TARAL ASTRON 7014 User manual

TSE-EN-ISO 9001:2000

KBK-520-2005703-2

Yayýn Tarihi: 01.05.2004

Revizyon Tarihi: 01.03.2007

7014 / 7020 ASTRON

Tanýtma ve Kullanma Kýlavuzu

Owner’s Manual

MOTORLU SIRT ATOMÝZÖRÜ

KNAPSACK MISTBLOWER

‘’FARMERS FRIENDLY’’

BU KILAVUZU DÝKKATLÝCE OKUYUNUZ !

PLEASE READ THIS MANUAL THOROUGHLY!

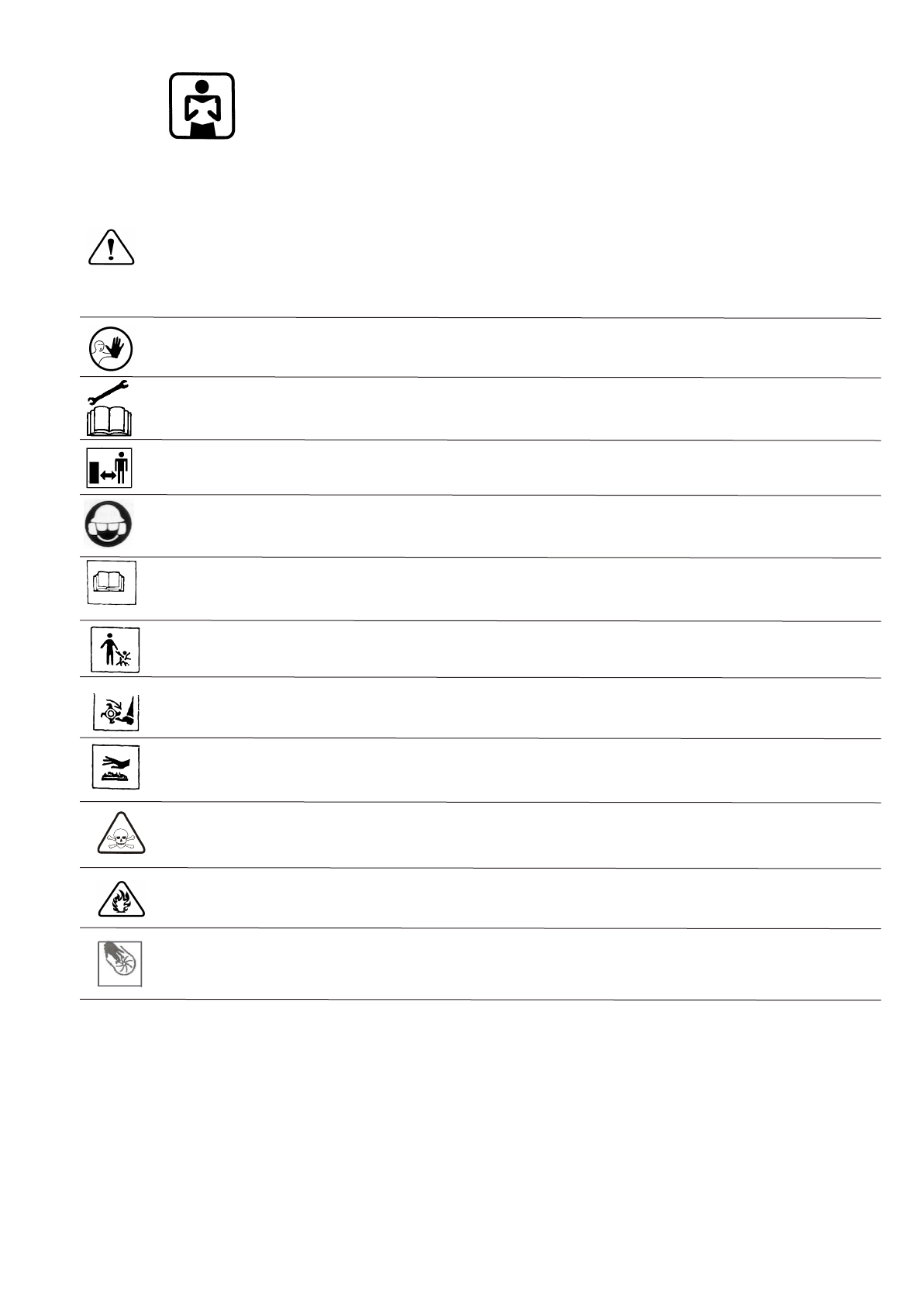

Bu sembol önemli güvenlik kurallarýna dikkat etmek için kullanýlmýþtýr. Eðer bu uyarýlar ihmal

edilirse kullanýcýnýn, çevresindeki nesnelerin ve canlýlarýn zarar görmesine yol açabilecek durumlar

oluþabilir.

This symbol is used to point out the important safety rules.If these rules are disregarded,situations

that may lead to harms to the user and the nearby objects and living creatures may occur.

Bu sembol önemle dikkat edilmesi gereken konularda kullanýlmýþtýr.

This symbol is used for subjects required to note seriously.

Makine tanýtma ve kullanma kýlavuzu.

Machine introduction and operating manual.

Emniyet mesafesini koruyunuz.

Please keep the safety distance.

Ýþitme kaybý riski.

The risk of hearing loss.

Kullanma komutlarýný okuyun.

Read carefully.

‘’Tehlike’’ çocuklarý makinadan uzak tutun.

Keep children away.

Dönen parçalar çalýþýrken el ve ayaklarýnýzý uzak tutun

Risk of cut.Keep your foot away from blades.

Yanma tehlikesi.

Hot zone.

Dikkat! Zehirli madde.

Danger! Poisonous material.

Dikkat! Yangýn riski.

Danger! Fire risk.

Parmaklarýnýzý fan kýsmýna sokmayýnýz.

Do not approach your fingers to the suction side of the blowes.

ALETÝN MARKASI/

TRADEMARK OF THE MACHINE :TARAL

ALETÝN MODELÝ/

MODEL OF THE MACHINE :7014 - 7020 ASTRON

TYPE OF THE MACHINE :MOTORLU SIRTATOMÝZÖRÜ

KNAPSACK MISTBLOWER

(2)

ÝÇÝNDEKÝLER

1-KULLANIM ÞARTLARI...............................................................................4

2-ALETÝN MONTAJI........................................................................................5

3-YAKITIN HAZIRLANMASI...........................................................................6

3.1-YAKITIN BÝDON ÝLE HAZIRLANMASI...................................................6

3.2-YAKITIN ÖLÇEK KABI ÝLE HAZIRLANMASI........................................6

4-ALETÝN KULLANIMI.....................................................................................7

4.1-ÞAMANDIRALI KARBÜRATÖRLÜ MOTORUN ÇALIÞTIRILMASI.....7

4.1.1-SOÐUK MOTORUN ÇALIÞTIRILMASI.................................................7

4.1.2-SICAK MOTORUN ÇALIÞTIRILMASI...................................................7

4.1.3-MOTORUN DURDURULMASI................................................................8

4.2-DÝYAFRAMLI KARBÜRATÖRLÜ MOTORUN ÇALIÞTIRILMASI........8

4.2.1-SOÐUK MOTORUN ÇALIÞTIRILMASI.................................................8

4.2.2-SICAK MOTORUN ÇALIÞTIRILMASI...................................................8

4.2.3-MOTORUN DURDURULMASI................................................................9

5-ÝLAÇLAMA.....................................................................................................9

5.1-ÝLACIN HAZIRLANMASI ...........................................................................9

5.2-DEBÝ AYARI..................................................................................................9

5.3-KULLANIM...................................................................................................9

5.4-TOZLAMA KÝTÝNÝN MONTAJI............................................................ .....10

6-TEMÝZLÝK ve BAKIM..................................................................................11

6.1-HAVA FÝLTRESÝ............................................................................................11

6.2-YAKIT FÝLTRESÝ..........................................................................................12

6.3-BUJÝ...............................................................................................................12

7-DEPOLAMA...................................................................................................13

8-GARANTÝ........................................................................................................13

8.1-ÝLK ÇALIÞTIRMA.......................................................................................13

9-ARIZA BULMA TABLOSU..........................................................................14

10-TEKNÝK ÖZELLÝKLER.............................................................................15

11-CE UYGUNLUK BEYANI...........................................................................16

12-FÝRMA ADRESÝ............................................................................................16

INDEX

1-

3.1-PREPARING THE FUEL BY USING A TANK................................................6

3.2-PREPARING THE FUEL BY USING A MEASURING CUP...........................6

4.1-STARTING THE ENGINE WITH FLOW TYPE CARBURETOR....................7

4.1.1-STARTING THE COLD ENGINE.................................................................7

4.1.2-STARTING THE HOT ENGINE...................................................................7

4.1.3-STOPPING THE ENGINE...........................................................................8

4.2-STARTING THE ENGINE WITH DIAPHRAGM TYPE CARBURETOR........8

4.2.1-STARTING THE COLD ENGINE.................................................................8

4.2.2-STARTING THE HOT ENGINE...................................................................8

4.2.3-STOPPING THE ENGINE............................................................................9

5.1-PREPARING THE FORMULA........................................................................9

5.2-HOW TO CHANGE DOSAGE RATE..............................................................9

5.3-OPERATION...................................................................................................10

5.4-POWDER SPRAYING.....................................................................................10

8.1-FIRST OPERATION........................................................................................13

CONDITIONS OF USAGE..............................................................................4

2-ASSEMBLY OF THE MACHINE...................................................................6

3-PREPARING THE FUEL ................................................................................6

4-OPERATION.....................................................................................................7

5-PESTICIDING...................................................................................................9

6-CLEANING AND MAINTENANCE................................................................12

6.1-AIR CLEANER................................................................................................12

6.2-FUEL FILTER................................................................................................12

6.3-SPARK PLUG..................................................................................................12

7-STORAGE..........................................................................................................12

8-WARRANTY.......................................................................................................13

9-TROUBLE SHOOTING....................................................................................14

10-TECHNICAL DATA...........................................................................................15

11-CE DECLARATION OF CONFORMITY......................................................16

12-CONTACT INFO OF THE COMPANY.........................................................16

(3)

1-KULLANIM ÞARTLARI

1.Sýrt atomizörünün kontrol ve kullanýmýný tamamýyla anlayana kadar bu kýlavuzu okuyun. Makinanýn nasýl kontrol ve

stop ettirileceðini öðrenin.

