Brano Z 100 Installation guide

BRANO a.s, 747 41 Hradec nad Moravicí

the Czech Repub ic

tel.:+420/ 553 632 316, 553 632 303

fax:+420/ 553 632 407, 553 632 151

http://www.brano.eu [email protected]

INSTRUCTION MANUAL

SAFETY PRINCIPLES, OPERATION, MAINTENANCE

F R

CHAIN BLOCKS

type Z 100

- ifting capacity 0,25t 0,5t, 1,6t, 7,5t , 10t ,15t and 20t

type Z 100-1 - ifting capacity 1t a 3,2t

type Z 100-2 - ifting capacity 5t

Read carefully this manual before using the chain block. It contains important safety,

operation, installation and maintenance instructions. Make this manual available to all

responsible persons.

Keep for futher use !

Edition 4.

MARCH 2011

Evidence number 1-52108-0-1

2

CONTENT

1 DEFINITION ..........................................................................................................................................3

2 DEVICE PURPOSE................................................................................................................................3

3 SAFETY PRINCIPLES ..........................................................................................................................4

3.1 SAFETY SUMMARY.....................................................................................................................4

3.2. SAFETY PRINCIPLES ..................................................................................................................4

3.2.1 Prior to us ....................................................................................................................................4

3.2.2 Wh n in us ...................................................................................................................................4

3.2.4 Risk analysis .................................................................................................................................5

3.2.5 Maint nanc ..................................................................................................................................5

4 PACKING, STORAGE AND MANIPULATION..................................................................................6

4.1 PACKING........................................................................................................................................6

4.2 STORAGE .......................................................................................................................................6

4.3 MANIPULATION...........................................................................................................................6

5

MAIN TECHNICAL PARAMETERS ...................................................................................................7

5.1 MECHANICAL CLASSIFICATION..............................................................................................9

5.2 MATERIAL AND DESIGN..........................................................................................................11

5.3 DATA ON PRODUCT ..................................................................................................................10

6 INSTALLATION OF THE CHAIN BLOCK.......................................................................................11

6.1 CHECKING BEFORE THE INSTALLATION............................................................................11

6.1.1 Load carrying structur ...............................................................................................................11

6.2 SUSPENDING OF THE CHAIN BLOCK....................................................................................11

6.2.1 Lubrication of chain....................................................................................................................11

6.2.2 Ch cking th chain position........................................................................................................11

6.2.3 SETTING OF THE HAND CHAIN...........................................................................................12

6.3 CHECKING PRIOR TO USE .......................................................................................................12

7 OPERATION ........................................................................................................................................12

7.1 USE OF THE CHAIN BLOCK.....................................................................................................12

7.2 LIFTING, LOWERING.................................................................................................................13

7.2 SAFETY WORKING ENVIRONMENT......................................................................................14

8 INSPECTION OF THE CHAIN BLOCK.............................................................................................14

8.1 INSPECTION ................................................................................................................................14

8.1.1 Insp ction classification..............................................................................................................14

8.1.2 Daily insp ction ..........................................................................................................................14

8.1.3 R gular insp ction.......................................................................................................................15

8.1.4 Chain block occasionally us d....................................................................................................15

8.1.5 Insp ction r cord.........................................................................................................................15

8.2 INSPECTION PROCEDURE........................................................................................................15

9 FAULTS FINDING ..............................................................................................................................19

10 LUBRICATION..................................................................................................................................19

10.1 GENERALLY..............................................................................................................................19

10.2 GEARINGS .................................................................................................................................19

10.3 LOAD CHAIN.............................................................................................................................19

11 MAINTENANCE................................................................................................................................20

11.1 SAFETY PRINCIPLES ...............................................................................................................20

11.2 REPLACEMENT OF THE LOAD CHAIN................................................................................20

11.2.1 SINGLE FALL CHAIN............................................................................................................20

11.2.2 MULTI FALL CHAIN .............................................................................................................21

11. 3 BRAKE ADJUSTMENT............................................................................................................21

11.4 GENERAL INSTRUCTIONS .....................................................................................................21

11.5 CHECK........................................................................................................................................22

11.6 REPAIR .......................................................................................................................................22

11.7 TEST............................................................................................................................................22

12 REMOVING FROM OPERATION – LIQUIDATION .....................................................................22

13 RELATED DOCUMENTATION.......................................................................................................22

14 FINAL REQUIREMENTS OF THE MANUFACTURER TO THE CUSTOMER...........................23

3

1 DEFINITION

! DANGER

Danger: is used to indicate the presence of hazard, which will cause

death or severe injury, if the warning is ignored.

! WARNING

Warning: is used to indicate a possible hazard, which could cause

death or severe injury, if the warning is ignored.

! CAUTION

Caution: is used to indicate a possible hazard, which could

cause light injury, if the warning is ignored. Caution can warn

against dangerous practices as well.

Lifting capacity (Q): indicates the maximum permitted mass of a load (working load

limit), which a chain block is designed to support in general service under conditions

defined in this manual.

2 DEVICE PURPOSE

2.1 The chain block

type Z 100, lifting capacity 0,5t, 1,6t, 7, 5t,10t, 15t and 20t

type Z 100-1, lifting capacity 1t and 3,2t

type Z 100-2, lifting capacity 5t

has been designed solely for hand vertical lifting and lowering of free loads in the

workplace. The load mass must not exceed the specified nominal lifting capacity.

