B+BTec Karat 180-BG User manual

bbtectools.com

TRANSLATION OF THE ORIGINAL INSTRUCTIONS

US

BUSM2001V1

US INHOUD

For your safety ........................5

Special tools safety warnings ..........5

Tool Specifications .................... 6

Operating Controls....................7

Safety guidelines......................7

Intended Use .........................7

Before Use ............................ 7

Initial Operation ......................7

Hand held drilling..................... 8

–Hand held wet drilling..............8

–Hand held dry drilling ..............9

Drilling with a drill stand .............. 9

Over head drilling....................10

Transport and Storage ...............10

Maintenance and care................11

Troubleshooting .....................11

Replacement parts ...................12

Guarantee ...........................12

Environmental Protection ............12

Information on Noise and Vibration...12

Declaration of Conformity............12

19

20

21

22

23

24

25

26

27

28

29

30

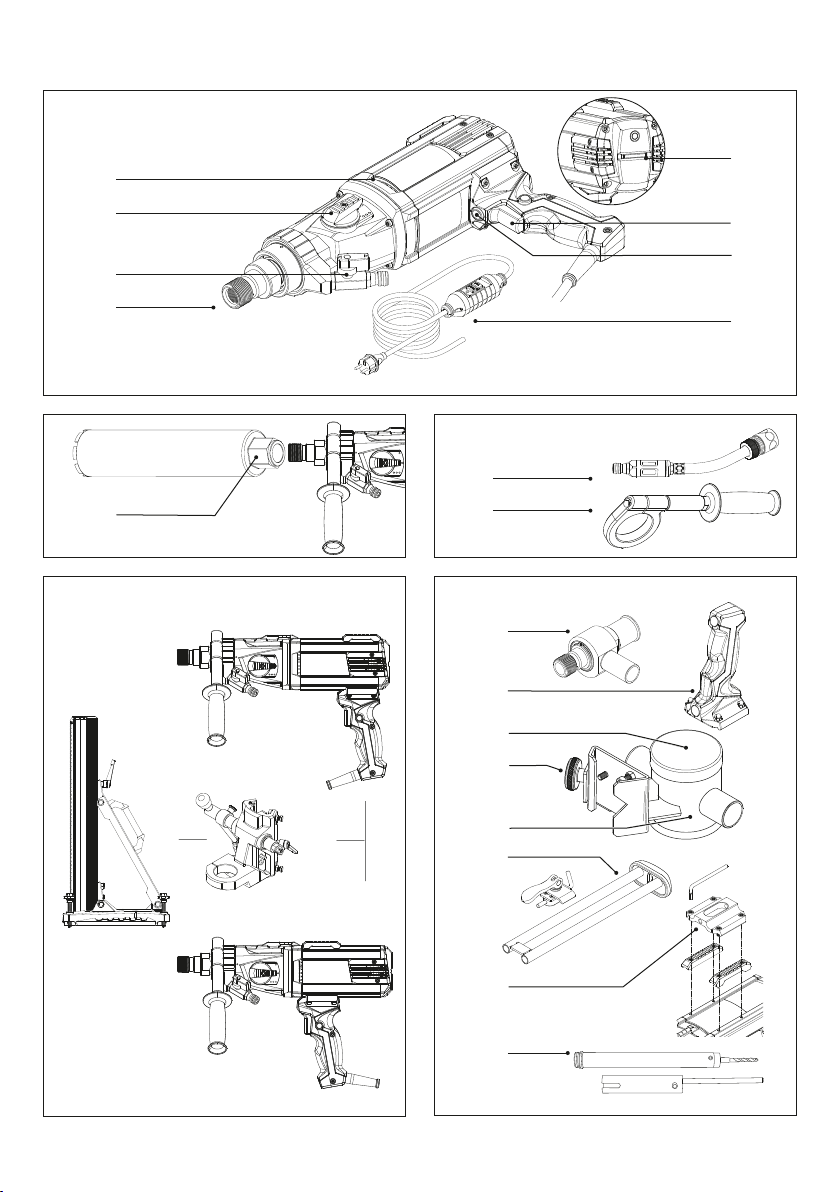

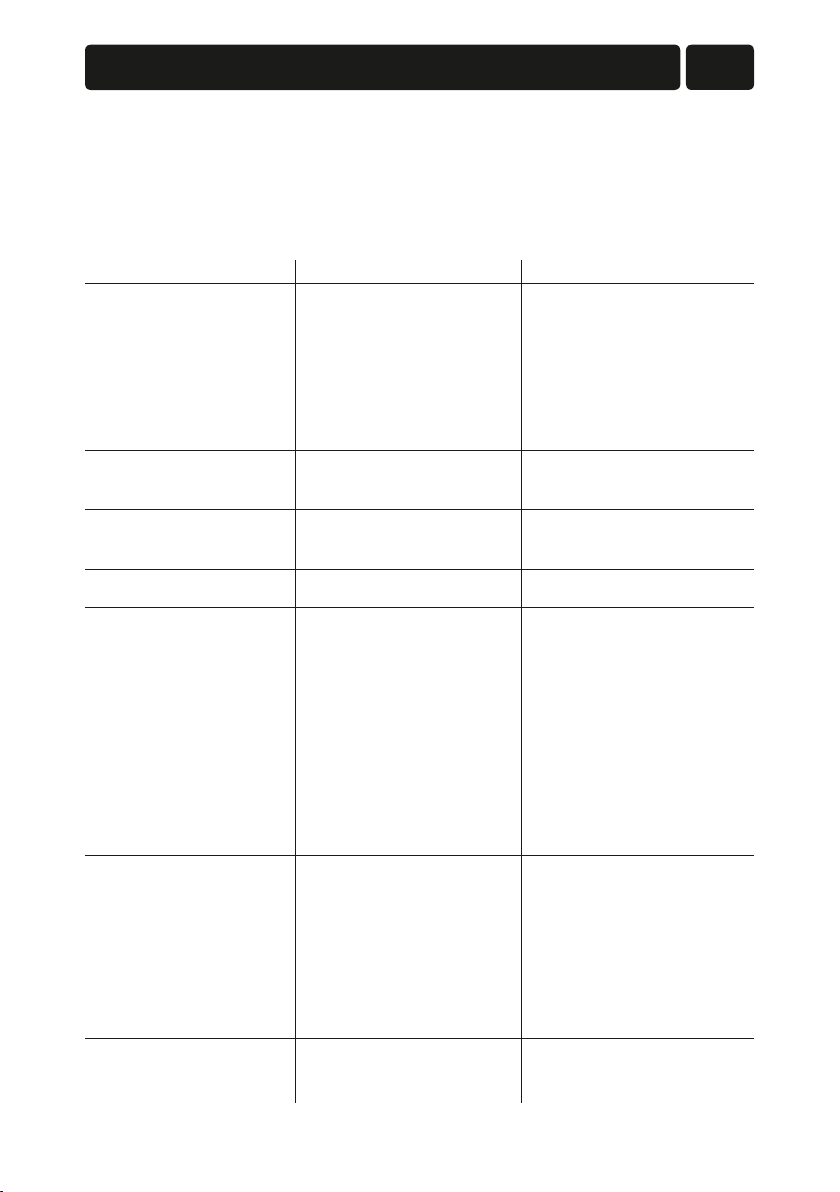

Compact

31

Optionals

11

12

Compact

Karat 180-MG

Karat 180-BG

Karat 180

1

2

3

4

8

7

6

5

Accessories

9

10

13

14

15

16

17

18

KARAT®180US

4 OPERATING MANUAL KARAT® 180

GENERAL POWER TOOL

SAFETY WARNINGS

WARNING: Read all safety warnings

and all instructions. Failure to fol-

low the warnings and instructions

may result in electric shock, fire

and/or serious injury.

Save all warnings and instructions

for future reference.

The term “power tool” in the warnings refers to

your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or

dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or

fumes.

c) Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased

risk of electric shock if your body is earthed or

grounded.

c) Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges and moving parts. Damaged or entan-

gled cords increase the risk of electric shock.

e) When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

f ) If operating a power tool in a damp loca-

tion is unavoidable, use a residual current

device (RCD) protected supply. Use of an RCD

reduces the risk of electric shock.

g) Make sure you have a proper connection of

the tool at a socket outlet.

3) Personal safety

a) Stay alert, watch what you are doing and use

common sense when operating a power

tool. Do not use a power tool while you are

tired or under the influence of medication.

A moment of inattention while operating

power tools may result in serious personal

injury.

b) Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes,

hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

c) Prevent unintentional starting. Ensure the

switch is in the off-position before connect-

ing to power source and/or battery pack,

picking up or carrying the tool. Carrying

power tools with your finger on the switch or

energising power tools that have the switch