2.18 yaþýndan küçükler ve aleti yeterince tanýmayanlar bu aleti kullanamazlar.

3.Aletle ilaçlama yaparken kulaklýk, kapalý elbise, kapalý ayakkabý, koruyucu gözluk, ilaçlamaya uygun eldiven ve maske

kullanýn (Þek. 1).

4.Aleti kullanan kiþi çalýþýrken diðer insanlar ve eþyalardan yeterince uzak olduðundan emin olmalýdýr. Direkt ve dolaylý

hasarlardan kullanýcý sorumludur.

5.Aský baðlantýlarýný ve kayýþlarýný her kullanýmda kontrol edin.

6.Gün ýþýðýnda ve yeterince aydýnlatýlmýþ ortamlarda çalýþýn.

7.Aleti çalýþýrken devirmeyin.

8.Aleti çalýþýr durumda asla yalnýz býrakmayýn.

9.Aleti kapalý alanlarda asla çalýþtýrmayýn ve kullanmayýn. Egzoz gazý saðlýða zararlýdýr.

o

10.Motorun egzoz çevresindeki sýcaklýðý 80 C yi aþtýðý için yanma tehlikesi mevcuttur. Egzoza dokunmayýn.

11.Eðer çalýþýrken bir cisme çarpýlýrsa aleti durdurun ve hasarý gidermeden çalýþtýrmayýn.

12.Yangýn tehlikesinden korunmak için;

·Yakýt Deposunu seviye iþaretinden fazla doldurmayýn.

·Motor ve Þasiye yakýt dökülmemesi için aletle beraber verilen ölçü kabý ve huniyi kullanýn.

·Yakýt deposunu doldururken sigara içmeyin.

·Yanýcý maddelerden uzak durun.

·Aleti parlayýcý ve patlayýcý ortamlarda kullanmayýn.

·Bakým ve ayar yapmak için yakýt deposunda yakýt varsa aleti devirmeyin.

·Motor çalýþýrken yakýt deposunu doldurmayýn.

·Motor çalýþýrken veya sýcak iken yakýt hortumunu sökmeyin.

·Aleti buji baþlýksýz çalýþtýrmayýn.

·Kükürtle tozlamada ince kükürt tozlarý sýcak motor ve aletin üzerine siner ve kükürtün alev almasý kolay olduðundan

tutuþabilir bu nedenle aleti sýk sýk fýrça ile temizleyin.

13.Sýrt Atomizörü üzerinde hiçbir parçayý iptal etmeyin.

14.Alette alýþýlmýþýn dýþýnda tireþim hissederseniz aleti durdurun ve yetkili servise müracaat edin.

15.Ýlaçlama yaparken aleti rüzgara karþý kullanmayýn.

16.Aleti direkt güneþ ýþýðýndan uzak bir yere koyarak ultraviyole ýþýnlarýndan zarar görmesini engelleyin.

17.Her kullaným sonunda ilaç deposunu su ile yýkayarak temizleyin.

18.Her kullaným sonunda yakýt deposunu boþaltýn.

19.Güvenli bir kullaným için daima orijinal yedek parça kullanýn.

20.Orjinal parça kullanýlmamasýndan doðacak sorumluluklar tümü ile kullanýcýya aittir.

21.Temizlik haricinde her türlü tamir ve bakým iþlemlerini yetkili servise yaptýrýn. Bunun dýþýndaki uygulamalardan

doðacak hasarlardan kullanýcý sorumludur.

22.Aletle iþiniz bittiðinde buji baþlýðýný çýkartýn.

23.Her ilaçlamadan sonra temizlenin.

24.Atomizörünüzü dirseksiz çalýþtýrmayýn.

25.Depoda kalan ilacýn ve tortusunun yok edilmesi

Geçerli emniyet kurallarýna göre olmalýdýr. Bu konuda ilaç üreticilerinin geçerli koruma yöntemlerini tatbik ediniz.

26.Atomizörü kullanýlmadan önce ve her 100 saatlik kullanýmdan sonra o-ring ve contalarý kontrol edin ve aþýnmalarý

durumda yenileri ile deðiþtirin.

27.Bu aleti kullanýrken diðer insanlarla ve nesnelerle aranýzda 15m'lik mesafeyi koruyun.

1-CONDITIONS OF USAGE

1.Read this manual until fully understanding the control and operation techniques of the

mistblower. Learn to control and stop the machine.

2.People younger than age 18 and people, who are not familiar enough to the machine ,

cannot use it.

3.Wear protective clothing, ear cap, overshoe, safety goggles, and protective gloves during

pesticiding and use a breathing mask. (Fig. 1).

4.While operating the device, be sure of keeping distance from other people as well as items.

Operator is responsible of the direct and indirect harms resulting from disobeying this regulation.

5.Control the carrying strap and their connection points.

6.Operate under daylight and in well-illuminated areas.

7.Do not overturn the device while operating it.

(4)

Þekil.1(Figure.1)

8.Never leave the device while it is in operation.

9.Never start up or operate the device in closed areas.

0

10.Do not touch the muffler. Since the temperature around the muffler of the engine is above 80 C, there is a danger of

hurting yourself.

11.During the operation if you hit any item with the device, stop the engine and do not operate before repair.

12.To avoid fire,

-Do not fill the fuel tank above the fuel level sign.

-To prevent pouring of fuel onto the engine and frame use the measuring cup as well as the funnel.

-While filling the tank with funnel do not smoke and keep flammable materials away.

-Do not operate the device in areas with explosive materials.

-Do not overturn the machine during servicing,when there is fuel in the fuel tank.

-Do not fill the fuel tank while the engine is operating.

-Do not pull out the fuel hose while the engine is operating or when it hot.

-Do not start up the device without ignition plug.

13.Do not omit any of the parts on the knapsack mistblower.

14.Stop the engine if you feel an unusual vibration and apply to the authorized service agent.

15.Do not operate the device against the wind.

16.Keep the product out of the direct sunlight to protect it against the influences of ultraviolet radiation.

17.Clean the formula tank after each use with clean water.

18.Empty the fuel tank after every use.

19.For a safe operation, always use original spare parts.

20.The operator will carry all responsibilities resulting from not using original spare parts.

21.Except cleaning, for all the maintenance operations, ask for an authorized service agent. The operator is responsible

from the consequences of not obeying this instruction.

22.Pull out the ignition plug after finishing the operation.

23.Wash yourself after each operation with clean wate

24.Do not operate the device without its elbow.

25.The excess saturated formula left in the tank have to be removed by observing the safety rules. Apply the valid security

methods of the formula producers.

26.Check the O-rings and gaskets before using mistblower, after 100 hours of operation and in case of wearing out they

must be replaced with new ones.

27.While operating this device, keep a distance of 15 m. from other people and items.

