BRAHMA 384 User manual

6609_r01 1/8

DIGITAL TEMPERATURE

ADJUSTMENT SYSTEMS

TYPE384

CONTROL BOARDFORAUTOMATIC-

IGNITION ATMOSPHERICBOILERS,

WITH INBUILT E.M.C. FILTER AND

REMOTE IGNITION DEVICE.

DESCRIPTION

Theseelectronicsystemsare suitableforoperating cycleand

temperature controlin closed-chamberandopen-chamber

atmospheric gas boilers.

GENERAL FEATURES

This controlboard is providedwiththe following features:

− single electrode or doubleelectrodeignitionand flame

monitoring (ionization) systemwithremote ignitiondevice;

− possibilityof multipleignitionattempts;

− controlof theboiler parts (systemcirculator,modulating

gasvalve, deflectionvalve, flow switch/flowmeter, air

pressureswitch, thermostats, etc.);

− controls,adjusters and signalsonacustomizedmodule

connected tothe mother boardbymeans ofa flat cable;

− electricalreset (withlockoutstatusstoragein the

EEPROM) or manualreset;

− use of NTCcontact and/or immersionprobes for

temperature measurement (upto 4probes);

− microcontroller-based controloftemperature adjustment

and ignitionand flamemonitoring functions;

− SELV (SafetyExtraLow Voltage) insulation;

− flamemodulationbymeansof aproportional,integraland

derivative (PID)electronic system;

− differentiatedsettingof therequired water temperaturefor

heating and domestic hot water operation mode;

− adjustable boiler max.heat capacityin heating mode;

− domesticmode prioritybymeansofaflowmeter/flow

switch;

− pumpoverrun and lockoutpreventionanddeflection valve

lockout prevention;

− post-purgefunction;

− temperature safetylimitin the boiler primaryhydraulic

circuit;

− prearranged forconnectionto electromechanicallimitand

safetythermostats;

− prearranged foruseinfloor heating systems;

− diagnosticfunctions: heatdemandsignal,boiler lockout,

probescut-off, lackof water inthesystem, lackof stack

draft;

− EMC systemapprovedaccording to the standardEN298;

− prearranged forburnerheat capacitymodulationthrough

gassolenoid valvemodulation;

− prearranged forpumpspeedmodulationaccordingto the

system characteristics;

− varistor protectingfromvoltage transients whichmaybe

generatedin the mainssupply;

− outgoingwater temperatureadjustmentprogramby means

of an outsideprobe;

− operationindependentfromlive-neutralconnectionand

suitable for live-live systems;

− RS232 andRS485interface.

− Opentherm protocolcompatible.

− possible cascadeconnection.

2/8 6609_r01

TECHNICALDATA

Supply voltage: 220/240Vac-50/60Hz

Operating temperature range: -10°C +60°C

Humidity: 95% max.at 40°C

Protectiondegree: IP00

Fuse current: 2A – quick acting

Consumption (withoutloads): 10W

Dimensions: 140mm X100mm

(h45mm)

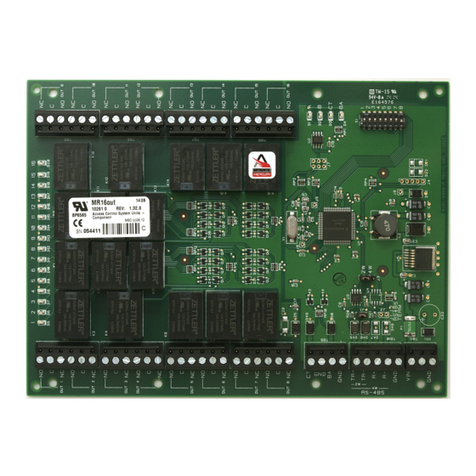

CONSTRUCTION

The system consists ofthe following operating units:

1. MotherBoard(SM),includingpower supply anda

microcontroller for temperature adjustmentandignition

and flame monitoring functions;

2. RelayModule(MR),onwhichtherelaysof theboard are

mounted;

3. ExpansionBoard (SE – optional) enablingthe

expansionoftheboard withtheadditionofconnections

type RS232,RS485,Opentherm, etc.(this moduleisnot

describedin this data sheet;forinformationpleaserefer to

the relevantproduct documentation).

Thesystemisequipped witha ControlPanel(TC),which is

connectedtothe MotherBoard(SM)bymeansofaflatcable

andrepresents the user'sinterface (push-buttons,

potentiometers, LEDs, 7-segment display,LCD).

Thissystemcan be fittedto a remote ignitiondevice type TR2.

ACCESSORIES

Thesystemcanbe suppliedcomplete withBrahmacontact

temperatureprobes type ST03, ST04, ST07,orimmersion

temperatureprobes type ST06,ST6B,ST09andST11.

For adescriptionabouttemperature probes,please see the

relevantdatasheets.

INTEGRATEDTEMPERATUREADJUSTMENTSYSTEM

Themainfunctions of theboard are mentioned below.

Gasvalvemodulator current control:

NaturalGasRange Current: 20..130mA

LPGRange Current(*): 25..170mA

(*)withJ12closed

Type oflockout

Volatilelockout (Standard)orNon-volatilelockout.

