Brasch GDCP-A Installation instructions manual

GAS DETECTOR CONTROL PANEL

(TWENTY CHANNEL)

Model GDCP

-A

Instruction/Operation Manual

Bulletin: I

-

690

Brasch Environmental Technologies, LLC

140 Long Road, Suite 101 July 2006

Chesterfield,

Missouri 63005

May, 2007

(314) 291

-

0440

FAX (314

) 291

-

0646

April, 2009

www.braschenvtech.com

2

Table of Contents

Section

Title

Page

1

Introduction and Specifications

6

1-1

Introduction

6

1-2

Model Description

6

1-3

Specifications

7

2

Installation

1

0

2-1

Introduction

1

0

2-2

Unpacking and Inspection

1

0

2-3

Choosing the Mounting Location

1

0

2-4

Mounting the Panel

1

0

2-5

Wiring Connections

1

2

3

Operation

1

8

3-1

Introduction

1

8

3-2

Applying Power

1

8

3-3

Initial Display

19

3-4

Default Program

2

0

3-5

Entering or

Changing

a

n Existing Program

2

2

3-5

.1

Time

2

2

3-5

.2

Date

2

2

3-5

.3

Sensors

2

3

3-5

.4

Zones

2

3

3-5

.5

Automatic Override

24

3-5

.6

Manual Override

2

4

3-5

.7

Power Restore After a Power

Interruption

2

5

3-6

Status Check

2

5

3-6.1 Sensors

2

5

3-6.2

Zones

2

6

3-6.3

Automatic Override

2

6

3-7

Loss of Power

2

7

3-7

.1

Operation During Power Loss

2

7

3-7

.2

Operation After Power Returns

2

7

3-7

.2.1

Power Restore Without Ventilation

2

7

3-7

.2.2

Power Restore With Ventilation

2

7

4

Maintenance

2

8

4-1

Introduction

2

8

4-2

Sen

sors

2

8

4-3

Fuses

2

8

4-4

Sensitivity Testing

2

8

5

Service and Repair

29

5-1

Introduction

29

5-2

Warranty

Period

29

5-3

Obtaining Service

29

5-

3.1

Service and Repair Procedure

29

3

Page

6

Appendix

Appendix A

3

0

Appendix B

3

1

Appendix C

3

3

Appendix D

3

4

Appendix E

35

List of Figures

Figure

Title

Page

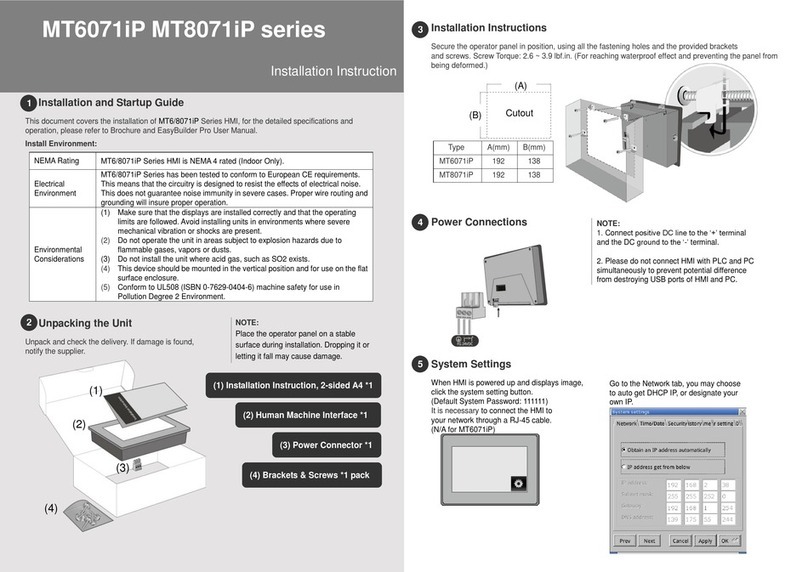

1

GDCP

-

A mounting dimensions

11

3

GDCP

-

A internal components, view from bottom end

13

4

GDCP

-

A power connection terminals

14

5

GDCP

-

A digital logic board component layout

15

6

GDCP

-

A wiring diagram showing transmitters wired in

17

daisy-

cha

in fashion, and location of terminals strips

TS1 and TS2.