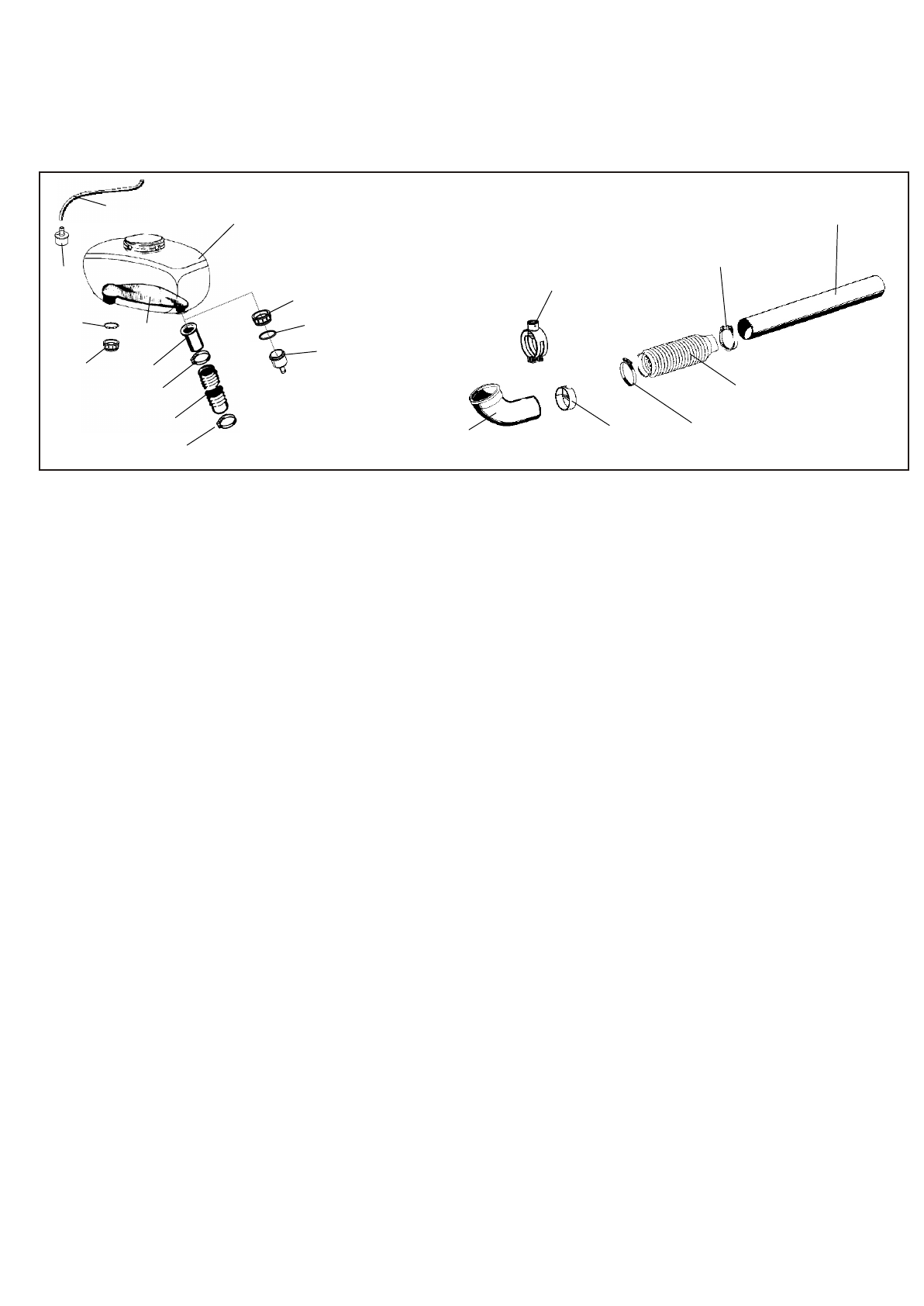

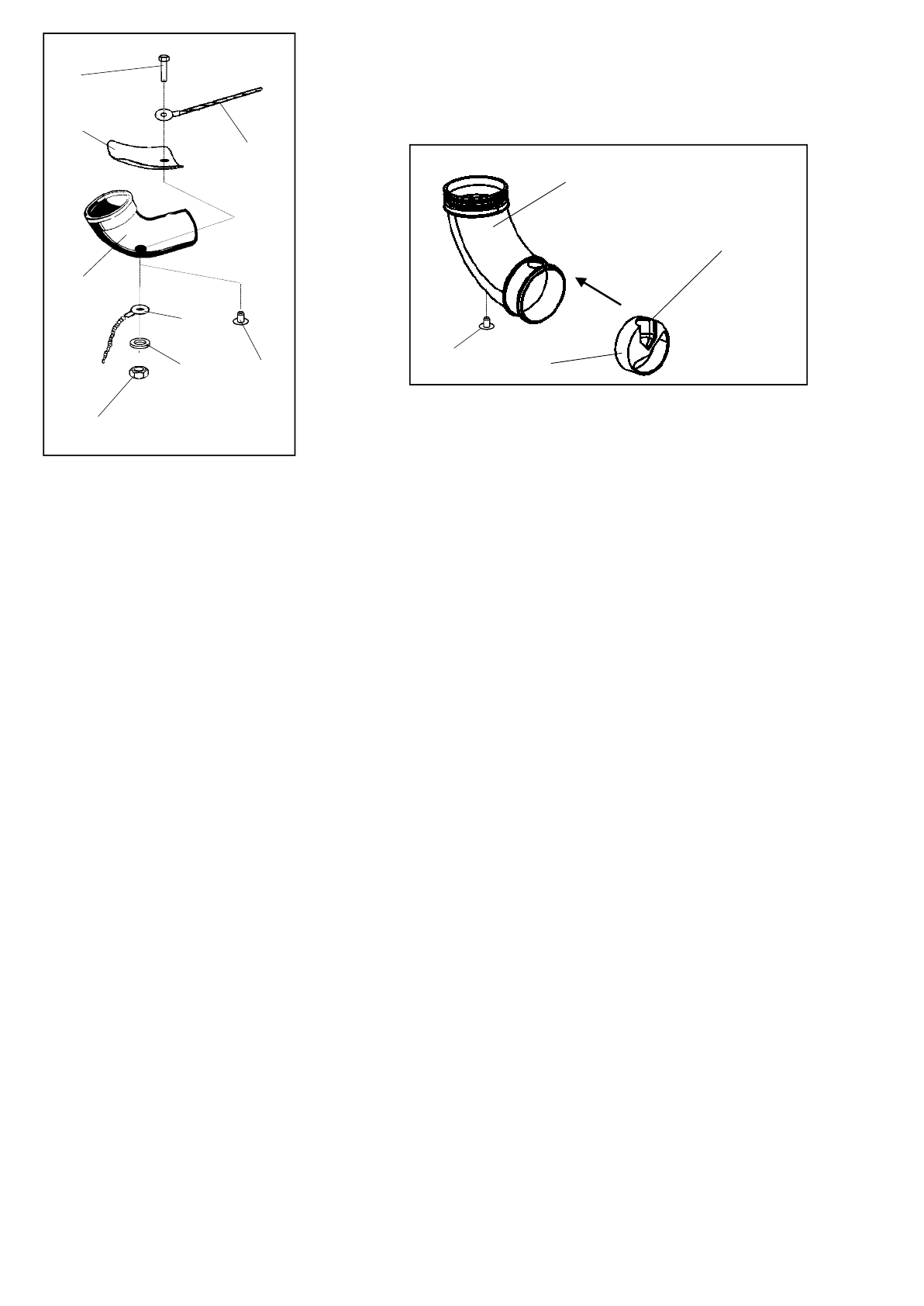

2-ALETÝN MONTAJI (Þekil. 2)

Boðumlu hortumu (3) dirseðe (4) geçirin.Kelepçe-1 (11) takýp sýkýn.Püskürtme borusunu boðumlu hortuma geçirerek

kelepçeye-12 yi sýkýn.Ýlaç hortumu-1 (10) musluðun çýkýþýný ve debi ayar musluðunu (7)birleþtirin.Ýlaçlama hortumunu

hortum tutucuya,sývý emiþ borusuna ise hava nipeline takýn.Püskürtme borusunun (5)ucuna,püskürtme baþlýðýný (6)monte

edin.Ayar somunu vasýtasý ile püskürtme baþlýðýný ileri ve geriye doðru hareket ettirebilirsiniz.Bu size geniþ ve dar açýda

ilaç atma imkaný saðlayacaktýr.

(5)

Þekil.2(Figure.2)

Parçalarýn Tanýmý (Þek.2)/Parts Description (Fig.2)

1-Depo/Tank

2-Motor/Engine

3-Boðumlu Hortum/Flexible Tube

4-Dirsek/Elbow

5-Püskürtme Borusu/Spray Tube

6-Püskürtme Baþlýðý/Nozzle

7-Debi ayar musluðu/Dosage Tap

8-Ýlaç hortumu-2/Chemical Hose-2

9-Musluk(On-Off)/Tap (On-Off)

10-Ýlaç hortumu-1/Chemical hose-1

11-Kelepçe-1/Clamp-1

12-Kelepçe-2/Clamp-2

13-Kabza/Handle

2-ASSEMBLY

Connect flexible hose to elbow of the machine and tighten the clamp.Connect spray tube to flexible hose and tighten clamp-

2.Connect chemical hose-2 to inlet side of on-off tap and also chemical hose-1 to outlet side of on-off tap chemical hose-1 to

outlet side of on-off tap and dosage sleeve.Connect chemical hose to the holder and pressure hose to air outlet nipple as

shown in Fig.2.Place the tank strainer.Assemble spray nozzle to spray tube.To obtain wide or short angle spraying loosen

plastic nut and move the nozzle forth and back.

3.YAKITINHAZIRLANMASI

Yakýtýn hazýrlanmasýnda 1. paragrafta anlatýlan güvenli kullaným kurallarýna uyunuz.

3. PREPARING THE FUEL

In the fuel preparation, apply the safety regulations indicated in paragraph 1.

TARALiki zamanlý motor yaðý kullanýmýný tavsiye eder.

TARALrecommends two-cycle engine oil to be used.

3.1-YAKITIN BÝDON ile HAZIRLANMASI

1.Yakýtýnýzý yalnýz temiz kaplara boþaltýn ve aletin orjinal hunisini kullanýn. Süper benzin kullanmayýn. Kursunsuz benzin

kullanýn.

2.Tablo 1 'de verilen oranlarda yakýt yað karþýmýný hazýrlayýn.(Örnek 10 Lt. benzine 0.4 Lt. iki zamanlý motor yaðý

karýþtýrýn).

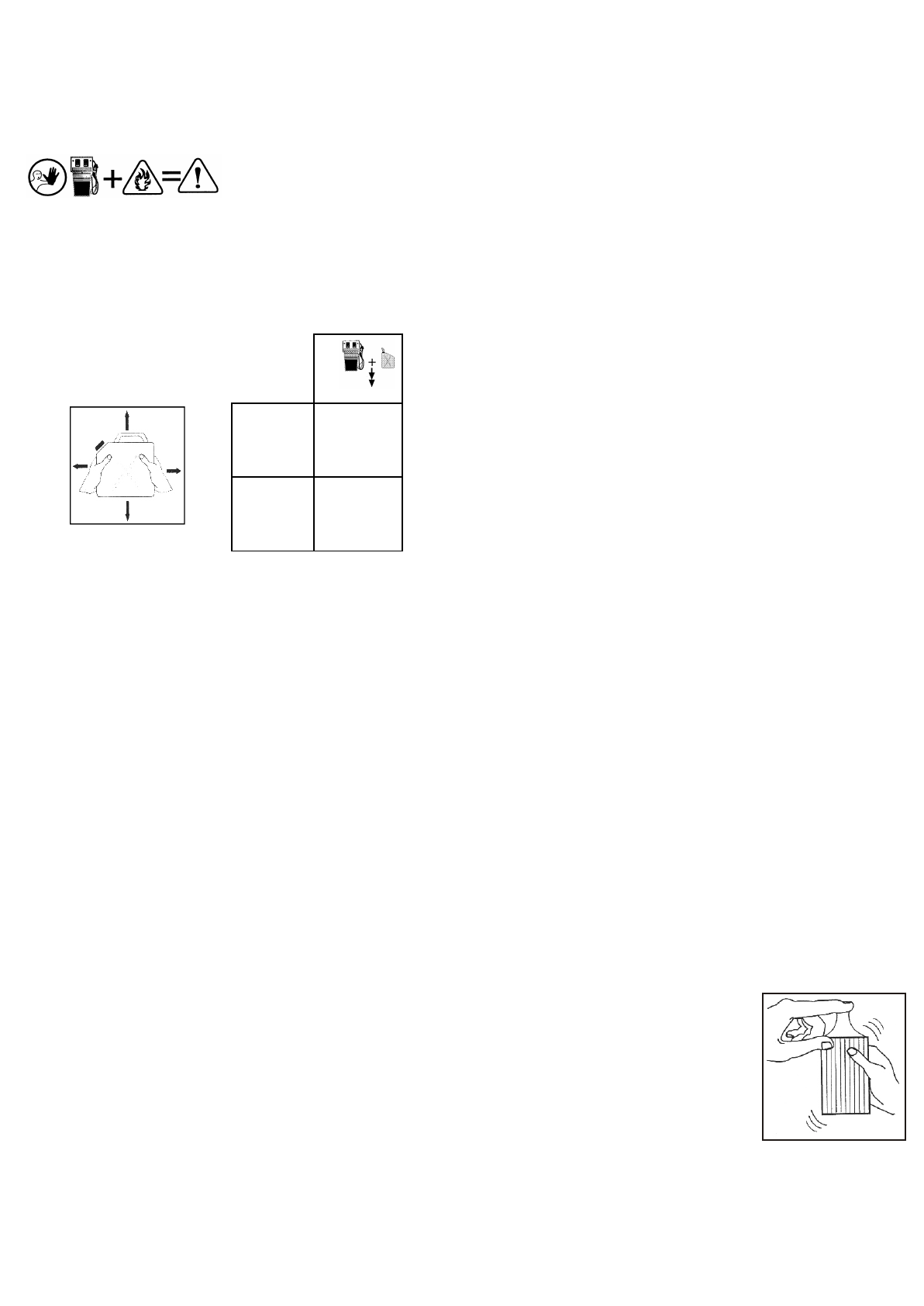

3.Karýþýmý hazýrladýktan sonra bidonu (Þek.3) 'deki gibi çalkalayýn.

