Pro-Lift G2000SA User manual

Other Pro-Lift Jack manuals

Pro-Lift

Pro-Lift B-033D Instructions for use

Pro-Lift

Pro-Lift F2000 User manual

Pro-Lift

Pro-Lift F-2332 Instructions for use

Pro-Lift

Pro-Lift B-1850 User manual

Pro-Lift

Pro-Lift F1500A User manual

Pro-Lift

Pro-Lift B-002NC Instructions for use

Pro-Lift

Pro-Lift B-002D Instructions for use

Pro-Lift

Pro-Lift F1800 User manual

Pro-Lift

Pro-Lift Garage in a Box Instructions for use

Pro-Lift

Pro-Lift F1650 User manual

Pro-Lift

Pro-Lift PRO-A1200 User manual

Pro-Lift

Pro-Lift PL3200 Instructions for use

Pro-Lift

Pro-Lift G2000 User manual

Pro-Lift

Pro-Lift G-4630 Instructions for use

Pro-Lift

Pro-Lift T-6902D Instructions for use

Pro-Lift

Pro-Lift F-2525 Instructions for use

Pro-Lift

Pro-Lift G-4630JSC Instructions for use

Pro-Lift

Pro-Lift F1800A User manual

Pro-Lift

Pro-Lift PL1002 User manual

Pro-Lift

Pro-Lift F1500A User manual

Popular Jack manuals by other brands

K Tool International

K Tool International XD KTI63228 owner's manual