2.2 The chain block has been designed to meet requirements provided by Directive

2006/42/EC of the European Parliament and of the Council as amended by the Czech

technical regulation – ministerial order No. 176/2008 of the Coll. of Laws as amended

as well as requirements of the ČSN EN IS 12100-1, ČSN EN IS 12100-2, ČSN EN

IS 14121-1 and ČSN EN 13157 harmonized technical standards.

2.3 The chain block has been designed to meet requirements for the group I of

devices (mine) category M2 according to the Directive 94/9/EC of the European

Parliament and of the Council as amended by the Czech technical regulation –

ministerial order No. 23/2003 of the Coll. of Laws as amended as well as

requirements of the ČSN EN 13463-1 harmonized Czech technical standard and

fulfils the conditions for use in the „dangerous atmospheric conditions 2“ environment

according to the ČSN EN 1127-2 standard with the limitation according to the national

regulation – CBM (Czech Bureau of Mine) regulation No.22/89 of Coll. of Laws § 232

section (1) c) up to 1,5% of mine gas accumulation.

2.4. The chain block has been designed to meet requirements specified for the group

II of devices (non-mine) category 2 and 3 according to the Directive 94/9/EC of the

European Parliament and of the Council as amended by the Czech technical

regulation – ministerial order No. 23/2003 of the Coll. of Laws as amended as well as

requirements of the ČSN EN 13463-1 harmonized Czech technical standard and

fulfils the conditions for use in the „zone 1 and zone 21“, „zone 2 and zone 22“

environments according to the ČSN EN 1127-1 standard.

Note: 2.3 and 2.4 articles apply for the chain block designed for use in environment

with explosion hazard.

4

3 SAFETY PRINCIPLES

3.1 SAFETY SUMMARY

Danger exists when loads are lifted, particularly when the chain block is not used

properly or is poorly maintained. Because an accident or serious injury could result,

special safety precautions apply to the operation with the chain block during its

assembly, maintenance and inspection.

! WARNING

NEVER use chain block for lifting and transporting people.

NEVER lift or transport loads over or near people.

NEVER lift more than lifting capacity shown on the chain block nameplate.

ALWAYS make sure the load carrying structure will provide adequate support to

handle fully loaded chain block and all the lifting operation.

ALWAYS let people around to know when a lift is about to begin.

ALWAYS read the operation and safety instructions.

Remember proper

rigging and lifting techniques are the responsibility of the operator.

Check all applicable national directions, regulations and standards for further

information about the safety use of your chain block.

3.2. SAFETY PRINCIPLES

! WARNING

3.2.1 Prior to use

ALWAYS ensure physically fit, qualified and instructed persons over 18 years of

age, familiarized with this manual and trained in safety conditions and way of

work, operate the chain block.

ALWAYS check the chain block daily before use according to the section 8.2.(1)

„Daily inspection“.

ALWAYS make sure the length of chain is long enough for the intended job.

ALWAYS check the brake function before use.

ALWAYS use original chain only.

ALWAYS ensure the load chain is not corroded, is cleaned and oiled.

ALWAYS make sure the last link of load chain is strongly fastened to the body.

NEVER use damaged or worn out chain block.

NEVER use chain block with jumped out, damaged or missing hook’s safety latch.

NEVER use a chain block without a visible marking of the lifting capacity.

NEVER use modified or deformed hooks.

NEVER connect or lengthen the load chain.

NEVER use a chain block marked by the label „OUT OF SERVICE“.

ALWAYS consult the manufacturer or his authorized representative, if you plan to

use a chain block in non-standard or extreme environments.

3.2.2 When in use

ALWAYS make sure the load is properly seated in the hook.

5

ALWAYS make sure the safety latches of hooks work in the correct way.

ALWAYS pay attention to the limit positions.

ALWAYS use manual power only.

ALWAYS when lifting loads approaching the nominal lifting capacity we

recommend, regarding the operating forces, the operation was ensured

by two persons.

NEVER use a chain block for tensioning, pulling or anchoring loads.

NEVER allow swinging the load, causing impacts or vibrations.

NEVER use a chain as a sling.

NEVER hitch a load on the tip of the hook.

NEVER pull the chain over any edge.

NEVER weld, cut or make any operation on a suspended load.

NEVER use a chain as a welding electrode.

NEVER operate a chain block, if chain is jumping or atypical or

excessive noise occurs.

3.2.3 After use

NEVER leave a load suspended.

ALWAYS ensure the chain block against incompetent use.

3.2.4 Risk ana ysis

The analysis of possible risks in light of design, operation and environment of the

chain block application is presented in freestanding document „Risk analysis“. This

document can be required in service centers.

3.2.5 Maintenance

ALWAYS enable qualified personnel inspect the chain block regularly.

ALWAYS ensure the chain was clean and oiled.

ALWAYS ensure the sliding parts were greased enough.

NEVER add other parts for lengthening the load chain.

nly such interventions can be done when maintaining that are in compliance with

requirements of the manufacturer specified in the chapters 11 and 14 of this manual.

IT IS NOT PERMISSIBLE to carry out repairs and maintenance in other way than

prescribed by the manufacturer. It concerns namely the forbiddance of using of

unoriginal spare parts or carrying out modifications on the product without an approval

of the manufacturer.

6

4 PACKING, STORAGE AND MANIPULATION

4.1 PACKING

Chain blocks by the lifting capacity 5t are supplied assembled and packed in carton

boxes. Chain blocks of lifting capacity 7,5t,10t, 15t and 20t are supplied free loaded on

pallets packed in foil.