on invites accidents.

d) Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power

tool may result in personal injury.

e) Do not overreach. Keep proper footing and

balance at all times. This enables better con-

trol of the power tool in unexpected situa-

tions.

f ) Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jew-

ellery or long hair can be caught in moving

parts.

g) If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does

not turn it on and off. Any power tool that

cannot be controlled with the switch is dan-

KARAT®180 US

OPERATING MANUAL KARAT® 180 5

gerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are dan-

gerous in the hands of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tool’s operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f ) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from

those intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a qualified

repair person using only identical replace-

ment parts. This will ensure that the safety of

the power tool is maintained.

b) For power tools with type X attachment,

where a specially preparde cord is needed

to replace the cord: if the supply cord of this

power tool is damaged, it must be replaced

by a specially preparded cord available

through a qualified service facilty.

FOR YOUR SAFETY

Please read and comply with these

instructions prior to the initial

operation of your device.

Retain these instruction manual for

future reference or for subsequent

possessors.

WARNING: Prior to the first start-

up, it is definitely necessary to read

the Safety instructions!

In case you do not adhere to this instruction

manual and the safety instructions, this may result

in damages on the device and cause dangerous

situations for the operator and other people. In

case of transport damage inform vendor imme-

diately.

SPECIAL TOOLS SAFETY

WARNINGS

Working safely with this machine is possible

only when the operating and safety informa-

tion are read completely and the instruc-

tions contained therein are strictly followed.

Before using for the first time, ask for a prac-

tical demonstration.

Before working on the machine

itself, pull the mains plug.

Wear safety glasses and

ear protectors when

impact drilling.

Wear light respiratory

protection and a hard

hat.

Be careful of hidden electrical lines

or gas and water pipes. Check the

working area, e.g., with a metal

detector.

Use auxiliary handle(s), if supplied

with the tool.

Loss of control can cause personal inju-

ry.

KARAT®180US

6 OPERATING MANUAL KARAT® 180

•Before commencing work, the PRCD pro-

tective switch must be checked for proper

functioning.

•Before commencing work consult the

responsible structural engineers, architects or

site supervision about any planned borings,

especially when cutting through reinforcing

steel.

•The machine may only be operated using

a power supply with protection earthing

according to the regulations.

