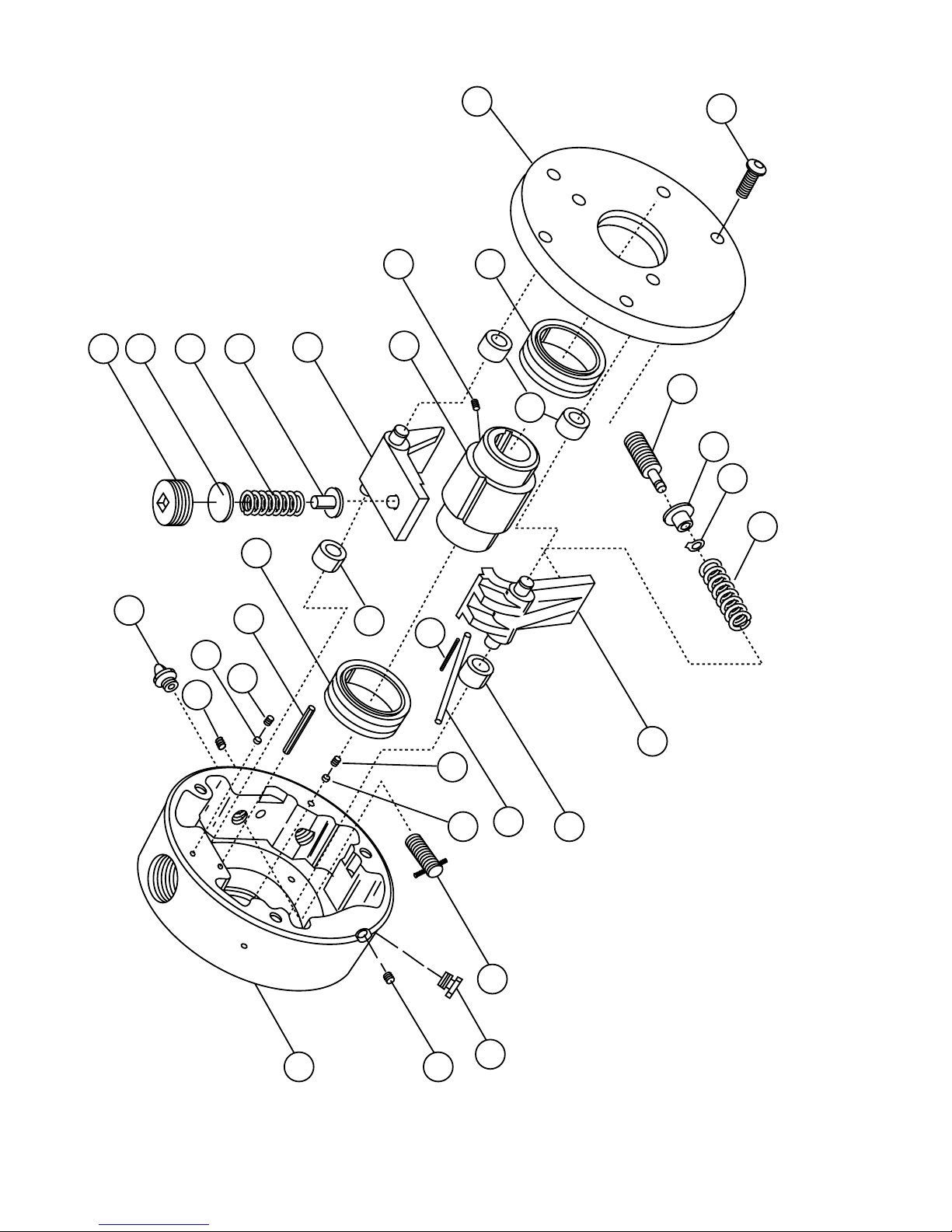

A. General Disassembly

1. All item numbers in parenthesis will refer to the key

numbers shown in the clutch exploded view drawing

and parts identification tables.

2. Place the clutch preferably in a three-jaw chuck with

the actuating plate or cover facing up.

