BOTTARO WEIGHING SYSTEMS MB01 User manual

FILENAME : mb01 rev.4 rel 1.16 - I -

MB01 Terminal

Instructions

Industrial weighing system

- Grassobbio -

- II -

FILENAME : mb01 rev.4 rel 1.16

This publication may contain information with typographic errors. Corrections will be included in new editions of

the publication.

Edition dated 23/02/2015- Rev. “3”

-

3

-

FILENAME : mb01 rev.4 rel 1.16

1. INTRODUCTION 2

1.1

UNINTENDED USES 2

1.2

SAFETY 3

1.3

CARE AND MAINTENANCE 3

2. TESTING AND INSTALLATION 4

2.1

Testing and storage 4

3. INTRODUCTION 5

3.1

Description 5

3.2

Technical specifications 6

3.3

Preliminary Operations 7

4. OPERATIONAL CONTROLS - INSTRUCTIONS 8

4.1

General information 8

4.2

Front panel 8

4.3

LED indicators 9

4.4

List of selectable functions 10

4.5

Key functions in normal mode 10

5. USING THE TERMINAL 11

5.1

Message on startup 11

5.2

Weighing operations 12

5.2.1

Zeroing device 12

5.2.2

Acquiring tare weight 12

5.2.3

Setting a pre-determined tare weight 13

5.2.4

Deleting a tare weight 13

5.2.5

Setpoint setup 13

5.2.6

Setting the clock 13

5.2.7

Deleting printouts from memory 13

5.2.8

Printing 13

5.2.9

Weighing and printing in WEIGH-BRIDGE mode 14

5.2.10

WEIGH-BRIDGE mode printing diagram 16

5.2.11

Weighing and single printing in BENCH SCALE mode 17

5.2.12

Weighing and totals printing in BENCH SCALE mode 18

5.2.13

BENCH SCALE mode printing diagram 19

5.2.14

Setpoint setup 20

5.2.15

Operating logic Error. The bookmark is not defined.

5.2.15

Setpoint setup diagram 22

5.2.16

Setting the clock 23

5.2.17

Deleting printouts from memory 24

5.2.18

Displaying 1/10 e 24

5.2.19

Multi-division function (MD) 25

5.2.20

Multiple range weighing function (MR) 26

6. INTERFACES 27

6.1

Maxidisplay repeater device 27

6.1.1

Maxidisplay cable connection 27

6.1.2

Transmission string format 27

6.2

TM 295 Cable connection 28

6.3

TM 295 printer programming 28

6.4

KUBE 200 Cable connection 29

6.5

KUBE 200 printer programming 29

6.6

DP 24 Cable connection 30

6.7

DP 24 printer programming 30

Table of Contents

-

5

-

FILENAME : mb01 rev.4 rel 1.16

INDEX OF SOME TERMS USED IN THE MANUAL FOR EASIER CONSULTATION:

e

=

minimum verification division

Max

=

maximum instrument capacity

Min

=

minimum capacity

n

=

number of divisions

Load receiver device

=

scale or structure

Absolute zero

=

instrument zero calibration (+/- 1/4 e )

Instrument

=

computerized device

Sample weight

=

mass to be used as a reference for calibration

G

=

gross weight

N

=

net weight

T

=

tare weight

PT

=

Pre-set tare weight

MD

=

abbreviation for "multi-division"

MR

=

abbreviation for "multiple range weighing"

Baud rate

=

serial channel transmission speed

Frame

=

transmission format

Lights

=

indicators (e.g., LED)

etc

=

etcetera

g

=

grams

kg

=

kilograms

g1

=

gravitational acceleration at the location where the instrument is

installed

g2

=

gravitational acceleration at the location where the instrument was

calibrated

s###

=

minute second

ms

=

thousandth of a second

=

note, important information or procedure

=

attention, information or procedure that, if not followed exactly, could

cause death or severe personal injury

=

mains socket

=

not approved function

Terminology

-

6

-

FILENAME : mb01 rev.4 rel 1.16

The purpose of the manual is to inform the operator of the fundamental criteria and indications for installation and correct use of the

instrument using illustrations and guided examples.

The equipment must be installed only by specialized personnel who must have read and learned the contents of this manual.

