Bradman Lake HS User manual

HS Former

- 1 -

MANUAL CONTENTS

1.0 ABOUT THIS MANUAL 4

1.1 Aftersales Support 5

2.0 INTRODUCTION 6

3.0 SAFETY FIRST 7

3.1 Put Safety First!!! 7

3.2 Local Safety aspects 7

3.3 Essential Do’s & Don’ts 8

3.4 Safety Rules 9

4.0 SPECIFICATIONS/DIMENSIONS 10

4.1 System Overview 10

4.2 Typical Machinery Layout 10

5.0 DESCRIPTION OF ASSEMBLIES 11

5.1 Plunger Slide Assembly 11

5.2 Plunger Head Assembly 11

5.3 Forming Head Assembly 12

5.4 Carton Feed Assembly 13

5.5 Feed Bar Ass’y & Feed Bar Drive Linkage 13

5.6 Vacuum Feed Assembly 13

5.7 Gate & Hopper Assembly 14

5.8 Drive Assembly 15

5.9 Drive Motor 15

5.10 Gearbox 16

5.11 Hand wheel 16

5.12 Drive Linkage 16

6.0 DESCRIPTION OF CONTROLS 16

6.1 Operator Interface 16

6.2 Logo Screen 17

6.3 Run Screen 18

6.4 Recipe Screen 19

6.5 Main Menu 20

6.6 Engineering Menu 21

HS Former

- 2 -

6.7 PLC Inputs Slot 1-2 22

6.8 PLC outputs Slot 3-4 22

6.9 Production Statistics 23

6.10 Current Alarm Screens 24

6.11 Alarm Statistics Screen 25

6.12 Machine Settings Screen 26

6.13 Changeover Screen 27

6.14 Setup Screen 1 28

6.15 Setup Screen 2 29

6.16 Main drive Speed 30

6.17 Clock Set Screen 31

7.0 OPERATING INSTRUCTIONS 32

7.1 Warning 32

7.2 Caution 32

7.3 Powering up the Machine 32

7.4 Pre-Start Checks 32

7.5 Starting the Machine 32

7.6 Jogging the Machine 33

7.7 Stopping the Machine 33

7.8 Turning Off the Main Supply 33

7.9 Safety Note 33

8.0 FAULT DIAGNOSIS/TROUBLESHOOTING 34

8.1 Troubleshooting 34

8.2 Vacuum System Diagnostic Chart 35

9.0 MACHINE ADJUSTMENT 36

9.1 Hopper Adjustment 36

9.2 Hopper Gate Frame Adjustment 37

9.3 Feed bar Adjustment 37

9.4 Plunger Adjustment 38

10.0 ROUTINE MAINTENANCE/CLEANING 39

10.1 Cleaning 39

10.2 Maintenance Schedule 39-40

10.3 Recommended Lubricants 41

11.0 INSTALLATION OF CHANGE PARTS 42

11.1 To Install A Forming Tool 42

11.2 To Install & Center The Plunger 42

11.3 To Set Corner Folders 43

11.4 To Set The Carton Blank To The Forming Tool & Plunger 43

HS Former

- 3 -

11.5 To Fit To The Frame Gate 44

11.6 To Fit The Hopper Back Plate 44

11.7 To Fit The Agitator Rods 44

11.8 To Fit The Guide Rods 44

11.9 To Change The Vacuum Cup Assembly & Feed Bar 44

11.10 To Renew The Vacuum Cups 45

11.11 To Change The Plunger & Forming Tools 45

11.12 To Change The Hopper Gate 46

12.0 GUIDELINES FOR CARTONS 47

12.1 Introduction 47

12.2 Manufacture Of Top Load Cartons 47

12.3 Handling & Storage Of Cartons 48-49

12.4 Packing Carton Blanks For Transit 50

APPENDIX

Recommended Spares List

Mechanical Assembly Drawings

Electrical Schematics

HS Former

- 4 -

1.0 - ABOUT THIS MANUAL

CONTINUOUS IMPROVEMENT POLICY

Bradman-Lake, Inc has a policy of continual research and improvement and we reserve the

right to make such modifications and design changes as are considered necessary in the

light of experience. For this reason illustrations and particulars given in this Manual may differ

in detail from machines in current production.

This manual is designed to help operators, maintenance personnel and engineers get the

best from the packaging machine.

Note: Please ensure that all operators and engineers read this manual in

its entirety before using the machine. Following the operating and

maintenance instructions will keep the machine operating at its maximum

efficiency and prolong its life.

The manual provides information on:

Routine maintenance

Machine operation

Safety

Cleaning

Troubleshooting

Changeover

The manual also gives a logical course of action and diagnosis for use in the event of a fault

occurring. The location and function of various components are illustrated and described to

enable personnel to understand and become familiar with the machine.

HS Former

- 5 -

1.1 AFTERSALES SUPPORT

Please call our dedicated Aftersales Team on: +1 704 588 3301

Or by e-mail: [email protected]

Our dedicated Aftersales Team exists to ensure that you get the best from your Bradman Lake

machine throughout its life. We aim is to ensure that your machine keeps running efficiently in

your production environment. We provide:

Spares Size Parts

Service Exchange Units Service & Support

Modifications & Upgrades Operator/Engineer Training

As the original machine manufacturer, we offer you the reassurance of expert service and

advice, providing the best solution to suit your needs.

Steve Privette

After sales Manager

Direct Dial: +1 704-940-1454

Mobile: +1 704-560-3277

E-mail: steve.privette@bradmanlake.com

Sarah Taylor

Spares Sales Engineer

Direct Dial: +1 704-940-1436

Mobile: : +1 704-661-1434

E-mail: bradmanlakespares@bradmanlake.com

HS Former

- 6 -

2.0 - INTRODUCTION

The Erector is an electrically operated, automatic, carton-erecting machine. It is powered

from an external 240 VAC supply and has a self-contained venturi vacuum system, which

forms part of the carton feed system.

Location of the machine relative to other equipment, such as conveyor systems, is assisted

by four wheels on the base of the cabinet. Jacking bolts near the wheels are used to stabilize

and level the machine after it has been positioned. An inclined hopper located at the back of

the machine is hand loaded with a stack of carton blanks. The feed system lifts them one at

a time from the end of the stack and places them on a forming tool ready for the erecting

operation. The hopper can be safely refilled without the need to stop the machine.

Mechanically agitated support rods in the hopper, acting in conjunction with a gravity

operated stack pusher, ensures consistent movement of the blanks along the hopper

towards the feed mechanism.

The forming head, onto which the carton blanks are fed, is mounted behind hinged guard

doors on the front of the machine. The forming head remains stationary while a sliding

plunger slides vertically through it, pushing the blank through the tool and folding it to form

the erected carton. The machine can be fitted with dedicated forming tools to produce

different sizes and / or styles of cartons.