•The machine may not be operated by per-

sons under the age of 16 years.

•The drill stand must always be mounted

firmly and must not be able to move during

drilling.

•Only mount the drill stand on an even, firm

and smooth surface using the vacuum pump

.

When carrying out

“over” head wet cut

core drilling, a

water collecting

ring and water suc-

tion are always to

be used. These must be in perfect

condition.

•When drilling “over” head always secure the

drill stand with the assembly.

•Prevent the drilling core from falling.

Use only original B+BTec parts and acces-

sories.

TOOL SPECIFICATIONS

Drilling machine 115V~ Karat 180-BG Karat 180-MG

Part nr. 2.000.226 2.000.229

Input power Watt 2400 W 2400 W

No-load speed Position 1-2-3 (n0) min-1 780 - 1690 - 3520 780 - 1690 - 3520

Bore diameter

Ideal in reinforced concrete Ø inch 5/8 - 6 1/4 5/8 - 6 1/4

1. Gear Wet / Dry Ø inch 3 - 7 / 4 3/4 - 8 3 - 7 / 4 3/4 - 8

2. Gear Wet / Dry Ø inch 1 1/2 - 3 / 2 3/8 - 4 3/4 1 1/2 - 3 / 60 - 122

3. Gear Wet / Dry Ø inch 5/16 - 1 1/2 / 1 1/2 - 2 3/8 5/16 - 1 1/2 / 1 1/2 - 2 3/8

Dimensions L x B x H inch 17 x 16 x 11 1/2 17 x 16 x 11 1/2

Weight

Motor lbs 15 15

Guide block lbs 9.25 9.25

Drill Stand Compact lbs 21 21

KARAT®180 US

OPERATING MANUAL KARAT® 180 7

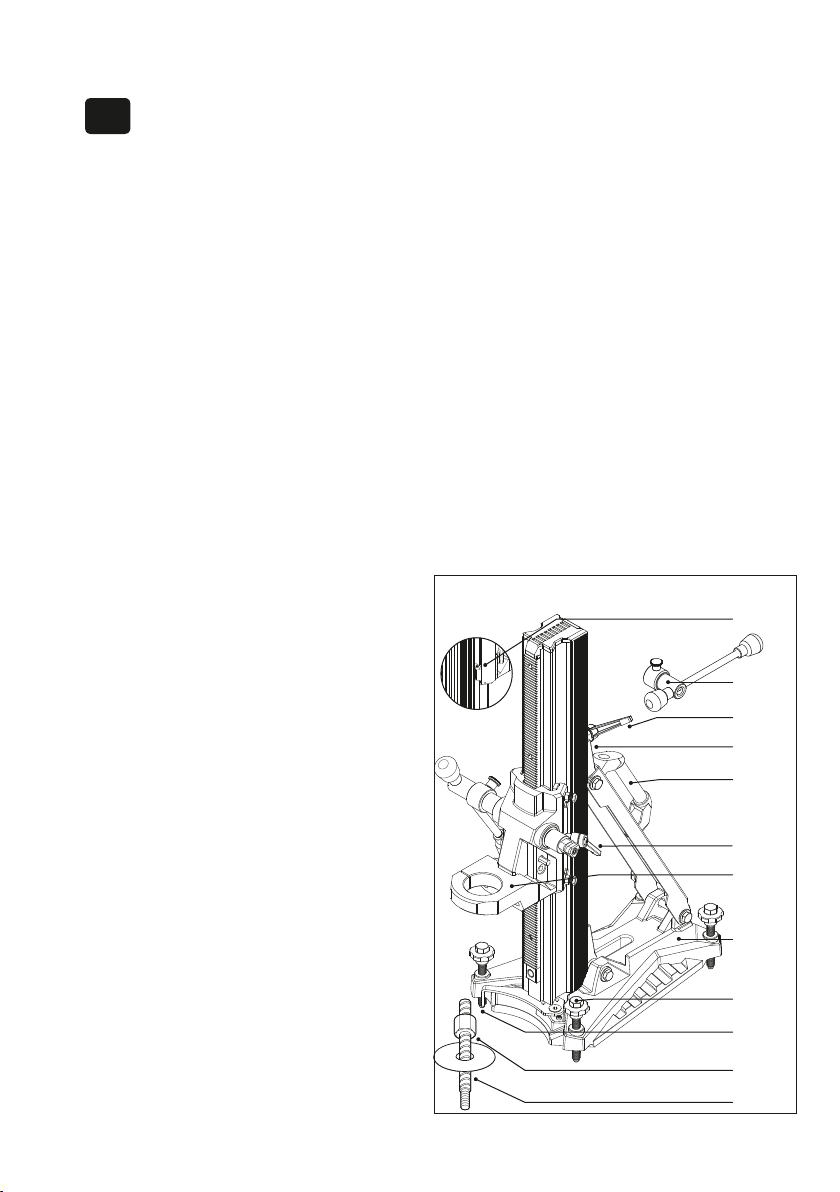

OPERATING CONTROLS

1LED motor load

2On/Off switch

3Soft starter button

4PRCD protective switch

5Drilling shaft 1¼” male - ½”female

6Water tap

7Speed selection switch

8Ventilation slots

9Waterflow Indicator

10 Grip

11 Dry Drilling Kit* (optional)

12 2nd Back Grip* (optional)

13 Rubber cover

14 Fastening screw for water collecting ring

15 Water collecting ring* (option)

16 Shoulder pad* (option)

17 Connection plate for 11, 12 and 16*

(optional)

18 Pilot center drill for dry drilling* (optional)

19 Safety screw

20 Feed lever

21 Clamping lever for 22

22 Drill angle adjustment with scale

23 Stand Grip

24 Guide block clamping lever

25 Guide block for Karat 180

26 Base plate

27 Adjusting screws

28 Centering plate

29 Spindle nut

30 Screw assembly

31 Drill bit

*Not all of the accessories illustrated or described

are included as standard delivery.