"Specialized personnel" refers to those individuals with training and professional experience

who have been expressly authorized by the Plant safety supervisor to install, use and maintain

the terminal.

During the design phase, particular care was given in order to be able to use the instrument according to European Standards,

fulfilling the requirements set forth in L.D. 29.12.1992 no. 517 that was modified with Legislative Decree no. 40 dated February 24,

1997. It is the user's responsibility to make sure that installation is compliant with the legislation mentioned above.

The installer shall be responsible for parametrizing and calibrating it according to the specific needs while strictly following the

indications above.

Tampering with the devices and use of the equipment by untrained individuals is forbidden. For

this purpose, the manual must be consulted and followed whenever operating on the installation

parameters.

In the event of any anomalies, contact your authorized service centre.

The information and illustrations below are updated as of the edition date shown on the cover. The technical information in this

manual is the exclusive property of the manufacturer and therefore it is forbidden to make copies or share the information contained

herein without the manufacturer's written authorization.

The edition date and document number identify the correspondence between the manual and the firmware installed.

According to its corporate quality policy, the manufacturer is committed to continuous improvement of its products. This could lead to

changes in system components without compromising its metrological characteristics.

If there is a difference between what is described in this manual and your equipment, contact your authorized service centre.

Unless otherwise agreed upon during the order process, the terminal or complete system you received must not operate on moving

machines or installations as it may not be possible to ensure weighing precision as specified in EN45501.

Anything not expressly described in this manual is to be considered improper use of the equipment.

Any attempt to tamper with the legal constraint points or change the programming parameters

related to the weight data and primary indications by the user or unauthorized personnel will

automatically void the warranty and will release the manufacturer of all liability regarding any

injuries or damage.

1.1 UNINTENDED USES

1. INTRODUCTION

-

7

-

FILENAME : mb01 rev.4 rel 1.16

1.2 SAFETY

The voltage is high enough to be life-threatening.

Maintenance and repairs done on electrical and electronic parts must only be performed by

qualified technicians, after having adopted suitable safety measures.

Strictly follow the electrical rating plate on the appliance. If it is missing or illegible, request it from your authorized service centre.

Tampering with the devices and use of the equipment by untrained individuals is forbidden. For this purpose, the manual must be

consulted and followed whenever using or maintaining the terminal.

The power supply for the equipment is single phase, from 230V + 10% - 15% and must be provided with an effective earth, making sure that

the equipotential earth is compliant with current regulations. Make sure there is not potential difference between the earth and neutral.

Failure to earth the equipment is an incorrect and dangerous use of the instrument.

The electrical supply line must be dedicated. If already existing, use the computer power line. When there is no stable line,

install a sine wave UPS or mains stabilizer.

If the terminal must be connected to other devices such as computers, etc. before hooking it up, unplug them from power.

The safety instructions contained in this manual are not intended to exclude other situations or

conditions that could be hazardous. Therefore, common sense, attention and caution are

important factors which cannot be made part of the machine and therefore must be followed by

the authorised person who uses it and performs maintenance on it.

If the system must be installed in areas where there is a risk of explosion, this must be indicated

in the order specifications. The standard equipment is not set up to operate in areas with a

potentially explosive atmosphere.

Before cleaning, the device must be unplugged from the mains.

Do not use harsh products (such as solvents). Use a cloth with detergent. Avoid liquid infiltrations

in the instrument. Dry with a soft cloth.

If the operating safety of the device is no longer assured, immediately shut it off, unplug it from the mains, store it in a safe place and contact

your authorized service centre. This could occur in the following situations:

The device shows visible signs of damage or tampering.

There is a visually obvious malfunction.

The device was stored for a long time in unsuitable conditions.

1.3 CARE AND MAINTENANCE

-

8

-

FILENAME : mb01 rev.4 rel 1.16

Each instrument produced and inspected is subjected to testing in order to ensure a functioning product with long life and, if provided,

legalized by an official from the Notified Body.

Upon receipt of the instrument, check for any damage that may have occurred during transport.

Carefully unpack the instrument. Keep the original packaging for any later transport or movement.

Store the instrument on a flat, solid and protected surface where there are no extreme changes in temperature and humidity and where

it is safe from possible tampering by unauthorized personnel.