Vacuum cups, mounted on a feed bar assembly and connected to the venturi vacuum

generator, grip each carton blank as it reaches the gate in the hopper and transfers it onto

the forming tool. A cam operated valve then vents vacuum system, releasing the carton

blank and the feed bar assembly then returns to the hopper gate to pick up the next carton

blank.

The electrical system components are housed in an enclosure mounted on one side of the

machine. Access to the enclosure is provided by a hinged panel fitted with an isolator switch

which interrupts power to the machine when the panel is unlocked. This is a safety feature

that ensures that the electrical supplies are isolated whenever the panel is opened. The

machine controls and an operator interface keypad are mounted on the side of the erector.

Mechanical safety switches are fitted to the transparent polycarbonate guards on the front of

the machine. If a guard is opened when the machine is operating, the electrical supply to the

motor is switched off and the motor brake is applied.

HS Former

- 7 -

3.0 - SAFETY FIRST

3.1 - PUT SAFETY FIRST:

The machinery described in this manual has been designed for the sole purpose of

packaging the specified product. Any other products must be approved beforehand by

Bradman-Lake Inc. Packaging of unsuitable products could result in damage to the

machinery and injury to the operator.

Suitable doors, guards and electrical safety devices are fitted to all Bradman-Lake

machines. These protective features are designed for the safety of the operator and are

tested in our plant before the machine is shipped.

The design of the guards and safety devices all follow the recommendations of OSHA and

satisfy the requirements of the Machinery Directive. The functions of the components must

not be altered in any way and they must not be replaced by alternative items.

3.2 - SAFETY ASPECTS OF LOCAL OPERATING INSTRUCTIONS:

Before delivery of your machine, prepare general operating instructions for the use of the

machine. The operating instructions must meet any requirements for:

Compliance with local safety regulations and codes.

Protection of employees against bodily injury, e.g. hard hats, gloves, safety glasses,

hearing protection etc. as required for local conditions.

Protection of employees against hazards such as hot surfaces etc.

Maintaining clear visibility of DANGER, WARNING and CAUTION notices and

labels.

Advisory indicating systems to alert employees near the machine that it is ready to

be started.

Piping all vents on pressure equipment to a safe location.

HS Former

- 8 -

Instructing operators how to deal with any foreseeable mishandling of the machine.

Although Bradman-Lake tries to guard against every possible misuse of the machine, there

are some circumstances where additional warning labels may be needed. Pinch Point

warning labels are positioned on the machine to warn operators/engineers of areas of

concern where fingers may get caught if misused. These are warning labels and therefore

must be kept visible at all times and must not be removed.

3.3 - ESSENTIAL DO’S AND DON’TS FOR SAFETY:

DO NOT operate the machine unless all guards are securely and correctly fitted.

DO NOT put your hands or fingers into the machine when it is running. If debris

needs removing ALWAYS stop the machine and open a guard door before

removing any obstructions.

DO NOT obstruct or remove any DANGER, WARNING or CAUTION notices /

labels that may be on the machine.

DO NOT use the machine if you have not received the necessary training.

DO check the security of all nuts and bolts, screws etc. After the machine has been

operating for a while.

DO keep the area around the machine clean and tidy.

DO disconnect any power supply when needing to work on the electrical system or

when cleaning the machine.

DO MAKE SURE YOU ARE AWARE OF WARNING SIGNS AND THEIR PURPOSE

HS Former

- 9 -

3.4 SAFETY RULES:

No one should operate this equipment unless they have read the service manual

and have been instructed on safety and operation of the machine.

All guards must be in their proper place before starting machine.

The operator should look to insure that the machine is clear before start-up, and

call a warning, “CLEAR”, to alert other personnel that the machine is being

started.

Do not reach into the machine until it has come to a complete stop.

Activate an EMERGENCY STOP prior to clearing jams and reaching into the

machine.

Turn the main power disconnects OFF and attach a padlock to assure that the

power to the machine remains OFF when performing maintenance on the machine.

Do not wear loose clothing or jewelry when operating this machine.

Personnel should be familiar with the location and function of the EMERGENCY

STOP SWITCHES on the machine.

GENERAL SAFETY INFORMATION

This machine has been guarded for the safety of all personnel that are involved with the

production process through the machine. When operating this equipment, all guards must be

in place. Guards, safety switches, and interlocks should not be bypassed for any reason.

Any change or modification to the safety equipment of this machine may produce a

hazardous condition that could cause injury to persons working with the machine. Electrical

cabinets and boxes should not be opened unless power has been disconnected.

WARNING: DISCONNECTING OR BYPASSING THIS MACHINE’S

SAFETY EQUIPMENT WILL VOID THE MANUFACTURER’S

WARRANTY.

HS Former

- 10 -

4.0 SPECIFICATIONS/DIMENSIONS

4.1 SYSTEM OVERVIEW

The HS Former is an electrically operated, automatic, carton erecting machine. It is powered

from an external power supply and has a self-contained vacuum system which forms part of

the carton feed system. The machine is designed to form cartons or trays from a supply of

specially profiled, flat, carton blanks.

Carton blanks are manually loaded into the Inclined Hopper in a vertical format. The blanks

are individually picked by vacuum cups on the Feed Bar, and placed onto the dedicated

Forming Tool for that specific product. The Plunger then descends, driving the carton blank

thru the Forming Tool causing the side flaps to be plowed, locked and closed. The Forming

Head continues to descend, finally discharging the formed carton onto a Product Conveyor.

The system uses a carton make on demand Photocell to control the formed carton supply to

the downstream conveyors.