4.1.2 The following accompanying documentation is a part of the delivery:

a) Instruction Manual

b) EC Declaration of Conformity

c) Certificates of Quality and Completeness and Guarantee Card.

c1) Guarantee period is stated in the Guarantee Card.

c2) The guarantee does not apply to defects caused by infringement of the

instructions stated in this Instruction Manual and defects occurred owing

to improper use and unskilled intervention.

c3) The guarantee does not apply also to modifications on the product or

using of unoriginal spare parts without an approval of the manufacturer.

c4) Claim of product defects is carried out according to applicable provisions

of commercial code eventually as amended.

d) List of service centers (for the Czech and Slovak Republics only).

4.2 STORAGE

Store chain blocks in dry and clean stocks free from chemical influences and vapours.

(1) Always store chain blocks without any suspended load.

(2) Remove all dust, water and impurity from the chain block.

(3) Lubricate chain, pivot of roller, pivots of hook and springs of hooks safety latches.

(4) Suspend the chain block in a dry place.

(5) During the further use follow instructions of the section 8.1.2 „Daily inspection” or

8.1.4 „Chain block occasionally used“.

4.3 MANIPULATION

During transportation and manipulation follow the applicable technical regulations and

standards for work with heavy loads.

7

5 MAIN TECHNICAL PARAMETERS

Lifting capacity 0,25 – 10 t

TABLE 5.

A

Type

Lifting

capacity

(t)

Number of

chain falls

Chain

ČSN

EN 818-7

(

strength

class 8)

perating

force

(N)

Lifting

1)

speed

(m/min)

Working

temperatu

re range

Basic

2)

lift

(m)

Weight

(kg)

Z100 0,25 1

∅3,1x9,3

270 2 4,4

Z100 0,5 1

∅5x15

300 1,1 8,5

Z100-1 1 1

∅7x21

350 0,7 14,1

Z100 1,6 1

∅9x27

320 0,36 24

Z100-1 3,2 1

∅11x31

400 0,29 37,4

Z100-2 5 2

∅11x31

400 0,15 52,3

Z100 7,5 2

∅11x31

480 0,15 70

Z100 10 3

∅11x31

400 0,1

-20°C

to

+50°C

3

85

Not s:

1) Calculat d on pr sumption of winding off 30m of th hand chain p r minut .

2) Maximum standard lift is 15m. R quir d lift is n c ssary to b sp cifi d in th ord r.

Lifts xc ding 15 m must b consult d with th manufactur r.

TABLE 5.

B

-

DIMENSIONS

Main dimensions – informative (mm) Lifting

capacity

(t) a D L

min

e

min

d

0,25 120 80 255 18,5 30

0,5 165 115 250 18,5 30

1 180 136 330 23,5 36

1,6 220 198 410 29,5 43

3,2 254 220 510 35,5 50

5 254 220 655 39,5 56

7,5 254 220 875 43 56

10 254 220 1000 47 63

8

Lifting capacity 15 and 20 t

TABLE 5.c - Technica parameters

Type

Lifting

capacity

(t)

Number of

chain falls

Chain ČSN

EN 818-7

(strength

class 8)

perating

force on one

chain block

(N)

Lifting

1)

speed

(m/min)

Working

temperat

ure

range

Lift

2)

max.

(m)

Weight

without

chain

(kg)

Increase of

weight for

1m of lift

(kg)

15 4 480 0,15 12 280 13

Z100

20 6

∅11x31

400 0,1

-20°C

to

+50°C

8 350 19,2

Not s:

1) Calculat d on pr sumption of winding off 30m of th hand chain p r minut on ach chain

block.

2) Lift bas d on th ord r. Lifts xc ding tabl valu s must b consult d with th manufactur r.

TABLE 5.

D

- DIMENSIONS

Main dimensions – informative (mm) Lifting

capacity

(t) a b L

min

e

min

D

15 510 980 910 53 71

20 510 1100 950 60 80

Chain blocks of lifting capacity 15 and 20t are standardly equipped with chain

stackers.

5.1 MECHANICAL

CLASSIFICATION

Safety and life of the chain block is guaranteed under presumption it works in

accordance with the specified classification.

Chain block is design for class 1Bm according to the regulation FEM 9.511 – see

table 5.1. (corresponds to classification of the mechanism M3 according to the IS

4301/1).

Average daily working time is set by the load spectrum.