Do not stack objects on it.

Caution is recommended when handling the instrument.

Store the instruments as they were received. Do not stack pallets or any other type of object on it.

2.1 Testing and storage

2. TESTING AND INSTALLATION

-

9

-

FILENAME : mb01 rev.4 rel 1.16

The instrument is an analogue to digital converter for loading cells built especially for an industrial environment.

Therefore its features allow operation in harsh conditions.

The instrument satisfies the requirements in International Recommendation EN45501.

For greater safety, the instrument is equipped with automatic tests and a diagnostics program that gives

the type of error.

It comes with either a table, wall or rack container. The control panel is splash proof with tactile sensation keys.

The visor is highly visible. Some information is highlighted with separate lighted indicators.

It is equipped with EMI/RFI radio frequency filters and optical isolation to ensure operation in harsh

environments.

The specific part of analogue / digital conversion is controlled with an integrated single - chip, suitably interfaced to

the microcontroller.

The type of conversion used is cascaded DELTA SIGMA modulation (2 channel). All gain adjustment and

zero filter functions are digitally controlled.

All electronic boards and instrument components ensure high quality.

It can be connected to any OIML R60 certified loading cell and is approved for single scale operation.

The instrument can be used individually or combined with other industrial equipment for various uses, some of

which are described below:

-

Weighing road and rail vehicles

-

Detecting weights within production lines

-

Weighing various products with different bench scale solutions (at floor level or elevated)

-

Weighing in automatic loading and/or dosing systems.

-

Weighing suspended loads (aerial weighing in the food industry, etc.)

-

Determination of mass for calculating a toll, fee, tax, bonus, penalty, remuneration, indemnity or similar

compensation, to determine price based on weight for direct sale to the public and for determining other factors

such as the quantity, parameters and characteristics related to mass.

-

Combination with data acquisition systems and computers

-

Management of coordination devices for weighing operations

-

Network connections for data transfer

-

Handling systems

-

With devices for automating the scale operation through automatic material handling.

3.1 Description

3. Introduction

-

10

-

FILENAME : mb01 rev.4 rel 1.16

hardware characteristics:

-

Display LCD 16 x 2 lines

-

20 key keyboard

-

RS232/485 serial channel on the CPU board

-

3 24 Volt setpoint outputs

-

3 inputs (selectable remote keys)

-

calendar clock

software characteristics:

-

Dual phase calibration management

-

Control of 1 RS232 printing device (TM295 / KUBE 200/DP24)

-

Control of 1 RS485 TX continuous device for repeater

-

Memory capacity up to a max. of 200 weights

-

Vehicle printing operation

ENTRY PRINTOUT (PRINT + YES) EXIT

PRINTOUT (PRINT + NO + YES)

PRINTOUT WITH TARE (PRINT + YES)

-

Sequential Ticket number deletion

3.2 Technical specifications

-

11

-

FILENAME : mb01 rev.4 rel 1.16

1-

Perform a new scale calibration

2-

Program the scale specifications (Max W., div, decimals, unit of measure) 3-

Set date and time

a.

Required at first startup

4-

Select the fields you wish to print

a.

F7 function key at terminal startup

5-

Set the connection characteristics for serial 1,2

a.

Setup machine menu "SERIAL"

6-

Weighing and printing operation

a.

Set the material on the scale

b.

Press the PRINT button to activate the vehicle weighing procedure

c.

Press the YES button to perform the entry printout

d.

Press the NO key to perform the exit printout after having recalled the num. from memory

7-

Setting the setpoints

a.

Press the PROG key

b.

Press the YES key to enter setpoint 1

c.

Press the key.

3.3 Preliminary operations

-

12

-

FILENAME : mb01 rev.4 rel 1.16

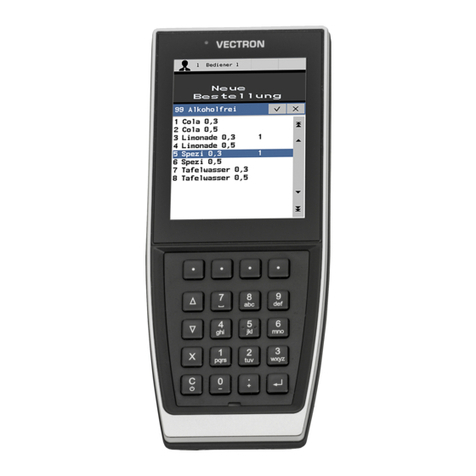

This chapter describes the control operations that can be performed using the keys on the front panel

Figure 1 shows the front panel of the instrument. The references along with the following description give

a complete view of the possible commands.

