BQT Solutions YD30D User manual

1

Installation and Operating Instructions

DN 01002/001 - 01/2023

YD30D Cobalt Double

Sideload Lock

2

Table of Contents

1. Document Information 3

1.1 Contents and Purpose 3

1.2 Target Group 3

2. Safety and Compliance 4

2.1 Safety Information 4

2.2 Regulatory Compliance Information 5

3. Product Information 7

3.1 Product Description 7

3.2 Package Contents 8

3.3 Technical Data 9

4. Product Dimensions 10

4.1 Lock Dimensions 10

4.2 Strike Dimensions 11

4.3 Housing Dimensions (Available Separately) 12

4.4 Dress Plate Dimensions (Available Separately) 12

4.5 Fitting Tab Dimensions (Available Separately) 13

5. Pre-Installation Assessment 14

5.1 Mounting Assessment 14

5.2 Wiring Assessment 15

5.3 Operating Mode Assessment 15

6. Mounting 16

6.1 Mortice Installation (Solid Wood) 16

6.2 Mortice Installation (Metal Extrusion) 17

6.3 Surface Mounting Installation (Solid Wood) 18

6.4 Surface Mounting Installation (Glass) 19

7. Wiring 20

7.1 Wiring Guide 20

7.2 Fail Safe Connection 20

7.3 Fail Secure Connection 20

8. Operating Mode 21

8.1 Fail Safe Operation 21

8.2 Fail Secure Operation 21

9. Maintenance 22

9.1 Maintenance and Cleaning 22

9.2 End of service life 22

3

1. Document Information

1.1 Contents and Purpose

This document describes installation, connection, operation, and maintenance of the lock YD30D.

Read the document carefully and observe the instructions it contains. They contain important

information for reliable installation and trouble-free operation.

1.2 Target Group

Target group of these instructions are:

• Installer

• Service Technician

Installers and service technicians are skilled personnel who have the specialist knowledge required for

installation, commissioning, and maintenance.

4

2. Safety and Compliance

2.1 Safety Information

WARNING

• Live parts inside.

• The handling and installation of this device is recommended for a professional.

• Use of an unsuitable power supply unit may cause product failure or injury.

• Do not remove the cover plates or face plate.

• Ensure installation does not expose sharp edges of the product to users.

5

2.2 Regulatory Compliance Information

This product is in compliance with the CE Directives including Electomagnetic Compatibility (EMC)

Directive, Restriction of the use of certain hazardous substances (RoHS) Directive, and Registration,

Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation.

EU Declaration of Conformity is available at www.bqtsolutions.com.

This product is in compliance with the United Kingdom (UK) Legislation including the Electromagnetic

Compatibility Regulation 2016, and the Restriction of the Use of Certain Hazardous Substances in

Electrical and Electronic Equipment Regulations 2012.

UKCA Declaration of Conformity is available at www.bqtsolutions.com.

This product is in compiance with the Regulatory Complaince Mark (RCM) for Australia and New

Zealand.

6

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two condi-

tions:

1. This device may not cause harmful interference.

2. This device must accept any interference received, including interference that may cause undesired

operation.

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a residential, commercial, or industrial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation.

Modications:

void the authority granted to the user by the FCC to operate this equipment.

Innovation, Science and Economic Development Canada ICES-003:

CAN ICES-3(B)/NMB-3(B)

In the European Union, Norway, Iceland and Liechtenstein: This symbol on the product, or in the

manual and in the warranty, and/or on its packaging indicates that this product shall not be treated

as household waste. Instead it should be taken to an applicable collection point for the recycling of

electrical and electronic equipment.

By ensuring this product is disposed of correctly, you will help to prevent potential negative

consequences to the environment and human health, which could otherwise be caused by

inappropriate handling of this product.

In Countries Outside the European Union, Norway, Iceland and Liechtenstein: If you wish to dis-

pose of this product please contact your local authorities and ask for the correct way of disposal.