SAFETY GUIDELINES

The definitions below describe the level of sever-

ity for each warning. Please read the operating

manual and pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not

avoided, will result in death or seri-

ous injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

NOTE: Indicates a practice not

related to personal injury which, if

not avoided, may result in property

damage.

INTENDED USE

The machine is intended for drilling into concrete

and reinforced concrete, when being used in con-

junction with diamond core bits for wet drilling

and a suitable water supply. Karat 180 can also be

used for dry drilling in masonry and other build-

ing materials with the dry drilling kit.

The vacuum pump is intended for the fixation of

drillstands Compact and Large. The pump is only

designed for sucking in air, and no other gases or

fluids.

For damage caused by usage other then

intended, the user is responsible.

BEFORE USE

When drilling through walls or floors, make

absolutely sure that there are no obstacles

in the adjoining rooms and cordon off the

building site. Prevent the drilling core from

falling.

Always use the correct supply voltage: The

power supply voltage must match the informa-

tion quoted on the tool identification plate.

INITIAL OPERATION

Functional test for the PRCD protective

switch

WARNING: The ON/OFF switch 2

must be switched off, in order to

avoid unintentional starting of the

machine when carrying out the

functional test of the PRCD protec-

tive switch 4.

Before commencing work, check that the PRCD

protective switch is functioning properly:

KARAT®180US

8 OPERATING MANUAL KARAT® 180

•Press the «RESET» button on the PRCD pro-

tective switch. The red control lamp indicates

when the protective switch is ready for

operation.

•Press the «TEST» button. The control lamp

must go off.

Setting the speed range

CAUTION: Actuate the gear selector

switch only when the machine is at

a standstill.

The gear selector switch allows for pre-selection

of three speed ranges. Wet drilling in concrete:

Position ●: low speed for

bit range Ø3” - 7”

Position ● ●: medium speed for

bit range Ø1 1/2” - 3”

Position ● ● ●: high speed for

bit range Ø5/16” - 1 1/2”

Ideal bit range for Karat 180 in reinforced concrete

is Ø5/8” - 6 1/4”.

For a smooth switch to another position, move

the drill shaft by hand or by supplied wrench and

turn the switch to the desired position.

Switching On/Off

WARNING: To avoid unintentional

starting of the machine, the ON/

OFF switch 2 is to be switched off

when the PRCD protective switch 4

releases.

Overload Protection

The 8 LED lights 1indicates the motor load,

whereby the following conditions are distin-

guished:

2x blue: No load/small drilling load

4x green: Regular drilling load

2x red: Overload

Excessive overloading the motor will pulsating

reduce the speed 6 times electronically to warn

the operator. The LED lights will flash red-green/

green-red en then remain red. The motor switches

off automatically and can immediately be

switched back on again.

Soft starter

An easy drill start of the surface to be drilled is

with this facilitated.

First switch on the machine. If the soft starter but-

ton 3is pressed, the machine runs for 10 seconds

at half speed. For that time the first LED then

lights up purple instead of blue.

NOTE: Use the soft starter only for a

short time at drilling start in the

surface to be drilled.

Slip clutch

With a clamping drill, the slip clutch is activated.

All LED lights could flash red. The machine is

switched off automatically. Carefully loosen the

drill. Never use the ON/OFF switch for this! You

can then calmly resume drilling.

Undervoltage protection

If the machine detects a too low supply voltage,

the machine is switched off. All LED lights will

then continue to lit blue.

Switch the machine off and on again.

HAND HELD DRILLING

WARNING: Use Karat 180 only in

combination with a drillstand when

drilling in position 1 (low speed).

WARNING: Pay attention on the

maximum drilling ranges when

drilling wet and dry with Karat 180:

Maximum bit diameters:

•Wet drilling in concrete: Ø 1 1/2”

•Dry drilling in masonry: Ø 7”.

Mounting the drill bit

•Clean and grease the thread on the drill bit

31 and the drilling shaft 5.

•Screw a core bit 31 onto the drilling shaft 5

and tighten with supplied wrenches.

Hand held wet drilling

Connecting the water feed

•Close the water tap 6.

•Connect the water feed hose to the water tap

or the water pressure tank.

•When using the water pressure tank, make

sure that there is sufficient pressure when

working.

•Check the waterflow indicator 9.

KARAT®180 US

OPERATING MANUAL KARAT® 180 9

Drilling

•For wet drilling open the water valve 6and

switch on the machine 2.

•Hold the machine as rigidly as possible.

•Always use the grip 10 at the front of the

machine.

•Start drilling by keeping the machine at a

slight angle. You can use the soft starter 3at

drilling start.

•After the bit is guiding itself into the material,

swivel back the machine into the right angle

position.

•Drill using an even forward feed. Do not over-

load the machine.

•The leaking water should be milky and not

clear.

•After drilling switch the machine off and shut

off the water tap.

Hand held dry drilling

Using the dry drilling kit

•Install dry drilling kit 11 on drill shaft 5.

•Mount the hose of an industrial dust

exhauster.

•Drilling is only possible if the masonry is

absolutley dry.

•Use a powerful industrial dust exhauster.

Change the filter regularly, there is risk of

obstruction.

