Field Controls Gas Spillage Sensing Kit GSK-250M User manual

GAS SPILLAGE SENSING KIT

Model: GSK-3, GSK-4, GSK-250M

Installation of a spillage SAFETY Switch is recommended for LP and Natural gas fired systems with draft

hoods, draft diverter, or gas barometric draft controls. This device is installed to detect flue gas spillage

caused by a blocked flue system and/or inadequate draft. This device MUST be installed by a qualified

installer in accordance with the manufacturer's installation instructions. Wiring MUST be in accordance

with the National Electrical Code and applicable local codes.

Before and after adding this safety control on existing appliances, an installation inspection in accordance

with the National Fuel Gas Code 54, Z223.1 Appendix H should be performed and a combustion analysis

is recommended to determine the operating condition of the appliance.

CAUTION: Disconnect Electrical Power When Wiring Spillage Switch

LOAD RATING

MODEL P/N CONTACT

MATERIAL AMPS VOLTS SETPOINT °F RESET SWITCH

TYPE APPLICATION

GSK-3 46086400 GOLD 24VA mV-24AC 180 MANUAL SPST NC Gas-fired mV or 24VAC

GSK-4 46086402 GOLD 24VA mV-24AC 200 MANUAL SPST NC Gas-fired mV or 24VAC,

where slower response

time is a requirement

GSK-250M 46086404 SILVER 24VA mV-24AC 250 MANUAL SPST NC Steam Boilers

Page 2

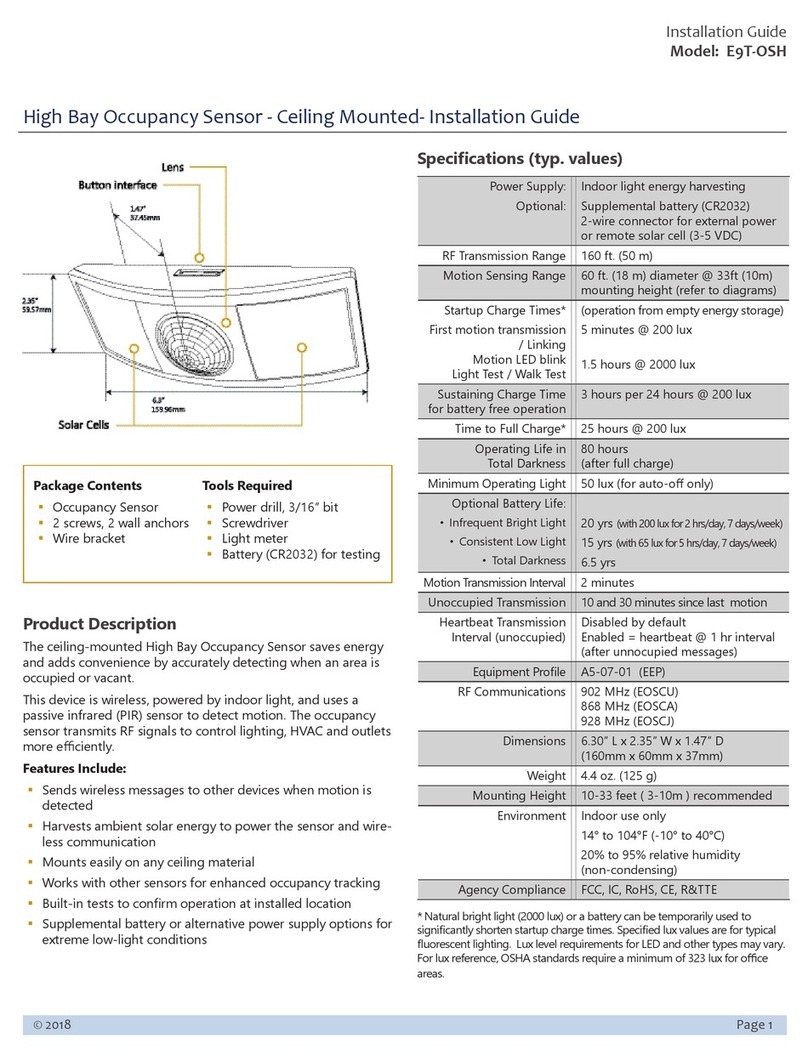

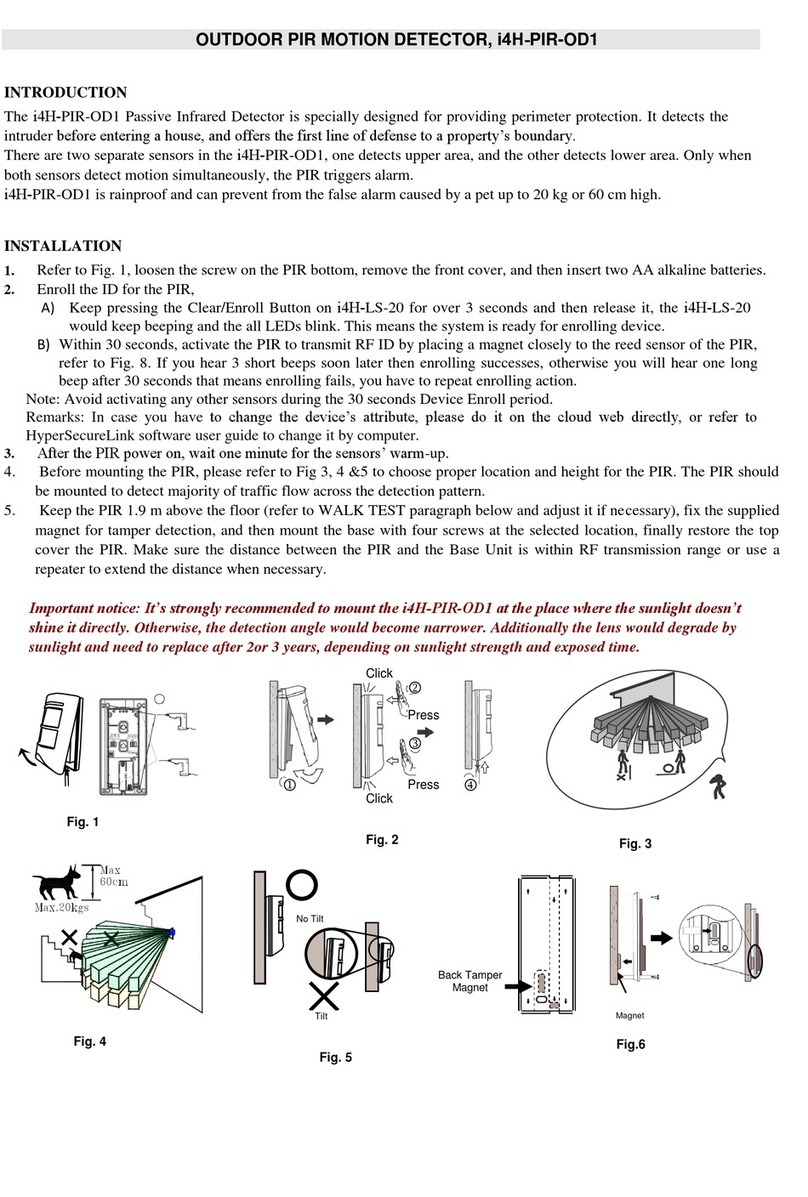

INSTALLATION ON DRAFT HOODS

IN-LINE HORIZONTAL DRAFT HOOD (See Figures 1 & 2)

1. Two (2) switches are recommended on these hoods. Mount the

switches approximately 2 1/2 inches from the opposite ends and

sides of the draft hood opening. (See Figure 1)

2. The switch should not contact the metal. They should be mounted at

least 3/4 inch below the hood opening. (See Figure 2) Mount with

supplied sheet metal screw.

BUILT-IN DRAFT HOOD (See Figures 3 & 4)

1. Two (2) switches are recommended on appliances without a factory

supplied spill switch. Mount the switches approximately 3 inches

from the side of the draft hood opening and the second switch (if

used) 3 inches from the opposite side of the draft hood. (See Figure

3) If the appliance has a factory built-in switch, mount a single switch

3 inches from the side opposite the factory switch.