3. There are two locking screws (25) located on the

face of the cover which lock down the reset spring

screw (14) and the drive spring screw (21). Loosen

these screws to relieve the pressure on the drive

spring screw and reset spring screw.

4. Turn the reset spring screw (14) counterclockwise to

relieve the compression on the reset spring (19).

5. Remove the sealing wax from the drive spring screw

(21) and turn the screw counterclockwise to relieve

the compression on the drive spring (18).

6. Remove the cover screws (27).

7. Pry off the cover (8). Use care not to break the inner

pilot of the cover. (See Figure 16)

8. Remove the reset screw (14) and take out the reset

spring (19), and the ball thrust (20) through the hole

stamped 9.

Limit Switch Pin

Standard

Limit

Switch

Pin

Limit

Switch

Start

Jog

Stop

To Motor

ORC

Overload

Clutch

Limit Switch Actuating Mechanism

Limit

Switch

Optional

Limit

Switch

Actuating

Mechanism

ORC

Overload

Clutch

Start

Jog

Stop

To Motor

Limit Switch Pin

Travel

Size Travel

1 .13 “

2 .13”

3 .13”

4 .13”

5 .13”

6 .25”

Figure 15 - Limit Switch Layout

12 Boston Gear • 800-825-6544 P-3003-BG

9. Remove the reset pawl (11 ) by simply lifting out.

10. Remove the drive pawl (10) and the drive spring (18).

This will require a little more effort because of the

slight pressure on the drive spring.

11. Remove the housing (1) from the mounting surface

and press out the rotor (12).

12. If clutch is manual reset, remove the reset screw (24)

by turning clockwise into the housing.

13. Inspect hardened bushings (3) in housing (1) and

cover (8) for excessive wear.

14. Replace any worn or broken parts.

B. Basic Unit Assembly

1. If clutch is manual reset, install the reset screw

(24) from the inside of the housing turning counter-

clockwise until the reset screw pin stops the screw

from turning.

2. Press the long end of rotor (12) into housing bearing

(2).

3. This step is for manual reset only. Go to next step

for automatic reset. Install the drive pawl (10) into

the appropriate hole in the housing (1), and the reset

pawl (11) into its appropriate hole in the housing.

Check the fit of the reset pawl into the notch of the

drive pawl with the clutch disengaged. The reset

pawl should fit approximately one-third of the way

into the notch. Grinding the nose of the reset pawl

may be necessary to obtain the proper fit. (See

Figure 17)

4. Remove the drive pawl (10). The drive pawl and

the drive spring (18) will have to be installed

simultaneously. If a drastic change in torque is

desired, use this step to change the drive spring.

Place one end of the drive spring over the drive

spring thrust washer (22). Insert the knob of the drive

pawl into the other end of the drive spring. Insert the

trunnion of the drive pawl into the hardened bushing

in the housing, while the nose of the drive pawl fits

into the notch of the rotor (12).

5. Coat the inside of the housing and all components

with a quality all-purpose grease. A Bentone type,

NLGI grade 0 grease or equivalent is recommended.

6. Insert the reset spring disc (15) inside the reset

spring screw (14). Apply grease to the surface of the

disc.

7. If a drastic change in torque is desired, use this step

to change the reset spring. Place the reset spring

(19) on the surface of the reset spring disc. Apply

grease to the end of the ball thrust (20) and insert

ball thrust into the reset spring.

8. Apply grease to the threads of the reset spring screw

(14) and insert the assembly of the reset spring

screw, reset spring disc (15), reset spring (19), and

ball thrust (20) through the hole stamped 9 on the

housing. Tighten the reset spring screw until it is

flush with the surface of the housing. (See Figure 17)

9. Fill the entire housing cavity with grease to ensure a

proper grease packing.

10. Press the cover on to the housing assembly. Make

sure that the trunnion holes and the cover screw

holes line up.

11. Install the cover screws and tighten to the

recommended seating torques in Table 10.