4.2 TYPICAL MACHINERY LAYOUT

Figure 4.1- Machine Dimensions

Optional Vacuum Pump

HS Former

- 11 -

5.0 - DESCRIPTION OF ASSEMBLIES

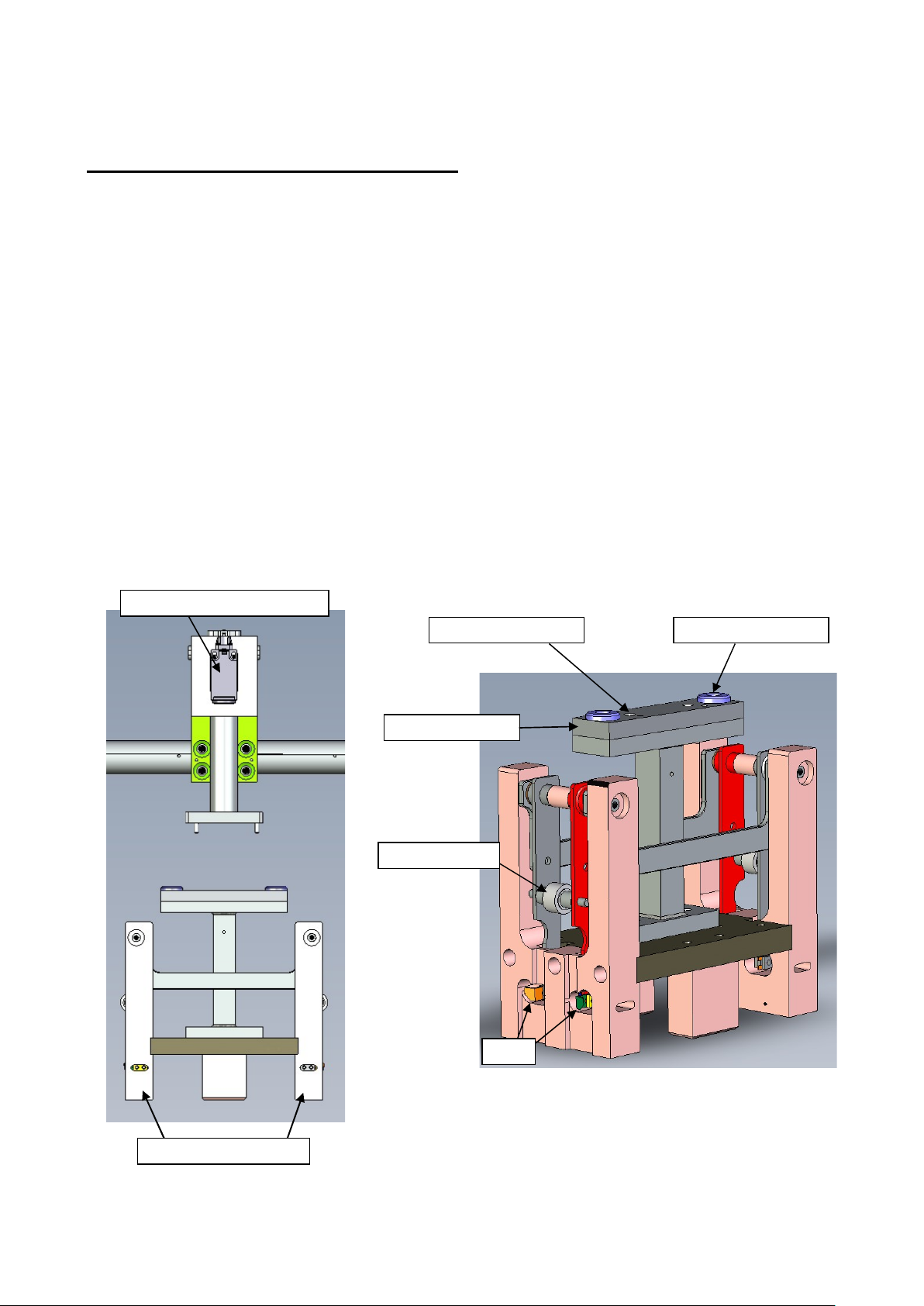

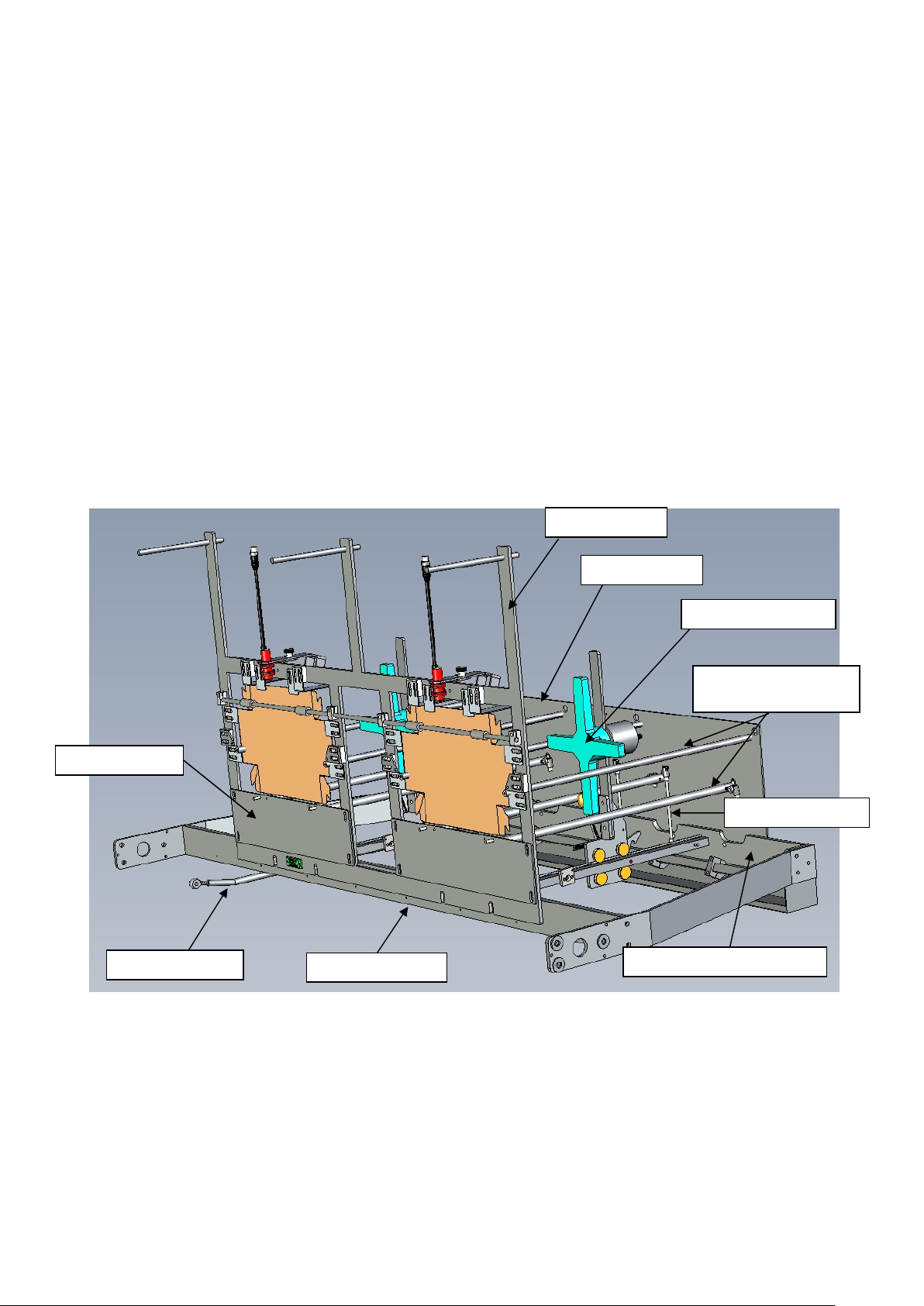

5.1 - PLUNGER SLIDE ASSEMBLY:

The plunger slide assembly comprises of two interconnected plunger slide castings, each

having an upper and lower bearing block bolted to it. The bearing blocks slide vertically on

two fixed pillars, one either side of the cabinet. A split clamp, integral with each plunger slide

casting, grips a transverse cross bar to which the plunger head mounting brackets are

attached again by an integral split clamp. An aligning plate is attached to the plunger head

mounting bracket and the plunger head assembly is secured to the aligning plate.