•

•Hold the machine as rigidly as possible.

•Always use the grip 10 at the front of the

machine.

•Start drilling by keeping the machine at a

slight angle. You can use the soft starter 3at

drilling start

•After the bit is guiding itself into the material,

swivel back the machine into the right angle

position.

WARNING: The machine has a very

high torque, especially in the first

gear. Therefor drill only extremely

concentrated, especially when

working in first gear and with

diameters of more than 3”. In case

of sudden blocking of the core bit

the machine, despite the safety

clutch, might get out of control and

hurt you considerably.

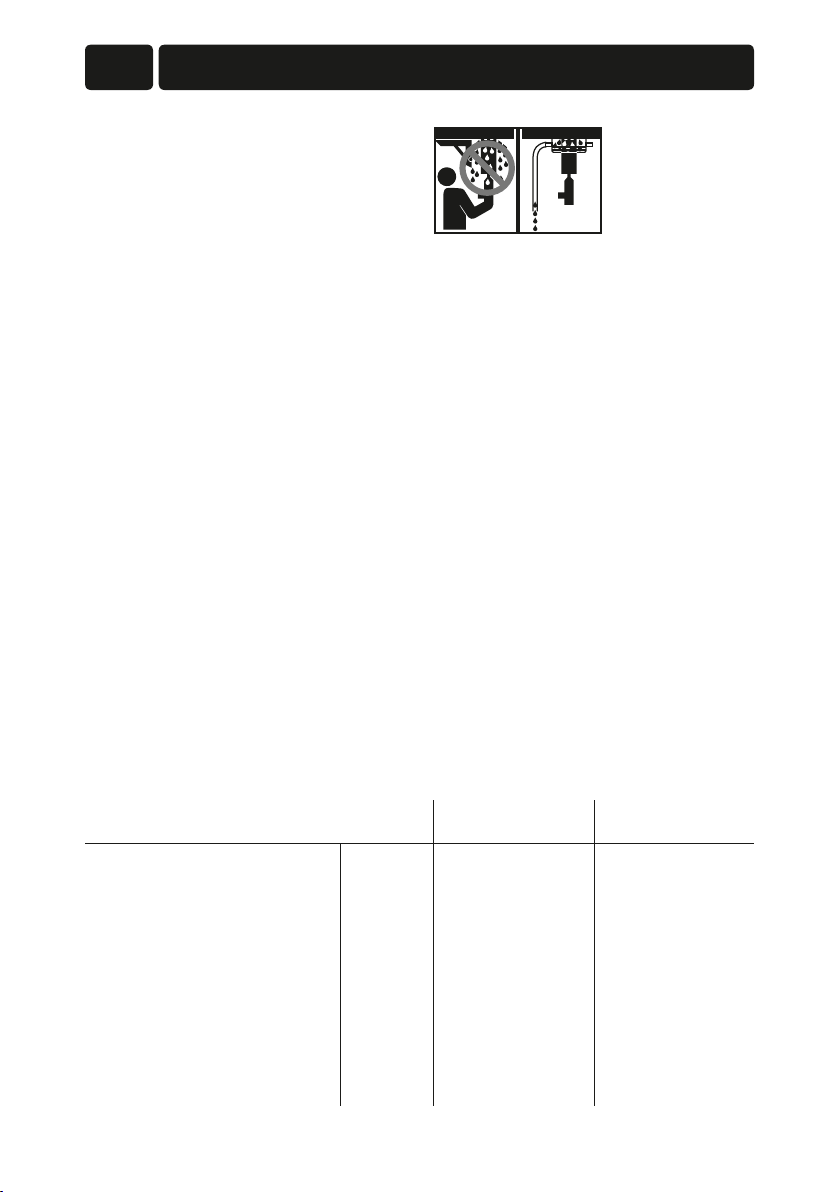

DRILLING WITH A DRILL

STAND

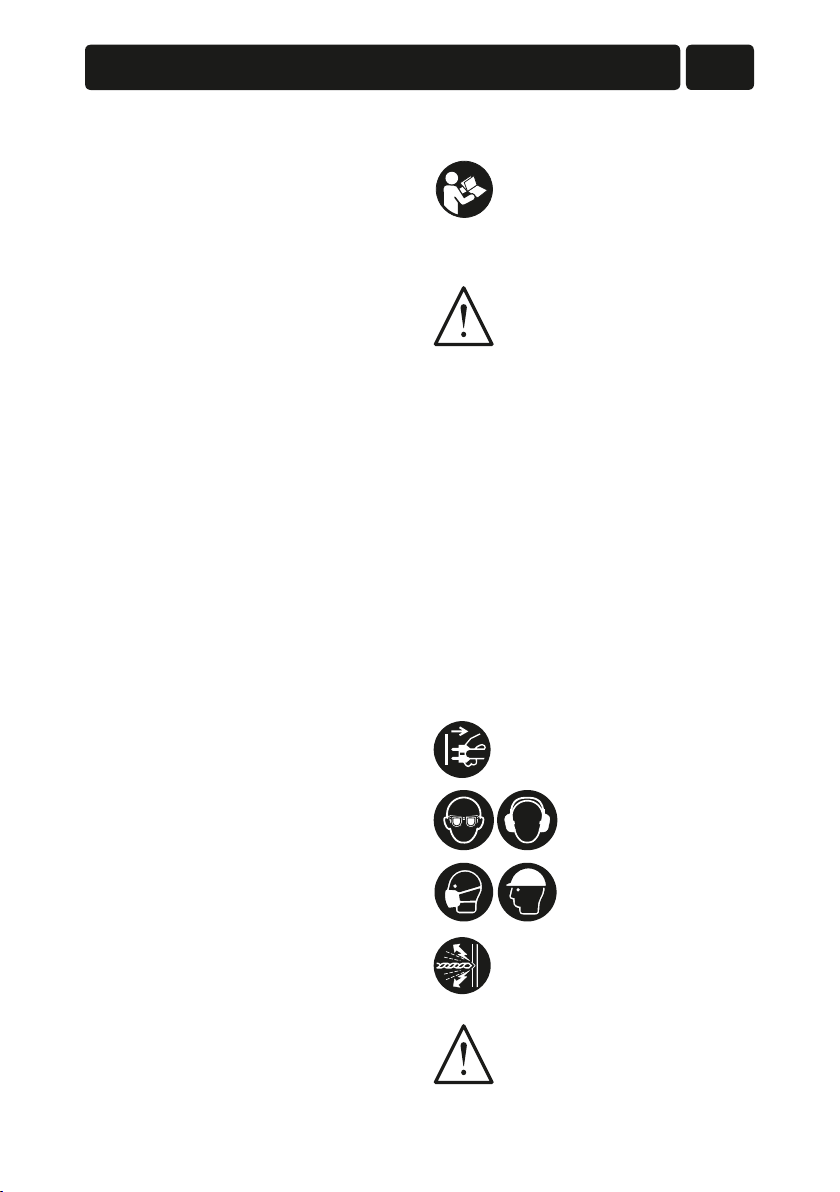

Guide block setting

AB

When using a drill stand a right setting of the

guide block is required. Guide blocks for Karat

core drilling machines features slide strips for fine

tuning on the drill stand.

•Loosen the safety nuts Ausing the supplied

wrench 13.

•Adjust the bolts Bfor an flexible sliding of the

guide block on the drill stand.

•Secure then the bolts with the safety nuts A.

Drill stand fixation

CAUTION: The drill stand must

always be mounted firmly and

must not be able to move during

drilling.

Aligning the drill stand

•Set up the drill stand at the drilling location.

•Rotate the centering plate 28 forwards, until

it snaps in.

•Align the drill stand in such a manner that

for the used machine the tip of the centering

plate is located directly above the required

drilling location.

•Fasten the drill stand.

Secure using assembly

•Drill the rawlplug hole Ø3/8” (see instruction

rawlplug).

•Insert rawlplug 1/2” (M12).

•Screw in assembly 30.

•Align the drill stand.

