BouMatic Robotics MR-S1 User manual

Service Manual

Original Service Manual

Version 1.7

23 June 2015

BouMatic Robotics B.V.

Transportweg 6

8304 AX Emmeloord

The Netherlands

Telephone: +31 527 788 500

Fax: +31 527 788 599

URL: www.boumaticrobotics.com

Copyright © 2015, BouMatic Robotics B.V., Emmeloord

All rights reserved.

No part of this publication may be reproduced, transmitted, transcribed, stored in a retrieval

system, in any form or by any means, electronically, mechanical, photocopying, recording or

otherwise, without the prior written consent of BouMatic Robotics B.V.This also goes for the

matching drawings, photo’s and diagrams.

BouMatic Robotics B.V.reserves the right to make changes to parts on every moment, without

prior notice to the customer. The contents of this manual can also be changed without prior

warning. For information concerning adjusting, maintenance or repair in which the manual does not

provide, you will be asked to contact the technical department of your supplier.

This manual is compiled with all possible care, but BouMatic Robotics B.V. cannot take

responsibility for possible mistakes in this manual or for the consequences there from.

Service Manual

Revision page

23 June 2015 Version 1.7 Page i

REVISION PAGE

Version 1.0

First book

Version 1.2

Other BRI pictures with new features.

TREATMENT option deleted.

Description WAITING ROOM report.

Description CALENDAR report.

GATE IN / GATE OUT settings.

Version 1.3

Renewed BRI application

Added appendices:

Appendix A: Numbers in viewers

Appendix B: Wear parts

Appendix C: Consumables

Version 1.4

New photos

Adjusted specifications

Moved to User’s manual:

Checking cow box gates

Checking vacuum pressure

Checking air pressure

Checking sprayer tank pressure

Replacing milk hoses

Lubricating robotic arm guides

Lubricating feeding trough guides

Updated Part III –Teaching Milking Box

Service Manual

Revision page

Page ii Version 1.7 23 June 2015

Version 1.5

Waiting room is now selection room

Version 1.6

Added Closing Bri application

Added Camera calibration

New maintenance schedule

Version 1.7

Other pictures emergency stops

New safety symbols

Added photos with position new safety symbols

Two post treatment sprayers on attachtool

New stickers for operating switches

Other picture teach pendant

Other pretreatment cup

Other milking cups

Added Spray robot setting

Added Double filter setting

Service Manual

Table of Contents

23 June 2015 Version 1.7 Page iii

TABLE OF CONTENTS

Foreword ------------------------------------------------------------------------------v