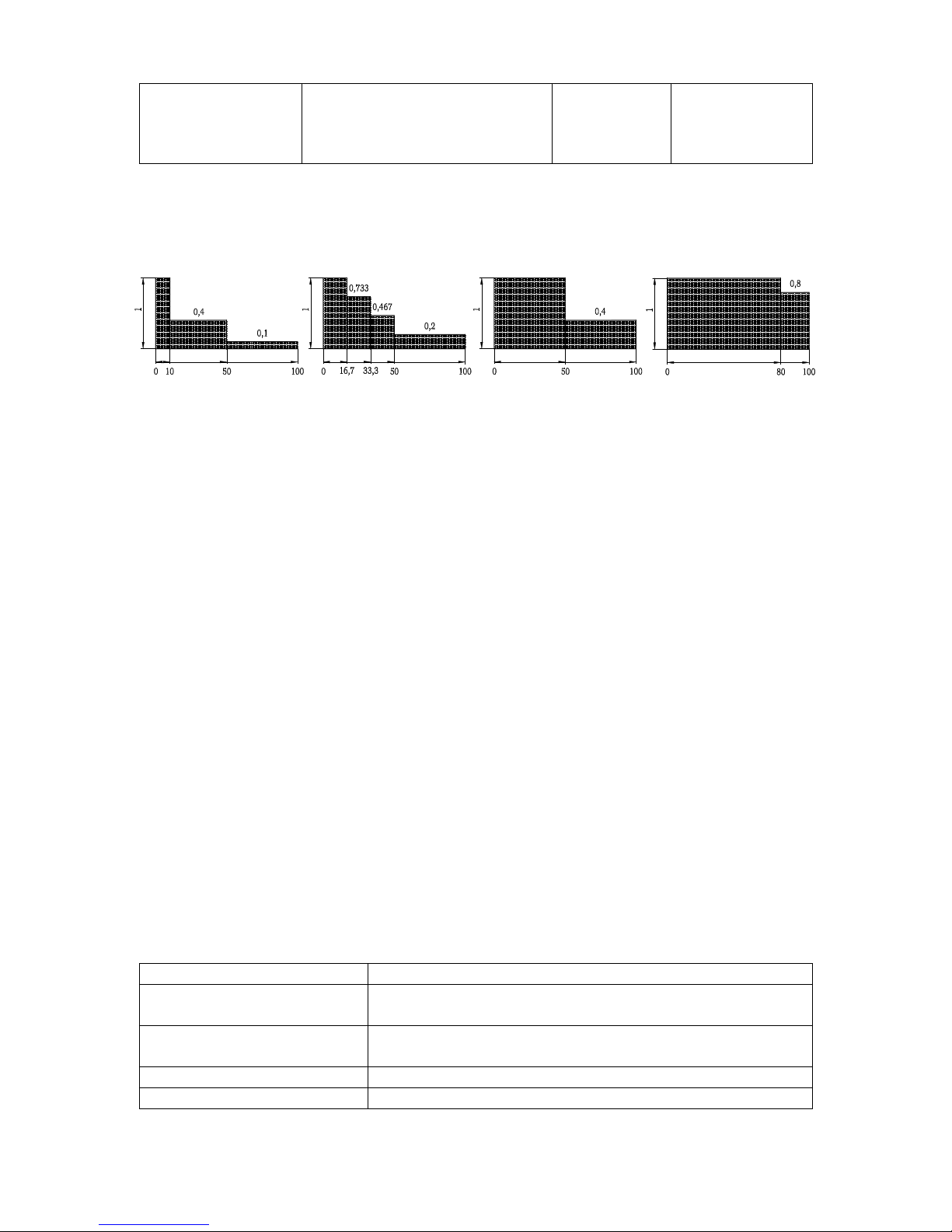

Tab e 5.1 MECHANICAL CLASSIFICATION

Load spectrum

(Load distribution)

Definition Cubic mean

value

Average daily

operating time

(h)

1

(light)

Chain blocks usually subj ct to

small load and in xc ptional

cas s only to maximum load.

k≤0,50

1 - 2

2

(m dium)

Chain blocks usually subj ct to

small load but rath r oft n to

maximum load.

0,50< k ≤ 0,63

0,5 - 1

3

(h avy)

Chain blocks usually subj ct to

m dium load but r p at dly to

maximum load.

0,63< k ≤ 0,80

0,25 – 0,5

b

L

D

e

min.

min.

a

10

4

(v ry h avy)

Chain blocks usually subj ct to

maximum or almost maximum

load.

0,80< k ≤ 1,00

0,12 – 0,25

Load spectrum Load spectrum Load spectrum Load spectrum

1 2 3 4

% operating time

5.2. MATERIAL AND DESIGN

5.2.1 Main parts of the chain block are manufactured from structural steel and cast

iron, braking inserts of brake from brass or ceramic-metallic material.

5.2.2. Materials inclinable to creation of an incendiary spark in terms of the annex No.

2 article 1.3.1 to the ministerial order No. 23/2003 of the Coll. of Laws and the

ČSN EN 1127-2 article 6.4.4 ČSN EN 1127-1 article 6.4.4 and ČSN EN 13 463-

1 article 8.1 harmonized technical standards are not used.

5.2.3 Materials with dangerous effects of static electricity within the meaning of the

ČSN EN 1127-2 article 6.4.7, ČSN EN 1127-1 article 6.4.7, ČSN EN 13463-1

article 7.4.3 and ČSN 33 2030 are not used in the chain block.

5.2.4 The chain block does not exceed the noise values specified in the annex 1

article 1.7.4.2 letter u of the M No. 176/2008 of the Coll. of Laws (EP and RE

directive No. 2006/42/EC)

Note: Articles 5.2.2 and 5.2.3 apply for chain block design to environment with

explosion risk.

5.3 DATA ON PRODUCT

Every product is fitted with label with specified data as follows:

Standard design: Design to environment with exp osion risk:

Manufacturer’s identification

Manufacturer’s identification

Address of the

manufacturer

Address of the manufacturer

Type of product Type of product

Lifting capacity Lifting capacity

11

Serial number Serial number

Year of production Year of production

CE marking CE marking

symbol of protection type(I M2 for group I , II 2G for

group II)

6 INSTALLATION OF THE CHAIN BLOCK

Prior to installation check the chain block for possible damages.

6.1 CHECKING BEFORE THE INSTALLATION

6.1.1 Load carrying structure

! WARNING

ALWAYS make sure the load carrying structure is firm enough to support the

weight of load and chain block. The installation must not be provided onto the

structure, where the carrying capacity cannot be checked.

ALWAYS the user is responsib e for the oad carrying structure!