•Fasten the drill stand with the spindle nut 29.

KARAT®180US

10 OPERATING MANUAL KARAT® 180

Vacuum pump fixation

WARNING: Maximum drilling diam-

eter of 4”. Mount the drill stand on

an even, firm and smooth surface

using the vacuum pump, never

“over” head. Always connect the

core drill and the vacuum pump to

the same power outlet. Never turn

off the vacuum pump during oper-

ation.

Position the machine horizontally. Maximum tilt of

10°. Fasten, mount suction hose and fasten with

hose clip.

See further the vacuum pump manual.

Mounting the drill bit

•Tighten the clamping lever 24.

•Clean and grease the thread on the drill bit

31 and the drilling shaft 5.

•Screw a core bit 31 onto the drilling shaft 5

and tighten with supplied wrenches.

Connecting the water feed

•Close the water tap 6.

•Connect the water feed hose to the water tap

or the water pressure tank.

•When using the water pressure tank, make

sure that there is sufficient pressure when

working.

•Check the waterflow indicator 9.

Setting the drilling angle

•Loosen the clamping lever 21.

•Use handle 23 to slide the column into the

desired drilling angle using the scale.

•Tighten the clamping lever 21.

Drilling

•Always ensure a adequate anchorage in the

underground.

•Open the water tap 6.

•Loosen locking lever 24 and hold the feed

lever 20.

•Actuate the ON/OFF switch 2.

•You can use the soft starter 3at drilling start

Drill using an even forward feed. Do not over-

load the machine.

•The leaking water should be milky and not

clear.

•Always loosen the locking lever 24 when

drilling.

•After drilling switch off the machine and shut

off the water tap. Lift the machine with feed

lever 20 and secure with locking lever 24.

Removing the drilling core

•Break off the drilling core and remove.