Cover

Pry Bar

Excessive Force

May Break Inner

Pilot of Cover

Pry Bar

Housing

Reset Pawl About 1/3

into Notch of Drive Pawl

Reset Screw Flush With

Surface of Housing

14

15

11

1

24

21

10

12

18

Figure 17

Figure 16

Boston Gear • 800-825-6544 P-3003-BG 13

C. Torque Verication

1. Place the clutch in a chuck or vise with the cover

facing upward.

2. Insert the appropriate size arbor and key into rotor.

(See Figure 18)

3. Turn the drive spring screw (21) clockwise until it is

flush with the surface of the housing.

4. The clutch is supplied with a torque selector dial.

The torque selector dial is the mill marks located at

the hole stamped 9 on the housing. If a drive spring

(18), reset spring (19), and/or a reset spring screw

(14) were replaced, chances are that the stamped

torque values on the dial are no longer valid. It may

be necessary to grind the old numbers off and to

stamp new ones.

5. Tighten the reset spring screw (14) until it reaches

the limit stop pin (4). This will be the maximum

torque position. If the maximum torque is not

desired, tighten the reset spring screw to one of the

locations on the torque selector dial.

6. Disengage the clutch with a torque wrench. Fine

tune the torque by turning the drive spring screw

(21) until the desired release torque is obtained.

7. Refer to Section I, C for further details on torque

adjustment.

8. Once the desired release torque is obtained, tighten

the locking screws (25) located over the drive spring

and reset spring screws to ensure that they will not

move. The unit is now ready for installation. Refer to

Section lll for installation of basic clutch.

Table 10 - Cover Screw Seating Torques

Clutch

Size Screw Size Quantity Seating

Torque

1 1/4-20 3 100 in.lb.

2 5/16-18 3 200 in.lb.

3 3/8-16 3 350 in.lb.

4 1/2-13 4 850 in.lb.

5 5/8-11 4 1,700 in.lb.

6 5/8-11 4 1,700 in.lb.

Figure 18

D. Limit Switch Actuating Mechanism (LSAM)

Assembly

1. Apply a graphite lubricant to the release ring groove

of the cover (8).

2. Insert the actuating stud (40) through the appropriate

hole in the release ring (35). To identify this hole

place the release ring in the groove of the cover.

When the trip pin holes line up with the through

holes of the cover, the actuating stud hole will line

up with the counterbored hole in the groove of the

cover.

3. Install the actuating stud nut (39) onto the actuating

stud (40) and tighten.

4. Install a spring terminal (43) on each end of the

return spring (38). Clutch sizes 5 & 6 require two

return springs.

5. Insert a spring terminal screw (41) through the hole

of the spring terminal (43), and place a spacer collar

(36) on the end of the screw. Insert the end of the

screw into the threaded hole of the release ring (35)

and tighten. The end of the screw may protrude past

the release ring. Grind the end of the screw flush

with the surface of the release ring. Install second

spring terminal screw on clutch sizes 5 & 6 as just

described. Move to Step 13 for clutch sizes 5 & 6.

6. Press the trip pins (32) into the trip plate (31).

7. Install a bowed snap ring (34) into the groove of

each trip pin located next to the trip plate.

8. Place the trip plate flat on a table with counterbored

holes facing up. Insert the thrust springs (37) into the

counterbores.

Torque Wrench

Arbor

Trig-O-Matic Clutch

Vice or Chuck Jaws

14 Boston Gear • 800-825-6544 P-3003-BG

9. Place the cover (8) over the trip plate, lining up the

counterbores in the cover with the springs.

10. Place the release ring (35) into the groove of the

cover. Make sure that all of the holes line up properly.

11. Insert a spring terminal screw (41) through the hole

of the other spring terminal (43) and place a spacer

collar (36) on the end of the screw. Insert the end

of the screw into the tapped hole of the cover and

tighten.

12. Push down on the cover and release ring until the

release ring engages into the grooves of the trip

pins. Install two snap rings (33) into the grooves of

each trip pin. Move to Step 22.

13. Place the release ring (35) into the groove of the

cover. Make sure that all of the holes are properly

aligned.