6.2 SUSPENDING OF THE CHAIN BLOCK

! CAUTION

Be careful during suspending the chain block on the pendant element and ensure

appropriate conditions for safety installation according to the environment character

(working platform, auxiliary lifting device, etc), to avoid endanger or injury of people.

Use safety equipment when suspending the chain block in heights.

User is responsib e for creating the working conditions for insta ation and

providing the insta ation of the chain b ock.

6.2.1 Lubrication of chain

Put the thin layer of oil on the chain, preferably by means of spray. Regular

lubrication will avoid wear and corrosion of chain and lengthen its life.

6.2.2 Checking the chain position

Check, whether the hook is not kinked or twisted as on the picture 1 and 2. If the

chain is twisted, put it to its correct position. Never suspend a load on the twisted

chain. Chain is not twisted, when the welded parts of all the links are in one row. It is

applicable for lifting capacity 5t and higher. Pay increased attention to checking of the

chain position at lifting capacity 15 and 20t.

THE CHAIN MUST

BE STRAIGHTEN S

AS THE LUGS

AFTER WELDING

WERE N NE SIDE

NLY

Obr. 1 Twisting of a chain

BY TURNING FF THE

PULLEY THE

TWISTING F THE

CHAIN APPEAR.

BY ITS TAKING BACK,

THE CHAIN GET

STRAIGHTEN AGAIN.

Obr. 2 Kinking of a chain

12

Lift

6.2.3 SETTING OF THE HAND CHAIN

After the installation of the chain block in the workplace we

check the position of the hand chain. The distance of the

end of bottom loop of the hand chain over the level of the

surface, on which operation staff of the chain block stands

during the operation, must be in the range 500 –1000mm.

Chain blocks are supplied with a hand chain, the length of

which is proportional to the lift of the chain block and during

the installation meets condition of correct setting of the chain

end.

In other cases, where regarding a way of use of the chain

block, the length of the hand chain does not meet prescribed

conditions, the chain must be shortened or lengthened.

Shortening of the chain: we disconnect the chain in place of

the coupling link by buckling free ends of the links. We

shorten the chain by required length and connect again by

coupling link. Free ends of the coupling link we bend to one

another.

Lenghtening: we disconnect the chain in place of the

coupling link by buckling free ends of the links. We attach

other part of chain of required ength by means of two

coupling links. Free ends of coupling links we bend to one

another.

Coupling links and hand chain of required length can be

bought as spare parts.

Note: the request for operating chain of other length than

standard one can be made just in the order.

6.3 CHECKING PRIOR TO USE

! CAUTION

(1) First look again through the previous articles of this manual and make sure all

steps were correctly done and all parts are safely assembled.

(2) check, whether hooks are correctly suspended and safety latches snapped in.

(3) Check visually load carrying structure or pendant elements, whether they are

without defects.

(4) By several motions of the hand chain check the function of the chain block without

a load.

(5) Provide several lifting and lowering with a suitable load (10% to 50% lifting

capacity). At the same time check the brake, whether it helds the load without

slipping during its lowering and stopping.

7 OPERATION

7.1 USE OF THE CHAIN BLOCK

The chain block is multipurpose device intended for lifting and lowering of loads

under normal condition in workplace and in environments with the explosion hazard

13

as well, if a protection type symbol is marked on the label – see articles 2.3, 2.4 and

5.3 of this manual. It is operated by means of the hand chain. It is designated for

organizations and private persons.

Since dealing with heavy loads may involve unexpected danger, all “Safety

instructions” according to the chapter 3 must be kept.

! WARNING

The last link of the load chain is anchored to the body of the chain block. The

anchoring just prevent sliding off the load chain and is not determined for holding the

load.

Do not continue in operation with if the tensioning of the anchored end of the load

chain occurs. Damage of the chain anchoring can cause fall of the load..

7.2 LIFTING, LOWERING

Lifting and lowering is provided by pulling on the hand chain of the chain block. Lifting

or lowering can be interrupted at any height of the lift.

! WARNING

At chain block with a great lift (15 and more meters) a dangerous heating up of the

brake can take place when lowering loads in exceptional cases (uninterrupted and

quick lowering). In such cases it is necessary to lower loads slowly and intermittently.

! CAUTION

When lifting loads being in a lifted state hanged over to other lifting device

(crane, forklift truck etc.) it is necessary to relieve the load chain (chains) of the chain

block only by means of the hand chain of the chain block not by lifting loads by

means of the other lifting device. nly the mentioned procedure guaranties a

trouble-free releasing brake of the chain block after removal of the load.