Grease nipples are fitted to the bearing blocks for routine lubrication. If it becomes necessary

to renew the bushes in the bearing blocks, this must be done without removing the bearing

blocks from the slide casting.

5.2 - PLUNGER HEAD ASSEMBLY:

This carries the forming block about which the carton is erected and is unique to each carton

size. The assembly is hung from the plunger mounting bracket.

The plunger head is a ' Change part ' and a component of the forming tool assembly.

TIP’S

ALIGNMENT SCREW

B

ALIGNMENT SCREW A

ALIGNMENT PLATE

CAM FOLLOWER

TIP ADJUSTING SCREWS

PLUNGER OVERLOAD SENSOR

HS Former

- 12 -

5.3 - FORMING HEAD ASSEMBLY:

This assembly forms the ' die ' which shapes the carton. It is mounted across the front of the

former, directly below the plunger head. Four curved plates form a rectangular aperture

conforming to the outside of the erected carton. The upper horizontal surfaces act as a

platform for the carton blank. Register pins locate the carton blank accurately in position. The

complete assembly is a ' Change part '.

STRIPPER SPRING STRIPPER FINGERS

SPRING HOOK

CROSSBAR SPRING

REGISTER PINS

REAR FORMING PLATE

FRONT FORMING PLATE

CROSS BAR ASSEMBLY

CROSS BAR ADJUSTER

RETAINING BOLT

HS Former

- 13 -

5.4 - CARTON FEED ASSEMBLY:

Two feed arms are mounted on the oscillating feed shaft. The feed shaft is driven by the

adjustable link connected to the pivot shaft. At the end of each feed arm is a pivoting block.

These two pivot blocks carry the square section feed bar assembly.

Two round section guide rods are freely suspended from fixed points either side of the

machine. Each rod is a sliding fit in a hole bored through their operating arc, the guide rods

cause the pivot blocks ( and feed bar assembly ) to rotate. This ensures that at each end of

the stroke the vacuum cups are presented at the correct angle to the hopper gate, or forming

head as appropriate. Vacuum control is via the encoder signal timing setting on the HMI to

control the suction cups. Suction is applied as the cups approach the carton blank in the

hopper gate and cut off when the carton is placed over the forming tool. The position of the

cam on the shaft is adjustable.

5.5 - FEED BAR ASSEMBLY & feed bar drive linkage:

The feed bar is the square section bar fastened to the two pivot blocks.

Clamped to this bar are the two suction cup arms. Positioning and clamping of the cup arms

is part of the initial setting up procedure. Once set, the feed bar assembly is dedicated to that

particular carton and is therefore regarded as a ' change part '.

The feed bar drive linkage has two adjustments, one to position the feed bar relative to the

hopper gate, the other to alter the length of the stroke. Feed bar position is adjusted by

unlocking and turning the link rod to alter the length of the rod. Stroke length is altered by

loosening the nut and bolt at the lower end of the link and sliding the bolt along the slot in the

drive shaft lever to shorten or lengthen the effective arc of the lever.

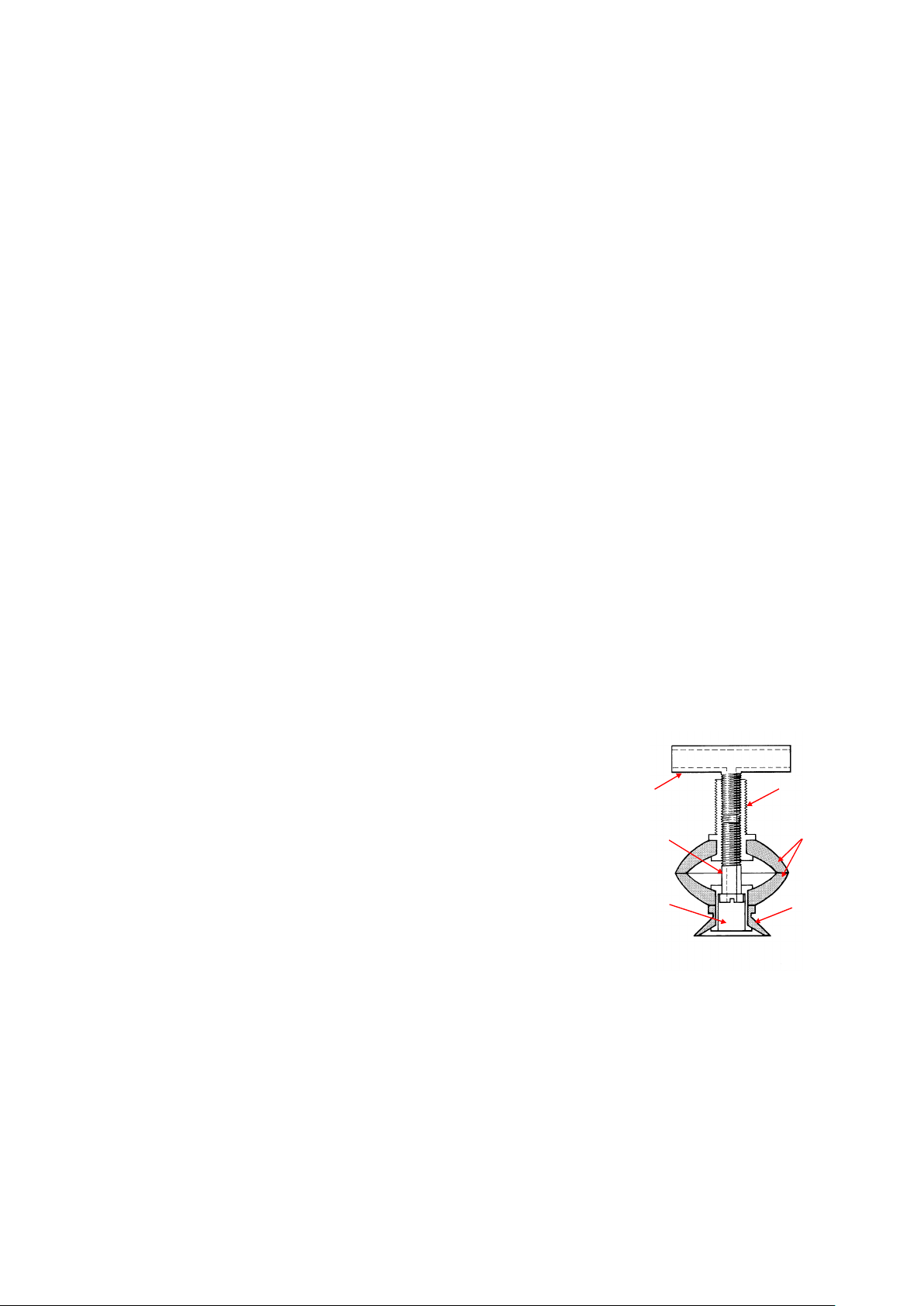

5.6 - VACUUM FEED SYSTEM:

The vacuum is generated by an electrical vacuum pump or an

air driven venturi pump. This vacuum operates through the

suction cups on the feed bar via a valve trigger by encoder

settings set on the HMI.

