Boumatic Opti-Flo II User manual

Opti-FloII Upgrade Kit 1 9E-832

Instructional Content and Purpose

These instructions aim to aid those responsible (outlined under

“Responsibilities”)forinstalling,operating,maintaining,troubleshooting,

and servicing this product.

Responsibilities

Procedures in these instructions are to be performed according to

applicable codes (state, local, and other) by the person(s) qualified

(licensed, if applicable) to do so—that is

• welding must be done by a qualified welder.

• high-voltage AC power wiring must be done by a qualified (licensed)

electrician in compliance with the latest edition of the ANSI/NFPA

Standard 70, National Electrical Code, and in compliance with the

local wiring codes as applicable.

• other installation, major maintenance, and service work must be

done by the dealer.

• product/system checkout and troubleshooting steps are to be

performed by the dealer or technician.

• deviation from these installation instructions could affect product

performance or create a hazardous situation. Under no

circumstances will Bou-Matic be responsible for any problems

causedinwholeorinpartbyanydeviationfrominstallationprocedures

specified in these instructions without prior written approval from

Bou-Matic.

• operation steps may be performed by the owner/operator once the

dealer or technician has successfully finished the product/system

checkout. The owner/operator is responsible for properly operating,

maintaining, and monitoring the product/system to ensure that it

works properly.

Closecompliancewiththeprocedureshereinisessentialfortheowner

to get maximum benefit from the product/system.

Disclaimers

No warranties are contained in these instructions. The division of

responsibilities,statedabove,isageneralreminderofthoseprovisions

in the applicable dealer contract and does not change any agreement

betweenBou-Maticandthedealer. Informationinthispacketisnotall-

inclusive and cannot cover all unique situations.

____________________________________________________________________________________

Opti-Flo II™ Upgrade Kit

InstallationInstructions

Introduction

Bou-Matic® part number 4024556 is a kit designed to

replace the ABB ACS 300, 230 Volt control with the

Magnetek GPD 315, 230 Volt control. The Magnetek

GPD 315 control provides the same features as the ABB

ACS300control.Whenproperlyinstalledandprogrammed

the Opti-Flo II™ with a Magnetek GPD 315 control will

operate the same as the Opti-Flo II with an ABB ACS

300control.

1.

Preparation

1.1 Verifying Part and Tool Requirements

The kit contains the following:

1. Magnetek GPD 315 control assy. ............................. 1

2. Wiring label ............................................................... 1

3. Screwdriver with small blade ................................... 1

4. Magnatek GPD 315 Instruction Manual ................... 1

When installing parts, the dealer should be equipped with

standardinstallation tools. Nonstandard toolswill be noted

where used.

1.2 Reviewing Personal Safety Messages

Follow the safety messages listed below and throughout

the packet to prevent possible bodily injury:

—WARNING——————————————————–

Before opening control box disconnect power from electrical

supply or severe injury or death could occur.

—WARNING——————————————————–

Dangerous voltage. Consult Magnetek users manual before

opening the Magnetek controller. Wait at least 5 minutes after

disconnecting supply before removing the cover. High leakage

current. Earthconnectionessentialbefore connecting supply.

Contents

Introduction .......................................................................... 1

1. Preparation ..................................................................... 1

1.1 Verifying Part and Tool Requirements.................... 1

1.2 Reviewing Personal Safety Messages ................... 1

2. Installation....................................................................... 1

3. Verifying Proper Operation............................................. 3

4. GPD 315 Parameters ...................................................... 8

Bou-MaticLLC

1919S.StoughtonRd.

P.O.Box8050

Madison,WI 53708-8050

(608)222-3484Fax:(608)222-9314

Internet:www.Bou-Matic.com

Opti-FloII Upgrade Kit 2 93-832

2. Installation

1. Disconnect power from the electrical supply.

2. Open the Opti-Flo II enclosure.

3. RemovetheplasticcoveroftheABBACS300control

by loosening the 2 screws at the bottom of the cover

andsqueezingthe2plastictabslocatedatthetopside

of the cover.

— NOTE ————————————————––––––––––––

Do not cut the wires going to the ABB ACS 300 control.

4. Remove ONLY the wires from the terminal blocks of

the ABB ACS 300 control.

5. Remove the solid color brown, red and orange wires

from the Opti-Flo II main terminal block which come

from the input filter. Discard the filter.

