●

Always observe the following items.

1. When using this product in a medium control system, use only

genuine Koganei parts or compatible parts (recommended

parts).

Use only authentic Koganei parts or compatible parts

(recommended parts) to do maintenance or repairs.

Always observe the prescribed methods and procedures.

2. Never inappropriately disassemble or modify the product in

relation to its basic construction, performance, or functions.

Koganei cannot be held responsible for any problems that occur as a

result of these safety precautions not being properly observed.

Other

CAUTION

●

Do not use the product in locations subject to direct sunlight (ultraviolet

radiation); in locations subjected to high temperature or humidity; in

locations where dust, salt, or iron particles are present; or in locations

with media and/or an ambient atmosphere that includes organic

solvents, phosphate ester type hydraulic oil, sulfur dioxide gas, chlorine

gas, acids, etc. It could lead to early shutdown of some functions, a

sudden degradation of performance, and a reduced operating life. For

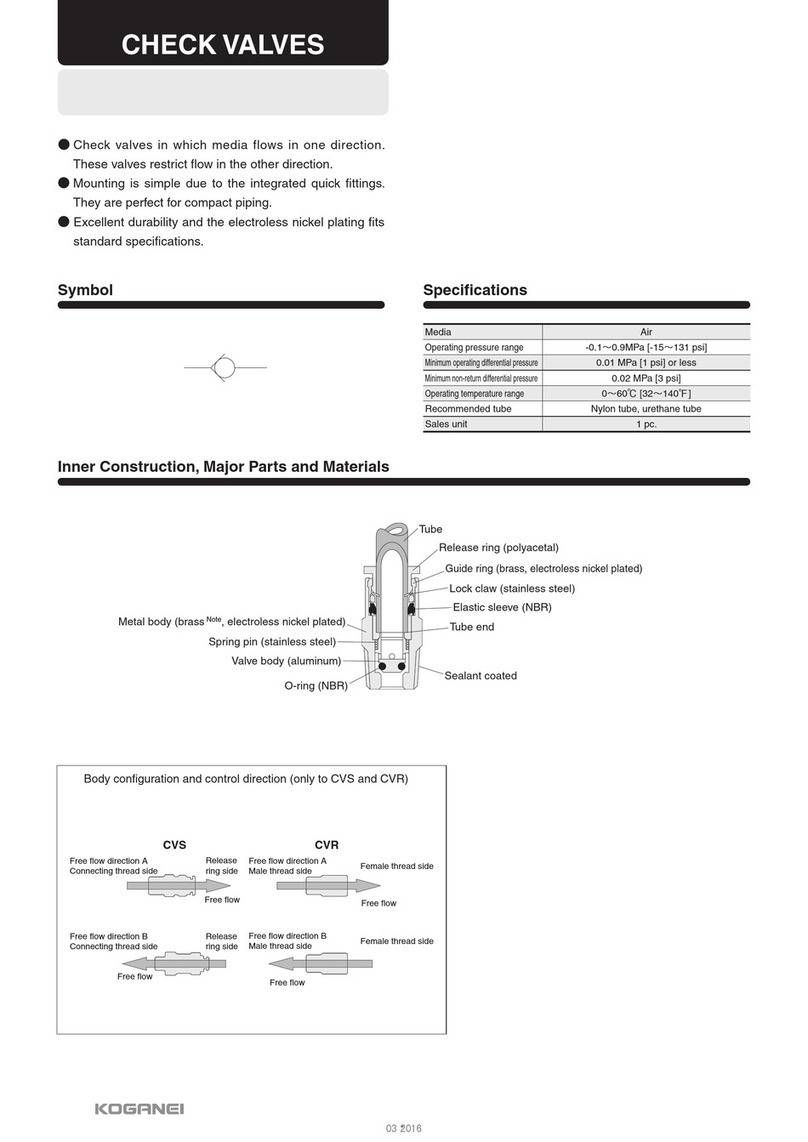

information about materials, see Major Parts and Materials.

●

When mounting the product, leave room for adequate working space

around it. Failure to do so will make it more difficult to conduct daily

inspections or maintenance, which could eventually lead to system

shutdown or damage to the product.

●

When transporting or mounting a heavy product, firmly support the

product using a lift or support, or use multiple people to ensure

personal safety.

●

Do not bring any magnetic media or memory within one meter of

energized proportional control valves. Doing so creates the risk of

damage to data on the magnetic media due to magnetism.

●

Do not use a proportional control valve in locations subject to large

electric currents or strong magnetic fields. It could result in erratic

operation.