14. Insert the trip pins (32) through the matching holes

in the release ring (35) and cover (8). Make sure that

the tapped hole of the trip pin is inserted first.

15. Slide the release ring (35) counterclockwise so that

the ring engages into the grooves of the trip pins.

16. Insert a spring terminal screw (41) through the other

spring terminal (43) and place a spacer collar (36)

on the end of the screw. Insert the screw into the

tapped hole in the cover and tighten. Repeat this

process for the other return spring .

17. Turn the cover over so that the release ring is facing

down against the surface of the table.

18. Insert the thrust springs (37) into the counterbores of

the cover.

19. Place the trip plate (31) over the cover making sure

that the springs will sit in the counterbores of the trip

plate and that all the holes properly line up.

20. Press down on the trip plate (31) until it stops

against the trip pins.

21. While pressing down on the trip plate (31) insert the

plate mounting screws (42) into the tapped holes of

the trip pins and tighten.

22. Press the cover assembly onto the housing

assembly (1). Make sure that the trunnion holes and

the mounting screw holes line up.

23. Install the cover screws (27) and tighten to the

recommended seating torques shown in Table 10.

Boston Gear • 800-825-6544 P-3003-BG 15

NOTES

3

1

5

724

26 25

16

3

10

17

3

2

4

25

26

5

6

14

15

19

20

11

12 13

98

27

18

23

22

21

16 Boston Gear • 800-825-6544 P-3003-BG

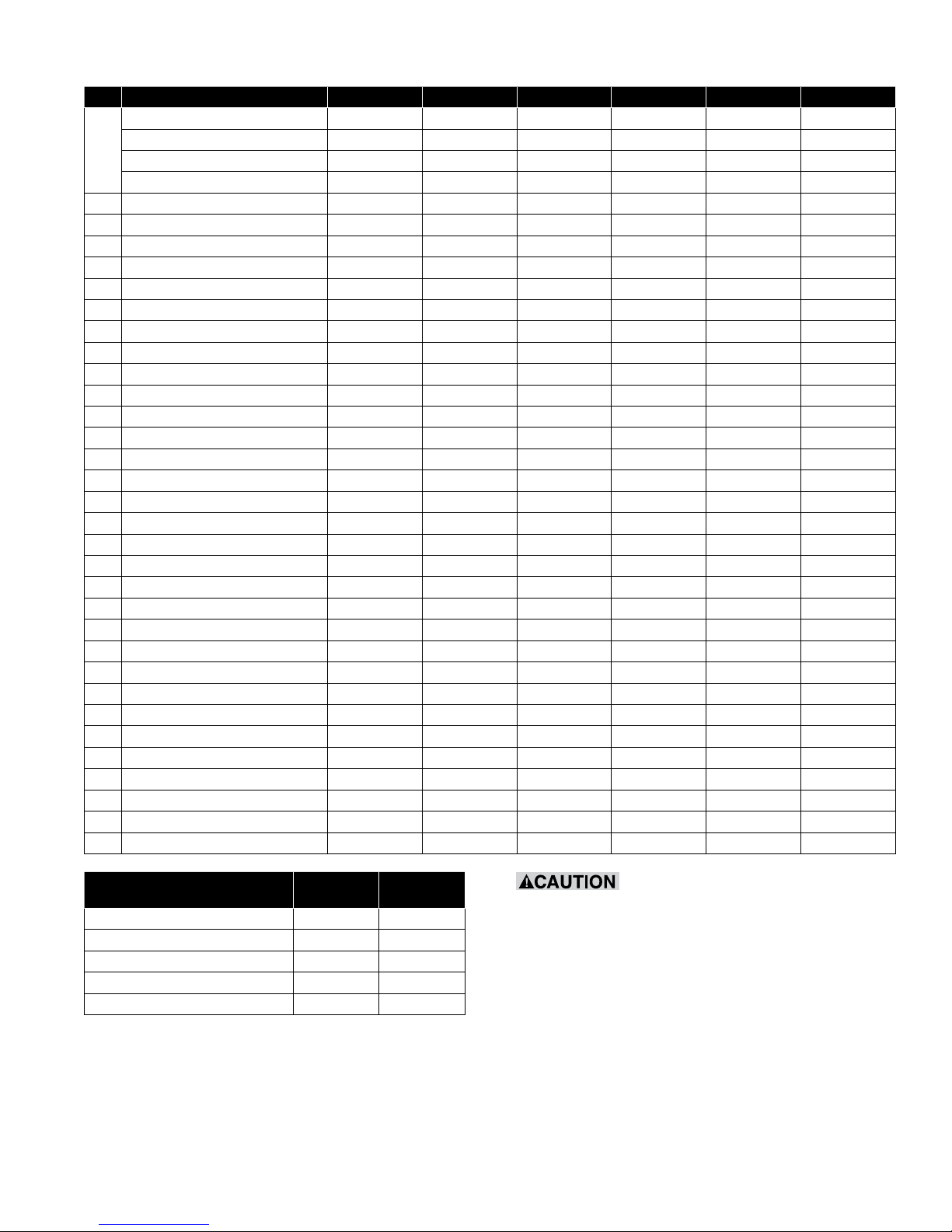

ORC Series, Model S with Limit Switch Pin (LSAP) Types SA & SM

Boston Gear • 800-825-6544 P-3003-BG 17

