BRAHMA TC340 User manual

14698_r00 1/18

DIGITAL TEMPERATURE

ADJUSTMENT SYSTEMS

Type TC340

DIGITAL IGNITION AND FLAME CONTROL

SYSTEMS FOR HOT AIR GENERATORS (TYPE

TC340A – TC340P) AND FOR MODULATING

PREMIX BURNERS (TYPE TC340P1)

DESCRIPTION

These systems are specifically designed for safety cycle control

and temperature adjustment in hot air generators equipped with

automatic-ignition fan-assisted gas burners and in modulating

premix burners.

GENERAL FEATURES

The systems are provided with the following important features:

− compliance with EN 298:2003-09 (European standard for

automatic gas burner control and flame monitoring systems);

− CE approval according to Gas Appliance Directive 90/396/EEC

and following amendments (Directive 93/68/EEC);

− suitable for both phase-phase and phase-neutral power supply

systems;

− non-polarized flame signal amplifier (the power supply polarity

may not be respected even in case of a phase-phase power

supply network);

− control of the hot air convector blower (FAN) by means of a

phase-cut driver;

− control of the burner motor by means of a phase-cut driver (for

fan-assisted gas burner appliances) or through a PWM signal

(for premix gas burner appliances equipped with brushless fan

with integrated management electronics);

− two independent safety contacts for driving the EV1 main

solenoid gas valve;

− inbuilt capacitive-discharge ignition transformer (version for fan-

assisted appliances);

− output for the control of an auxiliary electronic ignition

transformer;

− prearranged for the control of the EV2 second valve stage by

means of two independent contacts taking the power supply

from the EV1 first valve stage (version for fan-assisted

appliances);

− burner power modulation by means of a current modulator

(version for fan-assisted appliances) or through a PWM signal

(version for premix appliances);

− possible interfacing with a BRAHMA digital chronothermostat

type ENCRONO GA1 through OpenTherm™ communication

protocol, or with a power-free contact room thermostat;

− possible interfacing with additional TC340 devices for

“cascade" applications (OpenTherm™ communication

protocol);

− summer ventilation function (only in connection with BRAHMA

chronothermostat type ENCRONO GA1);

− control of a BRAHMA double NTC temperature probe type

ST16 with outlet air temperature adjustment and safety

functions;

− control of a BRAHMA double NTC temperature probe type

ST08 with outlet air temperature adjustment functions;

− possible control of a safety thermostat;

− prearranged to control a BRAHMA NTC temperature probe

type ST07 with room or outside temperature adjustment

functions;

− possible connection to a fire damper contact (optional);

− possible application in modulating premix burners equipped

with three-point adjuster or adjustment thermostat;

− possible application in appliances provided with 0÷10V

analogue signal adjustment (e.g. PLC);

− on-board manual reset push-button;

− operation status and failure signalling by a two-colour LED;

2/18 14698_r00

− prearranged for the remote connection of the manual reset and

status displaying signals through a BRAHMA module type 865

(containing a two-colour LED and a reset push-button);

− communication interface type RS-232 for diagnostic and set-up

functions (through BRAHMA serial interface type 810 and

management software);

− inbuilt EMC filter;

− two fuses provided with removing tool to protect the power

supply network on both potentials;

− connections for on-board safety earthing.

TECHNICAL DATA

Nominal supply voltage: 220÷240V

AC

@ 50/60 Hz

Power consumption: 20 VA

Operating temperature range: -20 °C ÷+60 °C

Humidity: 95% max. @ +40 °C

Protection rating: IP00

IP40 with box (upon

request)

Internal fuse rating: 6.3 A slow-blow

for TC340P1:

3.15 A slow-blow

External fuse rating (recommended): 6.3 A fast-blow

1

for TC340P1:

3.15 A slow-blow

1

Max. total weight: 250 gr. approx.

EC type certificate: CE0051-PIN0051BU3887

NOTES

1)

The external protection fuse rating should be selected considering the max.

load consumption in the most unfavourable operation stage and conditions.

Classification codes according to EN 298:

TC340A.**.** F T C L X N

TC340A.**.** opt. V F T L L X N

TC340A.**.** opt. E F T C V X N

TC340A.**.** opt. V E F T V V X N

TC340P.**.** F M C L X N

TC340P.**.** opt. V F M L L X N

TC340P.**.** opt. E F M C V X N

TC340P.**.** opt. V E F M V V X N

Times:

Pre-purge time (TP): 0 … 60 s

Safety time (TS): 3 … 120 s

Response time in case of flame failure: < 1 s

Post-purge times

- on burner motor (EF) (t

POST

):

- on hot air blower (FAN) (t

FS

):

2

0 … 1200 s

0 … 1200 s

Delay time on FAN activation (t

FA

):

2

0 … 1200 s

Inter-waiting or inter-purge time: 1 … 240 s

Waiting time for modulation start (t

RP1

): 1 … 240 s

Lockout delay for extraneous light (opt.

Knn): 0 … 60 s

Lockout for insufficient air flow (opt.

Qnn)

3

: 3 … 120 s

Pre-ignition time (opt. Jnn): 1 … 60 s

Recycling attempts (opt. Ynn): 1 … 10

Varnishing / Box: upon request

NOTES

2)

This parameter will be described in detail in the “Heating mode (FAN

function)” section. It can be modified through BRAHMA serial interface type

810 and management software.

3)

If the air pressure switch remains in “no-air-flow” position (fan-assisted

versions) or if the burner motor revolutions per minute are insufficient in

case a brushless fan is used (premix versions).

4)

This parameter can be modified through BRAHMA serial interface type 810

and management software.

Max. contact rating (@ 240V - 50Hz):

Hot air blower (FAN): 3.5 A cos ϕ≥0.4

Burner motor (EF): 0.5 A cos ϕ≥0.4

Remote ignition device (ACC1): 0.8 A cos ϕ≥0.4

First valve stage (EV1): 0.4 A cos ϕ≥0.4

6

Second valve stage (EV2): 0.4 A cos ϕ≥0.4

6

Current modulator:

≤170 mA

DC

@ 24 V

DC 5

NOTES

5)

The limit can be increased up to 350mA upon request.

6)

The valve load power supply is available on two independent connectors

(J7 and J8). In case both connectors are used, the max. rating for each

output should be considered equal to 0.2 A cos ϕ≥0.4 approx.

Max. cable length for external components:

OpenTherm™ interfaces: 50 m

Ignition device (high voltage cables): 2 m

Any other cable (load power supply cables, user

interface connection cable, …): 1 m

Inbuilt ignition transformer (ACC2):

7

Peak voltage:

8

upon request:

15 kV

18 kV

Peak current: 800 mA

Spark repetition rate:

9

upon request:

25 Hz

1 … 50 Hz

Recommended spark gap: 2 ÷ 4 mm

Power consumption: 2.5 VA

Spark energy: 20 mJ

NOTES

7)

For appliances equipped with fan-assisted burner only.

8)

Value measured with 30 pF load.

