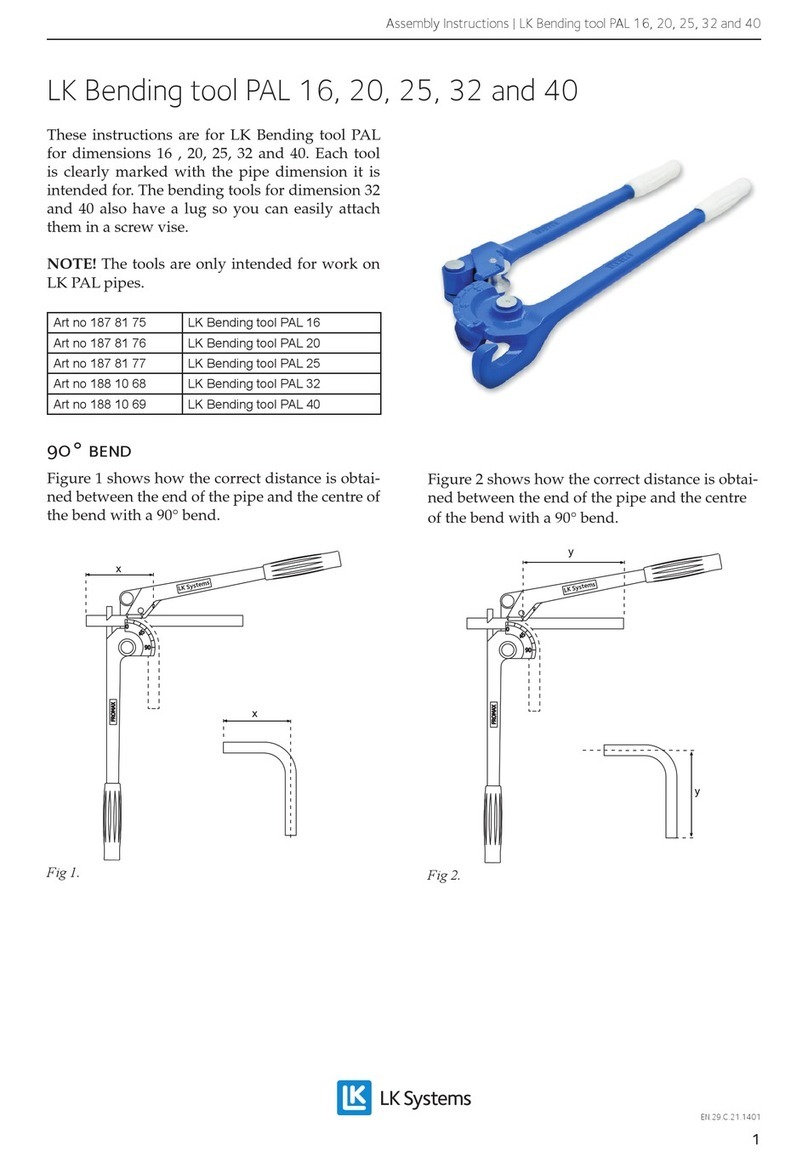

Bramley Models 42 (AB2) & 62 (AB1) Angle Bending Machines

M12 X 50

CAPSCREW

(P42C1)

CLAMP PAD P4207

VICE PLATE

(P4223)

LIMIT STOP

BOLT (P4220)

LIMIT STOP

WASHER (P4222)

HANDLE (P4214)

BASE (P4201)

VICE GUIDE

SPRING (P4216)

VICE SCREW(P4205)

KNOB (P4208)

KNOB (P4208)

M8X60 BOLT & NUT

(P42C4)

SWIVEL HEIGHT

ADJUSTER (P4218)

SWIVEL (P4202)

HINGE PIN (P4203)

BENDING PLATE

PIN (P4210)

BENDING PLATE

SCREW (P4211)

BENDING PLATE (P4209)

VICE SCREW

HANDLE (P4206)

SPLIT PIN

(P42C3)

WASHER (P42C2)

VICE GUIDE LONG (P4217)

VICE GUIDE SHORT (P4217)

BENDING PLATE

SCREW HANDLE (P4212)

BRAMLEY No.2 ANGLE BENDER (MODEL 042 / AB2)

Due to the variations between metric and imperial

bar specifications the Eccentric Block type clamp

may require shimming behind the Clamp Pad

(P6207) to achieve sufficient clamping force for

some sizes of material.

With the material to be bent secured in the Vice,

adjust the Bending Plate (P6209 / P4209) so that

it just comes in contact with the material.

By backing the Bending Plate (P6209 / P4209)

slightly off the material to be bent a larger bend

radius may be achieved.

Then by pulling on the Bending Handle (P6208 /

P4214), pull around until the desired bend angle

is achieved.

The bend angle can be limited by sliding the Limit

Stop (P6214 / P4222) around the angle quadrant

slot and tightening in the desired position. This is

useful for multiple bends of the same angle.

By loosening both the Clamp Vise and the Bending

Plate, the bent piece of material can then be

removed from the machine.

It is not recommended, or necessary, to use heat

during the bending process as this destroys the

grease lubricant in the swivel casting in which

case seizure may result and affect warranty on

the machine.

When bending softer materials such as aluminium

or copper for electrical bus-bars, it may be

preferable to remove the Clamp Pad (P4207 /

P6207) from the bender and, with a belt grinder or

similar, turn the sharp bending corner into a small

radius to avoid cracking of the material.

Figure 2