7

3. Product Information

3.1 Product Description

The YD30D is a motor driven low voltage electric lock designed to secure commercial and residential

swing-through (180°) doors. The lock has been designed to address the two biggest issues in

concealed electric locking today;

1. The ability to ‘pull’ a door into alignment even if the door has not closed in a central position.

2. The ability to release when requested even if there is excessive load on the door.

The design of the YD30D is unique as it has two motors which independently operate two bolt pins.

The bolt pins operate on a cam action which enables each bolt pin to pull a door into place. In practice

as the door closes it may come to rest in a position that is not fully closed. The YD30D senses when

from its resting position to the closed and secured position.

With the door secured and locked the YD30D can be given an unlock signal and it will instantly unlock.

If the door is loaded (pre-load) when the unlock signal is given the YD30D will still unlock, even with

loads in excess of 100kg on the door from either side. Critically the ability of the YD30D to instantly

release with excessive pre-load on the door even occurs in the event of a power failure if the lock is

Additional features of the YD30S are;

• Multi-voltage input (12 - 24VDC)

• Very low current consumption

• Door position and bolt position monitors

• High physical strength

• Fail-safe / Fail-secure on-site conversion with the re-positioning of a single switch

8

3.2 Package Contents

1x Lock 1x Strike Plate

4x 10G self-tapping screws 1x 300mm 7-way wire loom

9

3.3 Technical Data

Materials

Bolt Stainless Steel 17-4PH

Lock / Strike Plate Stainless Steel 304

Mechanical

Bolt Extension 13mm

Door Gap

Misalignment Correction

Cycle Life 1,000,000 cycles

Holding Force 10,000N (2,250 lbf) (factory tested)

Side Load Release 6,000N (1,350 lbf) (factory tested)

Locking Time 1.0 seconds (typical)

Unlocking Time 0.3 seconds (typical)

Electrical

Power Requirements 12-24 VDC ±15%

Initial Power Up Time 11 seconds

Initial Current Draw 750mA@12VDC, 400mA@24VDC

Standby Current 40mA@12VDC, 25mA@24VDC

Signal Contacts Bolt Position (NO) 30VDC max., 100mA max.

Door Position (NO)

Compliance

CE, UKCA, FCC, IC, RCM, RoHS 2

10

4. Product Dimensions

4.1 Lock Dimensions

The dimensions shown are approximate and subject to change without prior notice.

183mm

7.205in

47mm

1.854in

3mm

0.118in

255mm

10.039in

10mm

0.394in

235mm

9.252in

10mm

0.394in

30mm

1.181in

11

4.2 Strike Dimensions

The dimensions shown are approximate and subject to change without prior notice.

255mm

10.039in

100mm

3.937in

55mm

2.165in

14mm

0.551in

3mm

0.118in

10mm

0.394in

235mm

9.252in

10mm

0.394in

30mm

1.181in

12

4.3 Housing Dimensions (Available Separately)

The dimensions shown are approximate and subject to change without prior notice.

259mm

10.205in

56mm

2.189in

220mm

8.661in

20mm

0.787in

34mm

1.346in

4.4 Dress Plate Dimensions (Available Separately)

260mm

10.236in

58mm

2.283in

13

4.5 Fitting Tab Dimensions (Available Separately)

The dimensions shown are approximate and subject to change without prior notice.

38mm

1.476in

24mm

0.945in

20mm

0.787in

M5x0.8 Thread

4mm

0.157in

14

5. Pre-Installation Assessment

5.1 Mounting Assessment

Mortice installation ensures a discrete solution as the lock and strike plate can be embedded into

the door leaf and frame, however in some instances this is not possible. Glass doors for example

require surface mounting which is done with the aid of the YD30D housing and dress plate (available

separately).

The lock and strike plate can be installed morticed (1), surface mounted (2), or a combination of the

two (3). Regardless of the installation method it is vital that the lock face plate and strike plate are

the door is closed.

either direction and the YD30D will pull the door into alignment with ease. This misalignment could be

caused by an automatic door closer not aligning the door or natural distortions in the door assembly.