9)

ATTENTION: the ignition device output is not safe to touch if the spark

repetition rate is higher than 25Hz; in this case the appliance will have to

be provided with further protection.

Flame monitoring

The flame detection device exploits the rectification property of the

flame.

An important safety aspect to note is that the control unit is more

flame-sensitive at start-up or during the waiting/pre-purge time

(negative differential switching).

Min. ionization current: upon request:

0.5 µA

1.2 µA

Recommended ionization current: 3 ÷ 5 times the

min. one

Min. insulation resistance of detection

cable and electrode to earth: ≥50 MΩ

Max. electrode stray capacitance: ≤1nF

Max. short-circuit current: < 200µA

AC

System adjustment temperatures:

Manual reset limit temperature (T

L

):

10

100 °C

Switch-off temperature (T

OFF

):

11

70 °C

Re-ignition temperature (T

ON

):

11

50 °C

Ventilation temperature (T

V

):

11

30 °C

Ventilation-stop temperature (T

SV

):

11

10 °C

NOTES

10)

Available in versions using BRAHMA safety probe type ST16.

11)

This parameter can be set up on customer's request and modified through

BRAHMA serial interface type 810 and management software.

14698_r00 3/18

System temperature probes

The BRAHMA system type TC340 is provided with several inputs

to control different temperature probes used for both temperature

adjustment and safety related functions. The characteristics and

functions of each probe are described in detail below.

- Heating circuit probe (SR)

The heating circuit probe has the purpose to measure the heat

exchanger temperature and is mainly used in the FAN heating

function (see description in “OPERATION” section).

This probe can be of three types:

1) with double NTC sensor (standard version): in this case the

probe has a double function, as it enables to avoid mounting a

safety limit thermostat. This probe will therefore be used for

both temperature adjustment and safety functions (e.g. safety

shutdown due to system overtemperature).

To this purpose, a BRAHMA temperature probe type ST16 is

required.

J10

BRAHMA

type

ST16

BROWN

BLACK

BLUE

Fig. 1 – Connection of a double NTC probe

2) with single NTC sensor with contact safety thermostat (opt. T)

:

in this case the probe is provided with temperature adjustment

functions only, and any system overtemperature will have to be

controlled by a contact safety limit thermostat.

To this purpose, a BRAHMA temperature probe type ST08 is

required.

J10

BRAHMA

type

ST08

Safety limit

thermostat

Fig. 2 - Connection of a single NTC probe

3) with single NTC sensor without contact safety thermostat (opt.

NT)

: in this case the probe is provided with temperature

adjustment functions only, and any system overtemperature will

have to be controlled by an external safety device.

To this purpose, a BRAHMA temperature probe type ST08 is

required.

- Room temperature probe (SA)

This (optional) probe can be used when the remote temperature

adjuster (BRAHMA chronothermostat type ENCRONO GA1) is not

directly mounted in the room requiring temperature adjustment, or

when this temperature adjustment should be related to the external

environment temperature. For further details about the functions of

this probe, please see the

"OPERATION"

section.

To this purpose, a BRAHMA temperature probe type ST07 (for

local room temperature detection) or type SSE (for outside

temperature detection) is required.

Fire damper (STF)

This input (option S) enables to check the status of the fire damper

contact: in case this contact is open (anomaly condition), the

ignition cycle is interrupted and the device goes to stand-by

position signalling the failure through a LED. The behaviour of the

device in case the fire damper contact is open can be customized

upon request.

Overall dimensions

Fig. 3 shows the overall dimensions of this type of control units. All

dimensions are expressed in millimetres.

Fig. 3 – Overall dimensions

INSTALLATION DIRECTIONS

−

Respect the applicable national and European standards

regarding electrical safety (e.g. EN 60335-1/ EN 50165),

bearing in mind that ignition and flame control systems are

safety devices: the manufacturer's responsibility and guarantee

are invalidated in case of Customer's tampering with the

product;

−

before the first start-up, make sure that the loads are well

connected to avoid any dangerous situation or failure in the

appliance. Particular attention should be paid to earth

connections: make sure that all loads (fans, gas solenoid

valves, ignition transformer, …) are connected to the appliance

safety earth, using for example the connector on board;

−

the system is designed to stay in running status for less than

24h (system for non-permanent operation). Reaching this limit

causes a regulation shutdown to enable the unit to check its

own efficiency;

−

connect and disconnect the control unit only after switching off

the power supply;

−

the unit can be mounted in any position;

−

avoid exposure to dripping water;

−

a ventilated installation environment and a suitably low

temperature ensure the longest life of the control system;

−

before installing or replacing the unit, make sure that the type,

code and times are correct;

−

the appliance in which the control systems are installed should

provide adequate protection against the risk of electric shock

(at least IP20);

−

keep signal cables and power cables as far from each other as

possible;

−

use heat resistant detection cables and electrodes, and make

sure that they are well insulated to the ground and protected

from possible moisture or water in general;

−

keep the ignition cable as short and straight as possible and

place it far from other conductors to reduce the emission of

electromagnetic interference (max. length <2m and insulation

voltage >25kV).

71

65

67,5

Ø4

145

136

145

60

80,1

40

TWO-

COLOUR

LED

RESET

P/BUTTON

4/18 14698_r00

!

!!

!

IMPORTANT NOTE

In order to further reduce irradiated interference and increase the immunity of the

control unit, it is strongly recommended to mount a wire-wound power resistor with

a value from 1kΩto 4.7kΩbetween the high voltage cables and the related

discharge electrodes.

CHECKING AT START-UP

Check the control system before the first start-up, after any

overhaul and after a long period of non-operation. Before any

ignition attempt make sure that the combustion chamber is free

from gas, then check the following:

−

if the start-up attempt occurs without gas supply, the control

system should go to lockout at the end of the safety time;

−

when stopping the gas flow while the control system is running,

the power supply to the gas valves should be interrupted within

1s, and the control system should proceed to lockout after a

recycling attempt (or more than one up to 10 depending on the

settings);

−

operating times and sequence should correspond to those

declared for the type of control unit you are using;

−

the level of the flame signal should be high enough (see Fig. 4);

−

the ignition probes should be adjusted in the most stable way

for a spark gap between 2-4 mm;

−

the intervention of limiters or safety devices should cause the

lockout or safety shutdown of the control unit according to the

type of application and the procedure provided for.

Microammeter

A

+

-

J2

I

ION

Fig. 4 – Flame signal measuring method

TC340(A-P) - OPERATION

The following description refers to the standard operating cycle of

BRAHMA control units type TC340A and TC340P. The operating

cycle can be modified both using the available options and

according to particular customer's requirements.

- First start-up

At the first start-up, the device carries out a “

self-test

” to verify that

all the conditions required at the beginning of the ignition cycle are

respected.

At the end of this stage, the system goes on checking the type of

heat demand used in the appliance (power-free contact or

OpenTherm™ connection to BRAHMA chronothermostat type

ENCRONO GA1 or to an additional TC340 unit): in this stage,

lasting about 30 seconds, the SL LED signal flashes with green

light indicating the stand-by status.