Fig. 1 - Front display

4.2 Front panel

4.1 General information

4. Operational controls - instructions

-

13

-

FILENAME : mb01 rev.4 rel 1.16

1: Stable

This is on when the stable indication conditions are met as per parameters P06 and P07.

2: Central zero

This is lit in the interval around zero from -1/4 e to+1/4 e.

3: Min min

This is lit when the gross weight is negative or between 0 and 20 ereduced to 5 in applications for determining

a transport fee.

4: Non metrological data symbol

When lit, the data shown is not bound to metric verification.

4.3 LED indicators

-

10

-

FILENAME : mb01 rev.4 rel 1.16

....... and during normal operation (pressing the two keys together)

Keys

Description of function performed

=

Displaying 1/10 e

Yes

=

Confirm the item displayed

No

=

Exit from the item displayed

ZERO

=

Scale zeroing

T

=

Tare acquisition

T

=

Setting known tare

PROG

=

Programming setpoint/clock/print deletion

Print

=

print

On/off

=

Display on/off

=

lock tare weight

=

unlock tare weight

0……9

=

Recall saved tare

Weighing scale zeroing key.

Key for setting the weight on the scale as the tare weight.

When this key is pressed, the tare weight must be set using the number keypad.

The indicator will show the net weight in the top line and the set tare weight in the bottom row.

Accesses the setup for the three setpoint values or, by pressing NO, to the date and time setup.

If the WEIGH-BRIDGE function is enabled, it accesses the entry printout or, when NO is pressed, the exit

printout.

If the BENCH SCALE function is enabled, when the key is pressed the weight detected at that moment is

printed.

Accesses the setup for the three setpoint values or, by pressing NO, to the date and time setup.

Keys from 0....9 - tare point memorization

Print Key - data printing (weigh-bridge/bench

scale)

Prog Key - programming setpoint/clock

T Key - setting the tare

T key - Tare acquisition

Zero Key - Zeroing device

4.5 Key functions in normal mode

4.4 List of selectable functions

-

11

-

FILENAME : mb01 rev.4 rel 1.16

When the terminal is started, the display test is performed and for about two seconds the following is

displayed:

The software version and the use ZONE will be displayed (for about two seconds).

The date and time in the machine memory will then be shown

The work screen will then be shown where the 2 lines usually display the following fields:

Line 1 shows N XXXXXXX and the unit of measure where N stands for net

Line 2 shows T XXXXXXX and the unit of measure where T stands for tare. The

following is an example:

N

T

2.100 kg

0

kg

08/08/2005

17:20:30

ZONE A

BOTTARO SYSTEM

…………

5.1 Message on startup

5. Using the terminal

-

12

-

FILENAME : mb01 rev.4 rel 1.16

The following are the usual terminal weighing and use operations.

Pressing the ZEROkey for two seconds will zero out the weight indicator with a precision of 0.25 e. When

the key is pressed, the gross weight displayed will be acquired as the new zero value as long as the following

conditions are met for 1 second:

a)

stable indication

b)

gross weight less than 2% (subsequent zeroing) of the F.S. around the calibration zero point. If out-of-

range, the display will flash for 3 seconds.

c)

no tare device is in operation

Please Note: if the requirements mentioned above are not met, NO ZERO will be displayed. The zero

value acquired will not be saved in the event of a power outage.

Place the tare that must be acquired on the scale and wait until the value stabilizes.

When the T key is pressed, the gross weight displayed will be acquired as the tare weight as

long as the following conditions are met for 1 second:

a)

the indication must be stable

b)

the value must be greater than or equal to 1 e.

c)

the value must be positive

d)

the value must be less than the F.S.

e)

the preset tare device must not be in operation.