Times (*):

Prepurge time (TP) 0 - 120s

Safety time (TS) 3 - 120s

Spark ignitiontime (TSP) TS –1

Drop-out timeonflamefailure <=1s

Ignitionattempts 1-10

(*) The above times correspond toguaranteedvalues.Actual

values maydiffer from declared ones, as waiting (TW) or

prepurgetime(TP) maybelonger and safetytime(TS)

shorter.

Loadrating:

Gasvalve (EV) 0,25Acos ϕ≥0.5

Fan 0.5Acos ϕ≥0.5

Electricalpump 0.5A cos ϕ≥0.5

Deflectionvalve 0.5Acos ϕ≥0.5

220Vac modulating output 0.5Acos ϕ≥0.5

NB: Theboard is provided withaninputfilter; the total load

currentallowedbytheboard is2A;therefore thetotal load

mustbe lowerthanor equal tothis value. Therefore the sumof

applied loadshastobelowerthan2A.

Flame monitoring:

Theflamedetection device makes use oftherectification

propertyoftheflame.

Min. ionisationcurrent: 0.5µA(*)

Recommendedionisation

current:

3 ÷5 times the min.

ionisationcurrent

Max. cable length: 1m

(*)Asensitivityof 1,2 µAis alsoavailable.

Ignitiondevice

The ignitiondevice is remote (typeBrahmaTR2).

Type: TR2

Peak voltage with30 pF load:

15KV or 18 kV

Peak current: 800 mA

Spark frequency: 12 – 25 – 50Hz

(different frequenciesare

available onrequest)

Supplycable standardlength:

0.6 m

(different lengths are

available onrequest)

High voltagecablestandard

length: 0,2 m

(different lengths are

available onrequest)

Siliconehighvoltage cable

withdiameter:

4mm

Electrodeconnection: cylindrical ∅4mm

(configurationuponrequest)

Recommendedsparkgap: 2-4 mm

Consumption: 2,5VA

Spark energy 20mJ

Max. operating temperature: 150°C

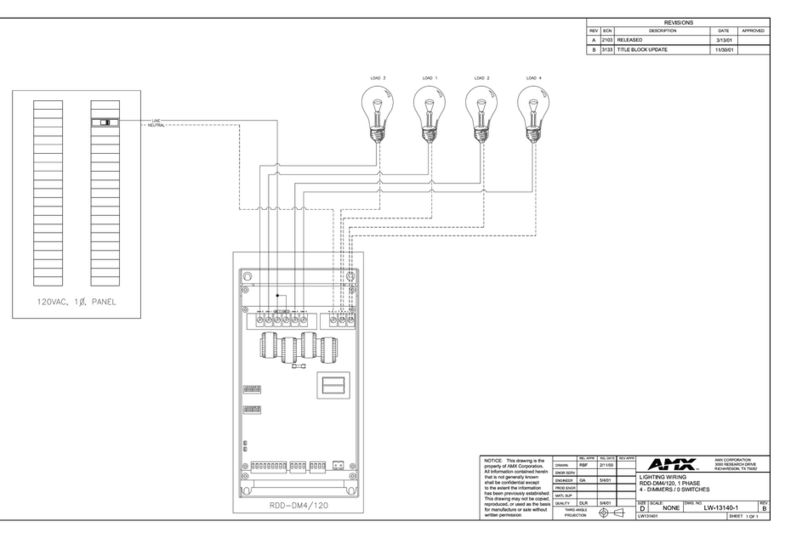

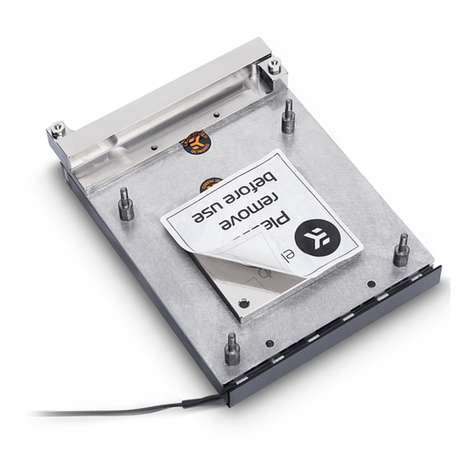

fig.1. RemoteIgnition Device: BRAHMA Type TR2

6609_r01 3/8

-Temperature measuring probes

Thesystemoperates withoneor twoorthree temperature

measuringprobes.TheBRAHMA contact probes type ST06

we usuallyemployenablegreatmanufacture andservice

advantages andguaranteethesameperformance as

immersion sensors.In caseofshort-circuitor interruptionof

the operation of oneof theprobes, depending onthetypeof

boiler thetemperature adjustmentsystemcan either operate

withthe remainingprobe, signallingafailure, orcancelany

heat demand,preventingthe boiler fromoperating. The

probe fitted to theprimarycircuitalso acts aslimit

thermostat,thusallowingany heat demand to be cancelledif

the water temperatureexceedsthe preset limit temperature.

- Safety thermostat

Ingeneral,theboiler isperfectly safe against possible

overheatingin theprimarycircuitbymeansofasafety

thermostatconnectedontheSMand inseriestothe gas

valvecontrol.The thermostatstops thegas flowand

consequently extinguishes theflame;thenastartingattempt

occurs followedbylockout. Beforetryingtostartanew

ignitioncycle, is necessarya manualreset.