4.Süzgeçli huni yardýmý ile karþýmý aletin yakýt deposuna doldurun.

3.1-PREPARING THE FUEL BY USING A TANK

1.Pour the fuel only in a clean container and use the original funnel of the device. Do not use super gasoline. Unleaded

gasoline is recommended.

2.Prepare the fuel by using fuel and oil in the ratios shown in table 1. (e.g. with 10 Lt. fuel, mix 0,4 Lt. two cycle engine oil.)

3.After preparing the mixture, shake the container. (Fig. 3)

4.By using a strainer funnel, fill the fuel tank with the mixture.

3.2- YAKITIN ÖLÇEK KABI ile HAZIRLANMASI

1.Eðer iki zamanlý motor yaðý kullanýyorsanýz ölçek kabýnýn içindeki 1:25 yazýsýna kadar yað doldurun.

2.Ölçek kabýnýn içine koyduðunuz yaðýn üzerine benzin dökerek kabý iþaretli yere kadar doldurun.

Ölçek kabýnýn üzerine süzgeçli huniyi geçirin.

3.Huninin aðzýný parmakla kapatarak iyice çalkalayýn (Þekil. 4)

4.Hazýrlanmýþ olan yakýtý huniyi çýkartmadan kabý çevirerek yakýt deposuna doldurun.

Not: Yakýt yað karýþýmýný kesinlikle direkt olarak yakýt deposu içinde hazýrlamayýn. Aksi taktirde

motorunuz zarar görebilir.

3.2-PREPARING THE FUEL BY USING A MEASURING CUP

1.If you are using two-cycle engine oil, fill the measuring cup up to the 1:25 sign.

2.Add gasoline to the oil that has already been put in the measuring cup and thus fill the cup up to the marked level.

3.Block the funnel with your finger and shake it well (Fig. 4).

4.Pour the prepared fuel into the fuel tank while keeping the funnel on the cup.

Note: Never prepare the fuel oil mixture in the fuel tank. The engine can be damaged.

2 zamanlý

motor

yaðý/2cycle

engine oil

Benzin/Fuel

(lt)

1:25 % 4

50.200

10 0.400

15 0.600

20 0.800

25 1.000

Tablo 1(Table 1)

Þekil.3(Figure.3)

(6)

Þekil.4(Figure.4)

4.ALETÝNKULLANIMI/OPERATION

4.1- ÞAMANDIRALI KARBÜRATÖR LÜ MOTORUN ÇALIÞTIRILMASI

4.1.1-SOÐUK MOTORUN ÇALIÞTIRILMASI

1.Kabza tertibatý üzerindeki durdurma düðmesini açýk (1) konumuna getirin (Þekil.5-2).

2.Kabza üzerindeki gaz verme tetiðini yarým gaz pozisyonuna getirerek sabitleme kolu (Þekil.5-1) ile sabitleyiniz.

3.Karbüratörün üzerindeki yakýt pompasýný 3-4 kez bastýrarak karbüratörün içerisine benzinin geldiðini görün.(Þekil.6)

4.Jikleyi yukarý kaldýrýn (Þekil.7)

5.Makinanýzýn saðlam bir þekilde tutarken diðer elinizle starter kolunu hýzla çekin.(Þekil.8)

6.Motor çalýþsýn veya çalýþmasýn starter kolunu yavaþca býrakarak ipin düzgün bir þekilde sarýlmasýný saðlayýn.

7.Karbüratörün jikle kolunu aþaðýya indirin.

4.1- STARTING THE ENGINE WITH FLOWTYPE CARBURETOR

4.1.1-STARTING THE COLD ENGINE

1.Push the switch on the control unit to start (1) position (Fig. 5).

2.Move the throttle trigger to half open position and lock it with locking knob (Fig. 5.1)

3.Push the premier fuel pump several times until overflow fuel flows out and seen in the semi-transparent fuel hose.

4.Pull up the choke lever (Fig. 7) to close.

5.While holding down the unit firmly, pull out the starter rope quickly. (Fig. 8)

6.Let the starter grip slowly back to starter housing with smooth orientation, even though the engine has started.

7.After the engine has started, open the choke gradually.

4.1.2-SICAK MOTORUN ÇALIÞTIRILMASI

1.Kabza tertibatý üzerindeki durdurma düðmesini açýk (1) konumuna getirin.(Þekil.5-2)

2.Kabza üzerindeki gaz verme tetiðini yarým gaz pozisyonuna getirerek sabitleme kolu ile sabitleyiniz.

3.Starter kolunu hýzla çekerek motoru çalýþtýrýn (Þekil.8).

4.Starter kolunu motor çalýþmýþ olsa bile ipin geriye sarýlmasý için yavaþ ve ipe yön vererek býrakýn.

5.Karbüratördeki jikle kolunun aþaðýda olmasýna dikkat edin.

Not: Motorun rolanti devri 2500 dev./dk.

4.1.2-STARTING THE HOT ENGINE

1.Push the switch on the control unit to start position (Fig. 5.2).

2.Move the trigger to half open position and lock it with locking knob.

3.While holding down the unit firmly, pull out the starter rope quickly. (Fig.8)

4.Let the starter grip slowly back to starter housing with smooth orientation, even though the engine has started.

5.While in operation, move the throttle trigger to desired position.

Note: The idle speed of the engine is 2500 rpm.

Þekil.5(Figure.5) Þekil.6(Figure.6) Þekil.7(Figure.7) Þekil.8(Figure.8)

(7)

ÝÞÝTME KAYBI RÝSKÝ

NORMAL ÞARTLARDABU MOTORUN KULLANIMI

SIRASINDA KULLANICI GÜNLÜK

85 dB (A)

VE ÜSTÜ GÜRÜLTÜYE MARUZ KALABÝLÝR.

RISK OF HEARING LOSS

IN STANDARD CONDITIONS THE OPERATOR CAN BE

EXPOSED TO ADAILY NOISE LEVEL OF

85 dB (A)

>

4.1.3-MOTORUN DURDURULMASI

1.Kabza üzerindeki gaz verme(Þekil.5-3) ve sabitleme kolunu (Þekil.5-1) yukarý kaldýrarak motoru rölanti devrine getirin.

2.Kabza tertibatý üzerinde bulunan durdurma düðmesini (Þekil.5-2) (0) pozisyonuna getirerek motoru durdurun.

Not:Motorun tekrar çalýþtýrýlabilmesi için stoplama (5-3) düðmesini mutlaka (1) pozisyonunda olmasý gereklidir.

4.1.3-STOPPING THE ENGINE

Release the throttle trigger to bottom position with releasing locking knob (Fig:5-1)

Push the swich on the control unit to stop (0) position (Fig:5)

4.2-DÝYAFRAMLI KARBÜRATÖRLÜ MOTORUN ÇALIÞTIRILMASI

4.2.1-SOÐUK MOTORUN ÇALIÞTIRILMASI

Atomizörü çalýþtýrýrken üfleme borusunun etrafýnda kimsenin bulunmadýðýna dikkat edin.

1.Kabza üzerindeki butonu (1) pozisyonuna getirin. (Þekil.5-2)

2.Gaz tetiðini (Þekil.5-1) yarým gaz pozizyonuna getirip kilitleme mandalý ile tetiði sabitleyin. (Þekil.5)

3.Karbüratör üzerindeki pompaya yakýt taþýncaya kadar basarak yakýtýn karbüratöre dolmasýný saðlayýn. (Þekil.9A)

4.Jikle kolunu kapalý pozisyona getirin.(Þekil.9B)

5.Makinanýzýn saðlam bir þekilde tutarken diðer elinizle starter kolunu hýzla çekin.(Þekil.8)

6.Motor çalýþsýn veya çalýþmasýn starter kolunu yavaþca býrakarak ipin düzgün bir þekilde sarýlmasýný saðlayýn.

7.Motor çalýþtýktan sonra jikleyi yavaþca açýn,gaz tetiðini serbest býrakarak motorun bir süre

rolentide çalýþarak ýsýnmasýný saðlayýn.

8.Ýlaçlama esnasýnda gaz tetiðini istediðiniz seviyeye getirip sabitleyerek ilaçlama yapýn.

4.2-STARTING THE ENGINE WITH DIAPHRAGM TYPE CARBURETOR

4.2.1-STARTING THE COLD ENGINE

While starting the engine keep other people away from blower pipe.

1.Push the switch on the control unit to start (1) position (Fig:5)

2.Move the throttle trigger (Fig:5-1) to half open position and lock it with locking knob (Fig:5)

3.Push the premier fuel pump several times until overflow fuel flows out and seen in the semi-transparentfuel hose

(Fig:9A)

4.Pull up the choke lever (Fig:9B) to close.