Part Identication - Model S with Limit Switch Pin (LSAP) Types SA & SM

Key No. Name Size 1 (Qty.) Size 2 (Qty.) Size 3 (Qty.) Size 4 (Qty.) Size 5 (Qty.) Size 6 (Qty.)

*1

T Housing Ass’y., or 711257-XXX (1) 711148-XXX (1) 711180-XXX (1) 711223-XXX (1) 711238-XXX (1) 711266-XXX (1)

B Housing Ass’y.,or 711258-XXX (1) 711149-XXX (1) 711181-XXX (1) 711224-XXX (1) 711239-XXX (1) 711267-XXX (1)

C Housing Ass’y.,or 711259-XXX (1) 711150-XXX (1) 711182-XXX (1) 711225-XXX (1) 711240-XXX(1) 711268-XXX (1)

N/R Housing Ass’y, 711260-XXX (1) 711151-XXX (1) 711183-XXX (1) 711226-XXX (1) O/A O/A

2 Housing Bearing 039273-041 (1) 039273-043 (1) 039273-044 (2) 039273-038 (1) 711900-006 (1) 711900-008 (1)

3 Hardened Bushing — 730634-002 (2) 730634-003 (2) 730634-004 (2) 730634-005 (2) —

4 Limit Stop Pin 730422-001 (1) 730422-001 (1) 730422-002 (1) 730422-002 (1) 730422-003 (1) 730422-003 (1)

5 Access Screws 040940-031 (2) 040940-042 (2) 074102-003 (2) 074102-078 (2) 074102-078 (2) 040940-078 (2)

6 Grease Fitting 034186-029 (1) 034186-029 (1) 034186-029 (1) 034186-029 (1) 034186-029 (1) 034186-029 (1)

7 Relief Fitting 034186-028 (1) 034186-028 (1) 034186-028 (1) 034186-028 (1) 034186-028 (1) 034186-028 (1)

8 Cover Ass’y 711261-001 (1) 711146-001 (1) 711185-001 (1) 711219-001 (1) 711242-001 (1) 711269-001 (1)

9 Cover Bearing 039273-040 (1) 039273-042 (1) 039273-045 (1) 039273-038 (1) 711900-005 (1) 711900-007 (1)

3 Hardened Bushing — 730634-002 (2) 730634-003 (2) 730634-004 (2) 730634-005 (2) —

10 Drive Pawl 730429-001 (1) 730430-001 (1) 730431-001 (1) 730432-001 (1) 730433-001 (1) 730434-001 (1)

*11 Reset Pawl 730367-XXX (1) 730368-XXX (1) 730369-XXX (1) 730370-XXX (1) 730371-XXX (1) 730372-XXX(1)