- Limit thermostat

Thisthermostatisreadby themicro andwhenitopenthe

systemstop the gas flowwithconsequentlyextinguishesthe

flameandthe controlboard displaythe errorstate.

- Airpressure switch(forclosed-chamberboilersonly)

It checks thecirculationofcombustionproductsinthe

combustionchamberandallowsboiler ignitiononly ifthe fan

is operating and the draftis regular;it alsoensures the boiler

safetyshutdown ifoneofthese conditionsfails during

operation.Uponrequest, inopen-chamberboilers the air

pressure switchcanbe replacedbyacombustion products

discharge safetydevice usingthesameconnector but

another pin.For the connectionseethe wiringdiagram

section.

- Water pressure switch

It ensures thatthe primarycircuitpressure iswithinthe

requiredoperation range. Incasethe pressure is toolow,the

temperature adjustmentsystemcancelsany heat demand

and the type of failure appearson the powerswitchboard.

- Water pressure trasducer

It ensures areadingoftheprimarycircuitpressure.The

valueof thepressure is displayed inthecontrol board. In

case the pressureistoolow,thetemperature adjustment

systemcancelsany heat demandandthe typeof failure

appearson the power switchboard.

- Water flow switch

TheSMisprearranged foran inputconnectionsignalling

domestic water drawing.Thissignal canbe generated bya

flowsensor (flow switchor flowmeter): in this case the three-

wayvalve(ifavailable) iselectrically controlledbythe

system; otherwisethesignalcanbegeneratedautomatically

byanhydraulicthree-wayvalve.

- Room thermostat

Theroomthermostat(orchronothermostat)isconnected to

theSMby twowires; itisdesignedto operatewithacontact

isolated fromthe powersupply line.

- Timer

TheSM isprovided withaconnectionfor atimer(12-24Vor

220V)mountedon theboard to adjust theheatingtime,as

requiredbythenewstandardsregardingenergy saving.

Thanks tothistimer, theuseof achronothermostatisnot

required.

- Externalprobe

Thesystemisprearrangedforthe connectionto anNTC

sensor (similar to the one usedin temperatureprobes),

whichmeasures theexternaltemperature outside the

buildinginwhichtheinstallationisplaced. Theavailable

adjustmentsinheatingmode are the requiredambient

temperatureandtheheatdispersioncoefficientoftheroom

walls. Thetemperatureappearingonthedisplayis the

primarycircuittemperature, resulting fromthetwopreset

parametersandtheexternaltemperature.Uponvariationin

thelatter one,theprimarycircuittemperature changes

automaticallyto adjustthe ambient temperature according to

the preset value.

- Control board

This mother boardsupply more types ofcontrol boardwith7

segmentdisplayorLDC, withpush-buttonsor regulator

trimmers.

NB: All the customcharacteristics are describe in the customer

use manual.

DIRECTIONSFOR INSTALLATION

• RespecttheapplicablenationalandEuropeanstandards

(e.g. EN60335-1/prEN50165)regardingelectricalsafety.

• Connect live and neutral correctly;the non-observanceof

live-neutral polarity maycause adangeroussituation.

Polaritymust be respected evenin casetheboardisin

non-polarized version.

• Theearthof theboard mustcomingfromthestarearthof

the boiler,notdirectlyfromtheearth-line.Theboard-earth

isnot safetybutonly functional. Theearthsignalmust be

connectedas shown in the figure below

• Beforestartingthe systemcheckthecablescarefully;a

wrong wiring candamage the devices and compromise the

safetyofthe installation.

• Connect anddisconnectthecontrolsystemonlyafter

switching off the powersupply.

• The system canbe mountedin anyposition.

• Avoid exposing the system todripping water.

• Theapplianceinwhichthis temperature adjustment

systemismounted must provideadequateprotection

against therisk ofelectricshock(atleast IP20).

• Avoidplacingcontrolsignalcablescloseto powercables.

Avoid placing ignitioncablesclosetoother cables.

4/8 6609_r01

Earthconnection

OPERATING CYCLE

Thefollowingoperatingcyclereferstothetemperature

adjustmentsystem describedabove.

Thisoperatingcyclereferstoastandardexampleand canbe

customizeduponrequest.Thecyclerefers to aboardfitted

withthe controlpanelillustrated in fig.2.

Starting cycle

The startingcyclebeginsonheatdemandbytheroom

thermostat(heatingmode)orthewaterflowswitch (domestic

hot water mode).

Thewater pump isenergized, and ifthe water temperature is

lower thanthepreset value, aburner starting demandwill

occur.

Incase of aclosed-chamberboiler, thecontrolunitstartsthe

fanonly iftheairpressureswitchisin "no-air-flow" position;

whenitswitches into "air-flow"position,the prepurgetimeTP

begins, at theendofwhichthe gas valveissupplied, the

ignitiondeviceisstartedandthesafetytime TSbegins. Inthis

stage,theburnerheat capacityiskept atacontrolledvalue

according to the application requirements (soft start).