At the end of this diagnostic phase, the unit is ready to receive the

heat demand and start the ignition cycle.

- Ignition cycle

The ignition and flame control cycle starts on receipt of the heat

demand, which can occur in three ways:

-

through a BRAHMA chronothermostat type ENCRONO GA1;

-

through a power-free contact with room thermostat function;

-

through an additional BRAHMA device type TC340 in case of

cascade systems.

The control unit starts the ignition cycle by checking the air

pressure switch status (fan-assisted version) or the number of

revolutions per minute of the EF burner motor (premix version). In

case no signal is detected, the system starts the EF fume extractor

at its max. speed; as soon as the air pressure switch goes to “air-

flow” position (fan-assisted version) or the necessary number of

revolutions per minute is reached (premix version), the pre-purge

time (TP) begins.

In premix applications, a few seconds before the beginning of the

safety time (about 3 seconds, customizable upon request), the

system reaches a stage of the pre-purge time in which the EF

combustion motor speed can be decreased (TP2): this function

enables to carry out the burner soft-start, if necessary, starting the

burner at an (adjustable) lower power than the first running stage

(RP1).

At the end of the pre-purge time the device is ready to perform the

safety time (TS) and activate the following:

-

the inbuilt ignition transformer;

-

the auxiliary electronic ignition transformer;

-

the EV1 first valve stage;

-

the modulator (if available) at the power level requested for

ignition.

If a flame signal is detected, the unit will go to running position; if

no flame signal is detected, the system will proceed to lockout due

to ignition failure at the end of the safety time.

- First running stage (RP1)

At the end of the safety time and in case of flame signal detection,

the control unit goes to running position. According to a delay

customizable upon request (waiting time for modulation start t

RP1

),

the system ignores all modulating parameters giving max. power to

the appliance in order to ensure a suitable heating of the heat

exchanger; in this stage, in fan-assisted versions, the EV2 second

valve stage is kept operating and the current modulator is kept

supplied at max. power.

At the end of this time the device enters the second running stage,

where the burner combustion power depends on the modulating

parameters provided by the temperature adjustment system.

- Second running stage (RP2)

In the second running stage the control unit can perform

temperature adjustment functions depending on the type of heat

demand used in the appliance, which can be:

-

an OpenTherm™ connection (to a BRAHMA chronothermostat

type ENCRONO GA1 or to an additional TC340 unit);

-

a contact room thermostat.

The behaviour of the control unit in the two above-mentioned

cases will be shortly described hereunder.

OpenTherm™ connection available

In this case, temperature adjustment will be carried out according

to four variables:

1)

room temperature (T

A

)

: which can be measured both through a

chronothermostat or through an SA room temperature probe (if

available);

14698_r00 5/18

2)

set-point temperature (T

I

)

: this is the temperature set up on the

chronothermostat by the user, i.e. the required room

temperature;

3)

thermal differential (d)

: the modulating power, on a percentage

basis, is calculated according to the T

A

room temperature and

the T

I

set-point temperature. In case the room temperature is

lower than or equal to (T

I

- d), the percentage of modulating

power is at its highest level (100%); in case the room

temperature is higher than or equal to T

I

, the percentage of

modulating power is zero (0%: heat demand OFF), as the

required temperature has already been reached/exceeded; in

case the room temperature is comprised between (T

I

- d) and

T

I

, the percentage of modulating power is calculated by means

of a specific formula which will be described later on;

4)

thermal hysteresis (i)

: any T

A

room temperature values next to

the T

I

set-point may generate a repeated sudden switch-on /

switch-off of the heat demand. The thermal hysteresis

parameter helps avoiding such unwanted occurrences: during

the T

A

increasing stage the burner switches off as soon as the

T

I

threshold is reached, while during the T

A

decreasing phase

the heat demand is activated again if the room temperature

drops below (T

I

- i);

5)

outside temperature (t

e

)

: if the system is equipped with an

outside temperature probe, this temperature value will influence

the final power percentage as shown in Fig. 5;

6) design min. outside temperature (t

ep

):

if the system is equipped

with an outside temperature probe, the design min.

temperature, i.e. the min. outside temperature that can be

reached by the system, will influence the final power

percentage as shown in Fig. 5.

The type of temperature adjustment performed by the control unit

can be LOCAL, REMOTE or assisted by an outside temperature

probe: in the first case, an SA room temperature probe is used and

the temperature adjustment is totally managed by the control unit,

while the remote adjuster is only used to establish the set-point

temperature; in the second case, no SA room temperature probe is

connected and the temperature adjustment is totally controlled by

the chronothermostat type ENCRONO GA1; in the third case, an

outside temperature probe is used and the final power percentage

is influenced by this parameter.

The calculated/acquired modulation percentage affects the power

supplied to the EF fume extractor, to the FAN hot air blower and to

the current modulator(s) according to the min. and max. pre-set

values.

Fig. 5 shows the three types of temperature adjustment available in

the system.

Outside temp.

probe (SE)

available?

Temperature adjustment by an OUTSIDE

PROBE

The system type TC340 directly manages the

temperature adjustment by calculating the required

percentage of modulation power through the

following parameters:

- the T

I

; set-point temperature;

- the T

A

room temperature (measured by

an SA room temperature probe or a

chronothermostat type GA1);

- the T

ep

design min. temperature (for further

details refer to the data sheets of the BRAHMA

remote adjuster type ENCRONO GA1);

- the T

e

outside temperature.

Room temp.

probe

(SA) available?

LOCAL temperature adjustment

The system type TC340 directly manages the

temperature adjustment by calculating the required

percentage of modulation power through the

following parameters:

- the T

I

; set-point temperature;

- the T

A

room temperature (measured by

an SA room temperature probe);

- the d

L

local thermal differential (adjustable

through serial interface);

-

the i

L

local thermal hysteresis (adjustable

through serial interface).

REMOTE temperature adjustment

The chronothermostat directly provides the system

type TC340 with the percentage of power to use for

the temperature adjustment, by using:

- the T

I

set-point temperature;

- the T

AR

room temperature directly measured;

- the d

R

thermal differential set up through

BRAHMA ENCRONO GA1 (remote thermal

differential);

- the i

R

thermal hysteresis set up through

BRAHMA ENCRONO GA1 (remote thermal

hysteresis).

Fig. 5 – Types of temperature adjustment

In case an outside temperature probe is used, the TC340 device

calculates the percentage of modulation power through the

following formula:

T-T )T-T(F+)T-T(

*100=P epI

AICeI

%

NOTE: the FCcoefficient (corrective factor) is a parameter which varies according to the

Teoutside temperature and is directly calculated by theTC340 device.

To better understand the behaviour of the system type TC340 in

running status in case no outside temperature probe is connected,

please refer to the diagram of figure 6, assuming a set-point

temperature of 22°C, a thermal hysteresis of 0.4°C (in this way, in

case of room temperature decrease, the system re-ignition

threshold will be 21.6°C) and a thermal differential of 2.0°C (in this

way, the modulation area starting threshold will be 20°C). The

thermal hysteresis and differential can be of local or remote type

YES

NO

YES

NO

6/18 14698_r00

depending on the availability of the SA room temperature probe, as

shown in the diagram of figure 6.

