Brasch GSE Generation 2 User manual

GSE Generation 2

Installation / Operation Manual

Brasch Environmental Technologies, LLC

1 0 Long Road, Suite 101

Chesterfield, Missouri 63005

31 -291-0 0

www.braschenvtech.com

Table of Contents

Introduction...................................................................................................................................

General Description..................................................................................................................

Features and Benefits..............................................................................................................5

Technical Specifications................................................................................................................6

Product Specifications..............................................................................................................6

Target Gas Specifications.........................................................................................................7

Carbon Monoxide.................................................................................................................7

Nitrogen Dioxide...................................................................................................................7

Description of Front Panel Indicators.......................................................................................8

Front Panel Indicators..........................................................................................................8

Operation Safety Notice................................................................................................................9

Types of Notices.......................................................................................................................9

Quick Start Guide.......................................................................................................................10

Step 1 – Mounting..................................................................................................................10

Step 2 – Input Wiring..............................................................................................................10

Step 3 – Remote Transmitter Wiring......................................................................................11

Step – Relay Wiring.............................................................................................................12

Step 5 – External Alarms........................................................................................................12

Step 6 – Applying Power........................................................................................................12

Step 7 – Self-Test Mode.........................................................................................................13

Installation...................................................................................................................................1

Mounting the Detector............................................................................................................1

Connecting the Power Supply................................................................................................15

Connecting the Remote Transmitters.....................................................................................17

Connecting the Ventilation System.........................................................................................17

Connecting the External Alarm...............................................................................................18

Connecting the Voltage or Current Proportional Output........................................................18

Applying Power For the First Time.........................................................................................18

Using the Self-Test Feature....................................................................................................19