If aflamesignalisdetectedattheend ofTS, the temperature

adjustment processwillbegin,andtheburner flamewillbe

modulated inorder to reachthesamewatertemperature as

the presetvalue. If no flame signalis detectedwithin the safety

time,ontheelapsingof TSthegas valvewillclose. If the

numberofattempts iscompletedthe lockoutconditionoccurs,

otherwise there isanother ignitionattempt.Theboilerlockout

issignalledonthecontrolpanel; to reset thesystem pressthe

corresponding push-button.Ifhot water demandstill occurs,

the boiler will start a newignitioncycle; iftheconditions

leading tolockoutstill occur,theboilerwill gobackto lockout.

The boilerkeeps onrunning until eitherheatdemand stops, or

oneof thesafetydevicesswitches on,or the flame

extinguishes.

Domestic hot water mode

Ignitiondemandin DHWmode haspriorityover heatingmode.

Theboilerburner ignitionoccurs whenhot waterisdrawn;the

boiler willtryandsupplythe user withdomestichot waterat

presettemperature.Ifthe requiredcapacityislower thanthe

min.modulationcapacity,theboiler willperform shortignition

andturnoffcycles.Iftherequiredcapacityishigher thanthe

boiler max.capacity, the water temperaturewill beproportional

to thequantityof drawnwater,butlower thanpreset

temperature.

Heating mode

Iftheboiler isin winter position,andonroomthermostat

switchingofftheoutgoingwatertemperature islower than the

presetvalue,boiler ignitionwilloccur and flamemodulationwill

begin untilthe boilerreachestherunningcondition.Ifthe

outgoingwater temperatureis5°C higher thanthevalue

previouslyadjustedbytheuser,theboiler willswitch off; re-

ignitionoccurs assoonasthewater temperaturedrops of 5°C

belowthepreset value, provided thatat least 150sec have

elapsed fromtheboiler switching off. Theboiler max.capacity

in heatingmode issetduring installationthroughthepush-

buttonson the controlpanel.

Circulator overrun

Everytimetheboiler switches off(inheatingmode), the

circulatorkeepsonrunning forashorttime(5 seconds),in

order toavoidwateroverheatingin theprimaryheat

exchanger.Suggested overrun timesare,forexample: 30s,

60s or 180s.

J29

Boiler case

Earth Terminal

Earth forloads

(Pump, LoadingValve, Fan andGasValve)

Earthforbielettrodsystem

Twowire connection

Airpressureswitch:

Common (C)

Normal open(N.O.)

Line

Neutral

J34

J1

J7 J5 J20

J23

J2 J21

MOD.1

J4

F1

2AF

250Vac

J22

J30

J26

J28

J33

J32

J35

TR1

J25

1

JP5

JP4

JP3

JP2

JP6

Ioniazation fast-on

Earth connection

(fast-on)

Earth signal

Earthconnection

(fast-on)