7

GDCP

-

A front, internal view of front panel layout

21

List of Tables

Table

Title

Page

1

-

3.1

GDCP

-

A Control Panel Specifications

7

2

-

5.2

Explanation of the connection points on terminals

16

TS1 and TS2.

4

Operation Safety Notice

Certain procedures and operations detailed in this manual require that specific

precautions be taken prior to beginning the procedure or operation. When precautions are

required, a notice will be printed in an appropriate

location in the manual

.

The user is

urged to read and understand all such notices before continuing.

Types of Notices

Three types of notices are used in this manual to describe t

he severity of the situation

encountered.

WARNING

This notice indicates that conditions exist that could cause personal injury or

loss of life.

CAUTION

Conditions exist that could cause damage to the equipment or other proper

ty.

Note

Special consideration should be given to the procedure or operation or an

unexpected operational result could occur.

5

L

imited

W

arranty

Warranty Statement

Limited Warranty

Brasch Manufacturing Co.,

Inc

., (the Company

),

warrants gas transmitters, gas detectors,

gas detector control panels and accessories for a period of one year from the date of

shipment

against defects in material or workmanship. Should any evidence of defects in

material or workmanship occur during the warranty period, Brasch Manufacturing Co., Inc.

will repair or replace the affected product, at its own discretion, without charge.

The

Company shall not be held responsible for any charges incurred by any other

company or person while

installing,

remov

ing

or replacing any allegedly defective

e

quipment

, or part thereof

, nor for incidental or consequential damages.

6

Section 1

Introduction and Specifications

1-1

Introduction

1-

1.1

This manual covers the capabilities, installation, set

-

up and operation of the

Brasch GDCP

-

A Control Panel.

The panel and its associated transmitters are

referred to as the

ventilation control system

. These systems can be as si

mple

as a panel and one transmitter controlling one ventilation fan, or as complex as a

panel with 20 transmitters controlling six output zones with two ventilation fans

each.

The user is strongly encouraged to read, and understand, this entire

manual bef

ore attempting to install and operate this equipment.

1-2

Model Description

1-

2.1

The Brasch GDCP

-A

Control Panel, along with its associated transmitters,

provides a complete monitoring

system for detection and removal of dangerous

concentration of spec

ific toxic gases. The system is capable of monitoring up to

20 remote locations for gases such as carbon monoxide and nitrogen dioxide.

The panel can then provide control signals

, based upon the actual gas

concentration,

to actuate warning alarms and

ope

rate ventilation equipment

within the monitored area.

The panel can control up to six ventilation zones. Two

,

dry

-

contact,

normally

open,

control relays are provided for each zone. The Low Alert set of contacts

have ten field adjustable levels. The con

centrations of these levels are

dependent upon the type of gas being monitored.

See Appendix E for the

actual Low Alert values.

The High Alert set of contacts are factory set to close

at a predetermined level.

This level is 100 parts per million, (

PPM

),

for carbon

monoxide and 5 PPM for nitrogen dioxide.

The Low Alert

relay

contacts

will

close, (open), once the gas level

is above

, (

below), the field selectable level and

a field selectable delay period has timed out. The High Alert contacts will close,

(open), once the levels are above, (below), the factory preset concentrations.

A dry

-

contact, normally open relay

, that is common to all of the six control zones,

will close 15 minutes after a High Alert level is exceeded and maintained. Once

the Hig

h Alert level drops below the factory settings, this relay will again revert to

the normally open state. This relay may be used to send warning signals to

remote locations, or actuate external alarm components to provide additional

warnings.