! WARNING

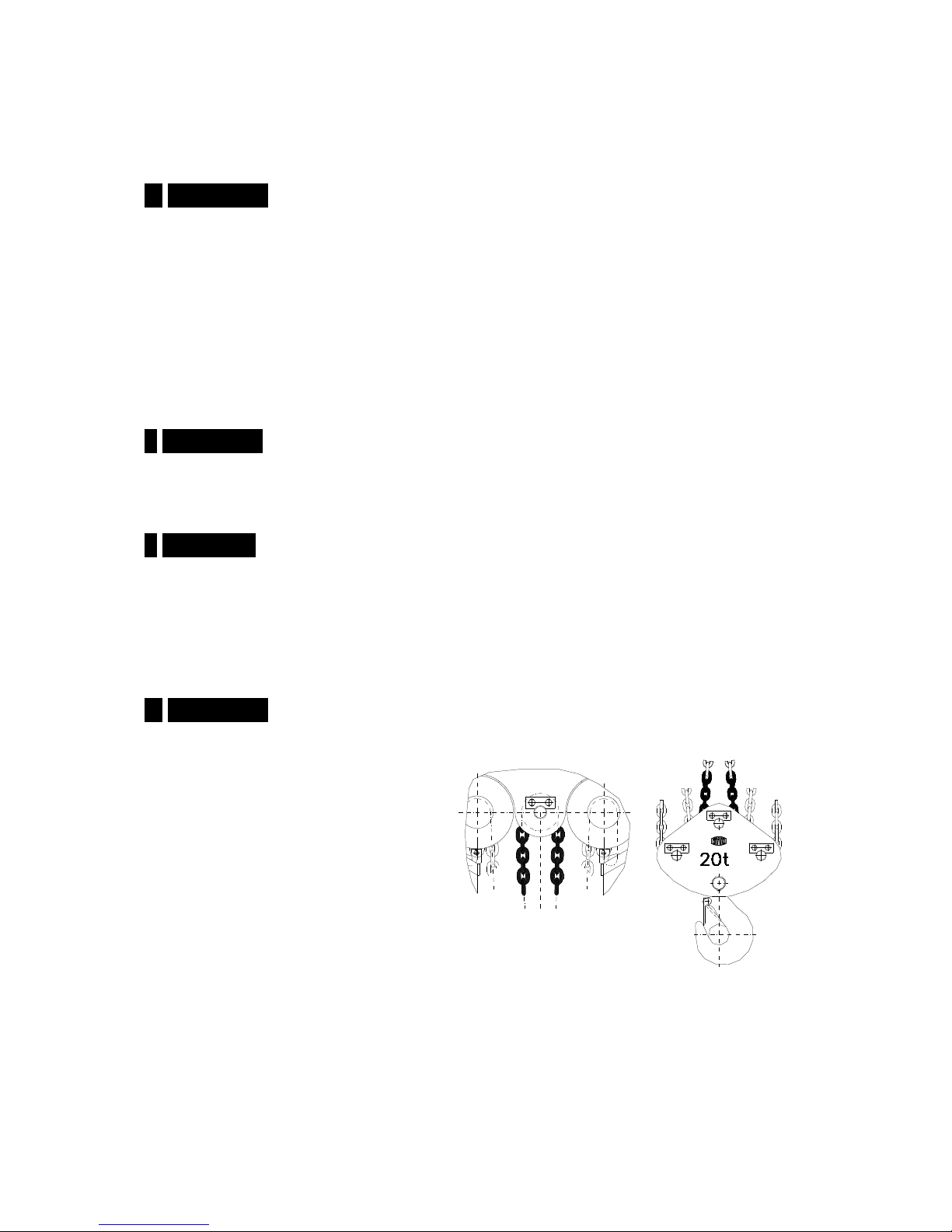

Cain blocks of lifting capacity

15t and 20t are intended in

principle for operational staff

consisting of several members

(at least of two ones). The

speed of winding off the chain

when lifting or lowering must be

balanced on both chain blocks

– synchronized so that in both

stackers was the same length

of the chain. The operating staff

must check a balancing of the

coulor coded central parts of

the chain on the upper sheave

(Z100/15t) or block pulley

(Z100/20t).

14

7.3 SAFETY WORKING ENVIRONMENT

! WARNING

(1) perator must be demonstrably familiarized with this instruction manual,

follow applicable safety and hygienic regulations and be qualified to this equipment

service.

(2) In the course of work with the chain block the operating staff must be equipped

with helmet, gloves and suitable footwear.

(3) nly verified binding means of appropriate lifting capacity is to be used for binding

loads.

(4) When more persons take part in the operation always one person responsible

for manipulation with the chain block and trained in work safety must be

determined.

(5) The operator must have a clear and unobstructed view of the working area before

staring the work. If it is not possible, a second or more persons must help to

supervise in the nearby area.

(6) The operator must check, the entire workplace is safe and whether there is a

possibility of escaping in case of endanger, before operating the chain block.

(7) During work with the chain block, the sufficient distance of the operator from the

load must be kept. It is prohibited to lift or lower bulky loads preventing to keep

sufficient distance.

(8) When operating the chain block in limited areas you must prevent the hook or

loads does not hit into obstacle or to chain block body.

8 INSPECTION OF THE CHAIN BLOCK

8.1 INSPECTION

8.1.1 Inspection c assification

(1) Initial inspection: prior to initial use. All new or repaired chain blocks shall be

inspected by a designated qualified person to ensure compliance with the applicable

provisions of this manual.

(2) Inspection procedures for chain blocks in regular service are divided into two

general classifications based on the intervals at which should be performed. The

intervals are dependent upon the nature of the critical components of the chain block

and the degree of their exposure to wear deterioration or malfunction. The two

general classifications are herein designated as daily and regular. The respective

intervals are defined in the following way:

(a) Dai y inspection: visual examination provided by the operating personnel or

person designated by the user at the beginning of each usage.

(b) Regu ar inspection: visual inspection provided by the qualified person

designated by the user.

1) normal operation – annually,

2) heavy operation – twice per year,

3) special or infrequent operation – as recommended by a qualified person

designated by the user prior to first use and according to the directions of the

qualified operating personnel.

8.1.2 Dai y inspection

Inspect for damages and defects items such as those listed in section 8.2(1) “Daily

inspection. Provide this inspection also during operation in the interval between

15

regular inspections. A qualified personnel shall determine, whether any defects or

damages constitute a hazard or will require more detailed inspection.