15

5.2 Wiring Assessment

Before installation begins, consideration must be made for where to run the wires and decide on

what feedback is required from the lock. There are a total of seven available connections; three are

compulsory power/control connections whilst the remaining four provide optional door and bolt position

feedback. These optional connections can be integrated into access control or alarm systems to

provide full monitoring.

The correct gauge of wire needs to be chosen as voltage drop across the power/control wires can limit

the locks operation. For all the remaining connections, a lower gauge wire can be used as these are

only signal wires. The following table shows the maximum distance that the wire runs can be between

the power supply and the lock, assuming the power supply outputs 12VDC or 24VDC.

Conductor Cross Sectional Area Maximum Distance

#AWG (mm²) at 12VDC at 24VDC

24 0.20 10m (33ft) 30m (98ft)

22 0.33 16m (52ft) 48m (157ft)

20 0.52 26m (85ft) 77m (253ft)

18 0.82 41m (135ft) 122m (400ft)

16 1.31 65m (213ft) 195m (640ft)

14 2.08 103m (338ft) 310m (1017ft)

5.3 Operating Mode Assessment

The YD30D can be set to one of two operating modes before installation, Fail Safe or Fail Secure.

When the operating mode is set to Fail Safe, supply voltage is applied to the control input to lock the

door, and the YD30D will unlock in the event of power loss.

When the operating mode is set to Fail Secure, supply voltage is applied to the control input to unlock

the door, and the YD30D will lock or remain locked in the event of power loss.

The failure mode of the YD30D is factory set as Fail Safe. Before the lock is installed this can be

changed to Fail Secure by repositioning the switch located at the end of the product.

16

6. Mounting

6.1 Mortice Installation (Solid Wood)

1. Cutting the mortice

Referring to the product dimension drawings, a mortice

frames require full mortices with space made behind the

lock body to accommodate the wire connections.

It is crucial to ensure that the mortices in the door leaf

and frame are aligned vertically and horizontally when

the door is closed as this aligns the bolt pin to the strike

opening and also the strike magnet to the locks internal

door position sensor.

strike plate once it is installed will be no more than 6mm

2. Wiring the lock

A hole needs to be drilled in the back of the mortice to

bring the wires out and a connection can be made to the

supplied wire loom which in turn plugs into the lock.

Refer to the Wiring section of this document for detailed

instructions on wiring.

3. Setting the operating mode

Ensure the operating mode switch is positioned to the required

state, Fail Safe or Fail Secure.

Refer to the Operating Mode section of this document for

detailed instructions on wiring.

4. Fitting the lock and strike plate

The lock can be slid back into the door frame mortice, ensuring

that the wiring integrity is maintained, and then secured in place

with the supplied 10G self-tapping screws. Please ensure the

lock is the correct orientation as to pull the door into the door

jamb.

The strike is then placed into the door leaf mortice and the

remaining 10G self-tapping screws are used to secure it in

place. Ensure the strike is oriented so that the bolt hole aligns

with the lock bolt.

17

6.2 Mortice Installation (Metal Extrusion)

1. Cutting the mortice

Referring to the product dimension drawings, a mortice is

being hollow, often only require a single rectangle cut-out to

accommodate the lock face plate or strike plate. For these

(available separately).

It is crucial to ensure that the mortices in the door leaf and

frame are aligned vertically and horizontally when the door

is closed as this aligns the bolt pin to the strike opening and

also the strike magnet to the locks internal door position

sensor.

strike plate once it is installed will be no more than 6mm

2. Wiring the lock

Feed the wires out of the hollow chamber of the frame and a

connection can be made to the supplied wire loom which in

turn plugs into the lock.

Refer to the Wiring section of this document for detailed

instructions on wiring.

3. Setting the operating mode

Ensure the operating mode switch is positioned to the required

state, Fail Safe or Fail Secure.

Refer to the Operating Mode section of this document for detailed

instructions on wiring.