-10

0

10

20

30

40

50

60

70

80

90

100

110

19,8 20 20,2 20,4 20,6 20,8 21 21,2 21,4 21,6 21,8 22 22,2

Fig. 6 – Parameter-based modulation diagram

Based on the room temperature value, three conditions can occur:

1)

T

AMB

room temperature lower than (T

I

– d)

: in this case the

percentage of modulation power will always be equal to 100%

(max. heat demand) and the second EV2 valve stage will be

activated;

2)

T

AMB

room temperature between (T

I

– d) and T

I

: in this case the

percentage of modulation power will be calculated according to

the following formula:

100*

d

T-T

=P

AMBI

%

3)

T

AMB

room temperature higher than T

I

: in this case the

modulation power will always be equal to zero (a condition

corresponding to the absence of heat demand).

The

thermal hysteresis

parameter takes effect on the modulation

only in case the room temperature exceeds the T

I

set-point value

and then decreases. In these conditions the percentage of

modulation power will remain equal to zero (no heat demand) until

the T

AMB

room temperature will reach the threshold (T

I

- i), below

which the formula on point 2 will be respected again.

Contact room thermostat

In this case, the modulation power depends on the status of the

adjustment thermostat only, i.e.:

-

TA thermostat closed (ON):

in this case the modulation power

will always be equal to 100% (max. heat demand) and the

EV2 second valve stage will be activated;

-

TA thermostat open (OFF):

in this case the modulation power

will always be equal to zero (a condition corresponding to the

absence of heat demand).

- Heating mode (FAN function)

The introduction of hot air into the environment is carried out by

means of a hot air blower (FAN). The operation of this type of load

is dependent upon different factors:

-

the operation status of the system (pre-purge time, first running

stage, …);

-

the heat exchanger (outlet) air temperature measured by

means of the SR heating circuit probe;

-

switch-on and switch-off delay times.

The FAN function begins when the system enters the first running

stage (RP1). As already described above, this phase of the cycle

enables a suitable heating of the exchanger: in fact, hot air can be

introduced into the environment only if its temperature is high

enough.

From the RP1 first running stage entering, the system guarantees

a waiting time (delay time on FAN activation) which is considered

to be necessary to enable an appropriate heating of the exchanger:

at the end of this time, hot air can be introduced into the

environment and the FAN hot air blower can therefore be

activated. If the heat exchanger temperature exceeds the T

V

(ventilation temperature) threshold during the switch-on delay time,

the activation of the FAN hot air blower will be anticipated, as the

system will have already reached suitable conditions for the

environment heating.

A similar operation is carried out during the heat exchanger cooling

phase: in case the control unit leaves the running status (due, for

example, to heat demand failure), the FAN hot air blower remains

activated at its max. speed for a time which can be set up on

request (post-purge time on FAN hot air blower); if before the end

of the cooling phase the temperature measured by the SR heating

circuit probe is lower than the T

SV

(ventilation-stop temperature)

threshold, the FAN hot air blower will be switched off and the post-

purge stage interrupted.

The device is prearranged for the (electrically parallel) connection

of two blowers.

- Summer ventilation

This function enables to use the FAN hot air blower for summer

ventilation. The FAN blower can be activated even in case the

control unit is in lockout status.

!

!!

!

IMPORTANT NOTE

The summer ventilation function can be activated only if a BRAHMA

chronothermostat type ENCRONO GA1 is used. For further details please refer to

the data sheets of this device. If this remote adjuster is not available, summer

ventilation will have to be managed externally by supplying the FAN hot air blower

as described hereunder.

J6

FAN

1 2 3 4 5 6 7 8 9

LINE

Fuse

Switch

TC340

- Manual reset limit temperature, switch-off temperature and

re-ignition temperature

The operation of the system also depends on three additional

temperature thresholds of the heat exchanger: the manual reset

limit temperature (T

L

), the burner switch-off temperature (T

OFF

) and

the re-ignition temperature (T

ON

).

The T

L

manual reset limit temperature is used in the versions

equipped with double NTC heating circuit probe (standard version)

and represents the threshold above which the control unit goes to

lockout. In the versions equipped with single NTC heating circuit

probe, this threshold corresponds to the contact safety thermostat

switch-on temperature: when the heat exchanger temperature

drops to acceptable values for a correct operation, the burner does

not restart automatically, but needs the manual reset of the control

unit by the user.

The T

OFF

burner switch-off temperature represents the threshold

above which the normal burner operation is stopped without

system lockout: in fact, the control unit will go to stand-by position,

while the FAN hot air blower will remain activated at its max. speed

to enable an appropriate cooling of the heat exchanger.

T

AMB

[°C]

P

[%]

OFF

MODULATION AREA

(T

I

– d)

(T

I

– i)

T

I

14698_r00 7/18

Once the heat exchanger has been suitably cooled (temperature

measured by the SR heating circuit probe lower than the T

ON

re-

ignition temperature), the system can start operating normally

again.

- Destratification gradient

Spacious rooms can be subject to air stratification phenomena: hot

air tends to rise above creating a considerable temperature

difference between the comfort zone and the room ceiling.

Higher temperature

Lower temperature

Comfort zone

Fig. 7 – Air stratification phenomenon

If the hot air generator is installed in a high position and an SA

local room temperature probe is used, the following directions will

have to be observed for a correct room temperature adjustment:

1) place the SA probe next to the comfort zone for a correct

room temperature detection (fig. 8a), or

2) use the

destratification gradient

(0

÷

10°C), which will be

deducted from the temperature measured where the hot

air generator is installed in order to calculate the

temperature of the comfort zone (fig. 8b).

Comfort zone

8a

Generator

Probe (SA)

Comfort zone

8b

Generator

Probe (SA)

Destratification

gradient

Fig. 8 – Solutions for a correct temperature adjustment

The destratification gradient factory setting is zero (0°C): different

parameter values can be set up on request.

!

!!

!

IMPORTANT NOTE

This parameter can be modified through BRAHMA serial interface type 810 and

management software.

- Outside temperature probe function

As already mentioned before, the outside ambient temperature can

contribute to the system temperature adjustment process: in fact,

through a remote controller it is possible to reserve the SA input of

the control unit no. "n" (in case of a cascade system) to this

function, enabling all units to adjust the modulation power

according to the outside temperature measured.

TC340(P1) - OPERATION

In this case, the device is used for the ignition, the flame control

and (if available) the modulation of premix burners equipped with

fan with PWM control.

To better understand the operation of the system, please refer to

the operating cycle diagrams in the next pages.

At the first start-up, the device is in stand-by status and the fan

control is disabled (point 1).

In case of heat demand (TC boiler thermostat closing, point 2), the

device performs the start-up cycle, carrying out the TP pre-purge

time at TP1_speed and then the TP2 second pre-purge time and

the TS safety time at start-up speed (TP2_TS_speed, point 3).