I GENERAL INFORMATION

1. Product information ------------------------------------------------------- 1-1

2. Safety---------------------------------------------------------------------- 2-1

3. Transport, storage, dismantling and disposal---------------------------- 3-1

II OPERATIONS FROM BRI

4. General information ------------------------------------------------------- 4-1

5. Operating box ------------------------------------------------------------- 5-1

6. Managing cows ------------------------------------------------------------ 6-1

7. Consulting attentions and reports ---------------------------------------- 7-1

8. Setting system ------------------------------------------------------------ 8-1

9. Operating milking box parts manually ----------------------------------- 9-1

10. Controlling system -------------------------------------------------------10-1

11. Setting stations-----------------------------------------------------------11-1

III TEACHING MILKING BOX

12. Teach pendant------------------------------------------------------------12-1

13. Calibrating Camera-------------------------------------------------------13-1

14. Teaching cup positions ---------------------------------------------------14-1

15. Teaching teat positions --------------------------------------------------15-1

IV CONNECTION AND COMMUNICATION OVERVIEW

16. Connection----------------------------------------------------------------16-1

17. Communication-----------------------------------------------------------17-1

Service Manual

Table of Contents

Page iv Version 1.7 23 June 2015

V MAINTENANCE

18. General information ------------------------------------------------------18-1

19. Service: Commissioning, 1, 2, 3, 4, 5, 6, 7 and 8----------------------19-1

20. Service: Continuation 2, 4, 6 and 8 -------------------------------------20-1

21. Service: Continuation 3 and 7 -------------------------------------------21-1

22. Service: Continuation 4 and 8 -------------------------------------------22-1

23. Service: Continuation 5 --------------------------------------------------23-1

24. Service: Continuation 1 --------------------------------------------------24-1

25. Every service -------------------------------------------------------------25-1

VI APPENDICES

26. Appendix A: Numbers in viewers ----------------------------------------26-1

27. Appendix B: Wearing parts ----------------------------------------------27-1

28. Appendix C: Consumables -----------------------------------------------28-1

VII INDEX

Service Manual

Foreword

23 June 2015 Version 1.7 Page v

FOREWORD

Target

This training guide gives instructions regarding

the operation and maintenance of the milking box

Target group

This guide is intended for service technicians that

perform maintenance and repair on the milking

box.

Knowledge and

experience level

Only qualified technicians are allowed to perform

service and repairs.

Contents of this manual

Table 1-1 shows an overview of the chapters in

this manual.

Table 1-1 Contents manual

PART

TITLE

DESCRIPTION

I

General information

Gives information about the requirements

demanded of the user. Technical properties and

safety aspects of the milking box are also shown

here.

II

Operations from

BRI

Describes how to use the BRI application to set

the milking box.

III

Teaching Milking

box

Describes how to teach the cup and teat

positions, using the teach pendant.

IV

Connection and

communication

overview

Describes the connection and communication

settings.

V

Maintenance

Describes maintenance instructions of the milking

box and robot, to be performed by a service

technician.

Suggestions for

improvement

Any suggestions for the improvement of this

manual are welcome.

See section 1.2 for contact details.