A piezoelect

ric buzzer, mounted beneath the GDCP

-A s front panel,

will also sound while the relay contacts are closed. This buzzer may be silenced

by pressing and then releasing the ALM OFF switch located directly below the

buzzer sound venting holes on the right s

ide of the front panel. This switch will

automatically reset itself after the alarm condition is no longer valid.

The GDCP

-A Control Panel can be field programmed to suit the user s

requirements. Program choices are displayed on

the

4 line

s

of a

20 cha

racter

per line

, liquid

crystal display.

The appropriate choice is selected through the

use of a four key keypad located directly below the display. The active keys

7

associated with the current choice are noted on the fourth line of the display. In

most

cases, the keys

that are not listed

are inactive at this time.

Programmed parameters are stored in a non

-

volatile memory circuit. In the case

of power failure, this circuit will retain the programmed parameters for a nominal

period of ten years. This ex

tremely long retention time allows the GDCP

-

A to be

programmed at the factory with the users specific program data. Once the unit

arrives at the user s facility, and is placed in operation,

no further programming is

necessary. The user may make changes

to the program, however, once the

system is operating.

To take advantage of the factory programming feature, the user must

convey their programming requirements to the factory at the time their

order is placed.

If no special programming is requested, the

panel will ship

programmed with a default program.

1-3

Specifications

1-

3.1

Specifications for the GDCP

-A

Control Panel are listed in

Table 1

-

3.1

.

Table 1

-

3.1

GDCP

-

A Control Panel Specifications

Note

All specifications

were

current at the time this manual was printed. Brasch Manufacturing

Co., Inc. reserves the right to make any changes to future production units when such

changes are deemed necessary. There is no implied responsibility to make future

changes available to current users of this equipment.

Electrical

Power requirements

Voltage

120 VAC, +/

-

10 %

Frequency

50/60 Hz.

Inductive power

120

VA

Ins

tallation category

II (Local level, over

-

voltage transients

below 1500 volts.)

Environmental

Temperature

Operating

-

15° C to 40° C, (5° F to 104° F)

Storage

-

50° C to 120° C, (

-

58° F to 248° F)

Humidity

Operating

10% to 90%, (n

on

-

condensing)

Storage

10% to 90%, (non

-

condensing)

8

Table 1

-

3.1

GDCP

-

A Co

ntrol Panel Specifications, (continued)

General

Size

14 in. W. x 10 ¼ in. H. x 5 in. D.

35.6 cm. W. x 26.0 cm. H. x 12.7 cm. D.

Weight

14 Lbs. (6.36 KGs)

Housing

Heavy gauge, painted steel, NEMA 1

classi

fication.

Recognition

Agency

ETL listed to U.L. Standard 61010B

-1

and

Canadian CSA C22.2, NO 1010

-1

System, Electrical

Display

20 char. X 4 line LCD with LED backlight

Keypad

5 embossed keys with tactile feedback

Timing

Rea

l-

time clock with output for minutes,

hours, day

-

of

-

week,

day, month and year.

Circuit

Microprocessor controlled digital circuitry

with battery backup, (nominal 10 year

lifetime).

Input channels

Number 20 inp

uts, (max.)

Input signal

8-

bit digital word, RS

-

485 transceiver

Connection

Inputs are true daisy

-

chain, both power and

communication.

Maximum distance

1000 feet between input transmitter and

panel.

Output channel

Number

6 outpu

ts, (max.)

Type of output

Two each, dry

-

contact, mechanical relays,

fused at 5 Amps.

Maximum voltage rating

125 VAC, 50/60 Hz.

Current capacity

5 Amps, resistive at 30 VDC.

Power (inductive)

250 VA, (1/8 H.P.)

9

Table 1

-

3.1

GDCP

-

A Control Panel Specifications, (continued)

Alarm channel

Number

Two each

, common to all output channels

Type

External

Type

One each, dry

-

contact, mechanical relay,

fused at 5 Amps.

Maximum voltage

125 VAC, 50/60 Hz.

Current capacity

5 Amps, (resistive) at 30 VDC

Power, (inductive)

250 VA, (1/8

H.P.)