6. Take the ABB ACS 300 control out of the enclosure

by removing and saving the 4 mounting screws and

lockingwashers.

—WARNING——————————————————–

Before opening control box disconnect power from electrical

supply or severe injury or death could occur.

—WARNING——————————————————–

Dangerous voltage. Consult Magnetek users manual before

opening the Magnetek controller. Wait at least 5 minutes after

disconnecting supply before removing the cover. High leakage

current. Earth connection essential before connecting supply.

7. InstalltheMagnetekGPD315assemblyintotheOpti-

FloIIenclosureusingthe4savedscrewsandlocking

washers(seeFigure2).

8. Connect thegreenwirewiththeyellowstripe(Ground)

fromtheMainterminalblocktotheGroundscrewofthe

MagnetekGPD315.TheGroundscrewislocatedjust

belowthe T3 terminalblockposition of theMagnetek

GPD315(seeFigure 1).

gniriWretliFtuptuO:1elbaT

htiweriwetihW epirtsnworb

lanimretoT fo1Tnoitacol 513DPG 1erugiFeeS

htiweriwetihW epirtsder

lanimretoT fo2Tnoitacol 513DPG 1erugiFeeS

htiweriwetihW epirtsegnaro

lanimretoT fo3Tnoitacol 513DPG 1erugiFeeS

9. Crimp the two white wires with the yellow stripe from

the existing wire harness into the wire adapter of the

samecolor (see Figure 1).

10. Crimpthetworedwireswiththeyellowstripefromthe

existingwireharnessintothewireadapterofthesame

color(seeFigure 1).

11. Usingthenewwiringlabelasaguideinstallthe3wires

from the ORIGINAL output filter, white wires with the

brown, red and orange stripes to the proper terminal

locations of the Magnetek GPD 315 (see Figure 1,2

andTable1).

— IMPORTANT ——————————————––––––––––

Miswiring will cause damage to the Magnetek GPD 315.

snoitcennoCssenraHeriW:3elbaT

eriweulB yaleroT 01noitacol,1K 1erugiFeeS

yargelbuodtrohS seriw yaleroT 9noitacol,1K 1erugiFeeS

yargelbuodgnoL seriw

ehtfo7JoT niamIIolF-itpO kcolblanimret 1erugiFeeS

dnaetihwelbuoD seriwyarg

ehtfo6JoT niamIIolF-itpO kcolblanimret 1erugiFeeS

htiwetihwelbuoD seriwepirtsegnaro

ehtfo2JoT niamIIolF-itpO kcolblanimret 1erugiFeeS

etihwdnaetihW epirtsteloivhtiw seriw

ehtfo4JoT niamIIolF-itpO kcolblanimret 1erugiFeeS

htiwetihwelbuoD seriwepirtsteloiv yaleroT 5noitacol,1K 1erugiFeeS

wolleyhtiwetihW eriwepirts yaleroT 2noitacol,1K 1erugiFeeS

gniriWretliFtupnI:2elbaT

eriwnworB noitacollanimretoT IIolF-itpOehtfo1L kcolblanimretniam 1erugiFeeS

eriwdeR noitacollanimretoT IIolF-itpOehtfo2L kcolblanimretniam 1erugiFeeS

eriwegnarO noitacollanimretoT IIolF-itpOehtfo3L kcolblanimretniam 1erugiFeeS

Opti-FloII Upgrade Kit 3 9E-832

13. Usingthenewwiringlabelasaguide,connectthesolid

brown,redandorangewiresfromtheinputfiltertothe

properterminalblocklocationsoftheOpti-FloIImain

terminal block (see Figures 1,2 and Table 2).

12. Usingthenewwiringlabelasaguide,removeexisting

wires from the Opti-Flo II main terminal block and

install the proper wire from the new wire harness

coming from the GPD 315 (see Table 3). The wire

colorsbetweenthenewandexistingwireharnessare

essentiallythesametohelptheinstallationandeliminate

confusion. Theoldwireharnessistobediscarded(see

Figure1).

14. Atthispointallwiringshouldbecompleted.Insureall

wiresaresecurelyinstalled.Usingthenewwiringlabel,

doublechecktoverifythatallwiresareinstalledatthe

properlocations(seeFigure2).

— IMPORTANT ——————————————––––––––––

Miswiring will cause damage to the Magnetek GPD 315.