General information

Overview

23 June 2015 Version 1.7 Part I

IGENERAL INFORMATION

1. Product information ------------------------------------------------------- 1-1

1.1. Technical properties ---------------------------------------------- 1-1

1.2. Contact details ---------------------------------------------------- 1-2

2. Safety---------------------------------------------------------------------- 2-1

2.1. Emergency stop--------------------------------------------------- 2-1

2.2. Entrance door ----------------------------------------------------- 2-3

2.3. Safety regulations while using milking box ---------------------- 2-4

2.4. Safety regulations during maintenance-------------------------- 2-6

2.5. Safety symbols---------------------------------------------------- 2-8

2.6. Position of safety symbols on the milking box------------------2-10

3. Transport, storage, dismantling and disposal---------------------------- 3-1

3.1. Transport precautions -------------------------------------------- 3-1

3.2. Hoisting ----------------------------------------------------------- 3-2

3.3. Storage------------------------------------------------------------ 3-4

3.4. Dismantling and disposal ----------------------------------------- 3-4

General information

Product information

23 June 2015 Version 1.7 Page 1-1

1. PRODUCT INFORMATION

1.1. Technical properties

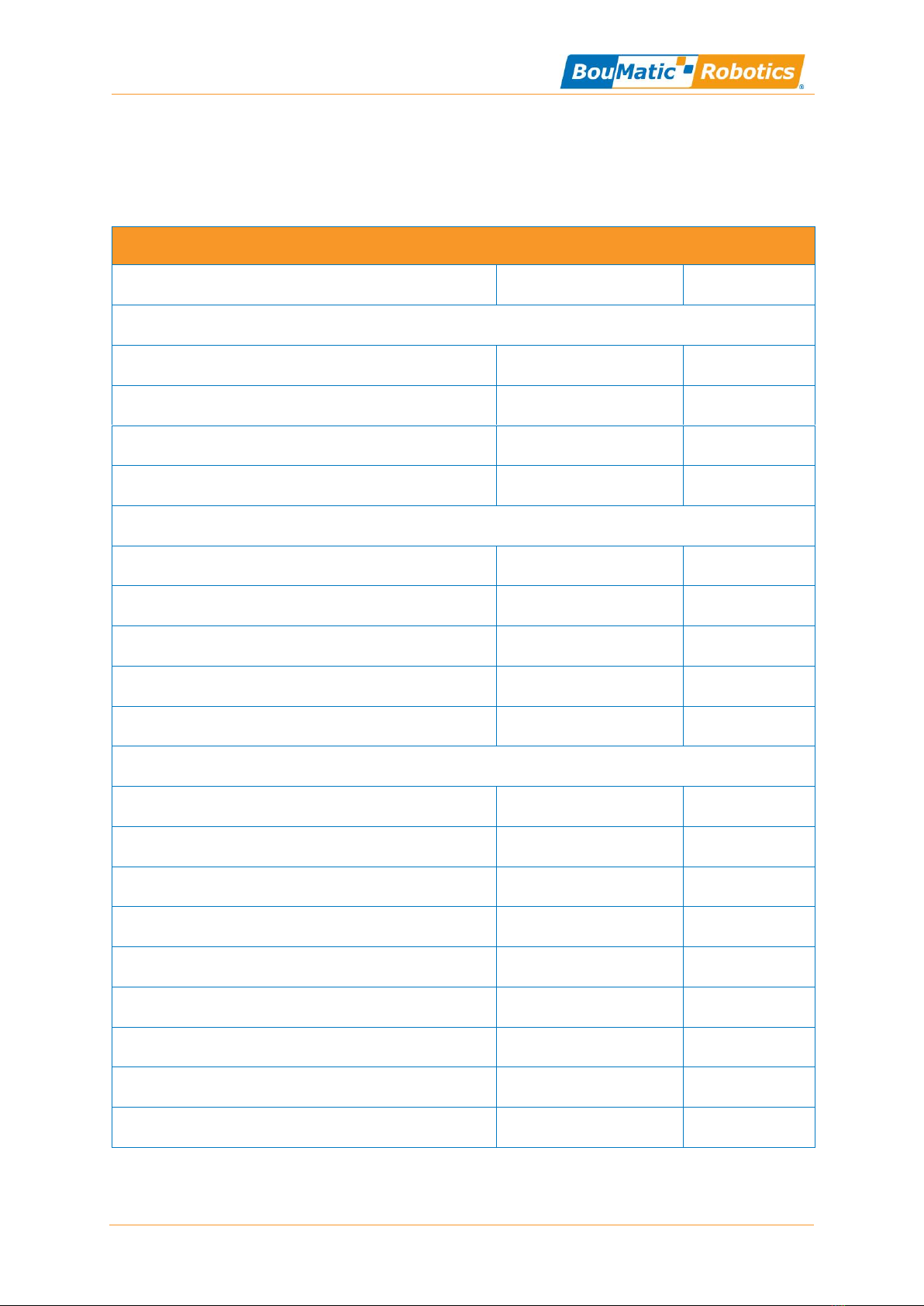

Table 1-1 Specifications

TYPE: MR-S1

UNIT

VALUE

DIMENSIONS

Height

[mm]

2400

Length

[mm]

5450

Width

[mm]

2200

Netto weight

[kg]

2600

ELECTRICITY

Net connection

[V], 3LNPE

400

Frequency

[Hz]

50

Max. power

[kW]

11

Max. current

[A]

22

IP

55

GENERAL

Loudness during production

[dB(A)]

70

Ambient temperature in use or by storage

[ºC]

+5 till +35

Network connection

[Mbit/s]

100/1000

Air filtration

[μm]

40

Air pressure

[Bar]

6

Air flow

[l/min]

150

Connection to drinking water

[l/min]

18

Water pressure

[bar]

2,5

Max. water hardness

dH / fH

4-8 / 7-15

General information

Product information

Page 1-2 Version 1.7 23 June 2015

1.2. Contact details

Manufacturer

BouMatic Robotics B.V.

Address

Transportweg 6

8304 AX Emmeloord

The Netherlands

Phone

+31 (0) 527 78 85 00

Fax

+31 (0) 527 78 85 99

E-mail

info@boumaticrobotics.com

URL

www.boumaticrobotics.com

General information

Safety

23 June 2015 Version 1.7 Page 2-1

2. SAFETY

Introduction

In this chapter you find information on all safety

aspects.