Internal

Type

Piezoelectric ceramic element

Frequency

3.7 KHz.

Sound level

110 db. @ 10 cm.

10

Section 2

Installation

2-1

Introduction

2-

1.1

This section of the manual provides instructions on the initial procedures required

to

make your GDCP

-

A Control Panel

operational.

In the following paragraphs,

you will find

detailed instructions on unpacking and inspection,

locating and

mounting the pan

el and

connecting the

wiring.

If for any reason, you have questions concerning the panel that are not

answered in this manual, please contact your distributor or Brasch

Manufacturing at the number listed on the front of this manual.

2-2

Unpacking and Inspection

2-

2.1

Depending upon the number of transmitters ordered, you may receive the

GDCP

-

A Control Panel system in more than one container. In any case,

carefully unpack all containers and check the contents against your purchase

order. Report any m

issing components to your distributor. Your distributor will

immediately contact Brasch Manufacturing Company

and inform us of the

discrepancy. You should save the packing containers in case there is a reason

to return any of the shipment to the factory

at a later date.

2-3

Choosing the Mounting Location

2-

3.1

The GDCP

-

A is designed to allow the remote monitoring of facilities such as

underground garages, maintenance facilities, large warehouses and enclosed

cargo terminals. Usually the panel is mount

ed in a utility room, electrical service

room, or a guard house where the data gathered from the remote transmitters

can be conveniently monitored. Other than the requirement that the panel be

within 1000 feet of the most remote transmitter,

easy access t

o the front panel

display will most likely determine the optimum mounting location.

Choose a location with easy access to the front panel controls. Remember that

not only will you require enough room to fully open the housing cover, but also

there must

be enough room around the panel for routing and connecting the

various wiring conduits. The availability of a

dedicated, 120 VAC power line

is

a must for proper operation.

Do not try to operate this system without a

dedicated line supplying the panel pow

er. This line should not be shared

with the control voltage that operates the fan motor control relays. Hug

e

electrical spikes, produced whenever these relays operate, can cause the

digital circuits in the panel to malfunction.

2-4

Mounting the Panel

2-

4.1

Mount this panel only indoors in a dry location. Ensure that the user has easy

access to the front panel controls and that the display can be easily read.

The housing is equipped with mounting holes

placed in the top and bottom edges

of the ho

using s back.

Please see Fig.

1

, page

11

, for the location of these

holes as well as the required mounting dimensions. Also, a full size

GDCP-A

MOUNTING

TEMPLATE

USE AT LEAST # 10 SCREWS.

USE ALL FOUR MOUNTING

HOLES. MOUNT ONLY ON A

SOLID FOUNDATION.

FIG. 1: GDCP-A mounting dimensions.

11

12

template is enclosed with the important papers shipped with the panel, and

may be used to locate the

mounting holes.

Attach the housing to a

wall, or

other solid support, using only these holes.

This

unit

must not

be mounted by

drilling or punching holes in the inside of the housing. Metal shavings, or

other foreign objects

,

may cause damage to the pa

nel

’s

circuit boards. The

damage created would, of course, not be covered by the manufacturer’s

warranty.

Mount the panel with at least #10 screws through all four holes. Make sure that

the screws are driven in fully and that the mounting surface is st

rong enough to

support the panel’s weight.

2-5

Wiring Connections

2-

5.1

Th

is

control panel is designed to operate from

120 VAC power at 50/60 Hz

. The

power circuit must be able to supply at least

120

VA

to the panel.

Th

is

supply

circuit must includ

e a disconnect device or switch located within easy

reach adjacent to the panel’s location. This component must be clearly

labeled as the disconnect device for the panel.

Use 12 or 14 AWG, stranded wires to provide the 120 VAC power to the control

panel

.

Although the panel uses less than 0.5 Amps of operating current,

extremely long lengths of wiring between the service breaker and the panel could

result in large voltage drops occurring across the wire lengths. If long lengths of

wiring are required, u

se 12 AWG wiring for the supply circuit.