3. Verifying Proper Operation

1. Refer to Figure 3 for a function block diagram.

2. VerifythatallReceiverProbesareintheOFFposition

and that there is an OPEN between Receiver Probe

COMMON ( J3 ) and the LOW, MEDIUM, and HIGH

Receiver probe inputs ( J5, J6, and J7 ).

3. Switch“ON”powerfrom the breaker tothe

Opti-Flo II.

4. Thecontrolshouldcomeupwiththegreen“RUN”LED

flashing,thegreen“FOUT”LEDONcontinuously,the

red4digitdisplayshowing“0.00” andthered“ALARM”

LEDOFF.

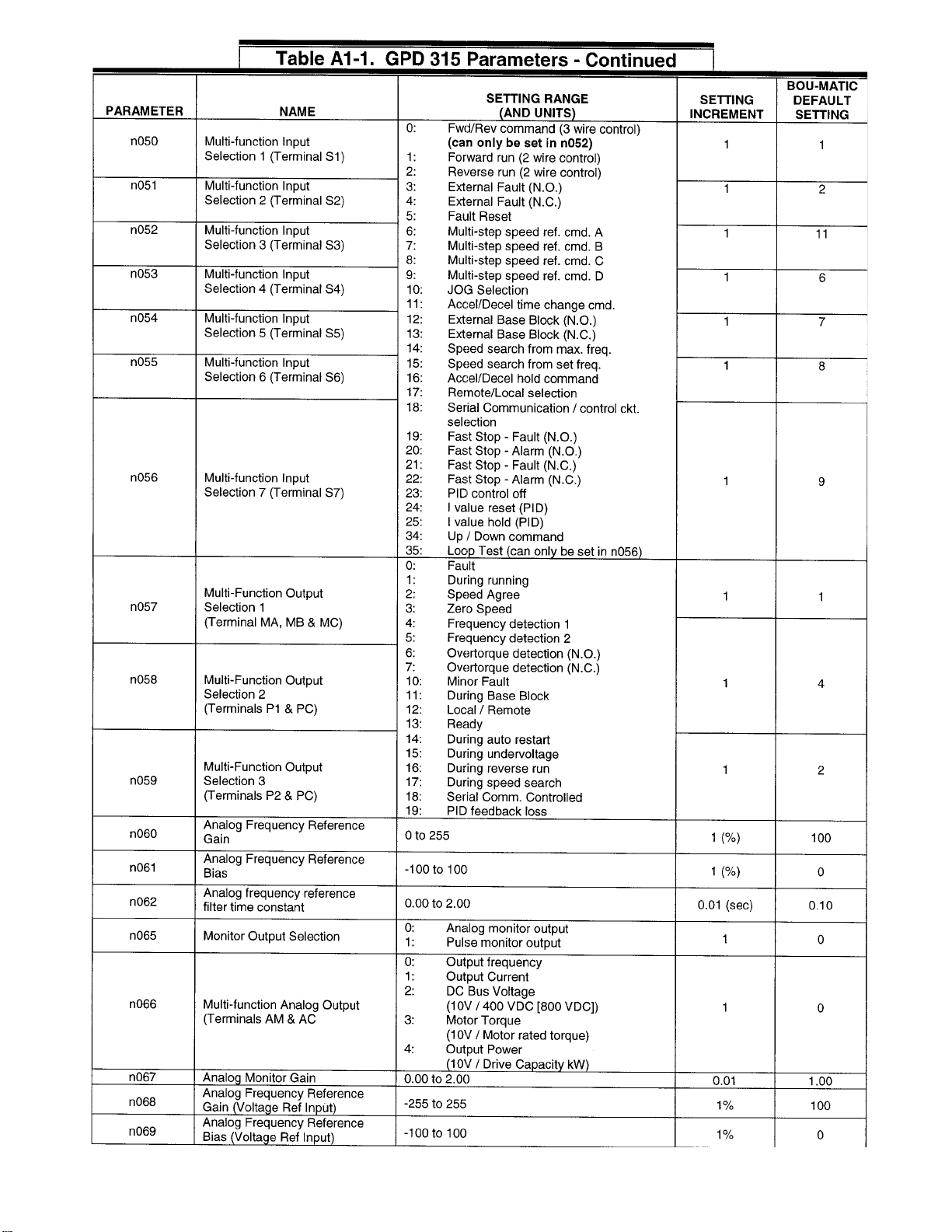