TEE PIECE

BL 054

BELLOWS SCREW

BL 039

BELLOWS

SLEEVE

BL 051

BELLOWS

CONNECTOR

BL 052

BELLOWS CUP

VCC0050

VACUUM CUP

VCC0051

VACUUM CUP ARRANGEMENT

HS Former

- 14 -

5.7 - GATE AND HOPPER ASSEMBLY:

This assembly comprises of a gate frame secured to a transverse mounting bar at the rear of

the machine, adjacent to the feed shaft. From the gate frame, rods extend rearwards to the

hopper back plate, which is mounted on a hopper support bar. These rods provide support

and guidance for the carton stack. There is a central bar parallel to the carton stack which

acts as a rail for the sliding stack pusher. The hopper assembly is inclined at an angle and

the stack pusher being weighted acts upon the carton stack to ensure an even and constant

presentation of carton blanks to the suction cups.

The hopper is fitted with a photo-sensor which stops the machine when the carton stack gets

to low and needs replenishing. The stack guide is fitted with a clamping knob to lock it to the

rear when fresh carton blanks are being loaded. Adjustable tabs are provided on the gate

frame to act as supports for the carton blanks. The two lower rods on which the stack rest are

connected to agitator links which oscillate to ensure an even and constant presentation of

cartons and is driven from the feed shaft. The gate frame, back plate and agitator links are all

' Change parts '.

DOUBLE GATE ASSEMBLY

GATE FRAME

BACK PLATE

HOPPER SUPPORT BAR

AGITATOR BAR

AGITATOR LINK

MOUNTING BAR

SIDE AND BOTTOM

HOPPER ROD

FRONT PLATE

CARTON PUSHER

HS Former

- 15 -

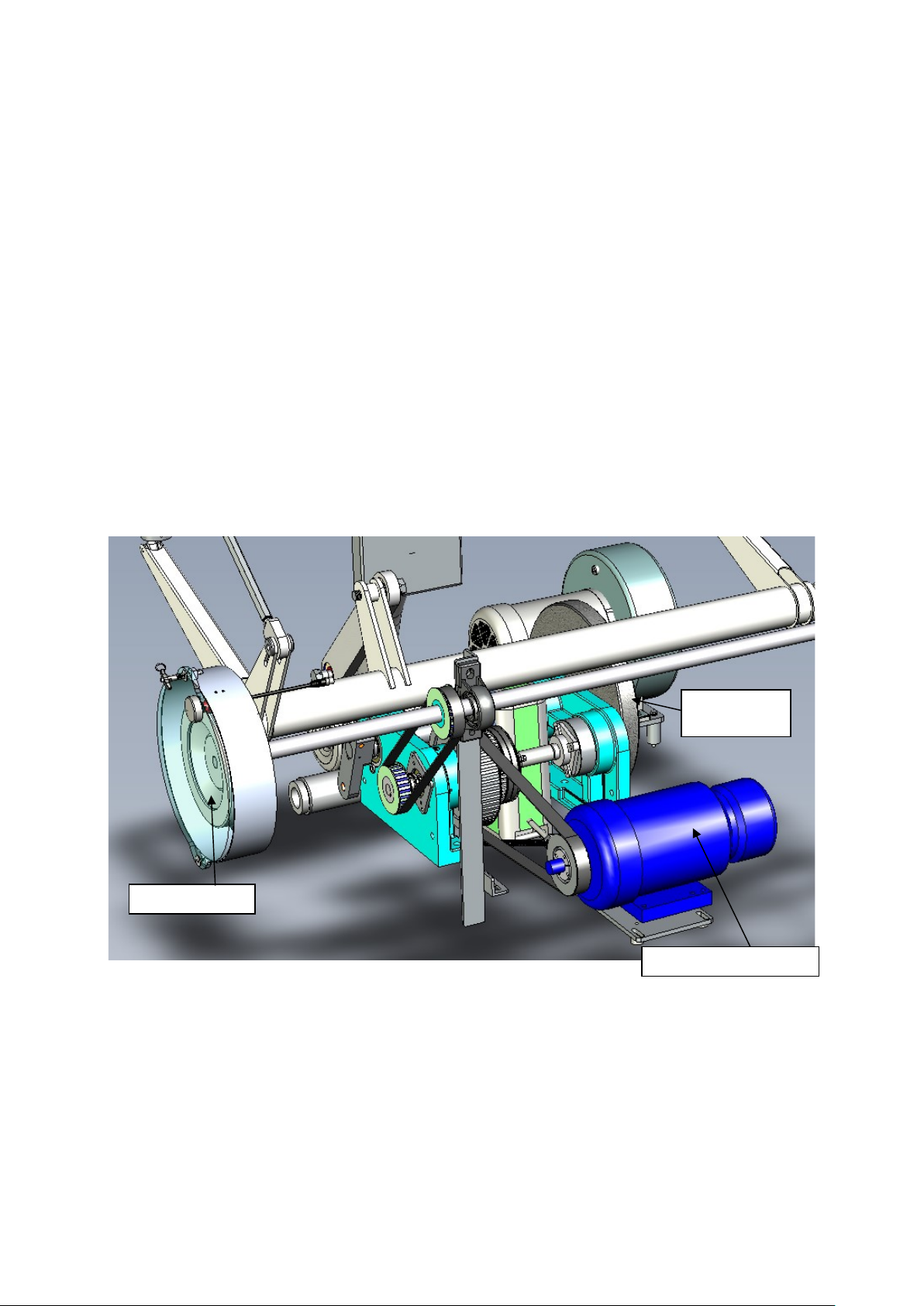

5.8- DRIVE ASSEMBLY

The drive unit consists of an AC motor mounted on a slide base. The motor drives the torque

limiter shaft by means of a timing belt on the motor shaft and a driven pulley on the torque

limiter shaft. A timing belt drive is taken to the Hand wheel shaft from the torque limiter shaft.

A timing belt drive is taken to the input shaft of the shaft mounted reduction gearbox. The

timing belt pulley on the torque limiter shaft is mounted in the torque limiter (slipping clutch

type) to protect the machine. This clutch should be set at a minimum torque value, such that

the machine will run with no signs of slippage. An adaptor bolted to the torque limiter hub

carries the pulley. The torque value is set by an adjuster nut, threaded onto the hub, which

acts against a disc spring to pre-load the friction linings against the pulley face.