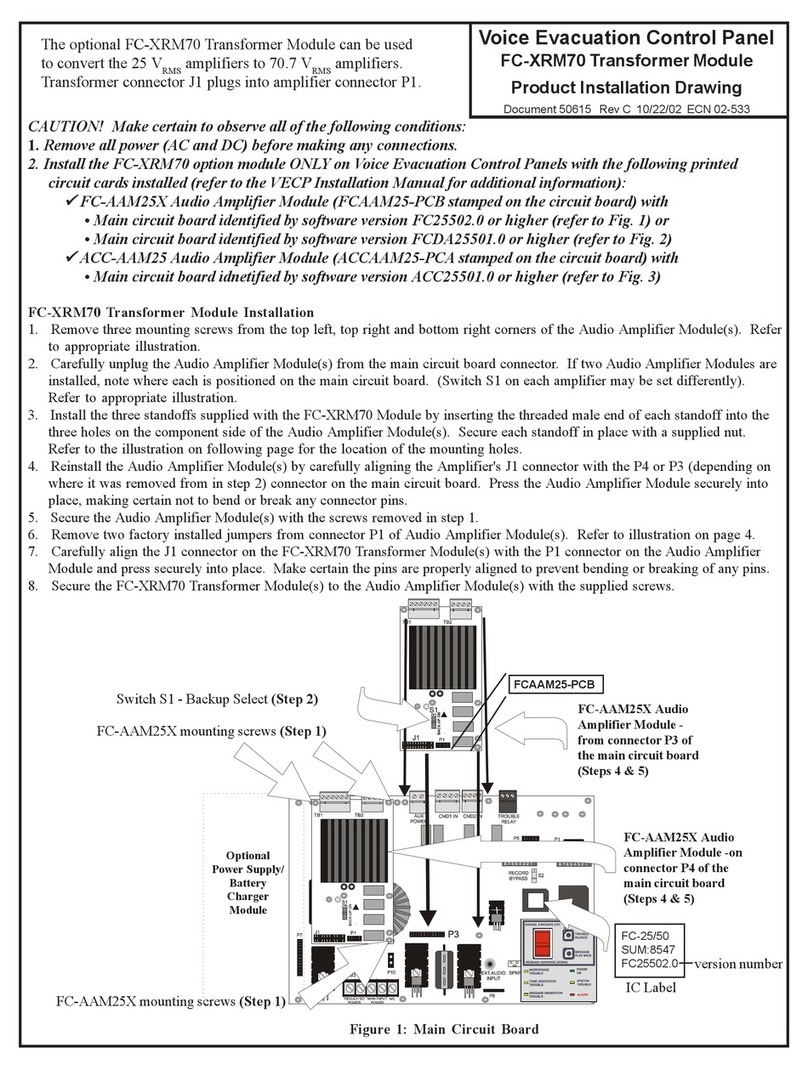

The power connections are made on the

Power Supply/Relay P.C. board.

Fig.

3, page 1

3

, shows an internal

, bottom

view of the assembled panel

.

Use this

figure to locate the Power Supply/Relay board.

Fig. 4, page

14

, shows the

location of the power terminal strip, TS1, where these connections are made.

L1

is for the 120 VAC hot

lead

,

while the

120 VAC neutral wire

connects

to L2.

The four ground points on terminals 3 through

6

can be used to attach the

circuit ea

rth ground.

2-

5.

2

Connections between the panel and the transmitters require a five conductor,

shielded cable.

This cable should have 18 AWG, stranded

conductors.

Each

conductor should have a distinct color to avoid any wiring errors at either the

pan

el or transmitters.

This cable provides both the operating voltage

to the

transmitters

and the digital communication lines

between

each transmitter

and

the control panel

.

The transmitters can be connected in a parallel fashion. This connec

tion

scheme is sometimes referred to as a daisy chain connection. The farthest

transmitter should be at, or less than, 1000 feet from the panel. The panel

contains two terminal strips for connecting the transmitter cable. As many

as four cables can be

c

onnected at the control panel.