6609_r01 5/8

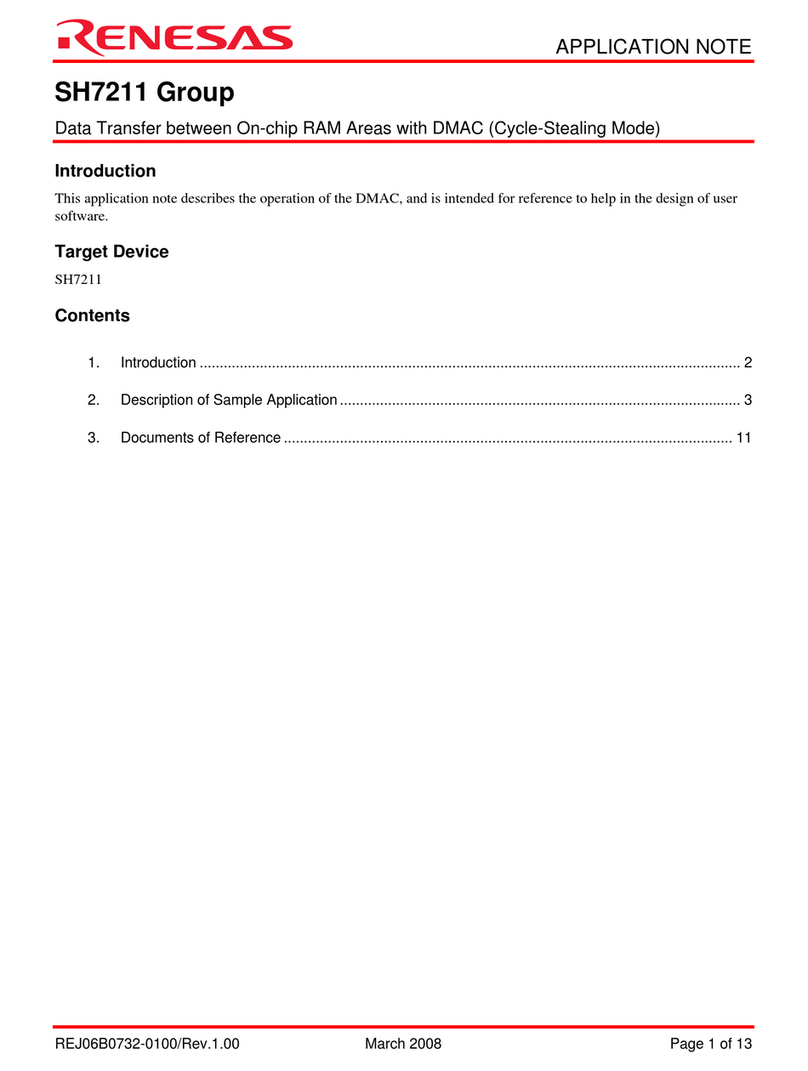

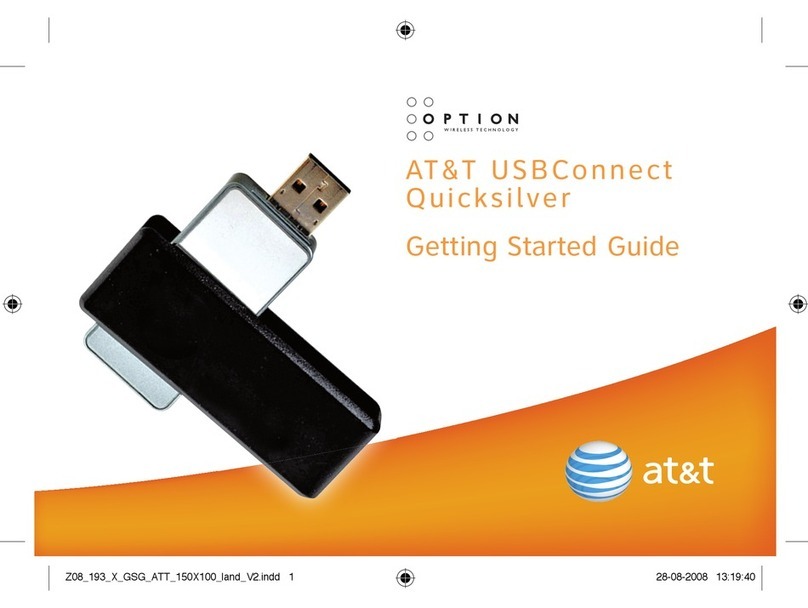

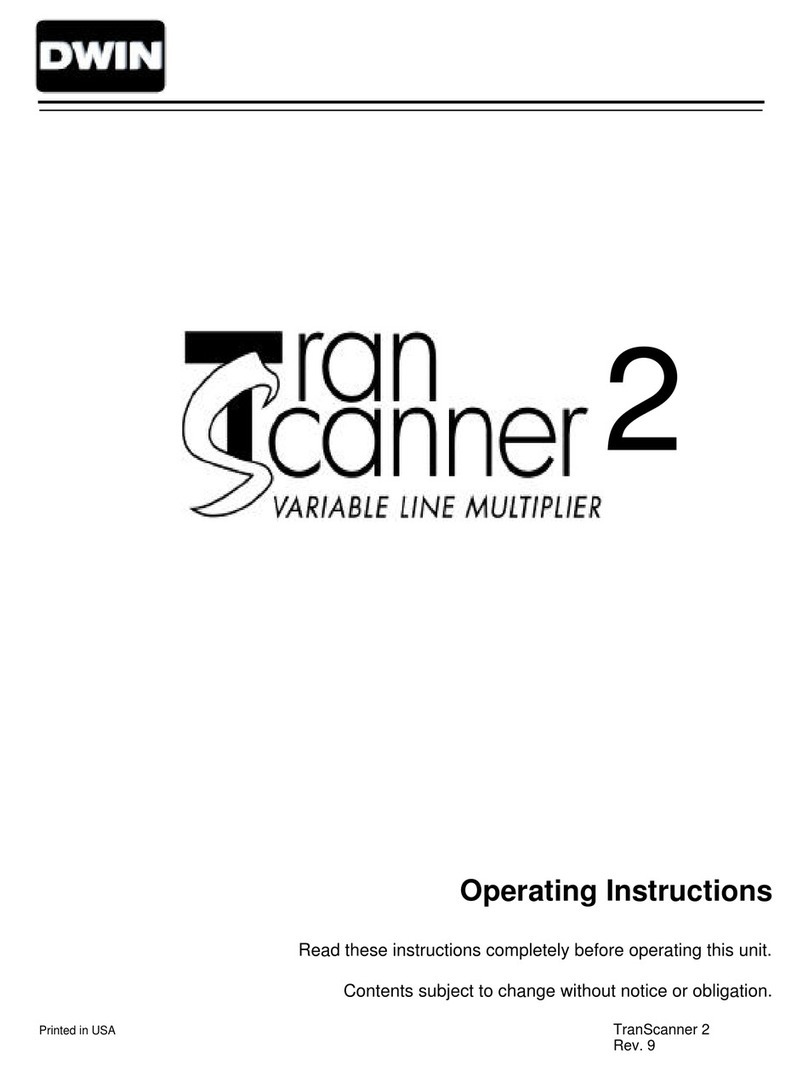

WIRING DIAGRAM

Thewiringdiagramisillustrated infig.3at theend of this

paragraph. Followingsarethe connectors of the board and the

meaning of eachsignal

ifsomeofthe loads are not available,thecorrespondingpins

or allthe connectormaynotbefitted.