4. Fitting the lock and strike plate

The lock can be placed into the door frame cutout, ensuring that

the wiring integrity is maintained, and then secured in place with

M5 machine screws (included with tting tabs). Please ensure the

lock is the correct orientation as to pull the door into the door jamb.

The strike is then placed into the door leaf cutout and then M5

machine screws (included with tting tabs) are used to secure it in

place. Ensure the strike is oriented so that the bolt hole aligns with

the lock bolt.

18

6.3 Surface Mounting Installation (Solid Wood)

1. Preparing the mounting surface

Install two 10Gx1” self-tapping screws (included with housing) in

the mounting surface, as per the product dimension drawings they

should be 220mm apart, 20mm from the surface edge.

2. Preparing the housing

An 8mm hole should be drilled through the housing wall at the

position chosen by the installer for the wiring to enter. The wiring

can be guided to the housing through surface mount conduit, or

through a hole in the mounting surface material. Push a rubber

grommet (included with housing) over the drilled hole to protect the

wires from any sharp edges.

3. Fitting the housing

Position the keyhole cutouts of the housing over the screw heads

screws in place to secure the housing.

4. Wiring the lock

Feed the wires through the 8mm hole in the housing and a

connection can be made to the supplied wire loom which in turn

plugs into the lock.

Refer to the Wiring section of this document for detailed

instructions on wiring.

5. Setting the operating mode

Ensure the operating mode switch is positioned to the

required state, Fail Safe or Fail Secure.

Refer to the Operating Mode section of this document for

detailed instructions on wiring.

6. Fitting the lock and strike plate

The lock can be placed into the housing, ensuring that the

wiring integrity is maintained, and then secured in place with

M5 machine screws (included with housing). Please ensure

the lock is the correct orientation as to pull the door into the

door jamb.

19

6.4 Surface Mounting Installation (Glass)

1. Fitting the housing

Clean the glass surface with isopropyl alcohol and

peel the protective layer from the double sided tape

edge of the glass, and press down to adhere tape to

surface.

2. Fitting the dress plate

Clean the glass surface with isopropyl alcohol and

peel the protective layer from the double sided tape

the edge of the glass and centered on the housing

location, and press down to adhere tape to surface.

3. Fitting the strike plate

The strike is then placed into the housing and then

secured in place with M5 machine screws (included

with housing). Ensure the strike is oriented so that

the bolt hole aligns with the lock bolt.

20

7. Wiring

7.1 Wiring Guide

The YD30D is supplied with a 7-way wire loom that plugs directly into the lock. The wires are colour

coded as per table below, with the power and control wires being essential connections and the four

monitor connections being optional.

Wire Colour Meaning Description

RED Power Supply

(12 - 24VDC)

Positive connection to DC power supply, “+”

BLACK Negative connection to DC power supply, “-”

BLUE Control Switched positive control input

VIOLET Bolt Position

Monitor

Normally open contact (NO), closed when the bolt pin is

extended (optional)

VIOLET

WHITE Door Position

Monitor

Normally open contact (NO), closed when the strike is

aligned with the lock (optional)

WHITE

7.2 Fail Safe Connection

lock (active-high locking signal). In the event of a power cut, the YD30D will unlock.

7.3 Fail Secure Connection

unlock (active-low locking signal). In the event of a power cut, the YD30D will remain locked.