5.While holding down the unit firmly,pull out the starter rope quickly (Fig:8)

6.Let the starter grip slowly back to starter housing with smooth orientation,even though the engine has started.

7.After the engine has started,open the choke gradually,move the throttle trigger to bottom position and allow the engine to

warm up.

8.While in operation,move the throttle lever to desired position and lock it.

4.2.2- SICAK MOTORUN ÇALIÞTIRILMASI

1.Kabza üzerindeki start butonunu (1) pozisyonuna getirin (Þekil.5)

2.Gaz tetiðini (Þekil.5-1) yarým gaz pozisyonuna getirip kilitleme mandalý ile tetiði sabitleyin (Þekil.5)

3.Makinanýzýn saðlam bir þekilde tutarken diðer elinizle starter kolunu hýzla çekin (Þekil.8)

4.Motor çalýþsýn veya çalýþmasýn starter kolunu yavaþca býrakarak ipin düzgün þekilde sarýlmasýný saðlayýn.

5. ilaçlama esnasýnda gaz tetiðini istediðiniz seviyeye getirip sabitleyerek ilaçlama yapýn.

NOT:Motorun rolenti devri 2500 dev/dak. Civarýdýr.

4.2.2-STARTING THE HOT ENGINE

1.Push the switch on the control unit to start (1) position (Fig:5)

2.Move the trigger (Fig:5-1) to half open position and lock it with locking knob (Fig:5)

3.While holding down the unit firmly,pull out the starter rope quickly.(Fig:8)

(8)

Þekil.9A(Figure.9A)

Þekil.9B(Figure.9B)

4.Let the starter grip slowly back to starter housing with smooth orientation,even though the engine has started.

5.While in operation,move the throttle trigger to desired position.

NOTE: Engine idle speed is approximately 2500 rpm.

4.2.3-MOTORUN DURDURULMASI

1.Kabza üzerindeki gaz verme(Þekil.5-3) ve sabitleme kolunu (Þekil.5-1) yukarý kaldýrarak motoru rölanti devrine getirin.

2.Kabza tertibatý üzerinde bulunan durdurma düðmesini (Þekil.5-2) (0) pozisyonuna getirerek motoru durdurun.

Not:Motorun tekrar çalýþtýrýlabilmesi için stoplama (5-3) düðmesini mutlaka (1) pozisyonunda olmasý gereklidir.

4.2.3-STOPPING THE ENGINE

1.Adjust the engine rpm to idling by lifting up the throttle trigger (Fig.5-3) and locking knob.

2.Stop the engine by pushing the switch on the throttle lever to positon (0).

Note:To be able to start the engine again, the switch (5-3) must be in the position (1).

5.ÝLAÇLAMA/PESTICIDING

Not:Atomizör kapalý mekanda çalýþtýrmayýn.

Etrafýnýzda bulunan diðer canlýlara ve zarar görebilecek nesnelere ilaçlama esnasýnda dikkat ediniz

Parmaklarýnýzý fan kýsmýna sokmayýnýz.

Atomizörünüzü rüzgara karþý kullanmayýn.

Note:Do not use the mistblower in close spaces.

While operating,be sure of keeping distance from other people as well as items,which could be harmed.

Do not approach your fingers to the suction side of the blower.

5.1- ÝLACIN HAZIRLANMASI

1.Ýlaç, ilaç deposunun dýþýnda, ilaç firmasýnýn direktifleri ve geçerli güvenlik kurallarý çerçevesinde hazýrlanmalýdýr.

2.Ýlacý hazýrlamak için mutlaka eldiven, gerekiyorsa maske kullanýn.

3.Ýlacý temiz kaplar içerisinde hazýrlayýn.

4.Ýlaç hortumundaki musluðu kapalý konuma getirin (Þek.2-9).

5.Hazýrlanan ilacý ilaç deposuna depo aðzýndan taþmayacak þekilde doldurun.Ve deponun kapaðýný sýkýca kapatýn.

5.1- PREPARING THE FORMULA

1.The formula must be prepared regarding the directives of the chemical producers and valid safety rules.

2.To prepare the formula you must wear protective gloves and mask if necessary.

3. Prepare the formula in clean containers.

4.Close the tap on the chemical hose (Fig:2-9)

5.Fill the prepared formula into the chemical tank so that it will not pour out of it and close the tank lid tightly.

5.2-DEBÝAYARI

Debi ayar musluðuna ve püskürtme konumuna göre püskürtme miktarlarý Tablo-2' de verilmiþtir.Ayar pozisyonlarýnda

debi ayar musluðunun (Þekil.2-7) köþelerinin baþlýktaki köþe ile üstüste gelmesine dikkat edilmelidir.

5.2-HOW TO CHANGE DOSAGE RATE

The quantity of sprayed formula in accordance with the dosage tap (Fig.2-7) and spraying cone position is shown in

Table- 2 Attention should be paid on that the corners of the dosage tap (Fig.2-7)coincide with the corner in the nozzle in the

adjusting positions.

5.3-KULLANIM

1.Motoru çalýþtýrýn ve aleti sýrtýnýza alýn.

2.Püskürtme borusunu sað eliniz ile kabza tertibatýndan tutunuz.

Ýlaç hortumundaki musluðu açýn ve istenilen bölgeyi ilaçlamaya

baþlayýn.

3.Ýlaçlama iþiniz bittikten sonra ilaç hortumundaki musluðu

kapatarak motoru durdurun.

Do not use the mistblower against wind.

(9)

Tablo:2

(lt/dak.)

(Lt/min)

Flowrate

Adjustment numbers

(10)

5.3-OPERATION

1. Start the engine as described above and take the machine on to your shoulder by means of carrying straps.

2. Hold up spray tube by means of handle with your right hand, open the chemical tap and spray the desired area.

3. At the end of work close the chemical tap and stop the engine.

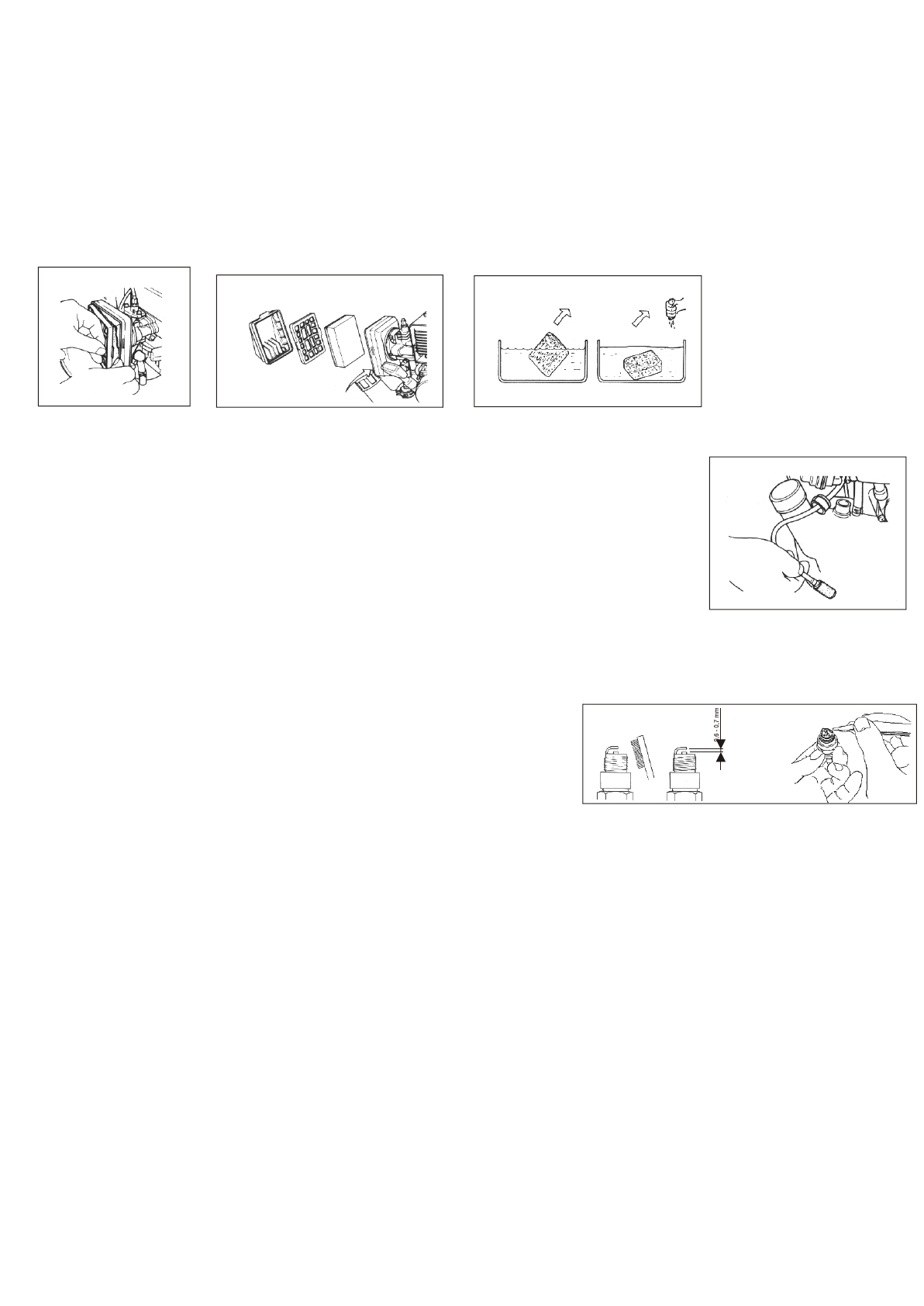

5.4-TOZLAMA KÝTÝNÝN MONTAJI/POWDER SPRAYINGASSEMBLY

ATOMÝZÖRÜNÜZÜ SIVI SÝSTEMÝNDEN TOZ SÝSTEMÝNE GEÇÝRÝRKEN ;

1-Ýlaç deposu rakorunu (1) bir tur sökme yönünde (sola) çevirin.

2-Tapayý (2) depo içerisinden yavaþça çekerek çýkartýn.

3-Hava daðýtýcýyý (3) depo içindeki yuvaya oringin (4) içine girecek þekilde bastýrarak takýn.