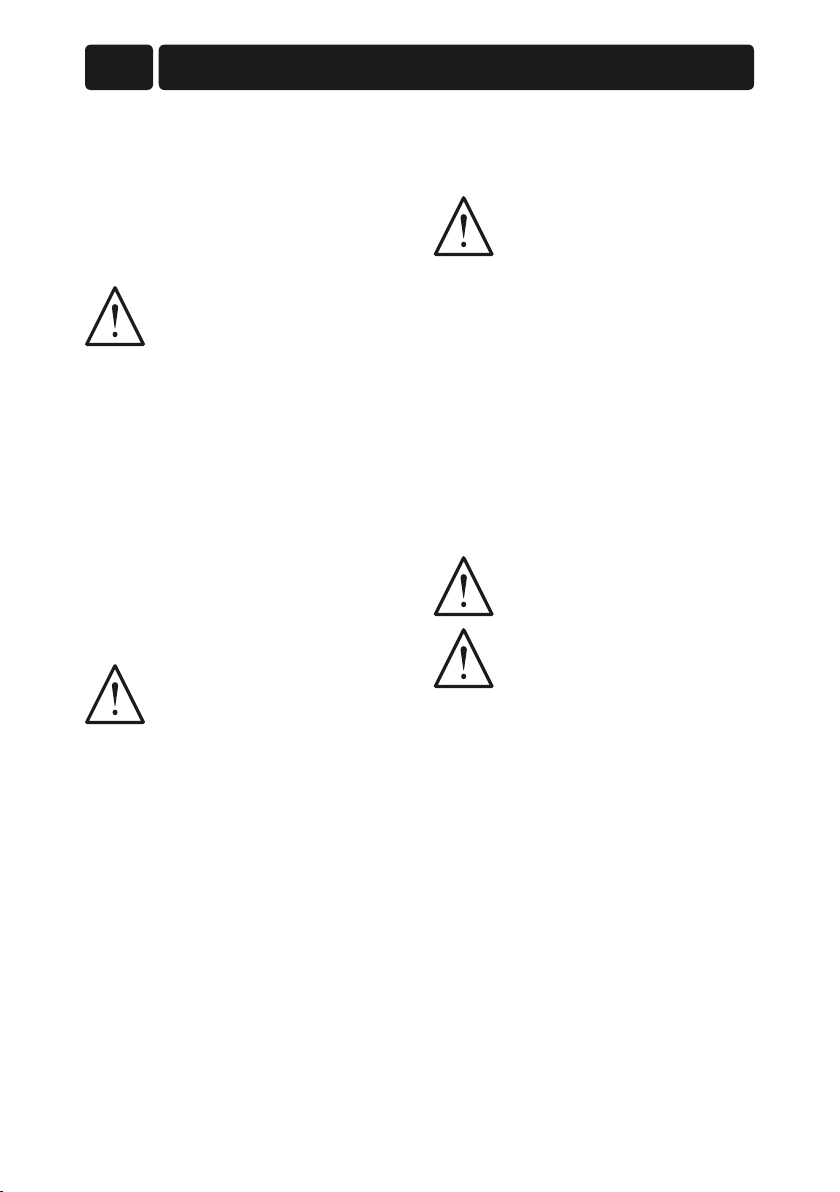

OVER HEAD DRILLING

DANGER: When drilling“over” head

always secure the drill stand with

the assembly.

DANGER: When drilling “over”

head, always use a water collecting

ring and a industrial wet-type vacu-

um cleaner!

Mounting the water collecting ring

•Loosen the fixation screw 14 on the water

collecting ring 15.

•Push the water collecting ring 15 onto the

drill stand and press it firmly against the

material to be drilled.

•Tighten fixation screw 14.

•Connect a industrial wet-type vacuum

cleaner.

•When using the water collecting ring,

attach a protective cover 13 onto it and drill

through. Remove te drilled part of the cover

from the core bit.

TRANSPORT AND STORAGE

CAUTION: Danger of injury and

damage! Pay attention to the

weight of the appliance when

transporting it.

•Clean the machine and remove the drilling

dirt.

•Transport the machine and core bit sepa-

rately.

•Blow out remaining water from hose and

machine when it freezes.

•This appliance may only be stored inside a

building.

KARAT®180 US

OPERATING MANUAL KARAT® 180 11

MAINTENANCE AND CARE

Always keep the machine and cooling air vents

free and clean. It must always be kept in a dry,

frost-free place.

TROUBLESHOOTING

For malfunctions that are not specified in this

chapter, when in doubt or when explicitly indi-

cated, seek assistance from an authorized service

facility.