In case of flame signal failure at the end of the safety time, the

system goes to lockout; else, the system goes on (point 4) carrying

out the modulation delay time lasting for DELAY_RP_STAB at

RP_STAB_speed in order to settle the burner flame.

At the end of this phase (which can be set up to "0" if it is not

necessary), the device enters the real operation stage (point 5,

running position), setting up the fan speed to the RP_speed value,

which can be increased (point 7) or decreased (point 9)

dynamically through the IN(+) and IN(-) adjustment inputs within a

range limited by the RP_MAX_speed and RP_MIN_speed values

(as soon as these two values are reached, as shown on points 8

and 10, the adjustment inputs do not affect the PWM output signal

value).

In running status, the output modulation power can be increased to

a predetermined RP_T2_speed value by means of the T2

adjustment input (point 6): this function can be used if the burner is

provided with two flame stages or if you wish to obtain a temporary

modulation “boost”.

As soon as the heat demand stops (point 11), during operation the

system can:

−

go to stand-by position;

−

proceed to post-purge at POST_speed (in case of option P or

PT).

The following table shows the modulation parameters of the

device, which can be pre-set and modified through serial interface.

Upon request it is possible to mount a vertical module with

microcontroller technology which enables to set up three of the

above-mentioned modulation parameters through a trimmer; these

parameters can be factory-set and can be modified through serial

interface and management software.

No. Parameter Range Description

1 TP1_speed 1

÷

100 %

PWM percentage during the first pre-purge time (TP1)

2 TP2_TS_speed 1

÷

100 %

PWM percentage during the second pre-purge time (TP2) and the safety time (TS)

3 RP_STAB_speed 1

÷

100 %

PWM percentage during the flame settlement time

4 RP_STAB_delay 0

÷

255 s

Flame settlement time duration

5 RP_speed 1

÷

100 %

PWM percentage during operation (RP), further to a flame settlement delay

6 RP_MIN_speed 1

÷

100 %

Min. suppliable PWM percentage in case of decrease through the IN(-) input in running status

7 RP_MAX_speed 1

÷

100 %

Max. suppliable PWM percentage in case of increase through the IN(+) input in running status

8 VARIATION_delay 0

÷

255 s

Modulation ramp time to vary the PWM from 0% to 100% during operation

9 RP_T2_speed 1

÷

100 %

PWM percentage during operation (RP) in case of T2 closing (boost function)

10 POST_speed 1

÷

100 %

PWM percentage during the post-purge time (if available)

11 POST_delay 0

÷

255 s

Post-purge time duration

8/18 14698_r00

RESETTING THE CONTROL UNIT

Non-volatile lockout (manual reset)

If the control unit goes to non-volatile lockout, to reset the system

press the reset push-button (mounted on board or on the BRAHMA

chronothermostat type ENCRONO GA1) till the lockout signal

switches off.

Volatile lockout (electrical reset)

In case of volatile lockout, the control unit can be reset by cutting

off and then restoring the power supply. It is not possible to reset

the system by switching off the heat demand device.

OPERATING CYCLE VARIATIONS

Followings are the available operating cycle variations of the

control units:

− Option 9 (“K”, “Knn”): lockout due to extraneous light

If extraneous light is detected at start-up or during the waiting/pre-

purge time, the control unit will proceed to lockout immediately

(option “K”) or with a delay (expressed in seconds) settable upon

request (option “Knn”).

− Option 10 (“Qnn”): insufficient or no air flow at start-up

If insufficient or no air flow is detected or the pre-heater thermostat

does not switch at start-up or during the waiting/pre-purge time, the

control unit will go to lockout within 3

÷

120 seconds (the time is

settable upon request).

− Option 11 (“R”): insufficient or no air flow in running status

In case of air failure in running status, the ignition and flame control

unit proceeds to immediate lockout.

− Option 12 ( “V”): flame failure in running status

In case of flame failure in running status, the control unit proceeds

to immediate lockout.

− Option 13 (“Pnn”, “PTnn”): post-purge time on EF burner motor

The control unit carries out a post-purge action on the EF

combustion motor fan (the time is settable upon request).

With option “Pnn”, post-purge is carried out regardless of the heat

demand status; with option “PTnn”, post-purge can be interrupted

by restoring the heat demand and having a new ignition cycle start.

− Option 14 (“Ynn”): recycling attempts

The control unit performs multiple recycling attempts in case of

burner ignition failure (the number of attempts is settable upon

request).

!

!!

!

IMPORTANT NOTE

The indication “nn” corresponds to the max. allowed number of recycling attempts

and is not therefore the total number of ignition cycles carried out in case of heat

demand switching on.

For example, a system with option Y2 can carry out a max. of 2 recycling attempts,

but the total number of ignition cycles starting from the heat demand switching on is

3 (1 ignition cycle + 2 recycling attempts).

− Option 15 (“Inn”): inter-waiting or inter-purge time

A waiting or pre-purge time (expressed in seconds) is performed

after a failed ignition attempt and before the next recycling attempt.

− Option 16 (“G”, "GP"): air pressure switch checking

Option "G", available in the devices type TC340A, enables the

control unit to start the ignition cycle without checking the air

pressure switch; option "GP", available in the devices type TC340P

and TC340P1, allows the air pressure switch checking during the

pre-purge stage and at start-up only.

− Option 17 (“Jnn”): pre-ignition time

The transformer is switched on at the end of the waiting/pre-purge

time and before the beginning of the safety time, for a time settable

upon request.

− Option 29 (“QS”): QuickStart function

This function enables to carry out a short pre-purge in case the

heat demand is restored before the end of a post-purge phase (for

this reason, this function can only be requested in case the PT

function is available), in order to perform the ignition as soon as

possible by exploiting the portion of post-purge already

accomplished.

To better understand this function, please refer to figure 9,

representing an example with a control unit having a pre-purge

time and a post-purge time of 10 seconds: if the heat demand (HR)

is restored, for example, 6 seconds after the beginning of the post-

purge, the device will carry out a pre-purge equal to 10 - 6 = 4

seconds, i.e. the difference between the nominal pre-purge time

and the performed post-purge time.

Fig. 9 – QuickStart function

SIGNALLING DURING OPERATION

The system can signal its operation status or the presence of any

anomalies by a two-colour LED. The following figure represents the

main standard displays of the unit, which can be modified upon

request.

Stand-by

Pre-purge

Ignition

Waiting time before running status (RP1)

Running status (RP2)

STF contact opening

General lockout

Lockout due to overtemperature

Extraneous light / SR probe failure

Fig. 10 – Main LED displays

In case the control unit is not installed in frontal position next to the

hot air generator panel, both the light signals and the reset signals

can be remoted by using, for example, a BRAHMA interface

module type 865. Otherwise, if requested, the SL2 outputs of the

J4 connector (see

"Wiring diagrams"

section) can be used to

manage any external auxiliary devices (e.g. a BRAHMA device

type 343).