4-Ýlaç deposu rakorunu (1) sýkma yönünde (saða) çevirin,sýkýn. Ýlaç doldurduðunuzda þayet sýzdýrma var ise; oringin

(4) yerine oturup oturmadýðýný ve saðlamlýðýný kontrol edin.

5-Ýlaç deposu rakorunu (5) çýkararak, tapa boþaltmayý (6) sökünüz.

6-Boþaltma burcunu (8), oring (7) ile birlikte depo çýkýþýna takarak rakor (5) ile sýkýnýz.

7-Toz boþaltma hortumunun (9) bir ucunu boþaltma burcuna (8) kelepçe (10) ile baðlayýn.

8-Diðer ucunu ise tozlama adaptörüne (11) kelepçe (10) ile baðlayýn.

9-Tozlama adaptörünü (11) dirsek üzerinden sökün,dirsek tozlama adaptörünü (12) toz akma yuvasý kendinize

bakacak, dirsek üzerinde bulunan delikle toz akma yuvasý deliði birbirini karþýlayacak þekilde dirseðin içine

yerleþtirin.

10-Tozlama kelepçesini (11) dirsek üzerindeki yerine monte edin.

Not: Toz akýþýnýn ayarlanmasý dirsek üzerine baðlý bulunan tozlama adaptörü (11) ile mümkündür.

TO TRANSFORM YOUR MISTBLOWER’S CHEMICAL SPRAYING SYSTEM TO POWDER SPRAYING SYSTEM

1-Turn the ring nut (1) of the chemical tank by one cycle in the counter clock wise direction.

2-Remove the plug (2) from the inside of the tank by pulling it slowly.

3-Mount the air distributing unit (3) in the housing inside the tank by pressing it, so that it fits in the O-ring.

4-Turn the ring nut (1) of the chemical tank in the clockwise direction, fix it. If there is leakage, while you are filling

the tank; check whether the O-ring (4) is tested properly and it has no defect.

5-Remove the drainage plug (6) by pulling the ring nut (5) of the chemical tank.

6-Tighten the drainage bushing (8) with the ring nut (5) after mounting it with O-ring (7) on the outlet of the tank.

7-Connect one of the ends of the hose of the powder drainage to the drainage bushing (8) with clamp (10).

8-Mount the other end to the atomizing adapter (11) by clamp.

9-Remove the atomizing adapter (11) from the elbow, insert the elbow atomizing adapter (12) into the elbow in such

a way that the powder drainage housing side is towards you and the axes of the hole on the elbow and the hole of

the powder drainage housing coincide with each other.

10-Mount the atomizing clamp (11) in its position on the elbow.

Note:The ad jusment of the flow of the powder is possible using the powder spraying adaptor attached to the elbow.

Þekil.10(Figure.10)

Ýlaç Hortumu/

Chemical Hose

Depo/Tank

5

6

7

8

10

9

10

2

4

1

3

Dirsek/Elbow

Püskürtme Borusu/

Spray Tube

11

12

Boðumlu Hortum/

Flexible Tube

Kelepçe/Clamp

Kelepçe/Clamp

(11)

Dirsek

1

4

5

3

6

13

1

2

Toz ilaç atarken oluþan statik elektriði topraklama için topraklama zincirini aþaðýdaki þekilde monte ediniz.

1-Dirseðin üzerindeki tapayý yerinden (13) çýkarýn.

2-Kaþýk statiðe (3), tel statiði (2) civata ile yukarýdan, þekildeki gibi baðlayýp, dirseðin içine civata delikten geçecek ve

dirseðin radyüsüne uygun gelecek þekilde kaþýk statiði yerleþtirin.

3-Civatanýn,dirseðin altýndan çýkan ucuna zincir statiði (4) arasýna gelecek pul (5) ile birlikte somun (6) ile baðlayýn.

To be able to make earthing because of the static electric, assemble the earhing chain according to the following steps.

1-Detach the tap from the elbow (13)

2-After connecting the wire static element (2) to the plate static element (3) with a bolt from the upper side as in the

figure, put the plate static element into the elbow so that it fits to the fillet of the radius and the bolt fits into the hole.

3-Connect the wire static element (4) to the tip of the bolt which is located under the elbow together with the washer

(5) and the nut (6).

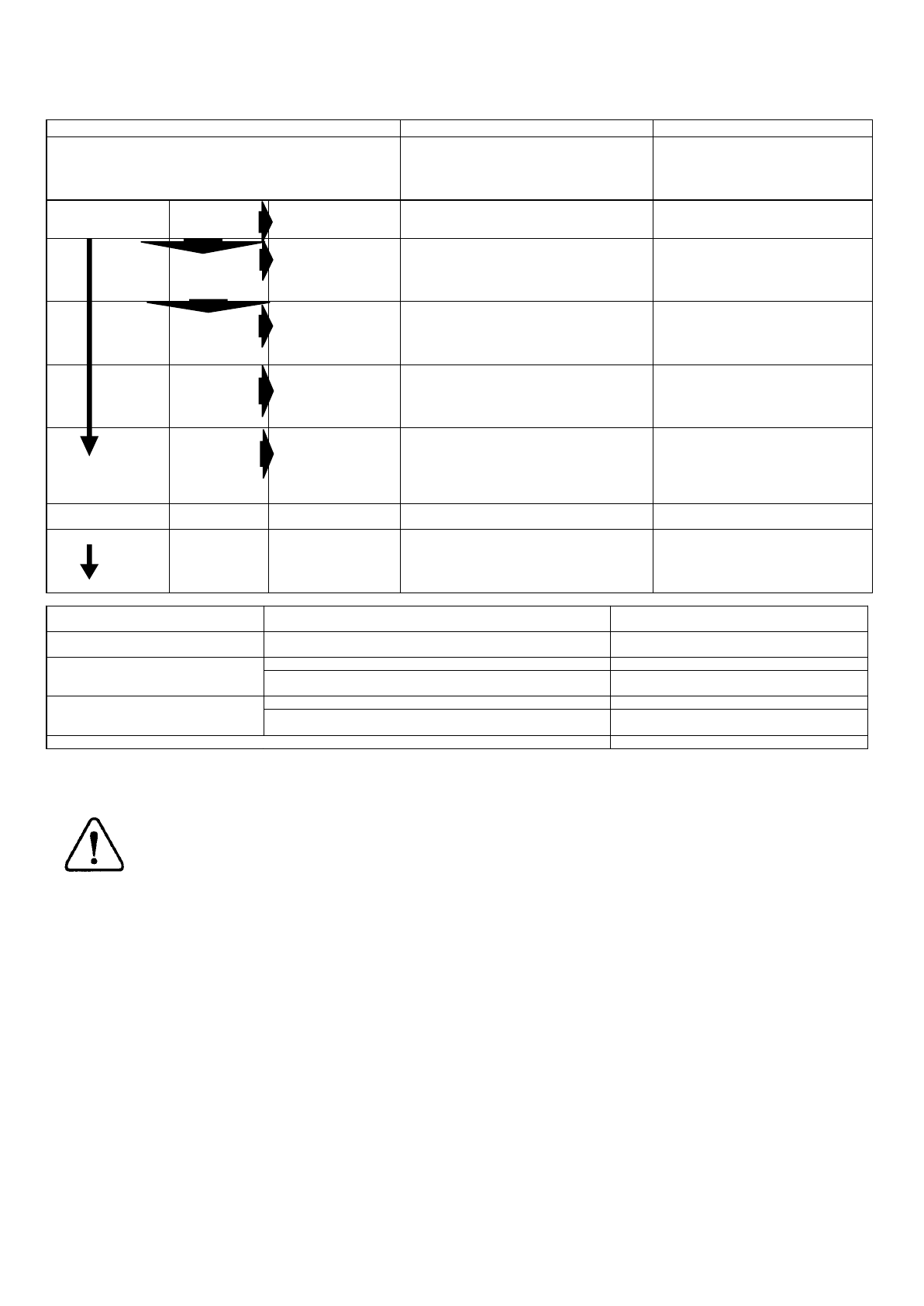

6-TEMÝZLÝK ve BAKIM

Atomizörünüzü temizlemeden ya da herhangi bir tamirden önce motorunun durmuþ ve soðuk olduðundan emin olun.

6.1-HAVA FÝLTRESÝ

Temizlik ve bakým sýrasýnda Madde-1' deki güvenli kullaným kurallarýna uyun.

1. Hava filtresini motor üzerinden sökün. Hava filtresini iyice temizleyip kuruladýktan sonra yerine takýn.

(Þekil.11-12-13).

2. Ýlaç depo kapaðýndaki contayý arasýra yaðlayarak bakým yapýn.

3. Orjinal parça kullanýlmamasýndan doðacak sorumluluklar tümü ile kullanýcýya aittir.

4. Atomizörü her kullanýmdan sonra temiz su ile yýkayarak temizleyin.

5. Ýlaç deposunda ilaç býrakmayýn.

6.Eðer hava filtreniz yýrtýlmýþ veya küçülmüþse yenisi ile deðiþtirin.

Þekil.10A(Figure.10A)

Dirsek(Elbow)

12

Toz Akma Yuvasý

13

Þekil.10B(Figure.10B)

6-CLEANING AND MAINTENANCE

Before cleaning or servicing the mistblower make sure engine is stopped and cooled.

6.1- AIR CLEANER

Before servicing your mistblower,apply the safety regulations indicated in paragraph 1.

1.Remove air cleaner of the engine,clean and dry thoroughly and install it back (Fig: 16-17-18)

2.Lubricate the gasket on the chemical tank cover occasionally.

3.The consumer will carry all responsibilities resulting from not using original spare parts.

4.Wash and clean your mistblower after each use with clean water.

5.Do not leave any chemicals in the chemical tank.

6.If the air cleaner is torn, or becomes smaller change it with a new one.

Þekil.11(Figure.11) Þekil.12(Figure.12) Þekil.13(Figure.13)

6.2-YAKIT FÝLTRESÝ

Motorunuz çalýþmadýðýnda yakýt gurubunun ve yakýt filtrenizin týkalý olup olmadýðýný kontrol

edin (Þekil. 14).