This manual suits for next models

1

Table of contents

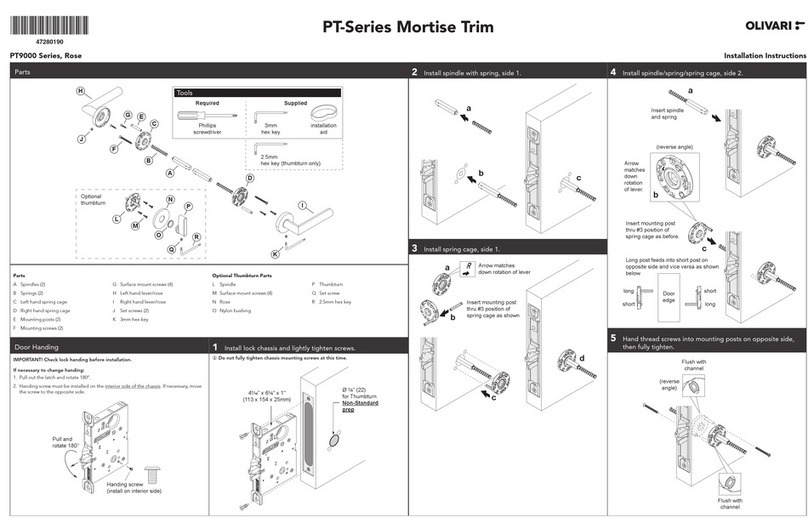

Popular Lock manuals by other brands

Dorma

Dorma ARCOS Office Mounting instructions

Motormate

Motormate Honda 10-401-SS installation instructions

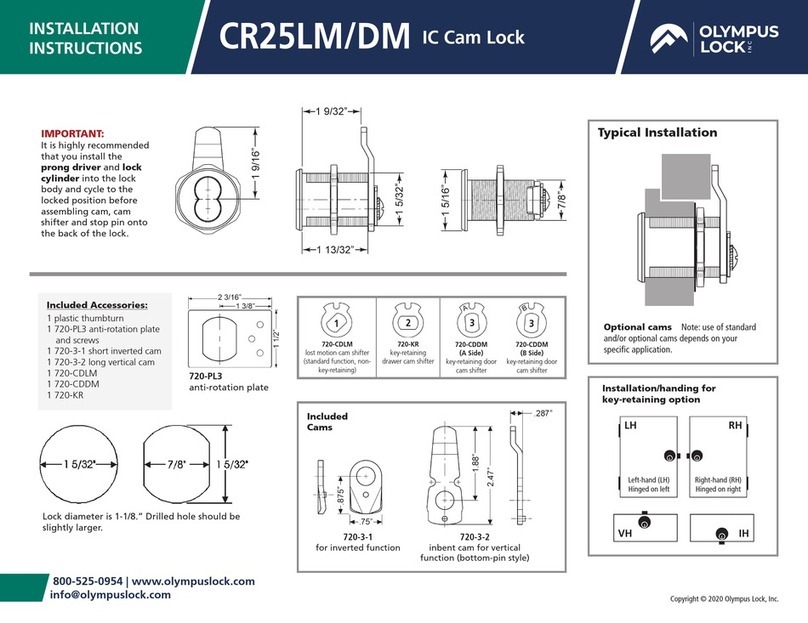

Olympus Lock

Olympus Lock CR25LM installation instructions

deconta

deconta ECO-Line instruction manual

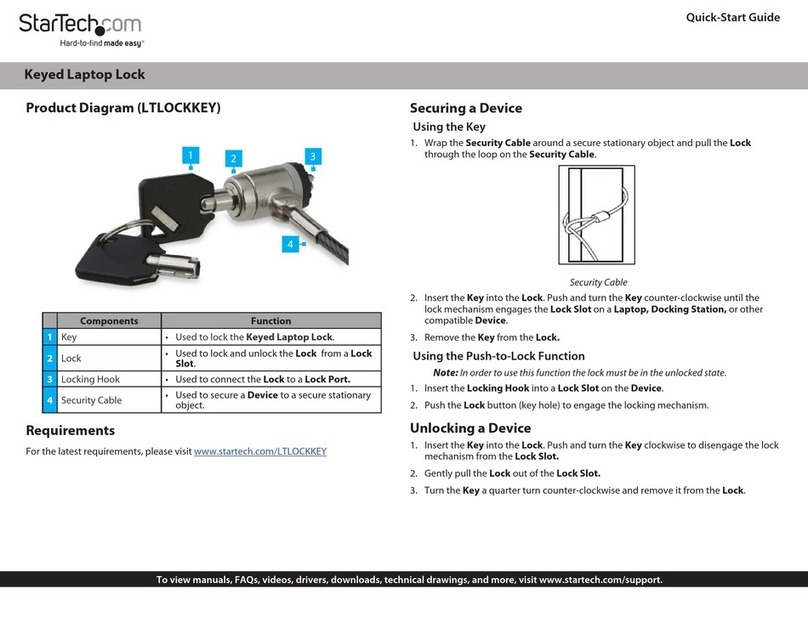

StarTech.com

StarTech.com LTLOCKKEY manual