Board power supply connector

(J4–2-POLESTELVIO)

Pin1 Live

Pin2 Neutral

Earthconnectors

(J7, J34, J35 – 6,3 mm fast-on)

Pin1 Earth

Flame sensor connector

(J5–4,8 mm fast-on)

Pin1 Flamesensor

High-voltageloadconnector for diverting valve

(J20 – 9-POLEMOLEX)

Pin1 Neutral

Pin2 NC

Pin3 NO

Fanconnector

(J23 – 2-POLEMOLEX)

Pin1 Neutral

Pin2 Fan (on/off)

Pumpandmodulating loadconnector

(J21 – 4-POLEMOLEX)

Pin1 Water electricalcirculator

Pin2 Neutral

Pin3 Neutral

Pin4 230Vac auxiliarycontrol

Gasvalve connector

(J2–4-POLESTELVIO CFM4A)

Pin1 Live forEVGgas valve

Pin2 Safety thermostat

Pin3 Safety thermostat

Pin4 NeutralforEVGgasvalve

Incaseno safetythermostat is used,connectionis as follows:

Gasvalve connector

(J2–4-POLESTELVIO CFM4A)

Pin1 Notconnected

Pin2 Notconnected

Pin3 Live forEVGgas valve

Pin4 NeutralforEVGgasvalve

Airpressure switch and limit thermostat connector

(J22 – 5-POLELUMBERG 2,5MSF)

Closed-chamberconnection

Pin 1 Airpressure switch

Pin 2 Air pressure switch

Pin 3 Notconnected

Pin 4 Limitthermostat(*)

Pin 5 Limitthermostat

(*)If nolimitthermostat isused, pins1and2mustbe short-

circuited.

Connectorforcombustion productssafetydeviceand

limitthermostat

(J22 – 5-POLELUMBERG 2,5MSF)

Open-chamberconnection

Pin 1 Combustionproductsdischarge safetydevice

(*)

Pin 2 Not connected

Pin 3 Combustionproductsdischarge safetydevice

(*)

Pin 4 Limit thermostat

Pin 5 Limit thermostat

(*)Ifnocombustionproductssafetydevice isused, pins1and

3mustbeshort-circuited.

Modulationandflow switchconnector

(J32 – 9-POLELUMBERG 2,5MSF)

FLOWMETER FLOW SWITCH

Pin 1 NOTUSED NOTUSED

Pin 2 NOTUSED NOTUSED

Pin 3 EVGvalve modulator EVG valve modulator

Pin 4 EVGvalve modulator EVG valve modulator

Pin 5 Water pressure switch Water pressure switch

Pin 6 Water pressure switch Water pressure switch

Pin 7 Flowmeter input Flowswitch

Pin 8 Flowmeter +5Vdc Notconnected

Pin 9 Flowmeter 0Vdc Flowswitch

In casethe option"modulating fanlow-voltage PWMcontrol" is

operating(inthiscase theairpressureswitch is necessary),

the connector is thefollowing:

Modulationandflow switchconnector

(J32 – 9-POLELUMBERG 2,5MSF)

FLOWMETER FLOW SWITCH

Pin 1 Modulator +24Vdc Modulator +24Vdc

Pin 2 Modulator 0Vdc Modulator 0Vdc

Pin 3 EVGvalve modulator EVG valve modulator

Pin 4 EVGvalve modulator EVG valve modulator

Pin 5 Water pressure switch Water pressure switch

Pin 6 Water pressure switch Water pressure switch

Pin7 Flowmeter input Flowswitch

Pin 8 Flowmeter +5Vdc Notconnected

Pin 9 Flowmeter 0Vdc Flowswitch

In thisapplicationisnecessarytheuseof theAirPressure

Switch.

6/8 6609_r01

Pressure transducer connector

(J33 – 4-POLE LUMBERG 2,5MSF)

Pin1 +5Vdc

Pin 2 0Vdc

Pin3 +24Vdc

Pin4 Input

NTC temperature sensorconnector (*)

(J28 – 8-POLE LUMBERG 2,5MSF)

Pin1 Outside NTC

Pin2 Outside NTC

Pin3 HeatingreturnNTC

Pin4 HeatingreturnNTC

Pin5 Domestic hotwaterNTC

Pin6 Domestic hotwaterNTC

Pin7 HeatingNTC

Pin8 HeatingNTC

(*)Thefunctionof NTCs isdetermined by thetemperature

adjustmentprogram. Thisfunctioncanvaryaccordingto

specific customer's requirements.

Roomthermostat connector

(J28 – 2-pole screwconnector)

Pin1 Room thermostat

Pin2 Roomthermostat

Selectionjumpers

JP6 LPG/Naturalgas

JP2 Customizable (*)

JP3 Customizable (*)

JP4 Customizable (*)

JP5 Customizable (*)

(*) The function ofjumpers isdeterminedbythetemperature

adjustmentprogram. Thisfunctioncanvaryaccordingto

specific customer's requirements.

Timer connector

(J26 – 4-POLE JST)

Pin1 0Vdc

Pin2 +24Vdc

Pin3 Input/output TTL 1

Pin4 Input/output TTL 2

The remaining connectorshave thefollowing function:

1. J30:connector forinterfacecontrol panelconnection;

2. J25:connector forin-circuitprogramming of U9;

3. J8, J9,J10,J11, J12: connectors for expansionboard

connection(SE).