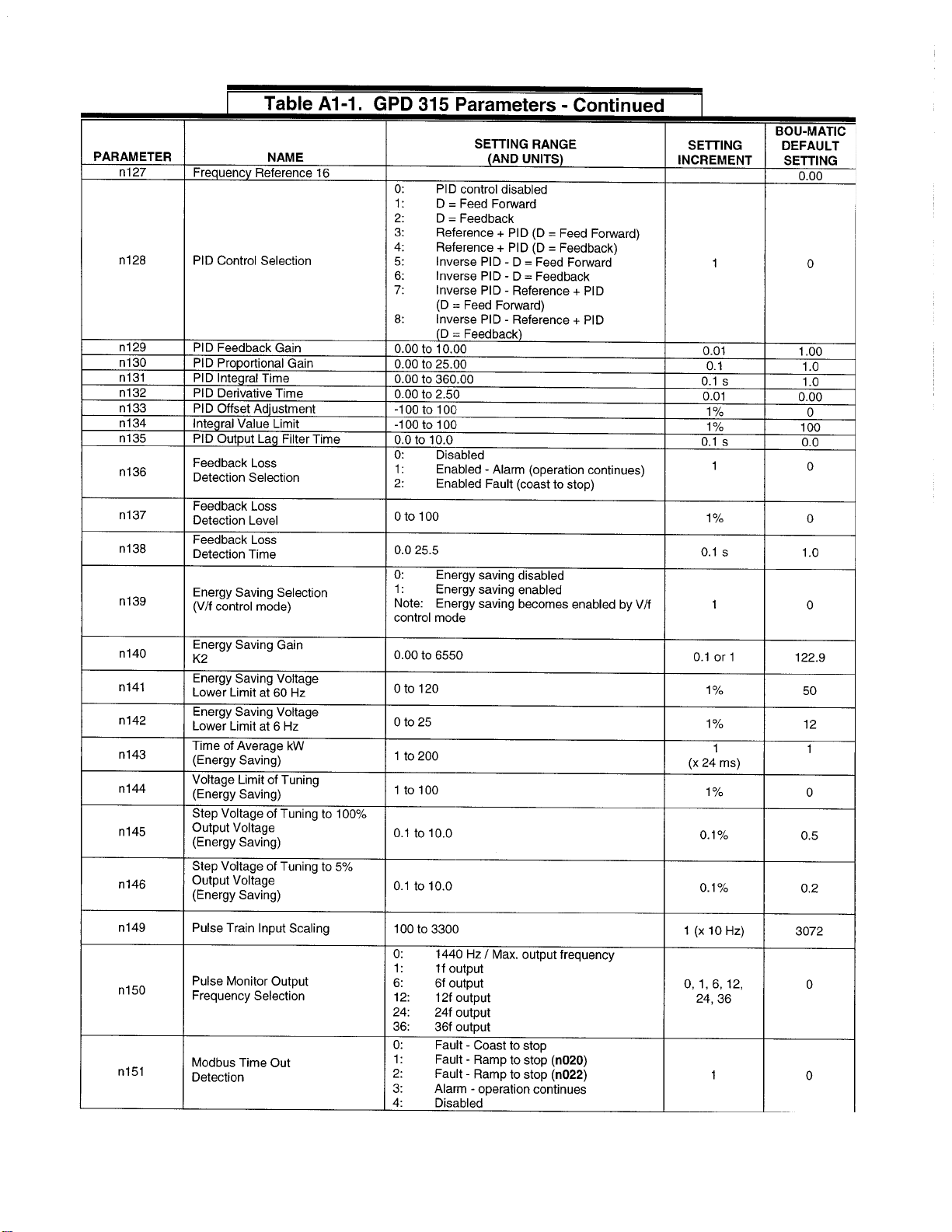

5. The Magnatek GPD 315 parameters can be viewed

and programmed by using the Digital Operator (see

Figure1).Pressthe“DSPL”keyuntilthegreen“PRGM”

LED turns ON. Each parameter starts with the small

letter “n” and is followed by a 3 digit number. The red

4 digit display will display “nXXX” where XXX is a

numberbetween001and179.Usethe“^”(UP)keyto

incrementupandthe (DOWN)keytoincrementdown

dependingonwhich parameter you are interestedin.