6.2-FUEL FILTER

If the engine does not start, check the fuel filter and the fuel system around for any blockages.

(Fig:14)

6.3-BUJÝ

Buji týrnak aralýðý 0,6 - 0,7 mm olmalýdýr. (Þek.15) Buji týrnak aralýðý zamanla karbon yada kurum kaplayacaðýndan bujinizi

kontrol edip, temizleyin. (Þek.15) Buji týrnaðýnda oluþan karbon yada kurum motorunuzun performansýnýn düþmesine yol

açabilir.

6.3-SPARK PLUG

The spark plug end clearance should be around 0,6 to 0,7mm.(Fig:15)

Since the end will be covered either carbon or other deposists, check the

spark plug and clean with suitable brush.The carbon formation and deposits

at the spark plugs can degrade the efficiency of the spark plugs.

7-DEPOLAMA

1.Aleti kullanýmdan sonra temiz su ile yýkayarak temizleyin.

2. Ýlaç deposunda ilaç býrakmayýn.

3.Yakýt deposunda kalan benzini temiz bir kaba koyun ve motoru duruncaya kadar çalýþtýrýn. Aksi halde benzin buharlaþýr

ve içinde karbüratör memelerini týkayabilir.

4.Bujiyi çýkartýn, silindirin içine pas önleyici veya motor yaðý koyun, kranký birkaç kez döndürerek karýþýmýn daðýlmasýný

saðlayýn. Bujiyi tekrar yerine takýn.

5.Tekrar kullanacaðýnýz zaman bujiyi çýkartýn ve temizleyin. Kranký bir kaç kez döndürün.

7-STORAGE

1. After every use of machine clean the chemical tank with water.

2.Do not leave chemical in the tank.

3.Empty the fuel tank and run the engine until fuel finish inside the carburetor. Otherwise gasoline will be vaporized and

clog the carburator orifices.

4.Take the spark plug out and pour corrosion inhibitor or thin engine oil into the cylinder.Revolve the crankshaft for a few

times to make the mixture to disperse.

5.Before using the device again,take out spark plug and clean it.Revolve the crankshaft a fewtimes.

(12)

Þekil.14(Figure.14)

Þekil.15(Figure.15)

(13)

8-GARANTÝ

Makine tanýtma ve kullanma kýlavuzundaki talimatlara uygun þekilde kullanýlmasý ve normal koþullarda çalýþtýrýlmasý

þartýyla,Taral firmasý tarafýndan imal edilmiþ olan ve özellikler garanti belgesinde belirtilen makine,satýþ tarihinden

itibaren 2 yýl süre ile garanti edilmiþtir.

23.02.1995 Tarihli 4077 nolu tüketicinin korunmasý hakkýnda kanun ile belirlenmiþtir.

1.Sanayi ve Ticaret Bakalnlýðý Ýstanbul Sanayi ve Ticaret Ýl Müdürlüðünce verilen 17.Mayýs.2002 tarih ve 34-2836 no ile

verilen garanti belgelerinde belirtilen garanti þartlarý geçerlidir.

2.Garantinin baþlangýç tarihi,satýcý firma tarafýndan alýcýya teslim tarihini Garanti belgesinde kendine ayrýlan yere yazarak

imzaladýðý tarihtir.

3.Ýmalatçý firmanýn sorumluluðu,defo veya imalat hatalarýna baðlý olsa bile,aracýn kullanýmý esnasýnda kiþilere ve eþyalara

verilen zararý kapsamaz.Buna baðlý olarak dolaylý ve doðrudan verilen zarar ve hasarýn bedeli ödenmeyecektir.

4.Makine üzerine damgalanmýþ seri numarasý deðiþtirilmiþ ise herhangi bir deðiþiklik yapýlmýþ ise,makine bir kazaya

uðramýþ ise satýn alan sözleþmedeki ödeme yükümlülüklerine gerektiði gibi uymamýþ ise montaj firmanýn yetkili

elemanlarý tarafýndan yapýlmamýþ ise,imalatçý firmanýn onayý alýnmadan deðiþiklik veya onarým yapýlmýþ ise,garanti

geçerli deðildir.

5.Herhangi bir anlaþmazlýk durumunda Tüketici,Sanayi ve Ticaret Bakanlýðý tüketicinin ve rekabetinin korunmasý genel

müdürlüðüne baþvurulabilir.Taral A.Þ. Garanti kapsamýna giren her türlü isteði dikkate alacaktýr.

6.Aletin kullaným ömrü (10) yýldýr.

7.Makinanýz ile birlikte size ‘’TARALYETKÝLÝ SERVÝS KÝTAPÇIÐI’’ verilecektir.Servis ve yedek parça ihtiyaçlarýnýz

için bu kitapçýktan yararlanabilirsiniz.

8-WARRANTY

The machine which is produced by TARAL and of which specifications are given in the warranty certificate has a

warranty period of 2 year beginning from the date of sale with the condition of using the machine according to the

instructions in the owner's manual and working in standard conditions.It is determined by the law about the consumer

rights with the date of 23.02.1995 and the number 4077.

1- The warranty conditions are valid which are explained in the warranty certificate given with the permission of the

Ministry of Industry, Istanbul Industry and Trade Office in the document no.34-2836 with the document permission

date of 17.May.2002.

2- The date of beginning of the warranty corresponds to the date when the seller firm writes down the date of delivery

to the buyer and signs on the warranty certificate.

3- The responsibility of the producer company does not include the damages to the human beings and other items

during operation, even if they depend on the flaw or production errors. Therefore in the case of a request of the price

of any direct damage and loss the price will not be paid.

4- If the serial number stamped on the machine is changed, or any modification is made, or the machine is involved in

an accident, or the buyer does not obey the responsibilities in the contract appropriately, or the assembly is not done

by the authorized personnel of the producer company,or any modification or maintenace is performed without the

permission of the producer company,the warranty is not valid.

5- In the case of any disagreement, the consumer can apply to the Protection of the Competition General Office of the

Industry and Trade Ministry.

6- The operation life of the machine is 10 years.TARAL will regard all the requests in the framework of the warranty.

7-TARAL AUTHORIZED SERVICE BOOKLET will be given to you with the machine.You can make use of this booklet

for your service or spare parts needs.

8.1-ÝLK ÇALIÞTIRMA

Deðerli müþterimiz, ürünümüzü kullanmaya baþlamadan önce, ürünle birlikte verilen ÝLK ÇALIÞTIRMA KUPONU

ile birlikte size en yakýn TARAL Yetkili Servisine baþvurarak makinenizin ÝLK ÇALIÞTIRMASINI yaptýrýnýz. Bu

iþlem için, makinaya eklenecek yað, yakýt vb. sarf malzemeleri hariç herhangi bir ücret ödemeyeceksiniz. Bu iþlem

sýrasýnda size makinanýn kullanýmý ve bakýmý hususunda bilgi verilecektir. TARAL Yetkili Servisince Ýlk Çalýþtýrma

iþlemi yapýlmamýþ makineler GARANTÝ KAPSAMI DIÞINA ÇIKACAKTIR.

8.1-FIRST OPERATION

Dear consumers, before starting to use our product, make the first operation of your machine by visiting the TARAL

authorized service, which is nearest to your location, together with the FIRST OPERATION COUPON supplied with

the machine. You will not be charged for this, except for the materials to be added to the machine like oil, fuel, etc.

During this procedure you will be informed about the operation and maintenance of the machine. The machines,

which are not gone through the first operation procedure performed by TARAL authorized service, will be

EXCLUDED FROM THE SCOPE OF WARRANTY.

Problem/Problem Sebep/Couse Çözüm/Remedies

Motor /Engine Zor çalýþýyor

Çalýþmýyor

Difficult starting

Fails to start

Karbüratörde

yakýt var

Fuel in carburetor

Karbüratörde yakýt yok

No fuel in carburetor

Benzin filtresi t ýkalý / Fuel filter is dirty or stuck

Benzin hortumu týkalý / Fuel hose is dirty or stuck

Karbüratör / Carburetor

Temizle / Clean

Temizle / Clean

Servis / Service

Silindirde yakýt

var

Fuel in cylinder

Silindirde yakýt yok

No fuel in cylinder

Karbüratör / Carburetor

Servis / Service

Egsoz yakýt la ýslak

Muffler is wet by the fuel

Yakýt karýþýmýçok zengin / The mixture is rich in fuel

Jikleyi aç / Open the choke

Hava filtresini t emizle/deðiþtir

Clean/Replace the air filter

Karbüratör ayarý/Adjust the carburetor

Servis / Service

Buji kablosunda

kývýlcým var

Spark in the spark

plug cable

Buji kablosu ucund a

kývýlcým yok

No spark in the spark

plugcable

Ateþleme düðmesi kapalý konumda/ The knob on the

handle unit is on ‘’STOP’’ position

Elektirik problemi/ Electrical failure

Kilitlenmiþ veya arýzalý ateþleme düðmesi/Defect

knob on the control unit

Açýk konuma getir/Push to ‘’START’’position

Servis / Service

Servis / Service

Bujide kývýlcým

var

Spark in the spark

plug

Bujide kývýlcým yok

No spark in the spark

plug

Buji týrnak ara lýðý ayarsýz/ Spark plug clearence is not

adjusted

Buji týrnaðý karb onla kaplanmýþ/ Deposit on spark

plug end

Boðulmuþ/Too much mixture in the engine

Buji bozuk/Defect spark plug

Servis/Service

Temizle / Deðiþtir/ Clean/Replace

Bujiyi temizle / Deðiþtir/Clean the spark

plug/Replace

Bujiyi temizle / De ðiþtir/ Clean the spark

plug/ Replace

Motor iç problemi / Internal engine problem Servis / Service

Motor ça lýþýyor

Engine runs

Boðuluyor veya sto p

ediyor/Stops

Gaz almýyor/Accelerate

slowly

Hava filtresi k irli/The air filter is dirty

Yakýt filtres i kirli/The fuel filer is dirty

Buji/Spark plug

Karbüratör/Carburetor

Temizle / Deðiþtir / Clean / Replace

Deðiþtir / Replace

Temizle/Ayarla/Desðiþtir/Clean/

Adjust/Replace

Servis/Service

Problem / Problem

Sebep / Cause Çözüm / Remedies

Motor hýzý yetersiz/Engine rpm is not enough. Kötü yakýt kulla nýmý / Dirty fuel usage Doðru yakýt ka rýþýmý , Kalites iz benzin kullanma /

Proper fuel oil mixture,no quality fuel usage

Motor ýsýnmýþ/ Hot engine Buji arýzalý / Defective spark plug Deðiþtir / Replace

Motor soð utucu kanatla r aþýrý kirli, t ýkalý hava akýmý ye tersiz.