Fig.

5

, page

15

,

shows the location of these terminal strips. The function of each terminal

point is written directly next to each point. Table

2-

5.2, on page 1

6,

explains the function of each terminal point on these strip

s.

FIG 3: GDCP-A internal components, view from bottom end.

CABINET COVER

CABINET

P.C. PACKAGE

TRANSFORMER

BOARD

FRONT PANEL

LABEL/KEYPAD

POWER SUPPLY/

RELAY BOARD

DIGITAL LOGIC

BOARD

13

TS1

GND

L2

T1

T1

T1

GND

L2

L2

GND

L1

L2

GND

POWER

OFF

ON

HA2

LA1

ZONE 1

LA2

HA1

XFMR1-1

XFMR1-1

T

S

9

H

A

1

H

A

2

L

A

2

L

A

1

POWER

GND

GND

GND

GND

L2

XFMR1-1

XFMR1-1

XFMR1-1

BACK 1

BACK 2

XFMR1-1

T

1

T

S

1

T

1

T

1

L2

L2

L2

L1

OFF

ON

ZONE 1

P.C. PACKAGE

POWER

CONNECTION

POINTS

POWER SUPPLY/

RELAY BOARD

SW1

FIG. 4: GDCP-A power connection terminals.

14

TS2

TS1

JP2

JP3

POWER IN

1

ZONE RELAYS

TRANSMITTER

CONNECTION

TRANSMITTER

CONNECTION MAX.

SENSOR

1

16

TP5

1

TRANS

POWER IN

+-1

TP1

BACKLIGHT

POWER IN

4-20 ma

OUTPUT

+

-

TS3

KEYPAD

1

JP1

+UNREG

COM

-UNREG

+COMM

-COMM

-UNREG

-COMM

+COMM

COM

+UNREG

FIG 5: GDCP-A digital logic board component layout.

COM

COM

15

16

Table 2

-

5.2: Explanation of the connection points on terminals

TS1 and TS2

Terminal

Id

entifier

Function

#1

+UNREG

Supplies the unregulated positive DC voltage for the

+15 VDC power supply.

#2

COM

Common connection for all circuit points.

#3

-

UNREG

Supplies the unregulated negative DC vo

ltage for

the

-

15 VDC power supply.

#4

COM

Common connection for all circuit points.

#5

+COMM

Provides one side of the RS

-

485 communications

port.

#6 -

COMM

Provides the second side of the RS

-

485

communications port.

See FIG. 5, page 1

5

, for the location of these terminal strips.

Connect the shielded cable as shown in

F

ig

.

6

, page

17

, being very careful to

av

oid

mistakes. Either of the two terminal strips, TS1 and TS2, can be used to connect

to

the transmitters. The two terminals will come in handy if the transmitters fan out in

opposite directions from the panel.

Be sure that all of the transmitters that

will be assigned to the system are

wired

correctly

before applying power to the panel. The panel initially polls

its active

transmitters when power is first applied in order to obtain a list of the transmitter

types. The panel will consider any transmi

tters not connected as failed sensors and

indicate this on the display.

18

S

ection 3

Operation

3-1

Introduction

3-

1.1

The following paragraphs discuss the steps to take

when first applying power to

the GDCP

-

A system. Also, discussed are the initial displays after start

-

up, the

default program parameters, how to enter the system and change program

parameters, how to check the status of all system parameters and what occurs

during and after a power loss

.

3-2

Applying Power

3-2

.1

Power

should only be applied when all wiring has been completed and

thoroughly checked for accuracy.

T

he GDCP

-

A Control Panel polls its

transmitters at start

-

up

. A

ll transmitters should be connected and ready for

operation

before applying power

.

Power to the

transmitters is supplied by a

D.C. power supply located in the panel which connects to each transmitter

using three of the conductors in the connecting cable.