8.1.3 Regu ar inspection

Complete inspections of the chain block shall be performed as recommended regular

inspection. These inspections may be performed with the chain block in its normal

location and do not require dismantling the chain block. The recommended regular

inspection defined in the section 8.2(2) must be performed by qualified persons

determining whether the complete disassembly is necessary. These inspections

include also the requirements of daily inspections.

8.1.4 Chain b ock occasiona y used

(1) A chain block that has been idle for a period of one month or more but less than

one year shall be given an inspection conforming to the requirements of the section

8.1.2 before it is placed again in operation.

(2) A chain block that has been idle for a period of one year shall be given an

inspection conforming to the requirements of section 8.1.3 before it is placed in

operation.

8.1.5 Inspection record

Keep always the record of the performed tests, repairs, inspections and maintenance

of chain blocks. Carry out dated inspection records at time intervals specified in the

section 8.1.1 (2) (b) and keep them available in the palce designated by the user.

Defects found by the inspection or recorded during the operation must be announced

to the person designated by the user who is responsible for work safety.

8.2 INSPECTION PROCEDURE

(1) Dai y inspection (provided by the operator or competent person)

PART INSPECTI N

METH D

LIMIT/CRITERIA

F R DISCARD

REMEDY

1. Function of chain

block

Visual, list ning Chain binds, jumps,

mak an xc ssiv

nois , tc.

Cl an and lubricat

th chain, if th

troubl is not

r mov d, r plac th

chain.

2. Fastening parts Visual ch ck of all

bolts, nuts, riv ts tc.

D f ctiv or missing

parts

Loos parts

R plac by th n w

on .

Fast n loos d parts

2. Hooks

(1) App aranc

(2) Hook rotating

(3) Saf ty latch of

hook

Visual

Rotat hook around

its axis by manual

springing of saf ty

latch.

Saf ty latch jump d

out from th top of

th hook, bind shank,

oth r visibl hook

d formation.

Hook do s not rotat

flu ntly or scrub.

Saf ty latch do s not

r turn aft r pushing

Prof ssional ov rhaul

of lifting d vic –

xchang of hook and

oth r damag d parts.

Cl an and lubricat .

Cl an, lubricat ,

r pair or xchang .

16

4. Load chain

(1) App aranc

Visually ch ck th

whol chain.

Cracks in th plac of

w lding, cross nocks,

d formation,

xc ssiv w ar,

corrosion

Exchang of th

chain.

Not :

Th compl t w ar of th

chain cannot b d t rmin d

by th visual insp ction.

Wh n w ar sign is found

ch ck th chain according to

“ R gular insp ction”.

(2) Lubrication

(3) S tting in th

chain

(4) Kink d chain

tackl block (only

at two loading

chain strands)

Visual

Visual ch ck

according to pic.1,

wh th r th chain is

not kink d.

Visual according to

pic.2

Chain is not

lubricat d.

Th chain is kink d or

twist d; w lds ar not

in a row.

Chain is kink d du to

kink d tackl block,

w lds ar not in a

row.

Cl an and lubricat

th chain.

Straight n th chain

and s t to normal

position.

Straight n th chain

by turning back th

tackl block

4. Hand chain

Visual Chain is kink d or

twist d.

Chain is d form d or

damag d and do s not

com corr ctly to

chain wh l.

Straight n th chain

and s t to normal

position.

Exchang of th

chain.

(2) Regu ar inspection (provided by a qualified person)

PART INSPECTI N

METH D

LIMIT/CRITERIA

F R DISCARD

REMEDY

1. Fast ning parts.

Visual ch ck of all

bolts, nuts, riv ts,

tc.

D f ct d or missing

parts

Loos parts

R plac by th n w

on .

Fast n loos d parts

2. All parts Visual ch ck. Worn or damag d

parts.

Dirty and not

lubricat d parts.

R plac by th n w

on .

Dismantl , cl an,

lubricat and

ass mbl again.

W ar in this part

W ld d part

17

3. Nam plat –

marking of lifting

capacity on th chain

block

Visual ch ck Ill gibl lifting

capacity.

R pair or r plac by

th n w on .

R pair marking on th

chain block.

4. Hooks

(1) D formation of

hook

(op ning)

(2) Hook w ar

M asur dim nsion

„C“ with slid

callip r.

Visual ch ck.

M asur dim nsion

„A“ and „B“ with a

slid callip r.

M asur d valu is

high r th n sp cifi d

by th tabl .

D formation is visibl

during visual ch ck.

Do not us th hook,

if dim nsions „A“ or

„B“ w r d cr as d

mor th n 10%.

T chnical insp ction

of lifting d vic –

xchang of hooks

and oth r damag d

parts.

Worn or d form d

hook r plac by th

n w on .

5. Chain - prolongation

- colour marking

(appli d for 15 and

20t)

M asuring of th

pitch with th slid

callip r, m asur at

th point that is most

fr qu ntly ngag d

with th sh av and

th nut.

Visual ch ck

Dim nsion „p“ must

not xc d limit

valu s shown in th

following tabl .

Colour is not visibl .

If limit valu s ar

xc d d ask for

r plac m nt of th

chain.

Paint th c ntral part

of th chain with r d

colour in l ngth about

600 mm

Standard Limit Standard Limit

0,25 17,6 15,8 16 14.5

0,5 17,5 15,8 16 14,5

1 22 19,8 19 17

1,6 26 23,4 23 20

3,2 36,5 32,8 34 30,5

5 42 37,8 35 31,5

7,5 48 43,2 38 34,2

10 58 52,2 45 40,5

15 67 63,3 53 47.7

20 75 67,5 60 54

59

66

24

52

47

24

35

41

45

29

Capacity

( t )

Dimension "A" (mm) Dimension "B" (mm) Dimension "C" (mm)

Limit

18

6. Brak

- function

Susp nd th load of

w ight qual to lifting

capacity of th chain

block, lift it at min. 250

mm and low r.