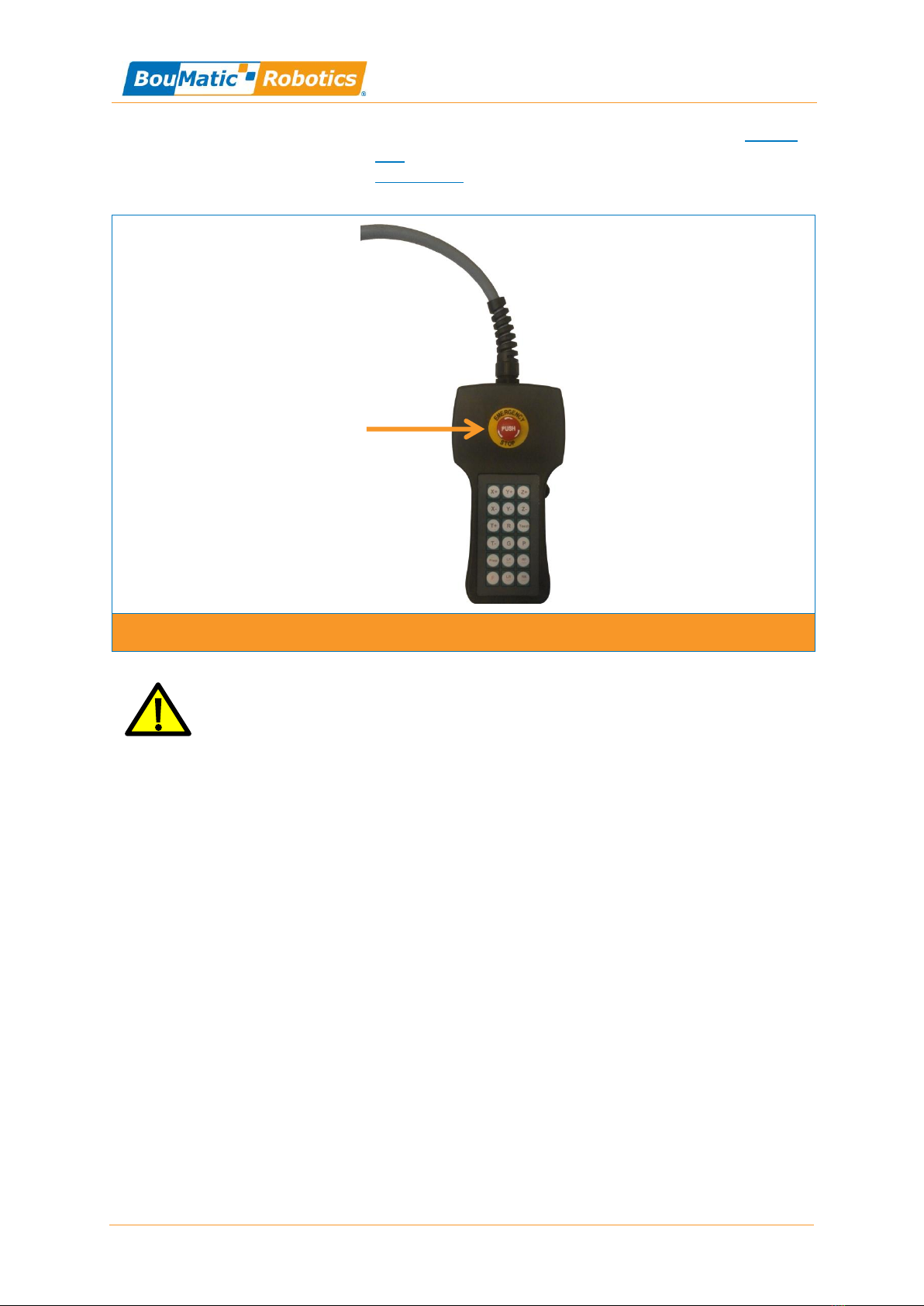

2.1. Emergency stop

Description

The milking box has two emergency stop buttons

(see Figure 2-1), to stop the milking box in case

of emergencies.

Figure 2-1 Emergency stop buttons

Emergency stop button

on milking box

One emergency stop button (1) (see Figure 2-1)

is located on the outside (1) (see Figure 2-2) of

the milking box below the touch screen at the

entrance door to the robot area.

Figure 2-2 Emergency stop button on milking box

1

2

1

General information

Safety

Page 2-2 Version 1.7 23 June 2015

Emergency stop button

on teach pendant

The other emergency stop button (2) (see Figure

2-1) is located on the teach pendant (1) (see

Figure 2-3).