The torque limiter shaft is supported at one end by a pillow block bearing mounted on a

mounting bracket. The mounting bracket can be removed to facilitate easy removal of the

timing belts.

The reduction gearbox is mounted on the main crankshaft. A flywheel is mounted on one

end of the main crankshaft to balance the drive. A sprocket is mounted to the crankshaft to

drive the Product Loading Conveyor and Top Loader

5.9- DRIVE MOTOR

The motor is a totally enclosed fan cooled unit fitted with an integral automatic brake, which is

spring loaded to stop the motor immediately when the electrical supply is terminated. While

the supply to the motor is uninterrupted, the brake is energized to the released position.

Manual release of the brake is provided by engaging the brake override key switch.

MAIN MOTOR DRIVE

HAND WHEEL

WEIGHTED

FLYWHEEL

HS Former

- 16 -

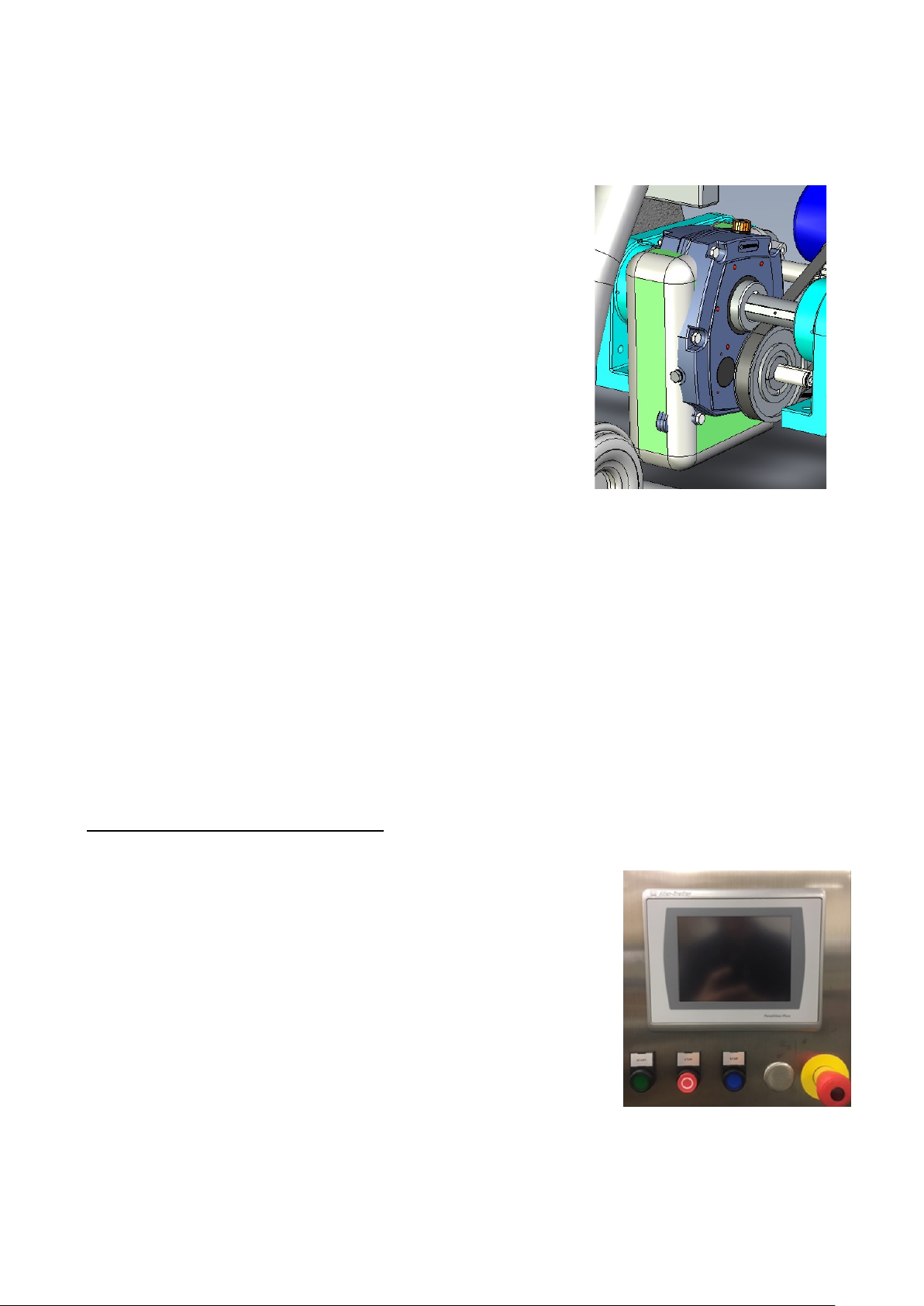

5.10- GEARBOX

The gearbox is of the shaft-mounted type. An anchor is fixed

to the main base frame to restrain the gearbox. The anchor

length is adjusted to give the correct tension to the timing belt

to the gearbox.

5.11- HANDWHEEL

The handwheel is at one end of the handwheel shaft and can be located on the outside of

the Former. A pulley on this shaft is connected via a timing belt, to the pulley on the torque

limiter hub. An arrow on the handwheel guard shows operating rotation. When clearing

jams, rotate handwheel in counter clockwise direction.

5.12 DRIVE LINKAGE

A crank arm keyed to the gearbox output shaft is linked by a connecting rod to an oscillating

pivot shaft. Two arms, one on either end of the shaft, carry the plunger links, which are

connected to the vertically moving plunger slide assemblies. Another link on the pivot shaft is

connected to the oscillating feed shaft, which in turn, carries the carton feed assembly. All

links are adjustable by means of threaded rod ends.