**12 Rotor Assembly 710354-001 (1) 710354-002 (1) 710354-003 (1) 710354-004 (1) 710354-005 (1) 710354-006 (1)

13 Rotor Setscrew 043243-012 (1) 043243-022 (1) 043243-041 (1) ** (1) 043243-058 (1) 043243-058 (1)

14 Reset Spring Screw 730382-001 (1) 730382-002 (1) 730382-003 (1) 730382-004 (1) 730382-005 (1) 730382-006 (1)

15 Reset Spring Disc 730383-001 (1) 730383-002 (1) 730383-003 (1) 730383-004 (1) 730383-005 (1) 730383-006 (1)

16 LSAP Assembly 710355-001 (1) 710355-002 (1) 710355-003 (1) 710355-004 (1) 710355-005 (1) 710355-006 (1)

17 Roll Pin 040942-044 (1) 040942-044 (1) 040942-045 (1) 040942-045 (1) 040942-046 (1) 040942-045 (1)

18 Drive Spring - Low Torque Range (L) 730385-001 (1) 730385-007 (1) 730385-014 (1) 730385-020 (1) 730385-026 (1) 730385-032 (1)

19 Reset Spring - Low Torque Range (L) 730385-005 (1) 730385-011 (1) 730385-018 (1) 730385-024 (1) 730385-030 (1) 730385-035 (1)

18 Drive Spring - Medium Torque Range (M) 730385-001 (1) 730385-007 (1) 730385-015 (1) 730385-020 (1) 730385-026 (1) 730385-032 (1)

19 Reset Spring - Medium Torque Range (M) 730385-006 (1) 730385-012 (1) 730385-019 (1) 730385-025 (1) 730385-031 (1) 730385-036 (1)

18 Drive Spring - High Torque Range (H) 730385-001 (1) 730385-009 (1) 730385-015 (1) 730385-021 (1) 730385-027 (1) 730385-033 (1)

19 Reset Spring - High Torque Range (H) 730385-006 (1) 730385-013 (1) 730385-019 (1) 730385-025 (1) 730385-031 (1) 730385-037 (1)

20 Ball Thrust — 730386-001 (1) 730386-002 (1) 730386-003 (1) 730387-001 (2) 730387-002 (2)

21 Drive Spring Screw 730379-001 (1) 730379-002 (1) 730379-003 (1) 730379-003 (1) 730380-001 (1) 730381-001 (1)

22 Drive Spring Washer 730388-001 (1) 730388-002 (1) 730388-003 (1) 730388-003 (1) 730388-004 (1) 730388-005 (1)

23 Snap Ring — 040682-029 (1) 040682-030 (1) 040682-030 (1) 040682-030 (1) 040682-031 (1)

24 Reset Screw Ass’y. 710356-001 (1) 710356-002 (1) 710356-003 (1) 710356-004 (1) 710356-005 (1) 710356-006 (1)

25 Locking Screw 074102-015 (2) 074102-015 (2) 074102-031 (2) 074102-031 (2) 074102-027 (2) 074102-027 (2)

26 Locking Insert 730389-001 (2) 730389-001 (2) 730389-002 (2) 730389-002 (2) 730389-003 (2) 730389-003 (2)

27 Cover Screw 041315-048 (3) 041315-062 (3) 041315-077 (3) 041315-106 (4) 041315-121 (4) 041315-021 (4)

* Dash Numbers Are:

SA/SB/SC

Automatic

SM/SP/SS

Manual

T Housing Ass’y. -001 -002

B Housing Ass’y. -001 -002

C Housing Ass’y. -001 -002

N/R Housing Ass’y. -001 -002

Reset Pawl -001 -003

**Dependent upon bore—consult the factory.

Note: Please include clutch catalog number when ordering any spare

parts.

Rotating equipment is potentially

dangerous and could cause injury or damage if not

properly protected. Follow all applicable codes and

regulations.

In accordance with our established policy

to constantly improve our products, the

specications contained herein are subject

to change without notice.