Yale

Yale Real Living Assure Lock YRD226 Installation and programming instructions

Simons Voss Technologies

Simons Voss Technologies PegaSys 2.1 quick guide

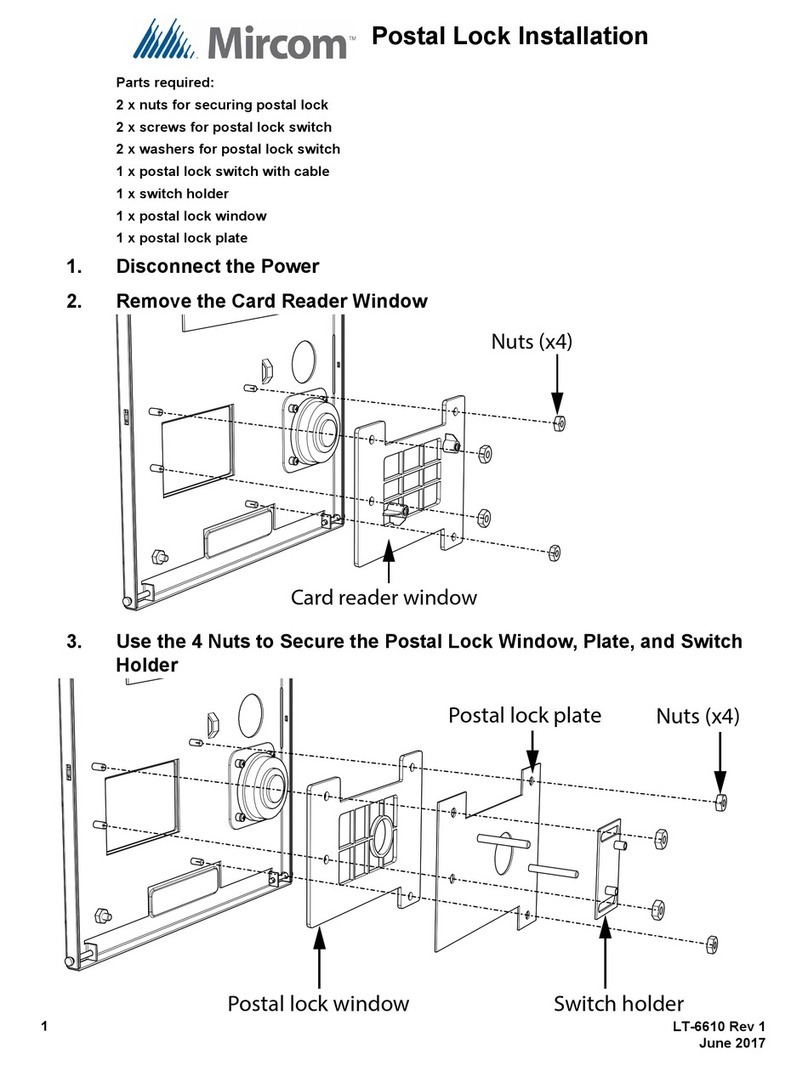

Mircom

Mircom LT-6610 installation manual

YLI

YLI YM-500 Wiring instructions

Tecnosicurezza

Tecnosicurezza MiniTech User operating instructions

Edsbyn

Edsbyn 59 manual

Simons Voss Technologies

Simons Voss Technologies LockNode SREL2.G2 quick guide