Figure 2-3 Emergency stop button on teach pendant

Use the emergency stop ONLY in emergencies

and NOT as an off switch.

Meaning emergency

An emergency is understood as:

When someone is exposed to potential injury

due to their proximity to the milking box.

Technical problems with milking box parts,

whereby this can potentially lead to damage

to these and others parts.

Effect using emergency

stop button

If you use the emergency stop button, the

hydraulic will remove from the system. This will

result in moving the robotic arm vertically

downwards to its lowest position.

You can move the robotic arm manually with

your hands.

You can remove a teat cup from the gripper

and/or hang the teat cups with the

corresponding buttons on the teach pendant.

1

General information

Safety

23 June 2015 Version 1.7 Page 2-3

2.2. Entrance door

Description

The technical area is secured by an entrance door

to prevent that someone enters the area when

the robot is working. A safety switch (1) (see

Figure 2-4) in the entrance door ensures that the

milking box is switched off, as soon as someone

opens the entrance door.

Figure 2-4 Entrance door

Additional information

Table 2-1 shows an overview of sections with

additional information on the entrance door.

Table 2-1 Additional information

LOCATION

DESCRIPTION

User’s manual

Starting after opening entrance door

1

General information

Safety

Page 2-4 Version 1.7 23 June 2015

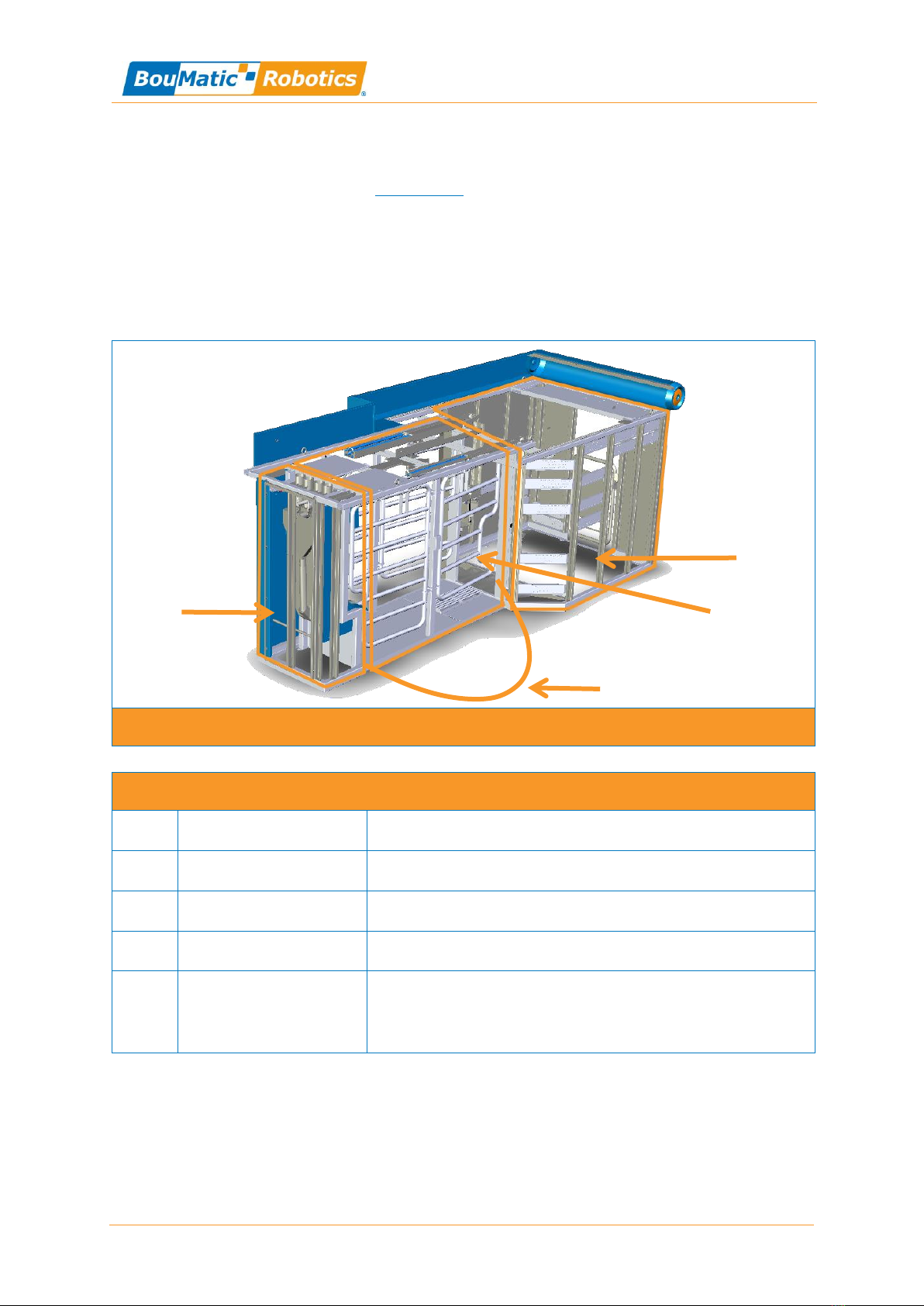

2.3. Safety regulations while using milking box

Unsafe areas

Figure 2-5 shows the unsafe areas of the milking

box, especially in AUTOMATIC operating mode.

You should always switch the milking box in

MANUAL or SERVICE operating mode, when you

enter one of these areas.

Never stay longer than necessary in these areas.

Figure 2-5 Unsafe areas

Table 2-2 Unsafe areas

NO.

COMPONENT

DESCRIPTION

1

Gates

Open automatically (left and right side).

2

Feeding trough

Moves automatically.

3

Cow tracker

Moves automatically.

4

Technical area

Contains the robotic arm, which makes

unexpected movements in AUTOMATIC control

mode.

3

4

2

1

General information

Safety

23 June 2015 Version 1.7 Page 2-5

Milking box users

The milking box and robot should only be

operated by trained and qualified personnel.

Unauthorized persons

Do not permit any unauthorized personnel,

children and animals in the neighbourhood of the

milking box, especially when the entrance door to

the technical area is open.

Cows

Your cows can panic or become stressed by noise

and movements in the milking box during

automatic milking. By panic or stress they can

wound themselves.

So give cows enough time to be familiarised with

the milking box.

Floor milking box

Always ensure that the floor is clean, to prevent

it becomes slippery.