After making sure that the breaker at the

facility’s service panel is in the on

position,

pl

ace the power switch for the panel to the on position as noted on the

power supply/relay board located at the back of the panel P.C. package. You will

have to open the package door to access this switch.

Please see Fig.

4

, page

14

, for the location of th

e panel’s power switch.

The switch is located on

the top, left corner of the P.C. board to the right of the power input terminal

strip.

Immediately place the power switch to the off position if you experience

any indications of circuit shorti

ng, unexpected noises or smoke. Do not

attempt to apply power until the reasons for these happenings are

determined and corrected.

3-2.2

Once the power switch is in the on position, close the door to the P.C. package.

Briefly examine the front panel for

the following:

The display should have a message indicating the date and time. There

should also be a statement indicating that the unit is warming up and

asking the operator to please wait.

The green power indicator at the upper, right corner of the f

ront panel

should be glowing.

All other panel indicators should be in their off positions.

WARNING

Dangerous, high voltage exists on the panel

’s

power supply/relay board.

Be especially

careful not to contact any of the terminal points on TS1 or the main power fuse, FH1,

while operating the power switch, SW1.

19

If you do not see the indications stated above, place the power switch to the off

position and remove the 120 VAC power by placing the breaker in the off

position.

Contact you Brasch distributor, or the Brasch factory, for

instructions on how to proceed.

3-3

Initial Displays

3-3

.1

Immediately after applying power, the panel

power indicator will be glowing and

the LCD

will display the following message.

After about 10 seconds, the panel will enter its startup ventilation mode. If any

ventilation zones are programmed to be on, they will actuate at this time. The

zone indicators associated with those zones will then glow.

The panel will

remain in th

e startup mode for approximately 2 ½ minutes. After this time is

completed, the panel will enter the measure mode. The display will then change

to the following.

The display updates about every five seconds. If there are any failed

transmitte

rs, the display will then indicate the following.

Press the “MENU” key and the display will then change to the following:

Press the “NEXT” key and the display will change to:

DATE

(

DOW

) (

CURRENT DATE

)

TIME (

HOURS:MINUTES

)

WARMING UP

PLEASE WAIT

DATE (

DOW

) (

CURRENT DATE

)

TIME (

HOURS:MINUTES

)

PRESS MENU KEY

FOR OPTIONS

DATE (

DOW

) (

CURR

ENT DATE

)

TIME (

HOURS:MINUTES

)

FAILED SENSOR

CHECK SYSTEM STATUS

PROGRAM SYSTEM

ENT/PREV/NXT

20

Press the “ENT” key to enter the system stat

us checking mode.

Once the panel is in the status checking mode,

you may

index to the

“CHECK SENSOR STATUS” display using the “NXT” key. You may then

press “ENT” followed by “NXT” to check the status of the current sensor

number, or use “NXT” to index to

a specific sensor number before

selecting it by pressing the “ENT” key.

The second line of the display will either indicate the current reading of the

sensor, or indicate that the sensor is in the failure mode.

Once you have finished checking the sensor

status, press the “MENU” key

to return to the main panel display.

3-4

Default Program

3-4

.1

If you have not asked the factory to ship your new GDCP

-

A Control Panel with a

specific program installed, the panel will arrive with

the factory default progra

m

active.

The following parameters will be set into the program.

CO transmitters:

Low Alert trigger point at

35 PPM.

The transmitter will be assigned to output zone #1

.

NO

2

transmitters:

Low Alert trigger point at

1.0 PPM

.

The transmit

ter will be assigned to

output zone #1

.

Active Zone:

Zone #1.

Zone ON/OFF Delay time:

3 minutes.

Type of exhaust:

50%/100%.

Auto. Override Active:

NO.

Power Back Status:

No fans active after power failure.

Of course, the High Alert sett

ings remain at

100 PPM for the CO transmitters,

and 5 PPM for the nitrogen dioxide transmitters. These settings are not

adjustable.

CHECK SYSTEM STATUS

ENT/PREV/NXT

Table of contents

Other Brasch Control Panel manuals