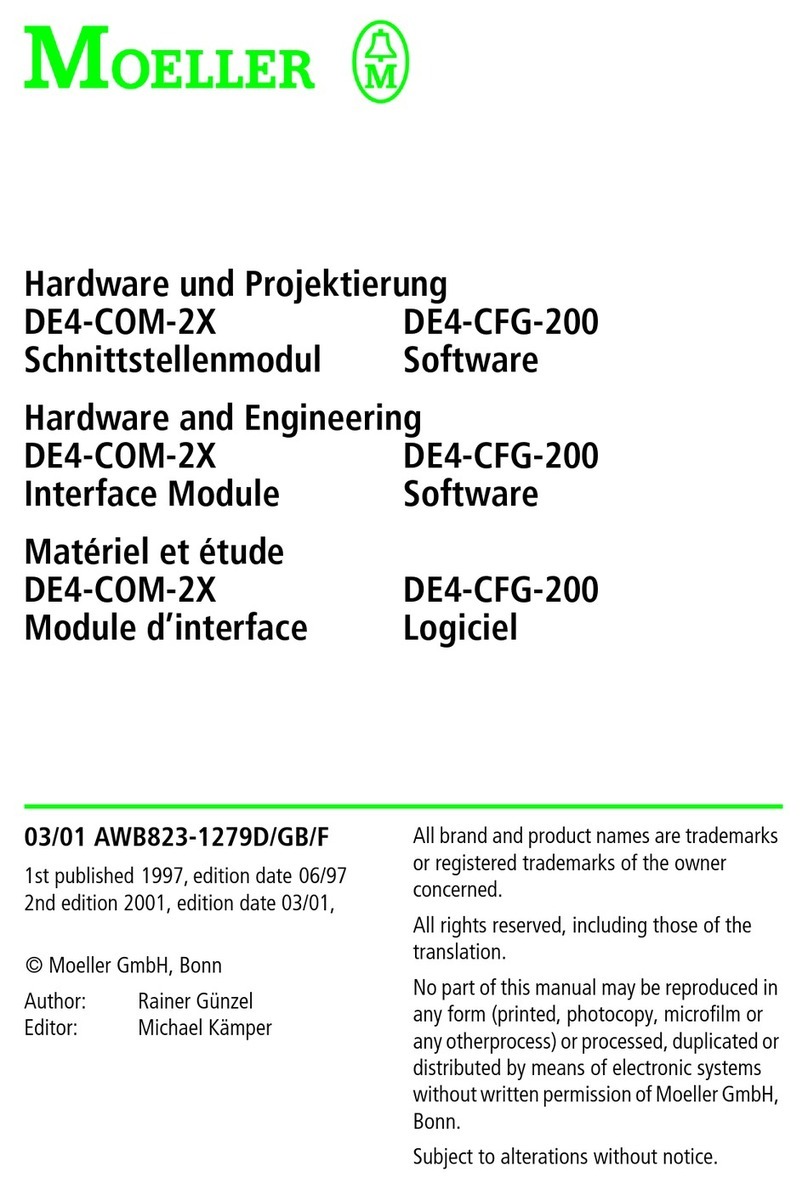

Inparticular,J30connects theboardtothecontrol panel,if

available. Anexample ofcontrolpanel isshownin fig.2.

In generalthe board candriveupto4seven segments

displays anditcan read up to7push-buttons.

Themeaningof eachpush-button canbe determinedby the

temperature adjustment program.

Only the resetbuttonhas tobefixed (asshown in fig.2).