If points b, dand eare not met, the "Tare no" error message is displayed. When the weight is unloaded

the weight removed will be shown with the minus sign

Please Note: the tare value acquired will not be saved in the event of a power outage.

With the multiple range weighing (MR) function, upon automatic switching to the higher weight range, the

tare division value will be compared automatically to the division related to the range obtained.

5.2.2 Tare acquisition

5.2.1 Zeroing device

5.2 Weighing operations

-

13

-

FILENAME : mb01 rev.4 rel 1.16

During operation, a known tare weight can be set, which will then be shown on the second line of the display.

The function is not accepted if:

a) an automatic tare device is already active

b) the value is greater than or equal to the F.S.

Press the Tkey and set the tare weight using the numeric keypad then confirm with the Yes key.

If points aand bare not followed, the display will automatically return to the standard mode

If a value is set that is not in line with the division of the instrument, the tare value is automatically rounded to

the correct division.

If a known tare has been set using key T, or acquired using key

T , the value can be deleted as follows: Press the T key.

The second line on the display will show

N

2,100 kg

T

>

0 kg

Confirm with Yes and the display will return to weighing mode and the tare will be deleted.

Press the Progkey to access the setpoint output setup (description in paragraph 6.2.11).

Press the Progkey to access the date and time setting (see paragraph 5.2.16)

Press the Progkey to delete the weights in the memory (see paragraph 5.2.17)

When Printis pressed, the machine can print in two different modes: 1

WEIGH-BRIDGE mode (see paragraph 5.2.9)

BENCH SCALE mode (see paragraph 5.2.11)

5.2.8 Printing

5.2.7 Deleting printouts from memory

5.2.6 Setting the clock

5.2.5 Setpoint setup

5.2.4 Deleting a tare weight

5.2.3 Setting a pre-determined tare weight

-

14

-

FILENAME : mb01 rev.4 rel 1.16

Press the PRINTkey when all the following conditions have been met:

stable and positive weight

net weight > 0

The display will show the message ENTRY PRINTOUT ?. When the YES key is pressed the machine will print the

weight of the entering vehicle. The printout will include the following data:

-

entry weight date

-

entry weight time

-

memory no. for recall upon exit

-

weight detected

Printout example:

Date

Time

Seq. no.

12-10-00

5:45

Memory no.

Entry weight

3

27940

kg

Note: The memory number is assigned automatically when the entry printout is performed and is deleted

automatically with the exit printout, therefore this number will increase each time a vehicle enters and, until the

exit printout is performed, the number will be occupied and not usable even in the event of a power outage

(maximum 200).

Please Note: This function is enabled in the internal programming of the

instrument and can only be changed by authorized personnel.

For more information call the help centre.

5.2.9 Weighing and printing in WEIGH-BRIDGE mode

-

15

-

FILENAME : mb01 rev.4 rel 1.16

Press the PRINTkey when all the following conditions have been met:

stable and positive weight

net weight > 0

the display will show the message ENTRY PRINTOUT ?. when the NO key is pressed the machine will switch

automatically to EXIT PRINTOUT?. When confirmed with the YES key the MB01 will show the message

Memory No. ?. At this point you will need to use the numeric keypad to enter the entry printout memory no.

(previously printed on the ticket) and then confirm with Yes. The machine will then printout the exiting vehicle

weight with the following data:

-

exit weight date

-

exit weight time

-

memory no. recalled upon exit

-

weight detected

-

the difference between the entry weight and exit weight

-

the sequential weighing number

Printout example:

Date

Time

Seq. no.

1

Memory no.

Entry weight

Date

Exit weight

12-10-00

27940

kg

Time

Entry weight

15:30

10000

kg

Memory no.

Net weight

3

17940

kg

Please Note: In the EXIT PRINTOUT phase, it is important to recall the exact

memory number because once it is confirmed and printed it will be

automatically deleted from the memory and can no longer be used!!!

-

16

-

FILENAME : mb01 rev.4 rel 1.16

PRINT

ENTRY PRINTOUT?

NO

YES

Perform the entry

printout

EXIT PRINTOUT?

Memory No.?

NO

YES

Exit the program

YES

Perform the exit

printout

Enter the

memory number

5.2.10 WEIGH-BRIDGE mode printing diagram

Table of contents