2. The switch should not contact the metal. They should be mounted at

least 1 inch below the hood opening. (See Figure 4) Mount with

supplied sheet metal screw.

VERTICAL DRAFT HOOD

(See Figures 5 & 6 or Figure 13 for water heaters)

1. Two (2) switches are recommended on appliances without a

factory supplied spill switch. Mount the spill switch onto the

bottom edge of the draft hood and the second switch (if used)

approximately 90 degrees from the first switch or 90 degrees

from the factory supplied switch. (See Figure 5)

2. The switch should not contact the metal. They should be

mounted at least 3/4 inch below the hood opening. (See

Figure 6) Mount with supplied sheet metal screw.

Figure 1

Figure 2

Figure 3

Figure 5 Figure 6

Figure 4

Page 3

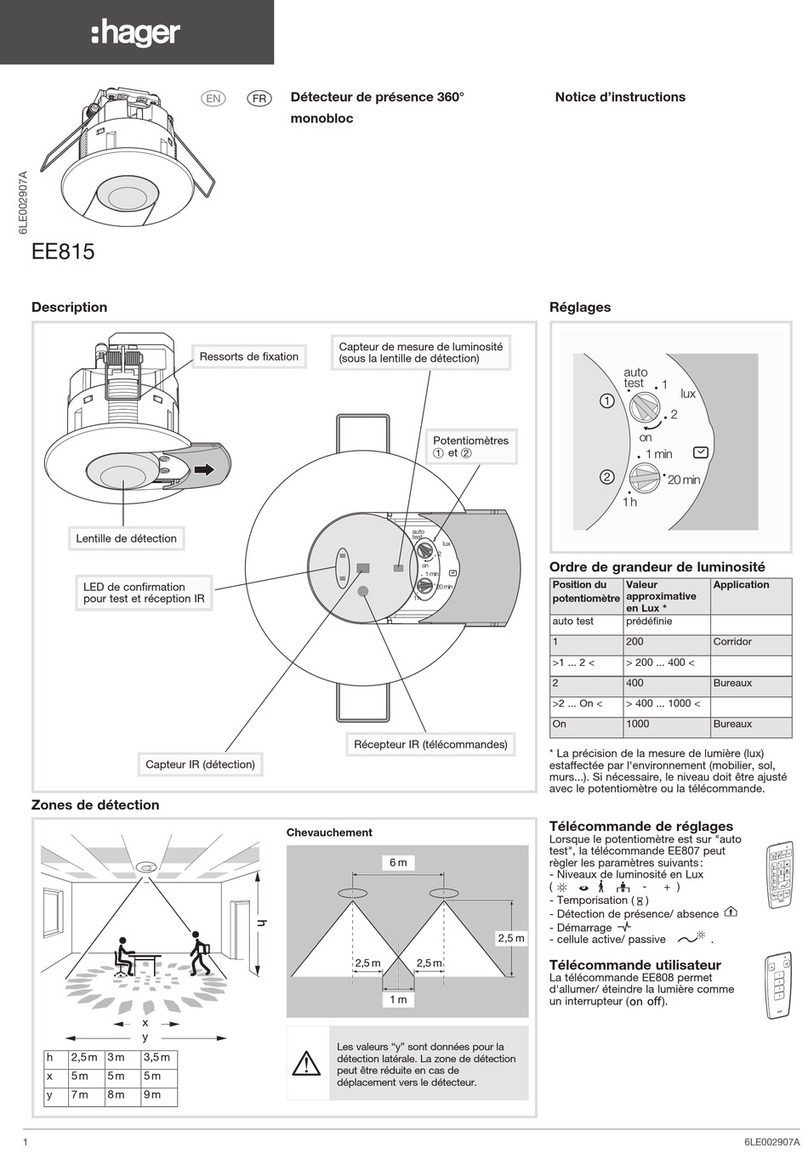

DRAFT CONTROLS (See Figures 7 & 8)

NOTE: GSK style switches are designed for draft control models 4" MG1 through 9"

MG1. Larger size draft controls require the FTS Series switches.