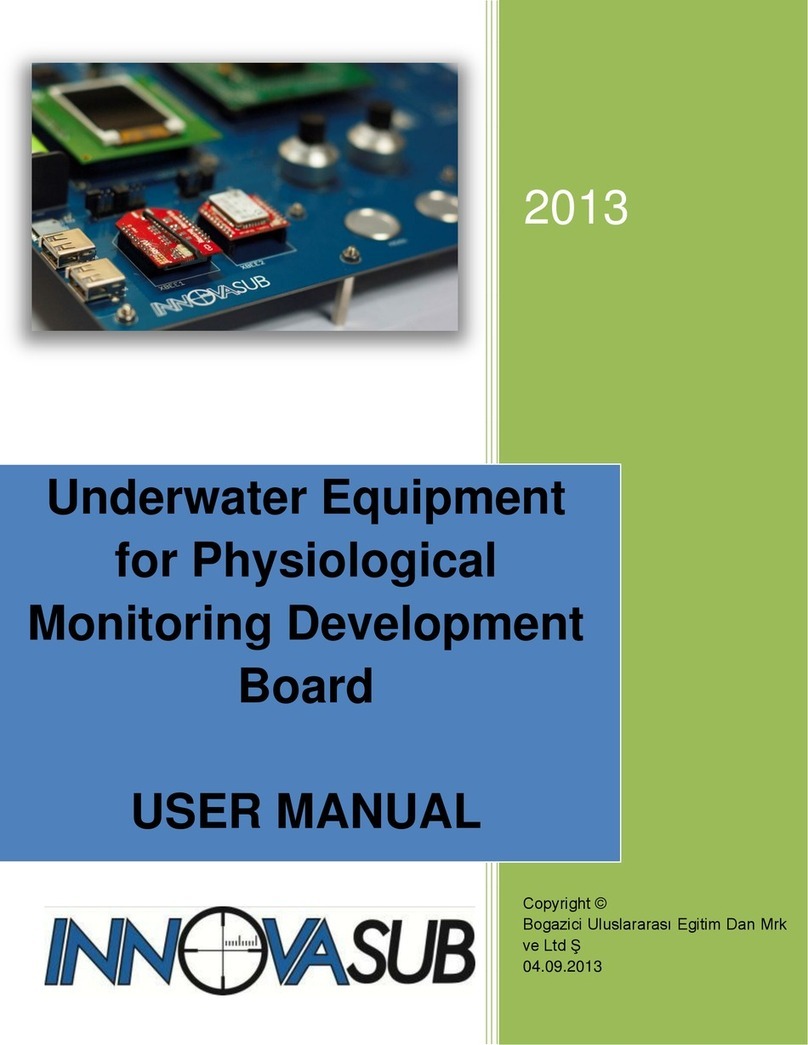

fig.2.Anexample ofinterfacecontrol panel

6609_r01 7/8

PARTREFERENCES

Type description

384 (1) (2)(3)(4)(5) (6) (7)(8).(9) (10)(11)

(1) Powersupply: (7) Modulation:

P:Phase-sensitive device D: Nomodulation

N:Nophase-sensitive device

(2) Interfaces : (8) Thermostat:

E:Economical Y:Noroomthermostat

C:Expansiontype 386

(3) Communication : (9) Letterrefers toacustomer:

S:number of standard inputs (Brahma document)

M: Multiplexer

(4) Type of controlboard : (10) Type ofsoftware:

0: Nocontrol onboard 0,1,2…:progressive numbering

1: LCD

2: 2digits

3: 3digits (11) Softwareindex revision:

4: 4digits 00,01,02….:progressive numbering

(5) Type of controlcirculator :

X:Nothing

F:Phase-shift

U:Output220V

(6) Deflaction relays:

1: Fanrelay – no deflectionvalve relay

2: Fanrelay – deflection valve relay

3: Nofan relay – nodeflection valve relay

4: Nofan relay – deflectionvalve relay

PARTS REFERENCES OFTHEBOARD OPTIONS

Options(printed on thelabel)

(1) (2) (3) (4) (5)(6) (7)

Optionsdescriptions

(1) M: manualreset

E:electricalreset(standard)

(2) TP:0-120s (standard3s)

(3) TS:3-120s (standard7,5s)

(4) Fan:

F1:withoutfan(openchamber)

F2:withfan

F3:withfan (open/close chamber compatible) (standard)

(5) Power supplyconnection

Noletter: phase-neutral polarization(phase-sensitive control).

N:no-polarization(oneindependentphase relayandone independentneutraland flamedetection relay for

no-polarized ionization)(standard).

N1:one independentphase relay and one independentneutralandflamedetectionrelay for polarized

ionization

(6) Ignitionattempts

Noletter: one ignition attempt after a safetyshutdown(standard).

Ynn:multipleignition attempts(nn =1 – 10)

(7) Ignitiondevice andflame detection mode

Noletter: remoteignition device(TR2) andflame detection throughadedicatedelectrode

X1:remoteignitiondevice (TR2) and single-electrodeflame detectione(one electrodefor bothflamedetection

and ignition)

BRAHMAS.p.A

ViadelPontiere,31/32

37045 Legnago(VR) - ITALY

Tel. +39 0442635211 – Fax+390442 25683 07/03/01Subject toamendmentswithoutnotice

http://www.brahma.it

E-mail: brahma@brahma.it

8/8 6609_r01

JP2

JP3

JP4

JP5

JP6

F1

2AF

250Vac

J32 J33 J28

J26

J10

J29

J22

J21J2J23J20

J5J7

J1

J4

11

1

1

1

1

1

1 1

MOD.1

J8

TR1

U1

L1

U6

U2

U9

U8

ION

+5Vdc

0Vdc

+24Vdc

INPUT

CH NTC PROBE

DHW NTC PROBE

CH RETURN NTC PROBE

OUTSIDE NTC PROBE

1

+5Vdc

0Vdc

FLOWMETER

INPUT

FLOWSWITCH

WATERPRESSURE SWITCH

GAS VALVE MODULATOR

PINUSEDIN

OPTIONM2

PRESSURE TRANSDUCER

ROOM

THERMOSTAT

LOCALUSERMANUAL

INTERFACE

TIMER

EARTH

NEUTRAL

LIVE

AUX 220Vac LOAD

PUMP

SAFETYTHERMOSTAT

GAS VALVE

FAN

N.C.

N.O.

3-WAY VALVE

FLAME

ELECTRODE

TR2

TOJ7

(IFMONOELECTRODETOJ5)

EARTH

LIMIT

THERMOSTAT

APS

COMBUSTION

SAFETYDEVICE

J34

EARTH

J35

J9

J11

J12

1

+24Vdc

0Vdc

Contacts

fig. 3.384 Wiring diagram(the dimensions are notinscale)

ATTENTION -> CompanyBrahmaS.p.A.declinesany responsibility for any damage resulting fromthe Customer's interferingwith thedevice

Table of contents