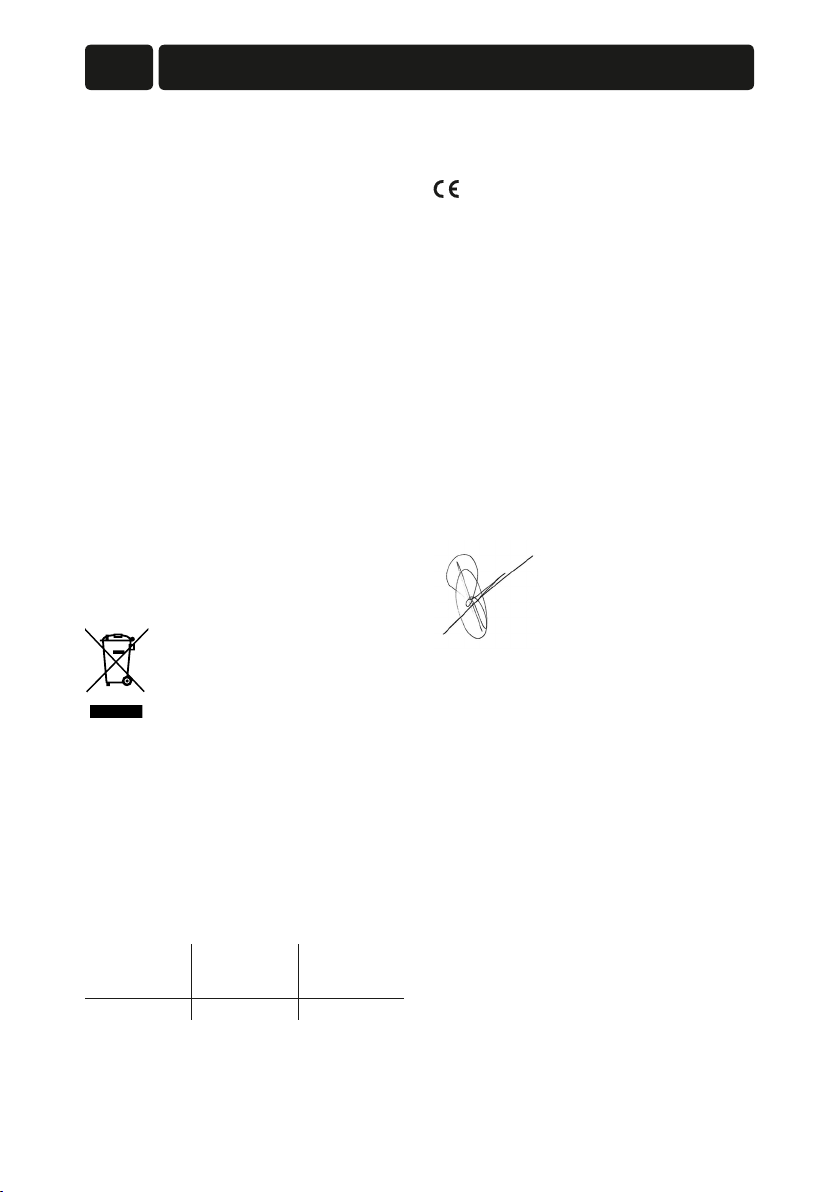

Problem Possible cause Possible solution

The motor doesn’t work. Defective cable of plug.

Defective switch.

The carbon brushes of the machine

are worn.

Defective motor.

PRCD protective switch is not

switched on, test!

Have inspected by a electrical

specialist and replaced if necessary.

Contact customer service.

Contact customer service.

Contact customer service. Never

repair the motor yourself. Danger!

Motor makes too much noise. Damaged windings.

The carbon brushes of the machine

are almost worn.

Have the motor inspected by

customer service.

Motor mildly overheats. Motor overload.

Motor doesn’t cool sufficiently

Prevent motor overload when drilling.

Remove the dust from the motor, so

that the cool air can flow.

Motor runs. Core bit doesn’t

rotate.

Gearing defective. Have the machine inspected by the

service facility.

Rate of drilling progress

decreases.

Core bit segments polished.

Water pressure/water flow rate too

high.

The core is stuck in the core bit.

Maximum drilling depth reached.

Core bit defective.

Gearing defective.

The clutch is releasing prematurely

or slipping.

Sharpen the core bit on a sharpening

plate while water is flowing.

Use the feed lever to reduce the water

flow rate.

Remove the core.

Remove the core and use a core bit

extension.

Check the core bit for damage and

replace if necessary.

Have the machine repaired at a

service center.

Have the machine repaired at a

service center.

Motor cuts out. The core bit has been jammed for

too long.

Electric power failure.

Too low power supply.

Electronics defective.

Free the core bit. Switch the motor off

and then on again.

Check the plug connections, electric

power supply and PRCD protective

switch.

Check power supply.

Too long/thin extension cord.

Too small aggregate.

Have the machine repaired at a

service center.

Water leakage at the water swivel

or gear housing.

Shaft seal defective.

Water pressure is too high.

Have the machine repaired at a

service center.

Reduce the water pressure.

KARAT®180US

12 OPERATING MANUAL KARAT® 180

REPLACEMENT PARTS

If – in spite of meticulous manufacturing and test-

ing processes – the device breaks down, have it

serviced by a B+BTec Service.

GUARANTEE

For this B+BTec appliance we grant a warranty in

accordance with the statutory/country-specific

provisions as from date of purchase (by evidence

of invoice or delivery note). Damage that has

occurred will be corrected either by replacement

or by repair.

Damage caused by improper handling is

excluded from the warranty.

Claims can be recognized only if the appliance

is presented in a not-disassembled manner to a

B+BTec branch office, your B+BTec field service

employee or a customer service office for power

tools authorized by B+BTec.

ENVIRONMENTAL

PROTECTION

Do not dispose of the appliance with

domestic waste. Dispose of the appli-

ance only via an authorized waste

management company or your

municipal waste management organ-

isation. Adhere also to the applicable regulations.

In case of doubt refer to your waste management

organisation. Recycle all packaging material in an

environmentally friendly manner.

INFORMATION ON NOISE AND

VIBRATION

Typically the A-weighted noise levels of the prod-

ucts are:

Sound pressure

level

EN-ISO 11203

Sound power

level

EN-ISO 3744

Karat 180 84.6 dB (A) 97.6 dB (A)

The typical hand-arm vibration for the main

handle is below 2.4 m/s2, for the auxiliary handle

below 4.6 m/s2.

Wear ear protection!

DECLARATION OF

CONFORMITY

We hereby declare that the appliance complies

with the relevant basic safety and health require-

ments of the EU Directives, both in its basic

design and construction as well as in the version

put into circulation by us. This declaration shall

cease to be valid if the device is modified without

our prior approval.

Karat 180: EN-IEC 62841-1, EN-IEC 62841-2-1, EN-

IEC 62841-3-6

Conforms to the following standards or normative

documents 2006/42/EG, 2014/30/EU.

Zevenbergen, November 2019

R.G.W. van den Boogaart

General manager

B+BTec

Munterij 8

NL - 4762 AH Zevenbergen

+31 (0)168 331 260

This manual suits for next models

3

Table of contents

Other B+BTec Drill manuals

Popular Drill manuals by other brands

Bort

Bort BAB-10,8N-Li user manual

Ferm

Ferm FRTD-13/350 user manual

Full Boar

Full Boar FBAD-038 instruction manual

EINHELL Bavaria

EINHELL Bavaria BBH 1500 operating instructions

Chicago Electric

Chicago Electric 42564 Assembly and operating instructions

Scheppach

Scheppach DH1300PLUS Translation of original operating manual