●

Oil from the compressor (with the exception of oil-free compressors)

may dramatically decrease the product's capabilities or cause the

functions to stop. Be sure to remove oil from the air by installing a

mist filter preceding the pneumatic equipment.

●

When the media is liquid, provide a relief valve on the circuit to

prevent a liquid seal around the circuit. Failure to do so can result in

the valve not being able to open.

ATTENTION

●

Whenever considering use of this product in situations or

environments not specifically noted in the catalog or in manuals, or

in applications where safety is an important requirement such as in

aircraft facilities, combustion equipment, leisure equipment, safety

equipment, and other places where human life or assets may be

greatly affected, take adequate safety precautions such as allowing

plenty of margin for ratings and performance, or fail-safe measures.

Contact the sales department at Koganei regarding use in such

applications.

●

Always check the catalog and other reference materials for product

wiring and piping.

●

When handling the product, wear protective gloves, safety glasses,

protective mask, safety shoes, and other protective clothing

whenever necessary.

●

When the product can no longer be used or is no longer necessary,

dispose of it appropriately as industrial waste.

●

A proportional control valve can exhibit degraded performance and

function over its operating life. Always conduct daily inspections and

confirm that all requisite system functions are satisfied to prevent

accidents from happening.

●

Proportional control valves are not completely leak-free. Designs

should take into considering the capacity and retention time required

for pressure retention within the pressure vessel, etc.

●

For inquiries about the product, consult your nearest Koganei sales

office or the Koganei Overseas Department. The addresses and

telephone numbers are shown on the back cover of this catalog.

●Do not use proportional control valves or the wiring that

controls them in locations subject to surges or near strong

magnetic fields or power lines through which large electric

currents flow. It could result in unintended operation.

●When a proportional control valve is turned off, it may

generate a surge voltage or an electromagnetic wave that

affects the operation of surrounding equipment. Use surge-

protected solenoids and use countermeasures for

electromagnetic waves and surges to electric circuits.

●Do not use the product near the ocean, in direct sunlight,

near mercury vapor lamps, or near equipment that generates

ozone. Deterioration of rubber parts caused by ozone may

reduce performance and functions or stop functions.

●Do not allow the product to be thrown into fire. Doing so

creates the risk of the product exploding or the release of

toxic gases.

●Do not sit on the product, place your foot on it, or place other

objects on it.

Doing so creates the risk of injury due to tripping or the

product tipping over or falling, resulting in product damage

and abnormal, erratic, or runaway operation.

●Leave all maintenance, inspection, repair, piping (attachment,

detachment, replacement) or similar work up to personnel

who have sufficient knowledge and experience in the

applicable products, media, media control systems, etc.

When performing work, be sure to totally turn off media

supply and also note the points below.

1. In the case of gas, make sure to confirm that pressure

inside the product and piping connected to the product is

zero. In particular, be aware that residual air will still be in

the air compressor or air storage tank. The actuator may

move abruptly if residual air pressure remains inside the

piping, causing injury.

2. In the case of liquid, remove all liquid from inside the

product and piping. Corrosive media, in particular, creates

the risk of chemical burns and contamination of the

surrounding area.

3.In the case of high-temperature media, observe the

precautions above and also make sure that the valve has

cooled sufficiently. Unintentional contact creates the risk of

burn injuries.

●When using an antifrost heater or heat insulation material to

keep the product warm, use it on the main part of the product

and not on the solenoid. Coil burnout creates the risk of

electric shock, fire, and abnormal operation.

●Use of this product under the conditions described below

comes under the jurisdiction of Japan's High Pressure Gas

Safety Act. Note that violations by individuals or corporations

are punishable by law.

Use of compressed gas with a gauge pressure of 1 MPa [145

psi] or greater under normal temperature or use of gas with a

pressure of 1 MPa [145 psi] under conditions converted to a

temperature of 35 ℃[95 ℉] (acetylene gas and liquefied gas

are subjected to even stricter standards).

For details, refer to the High Pressure Gas Safety Act.

●When installing a proportional control valve in the control anel

or when the energizing time is long, use countermeasures for

heat dissipation so that the ambient temperature of the

proportional control valve is always within the specified

temperature range. In particular, note that continual charging

of a proportional control valve that is fully open can cause an

increase in resistance due to a rise in solenoid temperature,

and loss of function of the temperature compensation circuit,

which stabilizes the flow rate.

●Long-term continuous charging can make the coil hot.

Unintentional contact creates the risk of burn injuries.

●After completing wiring work, check to make sure that all

connections are correct before turning on the power.

●Design devices so fluid control equipment is not operated by

an emergency stop, power outage, or other system

abnormality, and so there is no chance of damage or

personal injury even upon return to the non-energized state.

❹