COMMUNICATION INTERFACE

The BRAHMA system type TC340 can communicate with a

personal computer through RS-232 communication protocol. The

communication interface enables to:

-

check the operation status of the unit and carry out some

diagnostic functions to locate any anomalies or errors in the

system;

-

programme the “open" parameters of the unit (e.g. the motor

speed in different modulation stages, the switch-on delay time

and the post-purge time of the FAN blower, the T

ON

and T

OFF

intervention thresholds, …).

The serial interface of the system can be used by means of the

BRAHMA interface device type 810 and dedicated management

software.

14698_r00 9/18

PART REFERENCES

Type

TC340

(1)

.

(2)(3)

.

(4)

.

(5) option (6) (7) (8) (9) (10) (11) (12) (13) (14) (15) (16) (17) (18) (19) (20) (21) (22) (23) (24) (25) (26)

Type description

Type of application

A: device for fan-assisted hot air generators

P: device for premix hot air generators

(1)

P1: device for premix burners with or without modulation

(2)

Customer's identification letter(s)

(3)

Progressive number identifying the type of board for a specific customer

(4)

Revision number of the microcontroller software with safety functions

(5)

Revision number of the microcontroller software with temperature adjustment functions

Options description

Ignition mode

No letter: the ignition spark operates for the whole TSP (TS-1) time. Standard mode

A: the ignition spark operates for the whole TS time

(6)

B: the ignition spark switches off as soon as a flame signal is detected

Ignition voltage of the inbuilt ignition transformer

No letter: 15 kV for TC340A; not available for TC340 (P-P1). Standard mode

(7)

H: 18 kV

Spark repetition rate of the inbuilt ignition transformer

No number: 25 Hz. Standard mode

(8)

nn: see “Inbuilt ignition transformer” section in “

TECHNICAL DATA”

paragraph

Lockout due to extraneous light

No letter: not available (the unit remains in permanent waiting/pre-purge status). Standard mode

K: immediate lockout

(9)

Knn: lockout with delay settable upon request (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Insufficient or no air flow at start-up

No letter: the unit remains in stand-by status. Standard mode

(10)

Qnn: lockout with delay settable upon request (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Insufficient or no air flow during ignition or in running status

No letter: recycling without lockout. Standard mode

(11)

R: immediate lockout (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Flame failure in running status

No letter: recycling. Standard mode

(12)

V: immediate lockout

Post-purge of the burner motor (EF)

No letter: no post-purge. Standard mode

Pnn: the post-purge is settable upon request and cannot be interrupted in case of heat demand restoration (see

“OPERATING CYCLE VARIATIONS”

paragraph)

(13)

PTnn: the post-purge is settable upon request and can be interrupted in case of heat demand restoration (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Recycling attempts after an ignition failure

No letter: single ignition cycle after a safety shutdown. Standard mode

(14)

Ynn: multiple recycling attempts upon request (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Inter-waiting or inter-purge time

No letter: no inter-waiting or inter-purge time. Standard mode

(15)

Inn: inter-waiting or inter-purge time settable upon request (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Air pressure switch checking

- For TC340A versions:

No letter: air pressure switch checking available. Standard mode

G: no air pressure switch checking (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Note:

option “G” is available for the control units designed for special applications where checking the air flow is not required by the reference

standard.

- For TC340 (P – P1) versions:

No letter: no air pressure switch checking. Standard mode

(16)

GP:

air pressure switch checking at start-up and during pre-purge

Pre-ignition

No letter: no pre-ignition. Standard mode

(17)

Jnn: pre-ignition settable upon request (see

“OPERATING CYCLE VARIATIONS”

paragraph)

Safety thermostat

No letter: function carried out by BRAHMA double NTC safety probe type ST16. Standard mode

T: device with contact safety thermostat control

(18)

NT: device without safety thermostat control

10/18 14698_r00

Options description

Type of lockout

No letter: non-volatile lockout. Standard mode

(19)

E: volatile lockout

Fire damper input (STF)

No letter: input not used. Standard mode

S1: input used for air damper control

S2: input used for the management of 0

÷

10 V analogue signals (PLC applications)

(20)

Sxx: for future applications

Flame signal detection mode

No letter: double-electrode configuration (separate ignition electrode and flame detection electrode). Standard mode

(21)

M: single-electrode configuration (one electrode with both ignition and flame signal detection functions)

EV1 gas valve

No letter: gas valve with 220-240V power supply. Standard mode

C1: use of BRAHMA gas valve type VCM01* S [0/P] [0/P] 24VDC (valve with pressure sensor)

(22)

C2: use of BRAHMA gas valve type VCM01* [0/P] [0/P] 24VDC (valve without pressure sensor)

EV2 gas valve (in case of standard EV1 only)

No letter: not available. Standard mode

D: with flame signal on

X: at the end of the safety time

(23)

Wnn: during operation, after “nn” seconds from the end of the safety time

FAN hot air blower switch-on delay (

t

FA

, for TC340A and TC340P versions only

)

(24)

RAnn: hot air blower switched on after “nn” seconds from the end of the safety time

FAN hot air blower switch-off delay (

t

FS

, for TC340A and TC340P versions only

)

(25)

RSnn: hot air blower switched off after “nn” seconds from burner stop

Waiting time for modulation start (

t

RP1

for TC340A and TC340P; RP_STAB_delay for TC340P1

)

(26)

RPnn: delay of “nn” seconds from the end of the safety time before modulation start

SR heating circuit probe:

No letter: available (BRAHMA type ST08 or ST16 depending on option 18). Standard mode

(27)

NS: system not provided with heating circuit probe

Current modulator (with reference to TC340P and TC340P1 versions only. In TC340A version this is always available):

No letter: not available. Standard mode

(28)

MD: available

QuickStart function (in combination with “PT” function)

No letter: not available. Standard mode

(29)

QS:

QuickStart

function available (see

“OPERATING CYCLE VARIATIONS”

paragraph)

14698_r00 11/18

WIRING DIAGRAMS

The following wiring diagrams refer to the most complete device versions.

WIRING DIAGRAM FOR BRAHMA DEVICES type TC340

A

.**.**.**

J12

J11

J10

JP1

J9

J8

J7 J6

J3

J5

J4

J2

STF

GA1

EX

APS

SA

SR

MOD

EV2

EV1

EF

FAN

ACC1

PS

N

L

PE

ACC2

SL

RESET

ION

J1

J13 J14

MARRONE

NERO

BLU

2

4

3

2

1

4

3

2

1

5

4

3

2

1

5

6

1

2

3

4

5

6

7

1

2

3

4

5

6

1

1 2 3 4

1 2 3 4

1 2 3 4 5 6 7 8 9

F1

F2

2

1

2

1

PE

FAN2

PE

Key to symbols

GA1 Chronothermostat type ENCRONO GA1 SR Heating circuit probe

EF Burner motor SA Room temperature probe (optional)