18 Boston Gear • 800-825-6544 P-3003-BG

ORC Series, Model S with Limit Switch Actuation Mechanism (LSAM) Types SB, SC, SP & SS

Boston Gear • 800-825-6544 P-3003-BG 19

Part Identication - Model S with Limit Switch Actuating Mechanism (LSAM)

Types SB, SC, SP & SS

Key No. Name Size 1 (Qty.) Size 2 (Qty.) Size 3 (Qty.) Size 4 (Qty.) Size 5 (Qty.) Size 6 (Qty.)

8 Cover Ass’y. (LSAM) 711262-001 (1) 711187-001 (1) 711108-001 (1) 710766-001 (1) 711190-001 (1) 711270-001 (1)

9 Cover Bearing 039273-040 (1) 039273-042 (1) 039273-045 (1) 039273-038 (1) 711900-005 (1) 711900-007 (1)

3 Hardened Bushing — 730634-002 (2) 730634-003 (2) 730634-004 (2) 730634-005 (2) —

10 Drive Pawl (LSAM) 710290-001 (1) 710291-001 (1) 710292-001 (1) 710293-001 (1) 710294-001 (1) 710295-001 (1)

28 Actuating Spring 730414-001 (1) 730415-001 (1) 730416-001 (1) 730417-001 (1) 730418-001 (1) 730419-001 (1)

29 Adjustment Screw 018006-004 (1) 018006-017 (1) 018006-047 (1) 018006-047 (1) 018006-047 (1) 018006-047 (1)

30 Mount. Rivet/Screw 730420-001 (2) 730420-001 (2) 730420-002 (2) 730420-002 (2) 730420-002 (2) 074110-018 (2)

Plate Ass’y (SB/SP), 710204-001 (1) 710205-001 (1) 710206-001 (1) 710207-001 (1) — —

Plate Ass’y (SC/SS) 710204-002 (1) 710205-002 (1) 710206-002 (1) 710207-002 (1) — —

31 Plate (SB/SP), or 730397-001 (1) 730398-001 (1) 730399-001 (1) 730400-001 (1) 730401-001 (1) 730402-001 (1)

Plate (SC/SS) 730397-002 (1) 730398-002 (1) 730399-002 (1) 730400-002 (1) 730401-002 (1) 730402-002 (1)

32 Trip Pin 730403-001 (3) 730404-001 (3) 730405-001 (3) 730406-001 (4) 730407-001 (4) 730408-001 (4)

33 Snap Ring 040682-035 (6) 040682-035 (6) 040682-036 (6) 040682-030 (8) — —

34 Bowed Snap Ring 040682-032 (3) 040682-032 (3) 040682-033 (3) 040682-034 (4) — —

35 Release Ring 730391-001 (1) 730392-001 (1) 730393-001 (1) 730394-001 (1) 730395-001 (1) 730396-001 (1)

36 Spacer Collar 730409-001 (2) 730409-002 (2) 730409-002 (2) 730409-002 (2) 730409-002 (4) 730409-002 (4)

37 Thrust Spring 730410-001 (3) 730410-002 (3) 730410-002 (3) 730410-002 (4) 730410-002 (4) 730410-003 (4)

38 Return Spring 730411-002 (1) 730411-001 (1) 730411-002 (1) 730411-001 (1) 730411-002 (2) 730411-001 (2)

39 Actuating Stud Nut 730412-001 (1) 730412-002 (1) 730412-003 (1) 730412-004 (1) 730412-004 (1) 730412-004 (1)

40 Actuating Stud 074111-126 (1) 074111-126 (1) 730413-001 (1) 730413-002 (1) 730413-002 (1) 730413-002 (1)

41 Terminal Screw 074110-003 (2) 074110-017 (2) 074110-017 (2) 074110-017 (2) 074110-017 (4) 074110-017 (4)

42 Plate Mount. Screw — — — — 730561-001 (4) 730561-002 (4)

43 Spring Terminal 730421-001 (2) 730421-002 (2) 730421-002 (2) 730421-002 (2) 730421-002 (4) 730421-002(4)

C Coupling Ass’y. 710296-001 (1) 710297-001 (1) 710298-001 (1) 710299-001 (1) O/A O/A