Once you get to the desired parameter press the

“DATA/ENTER” key to display the present value

programmedintotheparameter.Tochangeorprogram

thedesiredparameterusethe“^”(UP)keytoincrement

upandthe (DOWN)keytoincrementdowndepending

onwhatvalueyouwanttoprogramintothatparameter.

Once the desired value is being displayed press the

“DATA/ENTER”keytostorethedesiredvalueintothe

parameter.Afterallparameterprogrammingiscomplete

pressthe“DSPL”keyuntilthegreen“FOUT”LEDturns

ON. A listing of installation specific parameters is

givenin Table 4. A completelistofall the parameters

can be found in Table A1-1.

—NOTE——————————————–––––––––––––––––

The parameters listed in Table 4 are the ONLY ones that may

need to be reprogrammed for proper operation. Of these,

Parametern036,“MotorRatedCurrent”isthesetfora1HpBou-

Matic milk pump motor and MUST be reprogrammed per the

motor nameplate to insure proper operation.

6. Activatethemanualpumpoutswitch.Themilkpump

motorshouldstartrunning. Verifythat the milk pump

isrotatinginthecorrectdirection. Ifitisnot,turn“OFF”

the breaker and check the wiring of the motor.

7. Aftercheckingmotordirection,checkthefloatswitches

forproperoperation.Thelowfloatshouldrunthemotor

at50Hz. Thehighfloatshouldrunthemotorat60Hz.

If an optional middle float switch is used, it will be

preset to run at 55 Hz. Check each float individually.

8. Check the Milk/Wash switch for proper operation. All

floatswitchesshouldbeloweredandthemotorshould

gnimmargorP513DPG:4elbaT

retemaraP foemaN noitcnuF tnemmoC citaM-uoB tluafeD

110n mumixaM ycneuqerF

rePteS rotoM etalpemaN zH06

210n mumixaM egatloV

rePteS rotoM etalpemaN stloV032

120n noitareleccA 2emiT

=,#rehgiH emitregnol tnioptesot .ceS4

220n noitareleceD 2emiT

=,#rehgiH emitregnol tnioptesot .ceS01

420n ycneuqerF 1ecnerefeR

ycneuqerF WOLrof EBORP zH05

520n ycneuqerF 2ecnerefeR

ycneuqerF MUIDEMrof EBORP ZH55

720n ycneuqerF 4ecnerefeR

ycneuqerF HGIHrof EBORP zH06

630n detaRrotoM tnerruC

rePteS rotoM etalpemaN spmA8.2

Opti-FloII Upgrade Kit 4 93-832

1

notberunning. SwitchtheMilk/WashswitchtotheWash

positionand raisethelowfloat. Themotorshouldrun up

to60Hzinjustafewseconds. Lowerthefloatswitchand

the motor should stop turning in just a few seconds.

9. Adjusttheparametersas required. All parameter defaults

are set for a 1 Hp motor. If a 2 Hp or 3 Hp motor is used,

someparametersmustbechanged.Alistingofinstallation

specific parameters is given in Table 4. A complete

parameter list is given in Table A1-1.

10. If the individual components of the system seem to be

operating correctly, run a wash cycle to check out the

completesystem.Duringthewashcycle,switchtheMilk/

WashmodebetweenMilkandWashmodes. IntheWash

modethecontroltriestorunthemilkpumpat60Hzaslong

as the low float switch is closed.

Thepumpwillslowdownquicklywhenthelowfloatswitch

opens. In the Milk mode the control tries to run the milk

pumpat50Hzwhenthelowfloatswitchisclosed,andwill

ramp up to 60 Hz only when the high float switch closes.

Itwill ramp slowly downfrom60 Hz onlywhenthe

high float switch opens. It will ramp slowly down

from the 50 Hz when the low float switch opens. If

the control is connected to a solenoid to control

waterflowtoaplatecooler,thesolenoidshouldbe

“OFF”whenthecontrolisintheWashmodeandthe

solenoid shouldbe“ON”whenthecontrolisinthe

Milk mode, with the milk pump running.

11. Replacetheexistingwiringlabelwiththewiringlabel

provided in the kit.

12. Mountthe plastic shroud backontothe Magnetek

GPD 315.

13. Mount the access panel back onto the Magnetek

GPD315.