FAN Hot air blower APS Air pressure switch

FAN2 Second hot air blower STF Fire damper

ACC1 Remote auxiliary ignition transformer SL LED signalling

ACC2 Inbuilt ignition transformer RESET Reset push-button

EV1 First valve stage JP1 LPG/GAS selection jumper

EV2 Second valve stage EX Connection for cascade appliances

MOD Gas valve current modulator ION Ionization electrode

12/18 14698_r00

WIRING DIAGRAM FOR BRAHMA DEVICES type TC340

P

.**.**.**

J12

J11

J10

J8

J7 J6

J3

J5

J4

J2

STF

GA1

EX

SA

SR

EV1

FAN

ACC1

PS

N

L

PE

SL

RESET

ION

J1

J13 J14

EF

+24V

RPM

PWM

GND

MARRONE

NERO

BLU

4

3

2

1

4

3

2

1

5

4

3

2

1

5

6

1

2

3

4

5

6

7

1

2

3

4

5

6

1 2 3 4

1 2 3 4

1 2 3 4 5 6 7 8 9

F1

F2

2

1

2

1

PE

FAN2

PE

Key to symbols

GA1 Chronothermostat type ENCRONO GA1 STF Fire damper

EF Burner motor SA Room temperature probe (optional)

FAN Hot air blower SL LED signalling

ACC1 Remote auxiliary ignition transformer RESET Reset push-button

EV1 First valve stage EX Connection for cascade appliances

SR Heating circuit probe ION Ionization electrode

14698_r00 13/18

WIRING DIAGRAM FOR BRAHMA DEVICES type TC340

A

.**.**.** opt.

C1 / C2

J12

J11

J10

J19

J8

J7 J6

J3

J5

J4

J2

STF

GA1

EX

APS

SA

SR

EV1

EF

FAN

ACC1

PS

N

L

PE

ACC2

SL

RESET

ION

J1

J13 J14

V

out

+5V

GND

SP (Nota 1)

+

-

MARRONE

NERO

BLU

4

3

2

1

4

3

2

1

5

4

3

2

1

5

6

1

2

3

4

5

6

7

1

2

3

4

5

6

1 2 3 4

1 2 3 4

1 2 3 4 5 6 7 8 9

F2

F1

2

1

2

1

2

3

1

FAN2

PE

PE

Key to symbols

GA1 Chronothermostat type ENCRONO GA1 SA Room temperature probe (optional)

EF Burner motor APS Air pressure switch

FAN Hot air blower STF Fire damper

ACC1 Remote auxiliary ignition transformer SL LED signalling

ACC2 Inbuilt ignition transformer RESET Reset push-button

EV1 BRAHMA valve type VCM01* # (0/P) (0/P) 24VDC EX Connection for cascade appliances

SP VCM01 valve pressure sensor ION Ionization electrode

SR Heating circuit probe

NOTES

1. Connector and wiring not available in C2 version.

14/18 14698_r00

WIRING DIAGRAM FOR BRAHMA DEVICES type TC340

P1

.**.**.** opt. G NT NS

J12

J11

J7 J6 J5

J4

J2

EV1

N L

SL

RESET

ION

J1

J14

+24V

RPM

PWM

GND

4

3

2

1

5

4

3

2

1

5

6

1

2

3

4

5

6

7

1 2 3 4 1 2 3 4 5 6 7 8 9

F1

F2

2

1

2

1

N1

FUSE

EF

ACC1

ACC2

JP2

T2 TC

P1 P2 P3

+ -

J3

M (Nota 2)

PE

PE

J13

IN(+)

IN(

-

)

Key to symbols

TC Heat demand room thermostat N1 Three-point adjuster

T2 Adjustment thermostat / BOOST function SL LED signalling

EF Burner motor RESET Reset push-button

ACC1 Remote auxiliary ignition transformer EX Connection for cascade appliances

ACC2 Inbuilt ignition transformer ION Ionization electrode

EV1 First valve stage

NOTES

2. Vertical module for setting up 3 of the 11 modulation parameters (available upon request).

14698_r00 15/18

WIRING DIAGRAM FOR THE CASCADE CONNECTION OF SEVERAL DEVICES THROUGH OpenTherm™

Nota 1

N

L

PE

J12

J12

J12

MASTER

SLAVE 1

SLAVE 2

SLAVE “n”

~ ~

~ ~

NOTES

1. The cascade connection is possible also by a contact chronothermostat. This configuration is not used in TC340P1 versions.

16/18 14698_r00

TYPES OF CONNECTION

All connections available in the system are listed below.

Reference Description Type of connector

J1 Functional earth (flame monitoring) Female fast-on 6.3 mm

J2 Flame detection electrode Female fast-on 4.8 mm

ACC2 Ignition electrode Female fast-on 2.8 mm

J3 Load safety earth connection Female fast-on 6.3 mm (7 pins)

J4 Earth connection input 2-pin screw terminal board for cables Ø 2.5 mm

2

J5 Power supply input 2-pin screw terminal board for cables Ø 2.5 mm

2

J6 Power supply for FAN hot air blower, EF burner

motor, auxiliary electronic ignition transformer and

modulation increase/decrease inputs

9-pin connector type MOLEX® 3001 series

(terminals type MOLEX® 2478 series)

J7 – J8

(note 1)

Power supply for EV1 first valve stage and EV2

second valve stage 4-pin connector type MOLEX® 3001 series

(terminals type MOLEX® 2478 series)

J9 Modulator (MOD) power supply connector 2-pin connector type LUMBERG® 3114 series

(terminals type LUMBERG® 3111 01 L series)

J10 Heating circuit probe (SR) and room temperature

probe (SA) 6-pin connector type LUMBERG® 3114 series

(terminals type LUMBERG® 3111 01 L series)

J11 Air pressure switch (APS) or PWM control brushless

fan low-voltage signals 7-pin connector type LUMBERG® 3114 series

(terminals type LUMBERG® 3111 01 L series)

J12 Opentherm® communication and fire damper input 6-pin screw terminal board for cables Ø 2.5 mm

2

J13 Serial communication type RS-232 for diagnostic

software interfacing 4-pin connector type LUMBERG® 3517 04 K series

J14 LED status signals and reset signal remoting

connector 5-pin connector type LUMBERG® 3517 05 K series

J19 Pressure sensor 3-pin connector type LUMBERG® 3114 series

(terminals type LUMBERG® 3111 01 L series)

NOTES

1. The J8 connector is mounted in parallel to the J7 connector, i.e. from the same position it is possible to take the same output signal.

This connector is useful for appliances equipped with double-coil gas valves.

14698_r00 17/18

OPERATING CYCLE DIAGRAMS

TC340(A-P) – Standard operating cycle using BRAHMA chronothermostat type ENCRONO GA1

TC340(A-P) – Standard operating cycle using a contact room thermostat

NOTES

− the EV2 second valve stage, if available, depending on option no. 23 may be activated in a different moment in comparison to what appears in the

diagrams (in these specific cases, option X);

− the modulation circuit may not be available depending on the type of device and on option no. 28;

− at the end of the heat demand, a post-purge on the EF burner motor may be performed depending on option no. 13.

18/18 14698_r00

OPERATING CYCLE DIAGRAMS

TC340P1 – Standard operating cycle

ATTENTION: Company BRAHMA S.p.A. takes no responsibility for any damage resulting from Customer's tampering with the device.