1. Locate the spill switch along the bottom edge of the draft control ring. (See Figure 7)

Mark and drill a 5/32" dia. hole through the ring.

2. Mount the switch with the supplied #5-40 machine screw and nut. Note, the head of

the screw is to be on the inside of the ring. (See Figure 8)

3. Swing the gate to make sure the gate does not hit the screw head or the switch.

NOTE: Mounting the spill switch on the top of the draft control ring will function properly,

but will react slower during a blocked flue condition. If GSK switch(es) are supplied in a

draft control kit, install the switches as directed in the kits instructions.

WIRING

CAUTION: When wiring the spillage switch into

the burner circuit route the wiring and secure

away from any hot surface. Shut off all

electrical power and gas supply to the

appliance before working with any electrical

connections.

24 VOLT APPLICATIONS

1. Disconnect the hot lead between the

thermostat or temperature control and the

TH terminal on the gas valve or the TH,TH-

W or 24V terminal on the ignition module.

Check the thermostat anticipator (if

applicable) circuit for proper setting.

CAUTION: Never wire to the 24V GND

terminal.

2. Wire the spill switch or switches into series

with this circuit by wiring from the

thermostat or temperature control to the

spill switch or switches then to the gas

valve or ignition module. (See Figure 9 &

10)

Fi

g

ure 8

Figure 9

Figure 10

Fi

g

ure 7

Page 4

750 MILLIVOLT PILOT GENERATOR APPLICATIONS

1. Disconnect the hot lead between the thermostat and the TH

terminal on the gas valve. On older bleed tube style

equipment split one lead of the E.C.O. (energy cut off)

circuit.

2. Wire the spill switch or switches into series with this circuit

by wiring from the thermostat to the spill switch or switches

then to the TH terminal on the gas valve. On older bleed

tube style equipment wire switches in series with one wire

of the E.C.O circuit. (See Figure 11)

30 MILLIVOLT WATER HEATER:

Two (2) switches are recommended for this application. The

application requires a TCA-1 Thermal Couple Junction block

(P/N 46082700 NOT INCLUDED) and a 6 foot length of 12 ga.

two (2) wire conductor (NOT INCLUDED) to wire between the

spill switches and the TCA-1.

CAUTION: Shut off gas supply before working on appliance.

1. Remove thermocouple from gas control valve. (See Figure

12)

2. Thread the junction block into the thermocouple port and thread

the thermocouple into the bottom of the junction block.

3. Mount the two (2) spill switches onto the draft hood so the

switches do not contact any metal. (See Figure 13)

4. Connect the one terminal of each switch with 12 ga wire and then

connect it to the thermocouple junction block. Next,connect the two

remaining terminals together using a short length of 12 ga wire.

(See Figure 14)

5. Route and secure the wires to the water heater enclosure with acceptable hold down

tabs, keeping the wires away from any hot surface area.

SYSTEM CHECK-OUT PROCEDURE FOR GAS SPILLAGE SWITCH CONTROL

1. Shut off gas supply to appliance(s).

2. Block the flue pipe above the draft control, draft hood or draft diverter.

3. Re-establish gas supply to appliance and re-light pilot (if required).

4. Adjust thermostat to call for heat.

5. Flue gases should be emitting from draft control, draft diverter or draft

hood. Note the location of the most flue gas spillage. Allow

approximately 2 minutes for the system to back up and the gas burner

to shut down. Wait 2 to 3 minutes, reset switches, and re-light pilot. If

the spillage switch does not trip within the 2 minute period, relocate the

switch onto the area where the observed highest spillage occurred.

Then perform this test again.

CAUTION: If for any reason the system has shut down during normal

operation, the cause of the system failure should be investigated and

corrected before resetting the safety switch and relighting the pilot.

P/N 46086300 Rev D 10/08

Figure 12

Figure 13

Figure 14

Figure 11

This manual suits for next models

8