Coupling Bushing 730275-001 (3) 730275-002 (3) 730275-003 (4) 730275-004 (4) — —

Setscrew 040940 041 (2) 040940-003 (2) 040940-003 (2) 040940-067 (2) — —

Coupling Pin 730278-001 (3) 730278-002 (3) 730278-003 (4) 730278-004 (4) — —

N/R Coupling Ass’y. 710301-001 (1) 710302-001 (1) 710303-001 (1) 710334-001 (1) O/A O/A

Mounting Screw 074118-062 (3) 074118-077 (3) 074118-093 (4) 074118-110 (4) — —

Flat Washer 074117-004 (3) 074117-006 (3) 074117-009 (4) 074117-013 (4) — —

Setscrew 040940-041 (2) 040940-003 (2) 040940-003 (2) 040940-067 (2) — —

Note: Please include clutch catalog number when ordering any spare parts.

ORC Model S Series Part Numbering System

C3 SA L9 P16 800

Type

T– Sprocket Mount

C– Flexible Coupling

N– Indexing Coupling

R– Rigid Coupling

Torque Range

L– Light

M– Medium

H– Heavy

(Specify

Torque Setting)

L9 – Light

M9 – Medium

H9 – Heavy

Model

SA – Standard Model, Fully

Automatic Reset with Pin

Actuator

SB – Standard Model, Semi-

Automatic Reset with

Plate Actuator

SC – Standard Model, Semi-

Automatic Reset with

reduced diameter Plate

Actuator

SM – Standard Model, Manual

Reset with Pin Actuator

SP – Standard Model, Manual

Reset with Plate Actuator

SS – Standard Model, Manual

Reset with reduced

diameter Plate Actuator

P20ORC 50A28

Series

Overload

Release

Clutch

Unit Bore

P– Bored to Size (in 1/16")

M– Metric Bored to Size

(mm)

Example: P 20 = 1-1/4 bore

Coupling Bore

(Type C, N, or R Only)

Blank–Non-Coupled Units

P– Bored to Size (in 1/16")

M– Metric Bored to Size (mm)

Example: P 20 = 1-1/4 bore

-B1SBK

Clutch Material/Paint

(Cast Iron)

Blank–Standard Paint

BK – White BostKleen Paint

SBK – Stainless BostKleen

Paint

Size

1

2

3

4

5

6

Sprocket Options

Blank–No Sprocket

Included

50A28

50 – Chain Size

A– Sprocket Type

28 – Number of Teeth

See catalog for

available options

Torque Setting

Set point within the torque range

Blank–Standard torque range with clutch

set at the minimum value

Special Options

T# – Special Feautures Contact Boston Gear Engineering

B1 – Ball Bearings for High Speed

Applications (sizes 1-4 only)

L1 – Pressure Lubed Bearings (Sizes 3-6 Only)

S1 – Static Balance

Z1 – Pin Removed on “SA” and “SM” Models Only

www.bostongear.com

701 Carrier Drive

Charlotte, NC 28216

704-588-5610

Warranty

Boston Gear warrants that products manufactured or sold by it shall be free from defects in material and

workmanship. Any products which shall within two (2) years of delivery, be proved to the Company’s satisfaction

to have been defective at the time of delivery in these respects will be replaced or repaired by the Company at its

option. Freight is the responsibility of the customer. The Company’s liability under this limited warranty is limited

to such replacement or repair and it shall not be held liable in any form of action for direct or consequential

damages to property or person. THE FOREGOING LIMITED WARRANTY IS EXPRESSLY MADE IN LIEU OF

ALL OTHER WARRANTIES WHATSOEVER, EXPRESS, IMPLIED AND STATUTORY AND INCLUDING WITHOUT

LIMITATION THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS.

No employee, agent, distributor, or other person is authorized to give additional warranties on behalf of Boston

Gear, nor to assume for Boston Gear any other liability in connection with any of its products, except an officer of

Boston Gear by a signed writing.

P-3003-BG 9/18

Table of contents

Other Boston gear Microphone System manuals