NOTES ABOUT PRODUCT DISPOSAL

The device contains electronic components and cannot therefore be disposed of as normal household waste. For the disposal

procedure, please refer to the local rules in force for special waste.

BRAHMA S.p.A.

Via del Pontiere, 31

37045 Legnago (VR) - ITALY

Tel. +39 0442 635211 - Fax +39 0442 25683

http://www.brahma.it

E-mail: brah[email protected]

19/11/10 Subject to amendments without notice

Table of contents

Other BRAHMA Security Sensor manuals

Popular Security Sensor manuals by other brands

DAKOTA ULTRASONICS

DAKOTA ULTRASONICS DFX-7 Operation manual

Heico

Heico STE RADIATION PAGER-S user manual

Essence Smartcare

Essence Smartcare Care@Home MDsense Getting started

HIK VISION

HIK VISION DS-K5032-3XFD quick start guide

Homematic IP

Homematic IP HmIP-SMI55-A Mounting instruction and operating manual

AMC

AMC MOUSE GS Installation

KPS

KPS DETELUX 180IP 110V instruction manual

UE Systems

UE Systems ULTRAPROBE 2000 instruction manual

Field Controls

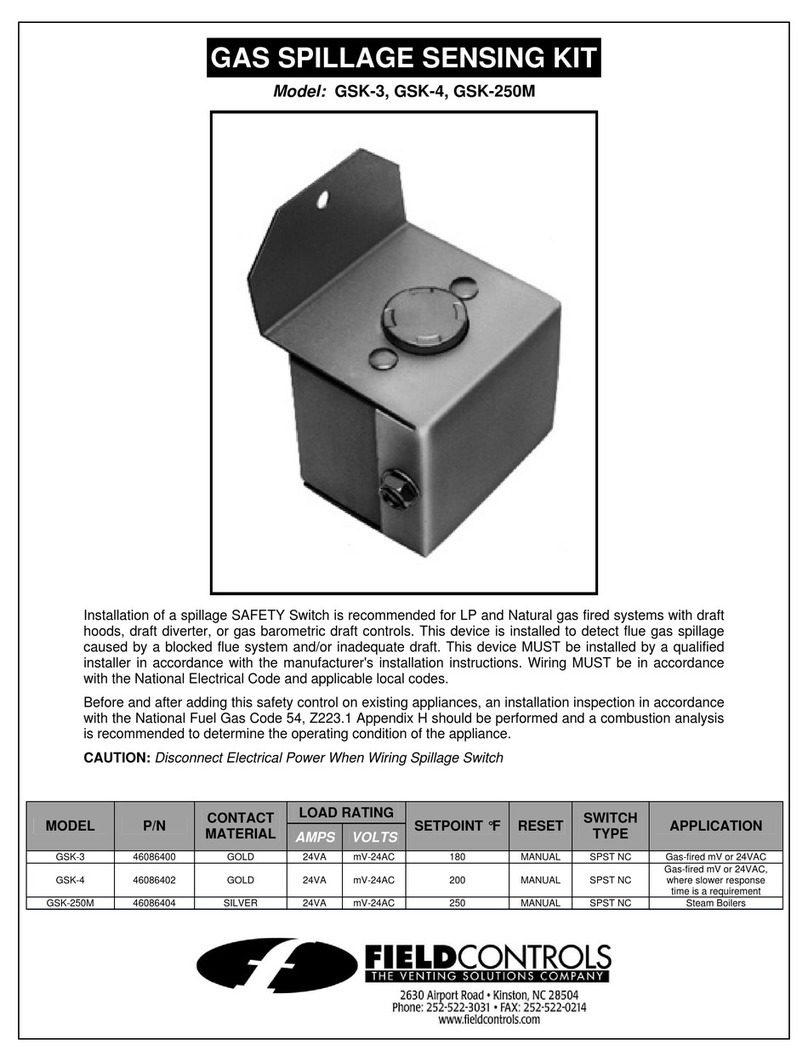

Field Controls Gas Spillage Sensing Kit GSK-250M instruction manual

Watts

Watts AMES Deringer 40G Installation, operation and maintenance manual

Tecnar

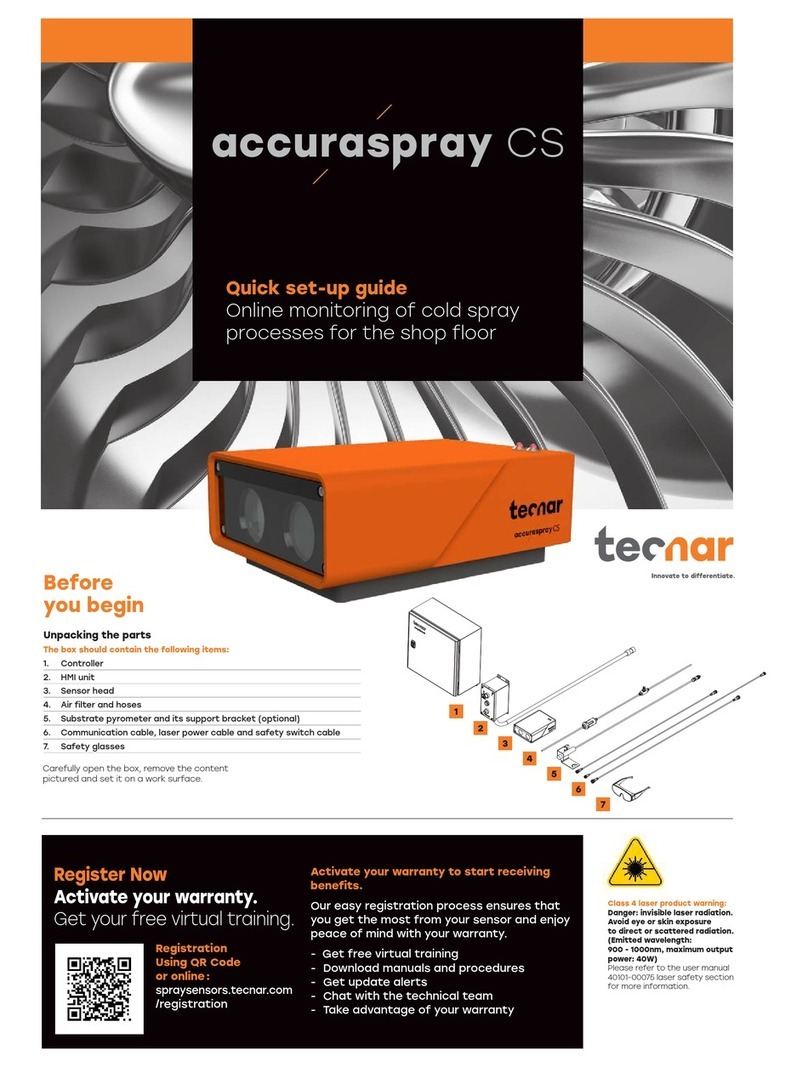

Tecnar accuraspray CS Quick setup guide

Toshiba

Toshiba RBC-AIP1 installation manual