Aft r int rrupting th

op ration, th brak

must k p th load in

any position of lifting

or low ring.

If this do s not

happ n, ask for r pair

and th brak

adjustm nt.

7. Anchoring th

chain.

Visual ch ck. Th nd of th chain

is not fast n nough

to th body.

Fast n th fixing bolt.

R pair damag d joint

or r plac .

8. Pawl - function Visual ch ck during

lifting.

Pawl do s not snap to

t th of ratch t wh l.

Cl an, lubricat or

r plac th spring.

9. Rotating of

block sh av .

Rotat th block sh av

by pulling th chain.

Th block sh av

rotat smoothly.

Cl an, lubricat or

r pair.

Standard Limit

∅3,1

11

102 105

3,2

∅55 75 77,3

4,5

∅75 105 108,2

6,3

∅9 5 135 139,1

8,1

∅11 5 155 159,7

9,9

Size of the

chain (d)

Number of

measured

links

Pitch of measured links

p x 5 (px11)

Discard limit

for (

d )

ppppp

19

9 FAULTS FINDING

Situation Cause Remedy

1. Th chain block do s not

k p th load.

Brak slipping. Brak adjusting or r pair

according to chapt r

„Maint nanc “.

2. Th chain block lifts hard

or fails to lift th load.

(1) Chain block is ov rload d.

(2) Damag d g aring.

(1) D cr as th w ight of

load to th nominal lifting

capacity.

(2) Ch ck th parts according

to th chapt r

„Maint nanc “.

3. Chain has bad approach,

jams.

Damag d or worn chain or

nut.

Ch ck th chain or parts

according to “R gular

insp ction“ or provid r pair

according to th chapt r

„Maint nanc “

4. Abnormal sounds com s

from th chain block.

1) Not nough lubricat d

chain.

2) Not nough lubricat d

g aring.

3) Worn sh av .

1) Lubricat th chain.

2) Lubricat th g aring.

3) R plac th sh av .

5. In audibl charact ristic

sound during falling of th

pawl to claw of ratch t wh l.

Loos of pawl function.

Rust, impuriti s, brok n

spring.

Cl an, r plac th spring.

6. Saf ty latch of hook do s

not work.

(1) Damag d saf ty latch.

(2) D form d hook.

(1) R pair th saf ty latch.

(2) Ch ck th hook – s

„Daily insp ction“.

10 LUBRICATION

10.1 GENERALLY

Before the application of the new lubricant, remove the old one, clean parts by the

solvent and put the new lubricant. Use the lubricant specified by the manufacturer.

10.2 GEARINGS

Dismantle the cover on the opposite side of the chain wheel.

Remove the old lubricant and replace by the new one. Use grease PM – A2 or its

equivalent.

10.3 LOAD CHAIN

! CAUTION

The wrong maintenance and inappropriate lubrication of the chain can be a cause of

a serious accident.

20

NUT

UN LOADED STRAND

OF C AIN

END LINK OF T E OLD

C AIN

LOADED STRAND OF

C AIN

END LINK OF T E NEW

C AIN

C - LINK

Pictur . 11.2 – R plac m nt of th load chain

ALWAYS lubricate the chain 1 x per week or more often according to the intensity

of the service.

ALWAYS lubricate more often in corrosive environment than under normal

circumstances (salt water, sea environment, acids, etc.).

ALWAYS use machinery oil according to IS – VG 46 or VG 48 or their

equivalent.

11 MAINTENANCE

11.1 SAFETY PRINCIPLES

! WARNING

With exception of rep acing the chain and brake adjustment on y qua ified

personne (service organizations) trained in safety and maintenance of these

chain b ocks can carry out maintenance, inspections and tests.

ALWAYS use parts supplied solely by the manufacturer.

It is not permitted to make repairs and maintenance in other way than prescribed by

the manufacturer. It concerns especially the forbiddance of using of unoriginal spare

parts or performing of modifications on the product without an approval of the

manufacturer.

ALWAYS check the function of the chain block after providing maintenance.

ALWAYS mark the defective or repaired chain block with the appropriate label (for

example: „ UT F SERVICE“).

NEVER do maintenance when a load is suspended on the chain block.

NEVER use a chain block that is under repair!

11.2 REPLACEMENT OF THE LOAD CHAIN

11.2.1 SINGLE FALL CHAIN

Unscrew the bolt and

remove the free end of the

chain. Hook C – link –

behind the last link of the

free end see pic. 11.2.

Provide the lowering until

the end of the new chain is

slipped out enough.

Fasten the free end of the

chain again by the bolt to

the body of the chain block.

The coupling with the hook

fix to the other end of chain.

Check, the chain is not

twisted.

This manual suits for next models

2

Table of contents

Other Brano Lifting System manuals

Popular Lifting System manuals by other brands

Sunrise Medical

Sunrise Medical Oxford/Hoyer Stature User instruction manual & warranty

Hofmann

Hofmann ME1500 Installation and operation manual

rav

rav KPX315WK Translation of the original instructions

pewag

pewag BLCW owner's manual

GEDA

GEDA AB 450 Assembly and operating manual

Happ

Happ 40 Installation and operation manual