6.0- DESCRIPTION OF CONTROLS

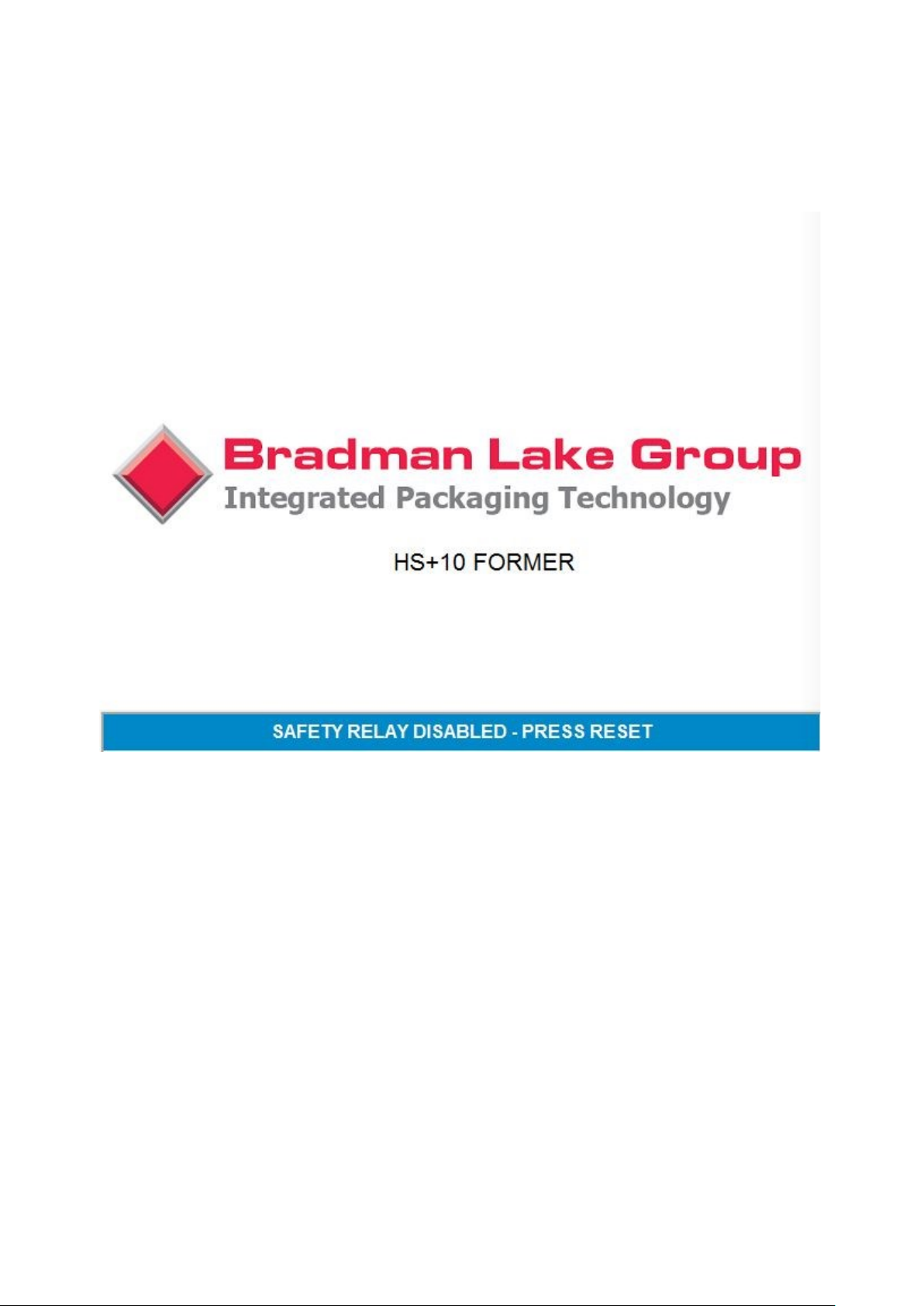

6.1- OPERATOR INTERFACE

The Operator Interface consists of (4) Manual pushbuttons and

an Allen-Bradley PanelView Plus 700 Touchscreen.

1. Start - Starts machine after power is on & faults have

been cleared.

2. Stop- Stops machine; press Run to return to operation.

3. Reset- Resets machine after fault(s) are cleared.

4. E-Stop- Shuts down machine in safe mode; pull out to

reset for running.

HS Former

- 17 -

6.2 - LOGO SCREEN

This is the first screen that appears after the machine is powered up.

Figure 6.2.1- Logo Screen

Pushing Shut Down shuts down the machine. (This prompt is only visible if the engineering

password is used.)

HS Former

- 18 -

6.3 - RUN SCREEN

This screen provides an overview of the machine using a status bar and graphical

representation of certain faults i.e. an open guard door will alarm in the status bar and the

corresponding door will flash red and yellow on the machine graphic.

The status bar will indicate if the machine is ready to run, needs resetting or has a fault that

needs clearing.

Basic machine speed outputs are displayed for example cycles per minute and cartons per

minute are shown.

Figure 6.2.2- Run Screen

Use the following Function Buttons to bring up the respective screens:

1. Left Feed On/Off- Toggles the vacuum feed on that side.

2. Right Feed On/Off- Toggles the vacuum feed on that side.

3. Machine Speed- Displays the erecting rate in machine cycles/min.

4. Main Menu- Returns to the Main Menu.

5. Alarms- displays the alarms screen, from which you can access alarms statistics.

HS Former

- 19 -

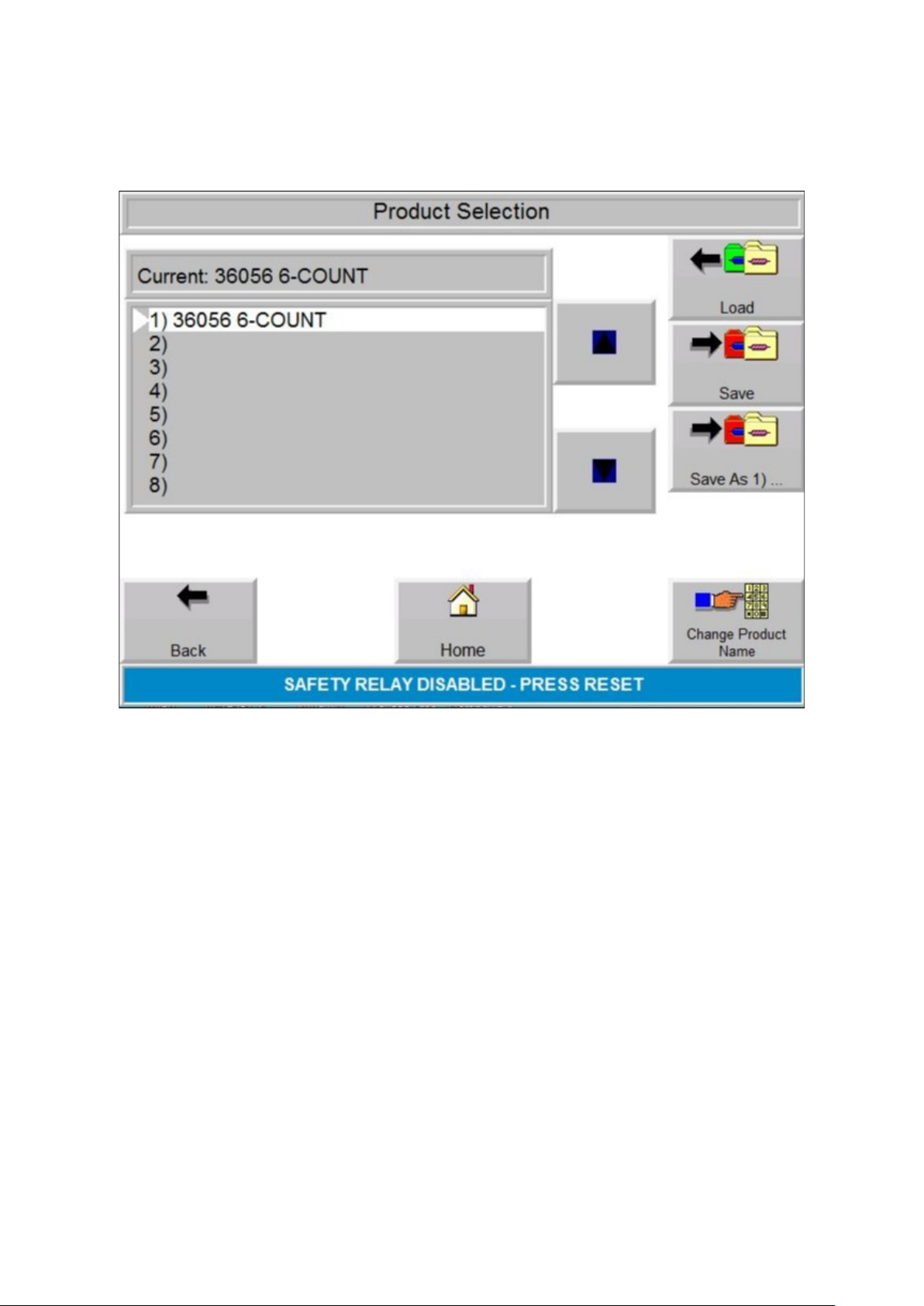

6.4 - RECIPE SCREEN

Figure 6.4.1 - Recipe Screen

The Recipe screen allows the operator or engineer to create, load and rename recipes

specific to individual products.

If you have a new product similar to an existing one, then you can modify the existing

program and save as thus reducing the amount of input to create a new product.

1. Back- Returns to the last screen (Run or Settings Screens).

2. Home- Displays the Run Screen.

3. Load- Loads the highlighted recipe into memory.

4. Save as- Copies the highlighted recipe settings to another recipe.

5. Change Product Name- Allows the user to change the name of the highlighted

recipe.

HS Former

- 20 -

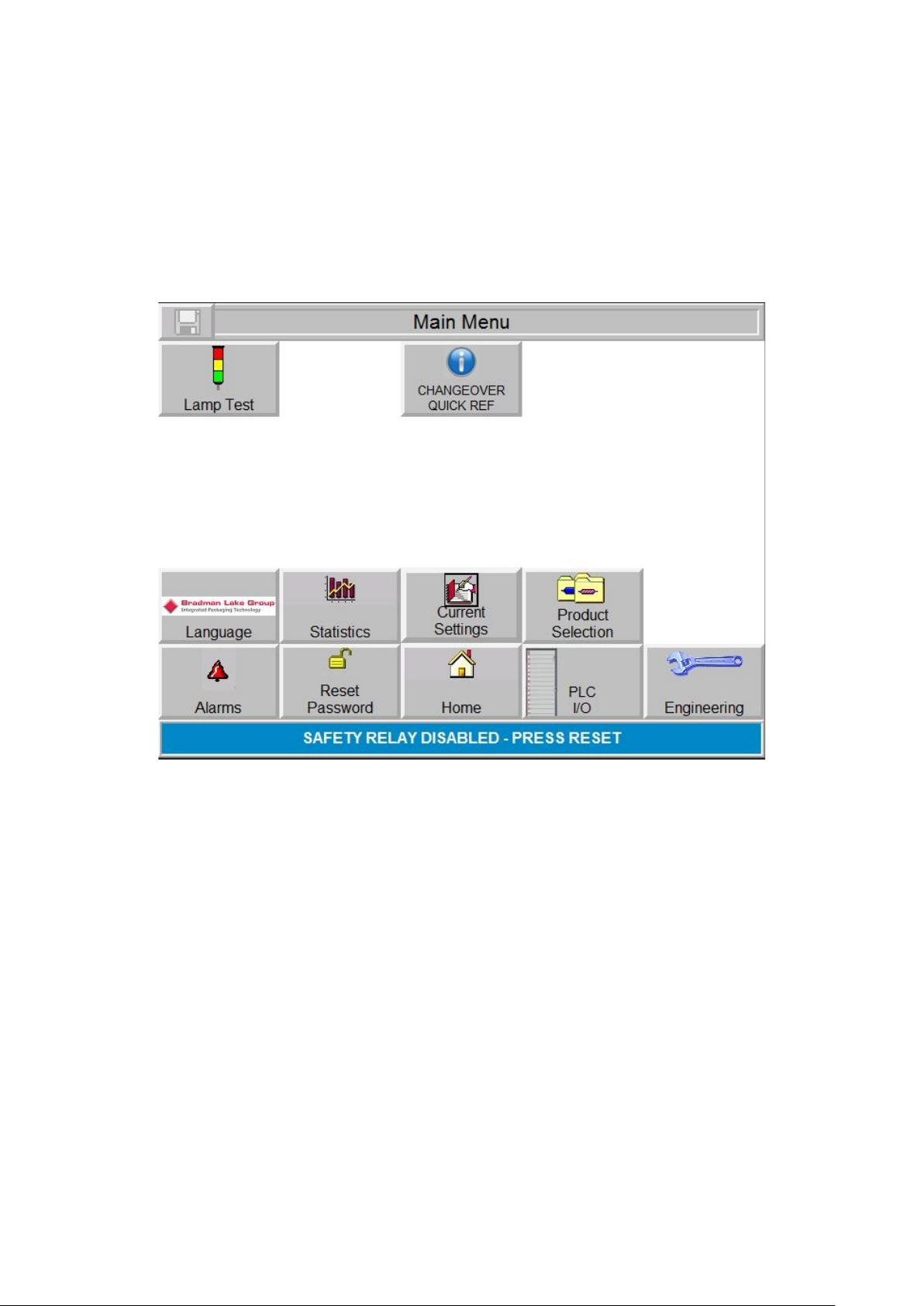

6.5 - MAIN MENU

The main menu screen is accessed from the Run screen. There are both operator and

engineer specific selections, engineering is usually password protected and may be

configured to have multiple levels of access.

6.5.1- Main Menu Screen

Figure 6.5.1- Main Menu Screen

Pushing the following functional buttons will access the indicated parameters:

1. Lamp Test- Tests the lamps for proper operation.

2. Machine Illumination- Turns on/off the machine lighting, if equipped.

3. Quick Changeover Ref- Displays the Changeover Screen.

4. Language- if multiple HMI translations are present then you can select here.

5. Statistics- Displays the Data Screen.

6. Product Selection-Displays the Product Selection Screen.

7. Alarms- Displays the Alarm Screens.

8. Password Reset- Allows the user to reset the password if the original is known.

9. Home- Displays the Run Screen.

10. Current Settings- this screen displays the current recipe settings, (display only)

11. Engineering- Displays the Engineering Menu.

12. PLC I/O- Displays a graph of all PLC inputs and outputs with real time on/off

illumination.

This manual suits for next models

1

Table of contents