14. Close and tighten the Opti-Flo II cover.

Opti-FloII Upgrade Kit 5 9E-832

2

1. Wiring the GPD 315 to the Opti-Flo II main terminal block 832_1

GPD 315

Opti-Flo II main terminal block

Digitaloperator

Opti-FloII Upgrade Kit 6 93-832

2. Opti-Flo II upgrade kit wiring label, P/N 4024550 832_2

Opti-FloII Upgrade Kit 7 9E-832

6

3. Wiring label, function block diagram, P/N 4024550 832_3

Opti-FloII Upgrade Kit 8 93-832

4. GPD 315 Parameters

Opti-FloII Upgrade Kit 9 9E-832

Opti-FloII Upgrade Kit 10 93-832

Opti-FloII Upgrade Kit 11 9E-832

Opti-FloII Upgrade Kit 12 93-832

Opti-FloII Upgrade Kit 13 9E-832

Table of contents

Popular Control Unit manuals by other brands

socomec

socomec DIRIS O-m quick start

Honeywell

Honeywell Braukmann FD300 installation instructions

HP

HP 81541MM Operating and programming manual

Niobrara

Niobrara QUCM 3964 Installation and programming manual

GESTRA

GESTRA QuickEM Original Installation Instructions

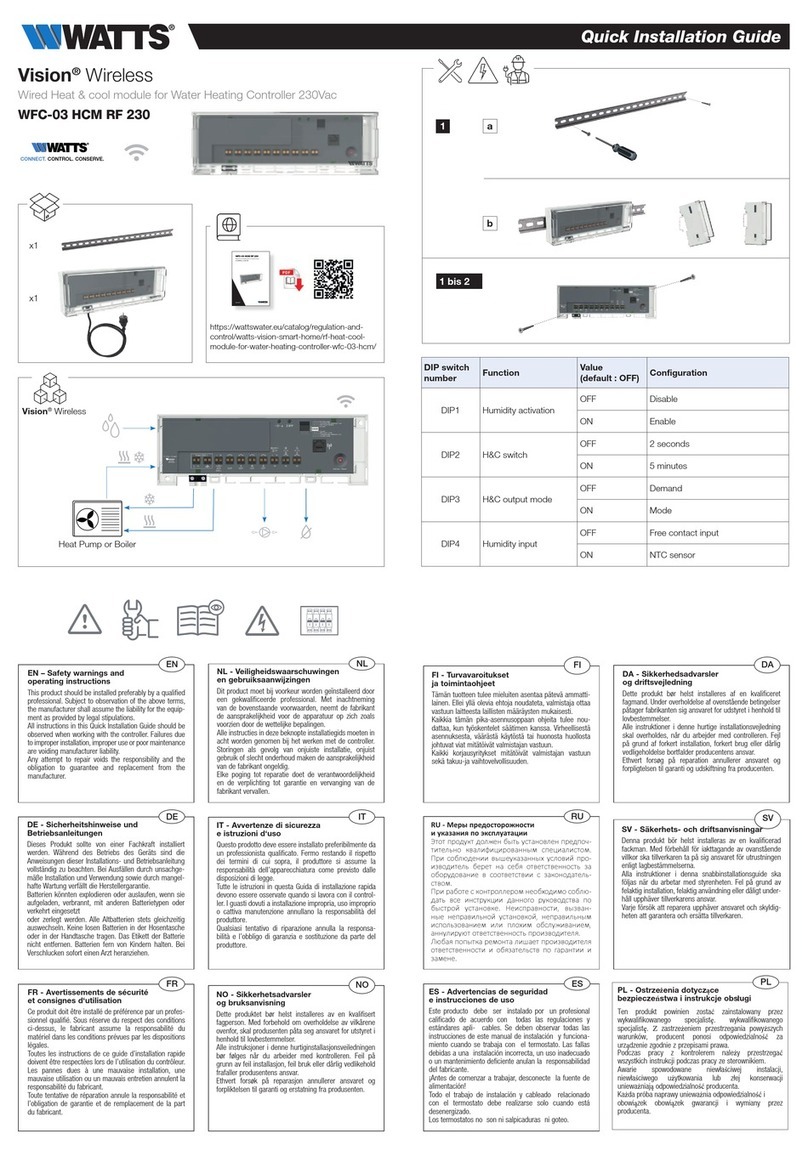

Watts

Watts WFC-03 HCM RF 230 Quick installation guide