Engine cooling fins are to dirty,air flow is not sufficient

Temizle/Clean

Ateþleme arýzalý/Faulty ignition Buji arýzalý / Defective spark plug Deðiþtir/Te mizle / Replace / Clean

Arýzalý buji ka blosu nedeniyle sýkýþtýrma düþ ük/Compression is low

because of flawed spark plug cable.

Kabloyu kontrol et / Check cable

Diðer arýzalar/Other problems Servis / Service

9-ARIZA BULMA TABLOSU/TROUBLE SHOOTING

(14)

Atomizörü her kullandýðýnýzda koruyucu gözlüðünüzü ve kulaklýðýnýzý mutlaka takýnýz.Bu sizi bazý

tehlikelerden koruyacaktýr.

Bu makina dýþ mekanlarda kullanmak için imal edilmiþtir. Havalandýrmasý olmayan yerlerde

kullanýlmamasý gereklidir.

Make sure that you wear your eyeglass and earphone. This will protect you from injuries. This machine is

produced for outdoor usage. It cannot be used in places without air ventilation.

DÝKKAT

DANGER!

Toz ilaç Püskürtme Miktarý/Quantit y of powder pestic ide

Sývý Ýlaç Püskürtme Miktarý/Quantit y of liqui d pesti cide

Motor / Engine

Güç / Power

Sili ndir hacmi / Displacement

Silindir çapý / Bore

Strok / Stroke

Devir sayýsý / Speed

Yakýt / Fuel

Yakýt serfiyatý / Fuel cons umption

Yakýt deposu hacm i / Fuel tank capaci ty

Yol verme / starter

Ateþ leme / Ignit ion

Tip / Type

Karbüratör / Carburetor

Gaz ayarý / Thrott ling

Vantilatör / Blower

Çap / Diameter

Hava debisi / Air volume

Hava çýkýþ hýzý / Air out let veloc ity

Boyut / Dimensi ons

Aðýrl ýk / Weight

* Vantilatörün rotoru direkt olarak krank milinin ucuna baðlanmýþtýr. Vantilatör v e motor bir ünite teþkil eder.

Bu ünite titre þimleri söndürmek için,taþýyýcý çelik çer çev eye lastik elemanlarla baðlanmýþtýr.Kauçuklu sýrt ve

omuz yastýklarý da çalýþmayý kolaylaþtýrýr.

* The fan wheel is directly coupled to the crankshaft.The blower housing and the engine form one unit .

This unit is connected t o the steel f rame w ith ru bber connect ing pieces.B ack cushion and straps facil itate

the operation of the m ist blower.

TARAL A.Þ. GEREK BU KILAVUZDA GEREKSE MAMÜLÜNDE HERHANGÝ BÝR DEÐÝÞÝKLÝK YAPMA HAKKINI SAKLI TUTAR

TARAL RESERVES THE RIGHT TO MAKE ANYCHANGE IN THIS MANUAL AND PRODUCT WITHOUT PRIOR NOTICE

ASTRON 7014 ASTRON 7020

14lt.

2 Zamanlý tek s ilindi rli / Single c ylinder two st rok e

20lt.Ýlaç deposu hacmi/ Chemical tank capact y

5 HP SAE 6000 d/d - rpm

70 cm³

48 mm.

Püsk ürtme mes afesi / Spraying dis tance Dikey / Vertical 8-10m. Yat ay / Horizont a l 12-15m.

Ort./Approx/ 3,5kg./dak.(Tam açýk)kg/min(max.)

0,45-2,66 lt./dak.-lt/min.

40 mm.

Yaylýotomotik starter / Recoil starter

Elektronik / Elec tronic

6000 dev./dak. - rpm

Benzin yað karýþ ýmý / Gasoli ne-oil mi xture

Takriben 0,9lt./ saat-Approx 0,9lt ./hour

1,4 lt .

Membranlý / M Model

Þamandýralý / Float t ype

Spiral t elli gaz kolu / With spiral wire

Radyal / Radial

310 mm.

640 m³/s aat - m³/ h

Püsk ürtme borus u ucunda / At t he outlet of spray t ube

95-100m/sn. (Baþ lýkta) / 95-100m. /secretary

760x500x350

15,4 kg.

780x500x350

15,5 kg.

10-TEKNÝK ÖZELLÝKLER/TECHNICAL DATA

(15)

TS-EN-ISO 9001-2000

Mail: [email protected]

Web : www.taral.com

Fabrika ve Genel Daðýtým

Factory and General Distribution Taral Tarým Makine ve Aletleri Sanayii

Gümüþsuyu Cad. Hastane Yolu No:1

34020 Topkapý-Maltepe-ÝSTANBUL

Tel/Phone: (0212) 567 95 50 (10Hat/Lines)

Fax : (0212) 612 12 39

(0212) 674 06 79

ÝRTÝBAT BÜROLARI/LIAISON OFFICES

ANKARA TEL/PHONE: (0312) 427 71 82 FAX: (0312) 467 73 82

ÝZMÝR TEL/PHONE: (0232) 479 33 36 FAX: (0232) 479 17 40

GSM: (0536) 314 87 61

BÖLGE TEMSÝLCÝLÝKLERÝMÝZ/REGIONAL OFFICES

TARALBATI AKDENÝZ BÖLGE TEMSÝLCÝLÝÐÝ

TARALWESTERN MEDITERRANEAN REGIONAL AGENCY GSM: (0536) 314 87 60

TARALDOÐU KARADENÝZ BÖLGE TEMSÝLCÝLÝÐÝ

TARALEASTERN BLACK SEA REGIONAL AGENCY GSM: (0532) 525 23 15

TARALDOÐU AKDENÝZ TEMSÝLCÝLÝÐÝ

TARALEASTERN MEDITERRANEAN REGIONAL OFFICE GSM: (0537) 424 56 88

(16)

11-CE UYGUNLUK BEYANI/CE DECLARATION OF CONFORMITY

This manual suits for next models

1

Table of contents

Other TARAL Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Raven

Raven SmarTrax installation manual

Tarter

Tarter BOX BLADE Operation and assembly manual

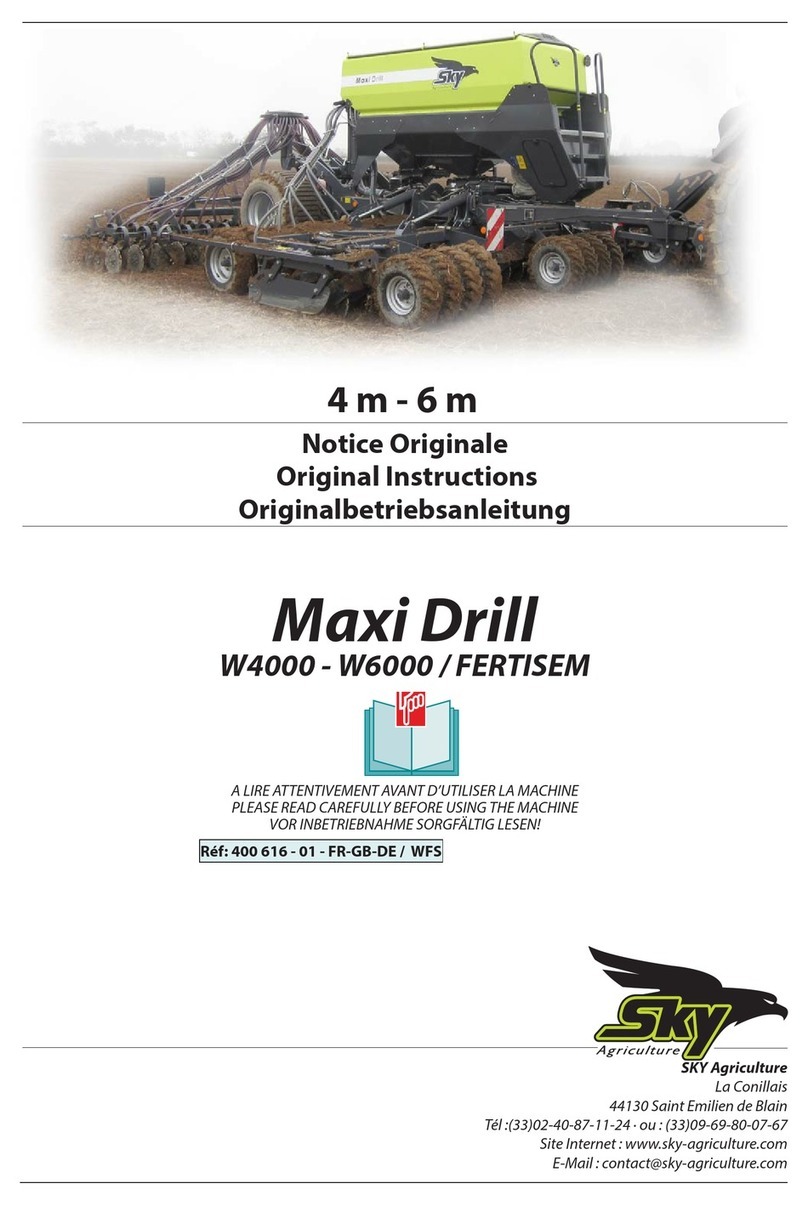

SKY Agriculture

SKY Agriculture Maxi Drill W Series Original instructions

Te Pari

Te Pari Racewell HD3 Operator's manual

New Holland

New Holland TC5040 Operator's manual

Garland

Garland SHAKER 310 DPG instruction manual