General information

Safety

Page 2-6 Version 1.7 23 June 2015

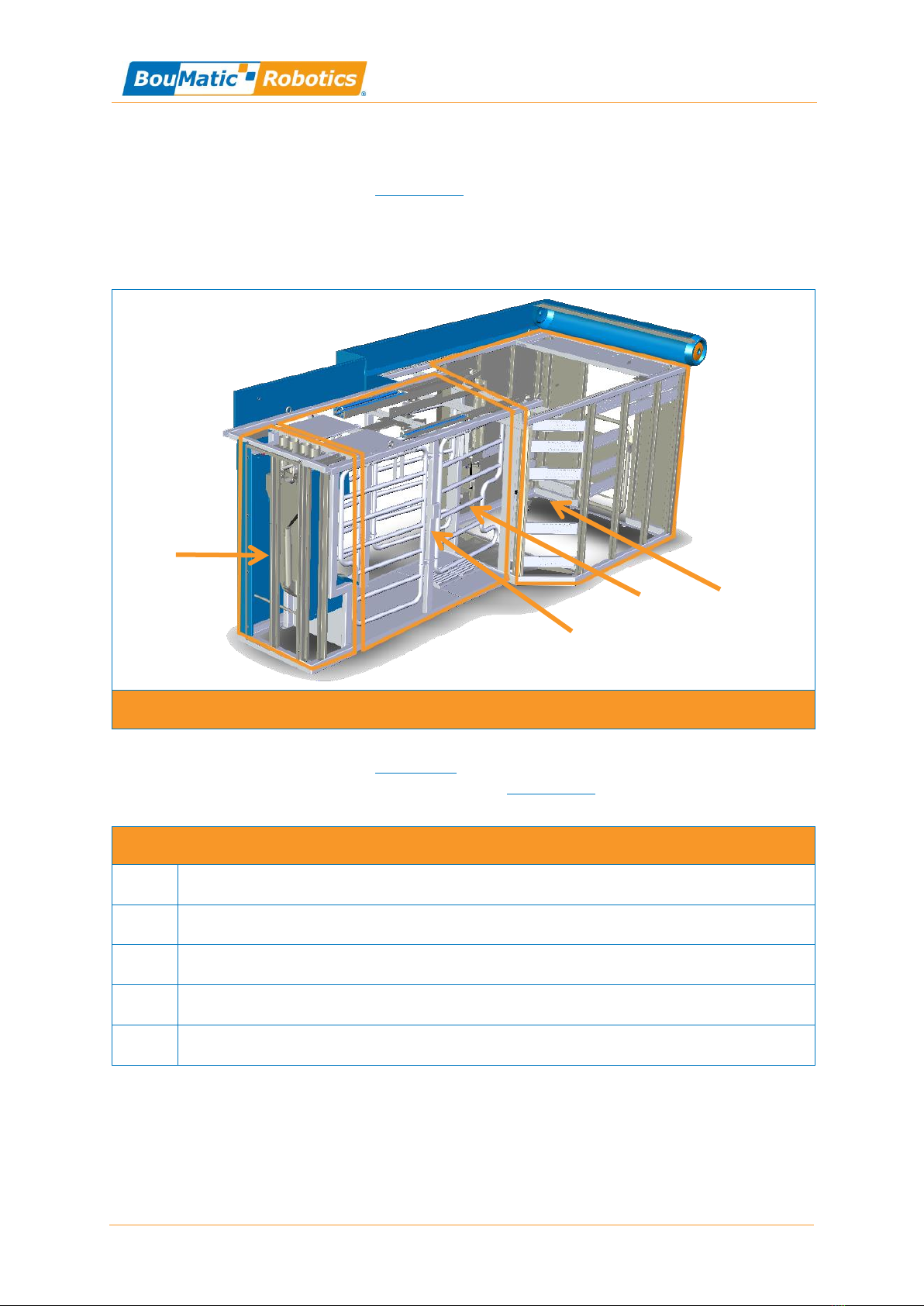

2.4. Safety regulations during maintenance

Risk of getting wedged

Figure 2-6 shows the areas with a severe risk of

getting wedged. Always make sure that the

entrance door of the technical area is open when

you are in the proximity of these areas.

Figure 2-6 Risk of getting wedged

Description components

Table 2-3 shows an overview of the numbered

components in Figure 2-6.

Table 2-3 Risk of getting wedged

NO.

DESCRIPTION

1

Between feeding trough and machine frame.

2

Between entrance / exit gates.

3

Between robotic arm and teat cup storage.

4

Between cow tracker and teat cup storage.

1

2

3

4

General information

Safety

23 June 2015 Version 1.7 Page 2-7

Maintenance scheme

Because of correct functioning and lifespan of

your milking box, it is very important to follow

the maintenance scheme (also see section 18.4)

of the milking box.

Periodic maintenance

Periodic maintenance is essential for the safety

for human and animals, who come into contact

with the milking box.

Service technician

The periodic maintenance of your milking box

should always be performed by trained and

qualified service technicians.

Service control mode

Ensure the milking box is switched to SERVICE

control mode during maintenance.

General information

Safety

Page 2-8 Version 1.7 23 June 2015

2.5. Safety symbols

Description

The milking box has different symbols to warn

users for dangers. It is very important to take

notice of these symbols and not to remove them

from the milking box.

Description symbols

Below you find an overview and a description of

the symbols that are present on the milking box.

1. BEWARE: high temperature.

2. BEWARE: high voltage.

3. Prohibited for unauthorized persons.

4. Read the manual for more information on

hoisting.

Displays the total weight of the milking box.

This manual suits for next models

1

Table of contents

Popular Farm Equipment manuals by other brands

Harvest TEC

Harvest TEC 795BBHD installation manual

Rain-Flo Irrigation

Rain-Flo Irrigation 1670 operating manual

Harvest TEC

Harvest TEC 300RB installation manual

Westeel

Westeel Bin on Hopper Pea Installation and Storage Instructions

Dairy Tech

Dairy Tech Perfect Udder 10G owner's manual

FENDT

FENDT 8380 P Operator's manual