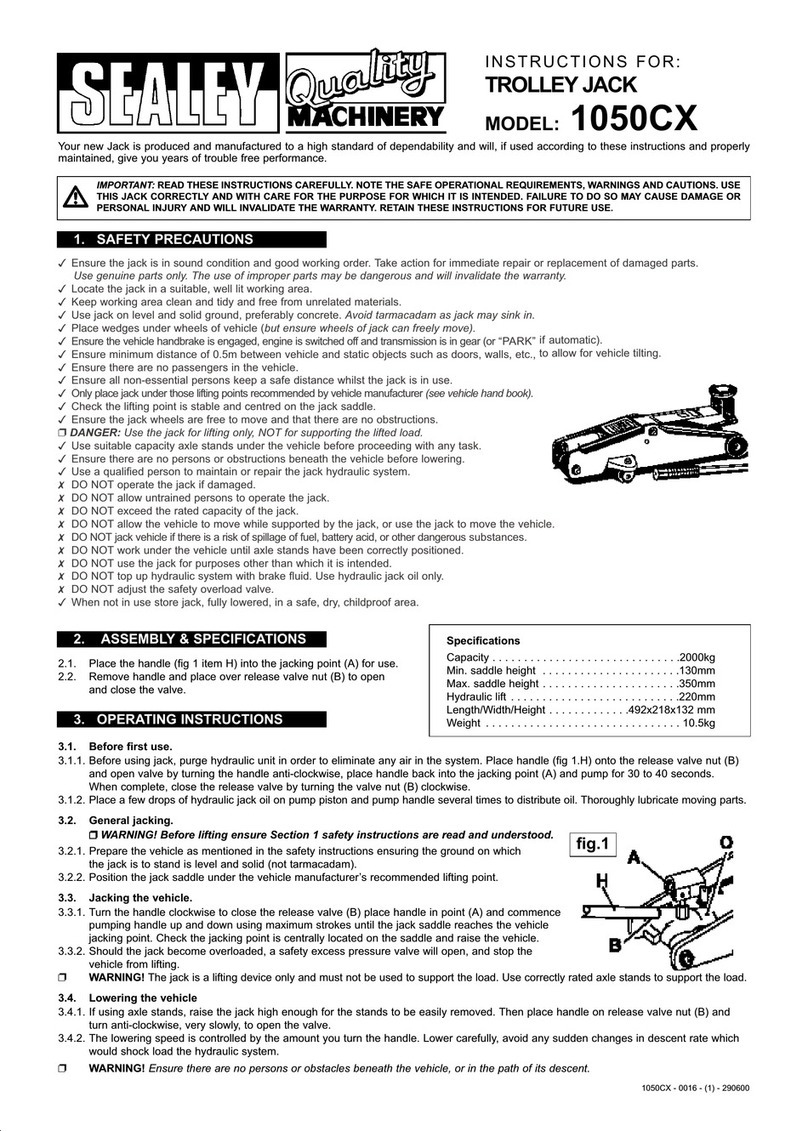

Sealey

Sealey YAJ15-30F.V2 instructions

Sealey

Sealey 1050CX instructions

K Tool International

K Tool International KTI-HD61222 owner's manual

Lippert

Lippert BaseCamp Series installation manual

ADENDORFF

ADENDORFF GJACKT-003 Operator's manual

Neilsen

Neilsen CT2421 Original manual

Urrea

Urrea 2463 User manual and warranty

AW Tools

AW Tools AW-20016 Operating and safety instructions

Pittsburgh

Pittsburgh 62590 Owner's manual & safety instructions

Valex

Valex 1650520 Translation of the original instructions

Grupo Urrea

Grupo Urrea Surtek 137087 User manual and warranty

Sealey

Sealey 3000ES instructions

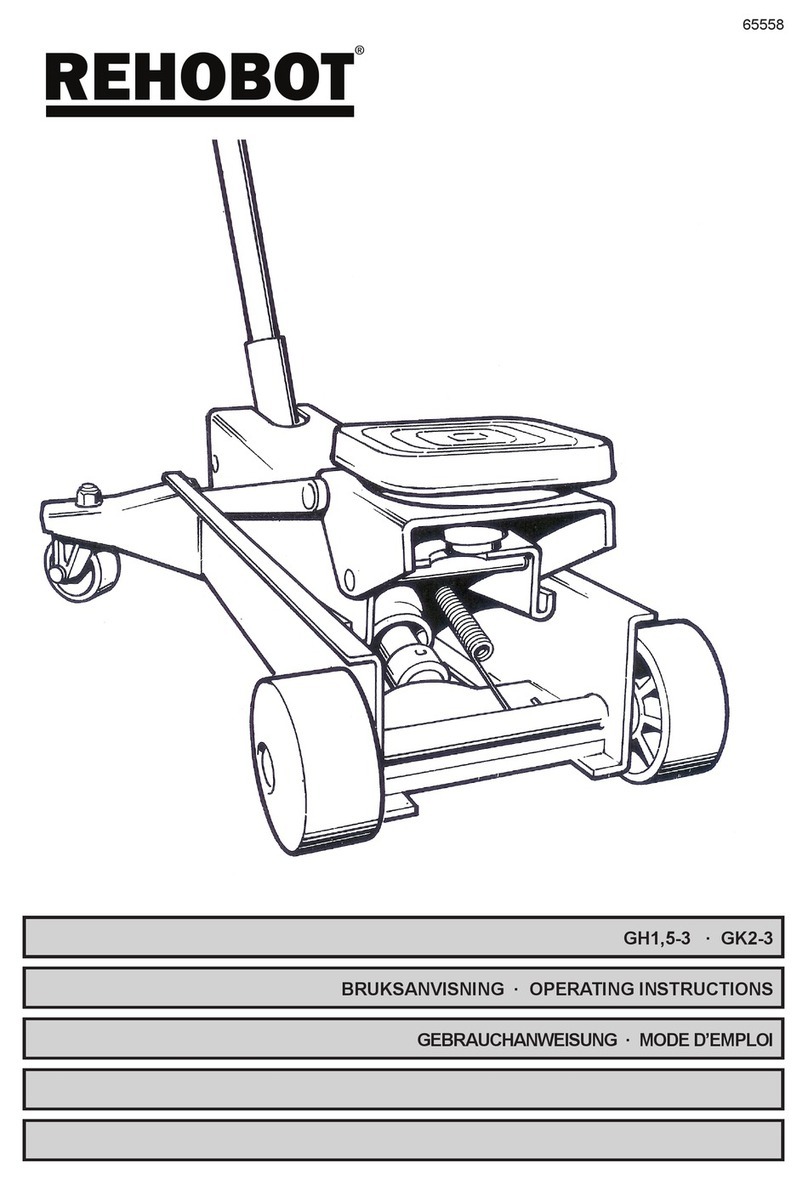

REHOBOT

REHOBOT GH1,5-3 operating instructions

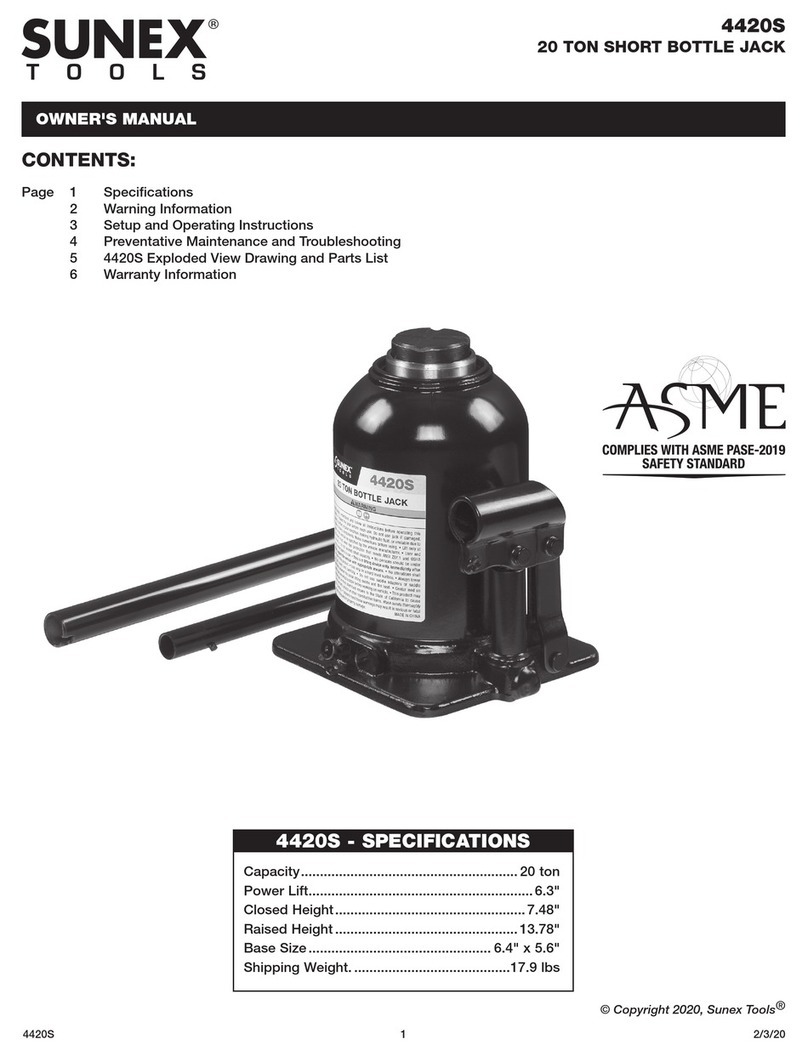

Sunex Tools

Sunex Tools 4420S owner's manual

John Bean

John Bean EELS904A Installation, operation & maintenance manual

Napa

Napa 791-5222 manual

Lippert Components

Lippert Components JT's Strong Arm 191023 Installation and owner's manual