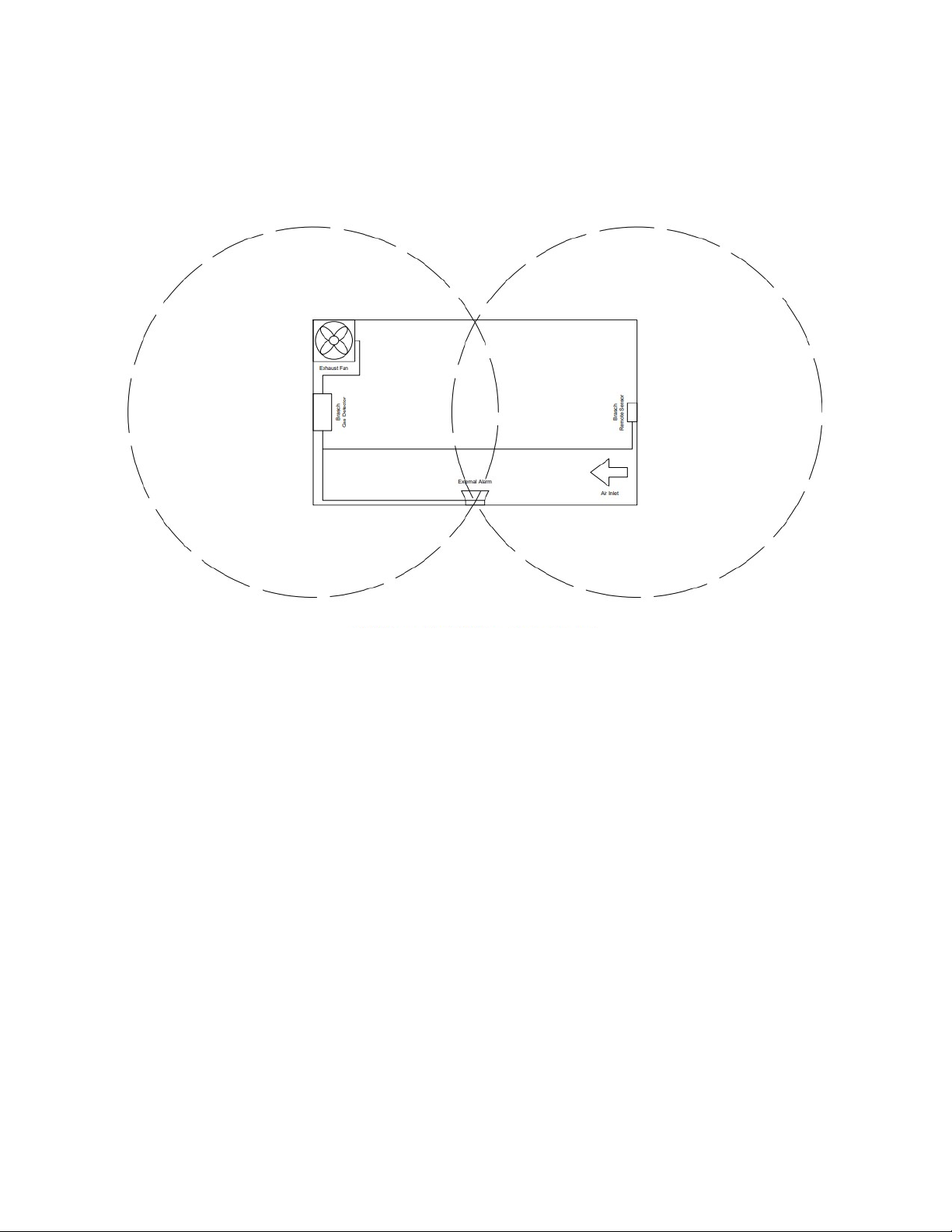

Typical Installation Diagrams..................................................................................................20

Operation....................................................................................................................................23

How the Detector Senses the Target Gas..............................................................................23

How the Detector Controls the Ventilation Equipment...........................................................23

Low Alert.............................................................................................................................23

High Alert............................................................................................................................23

Alarm..................................................................................................................................2

Proportional Output............................................................................................................2

Manual Fan Activation........................................................................................................2

Factory Default Settings.........................................................................................................25

Adjusting the Settings.............................................................................................................26

Sensor Number..................................................................................................................26

Active Sensors...................................................................................................................26

IOM01

Rev 1.0 – December 22, 2020 2

Active Zones.......................................................................................................................26

Zone Delay.........................................................................................................................26

Zone Alert...........................................................................................................................26

High Alert Relay Operation.................................................................................................27

Fan Speed..........................................................................................................................27

Proportional Output............................................................................................................27

Using the Proportional Outputs..............................................................................................27

Obtaining the Best Operation.................................................................................................28

Carbon Monoxide and/or Nitrogen Dioxide Detectors.......................................................28

Maintenance...............................................................................................................................30

Testing the Response to the Target Gas................................................................................30

Carbon Monoxide and/or Nitrogen Dioxide Detectors.......................................................30

Replacing the Sensor.............................................................................................................31

Suggested Repair Parts.........................................................................................................32

Troubleshooting..........................................................................................................................33

Error Codes............................................................................................................................33

Transmit Timeout – 9501....................................................................................................33

Failed Sensor – 960x.........................................................................................................33

Cannot Run Self-Test – 9802.............................................................................................3

End-of-Life – 9995..............................................................................................................3

Sensor Not Installed – 9996...............................................................................................3

Invalid Calibration Values – 9997.......................................................................................3

No Active Zones – 9998.....................................................................................................35

No Active Sensors – 9999..................................................................................................35

Checking and Replacing Fuses..............................................................................................35

Common Installation/Operation Mistakes..............................................................................36

Ventilation Components Connected to the Wrong Relays.................................................36

Ventilation Components Connected to the Wrong Zone....................................................36

Configuration Jumper in the Wrong Position.....................................................................36

Low Alert Level Set at Wrong Concentration.....................................................................36

Delay Period Set Incorrectly...............................................................................................37

Setting the Proportional Output Incorrectly........................................................................37

Detector Mounted in an Unsatisfactory Location...............................................................37

Limited Warranty.........................................................................................................................38

Warranty Statement...........................................................................................................38

Service and Repair Procedures.........................................................................................38

Appendix.....................................................................................................................................39

Model Numbers and Descriptions..........................................................................................39

Detector Model Number and Description...........................................................................39

Complete Model Number List............................................................................................. 0

Figures and Diagrams............................................................................................................ 1

IOM01

Rev 1.0 – December 22, 2020 3

Introduction

General Description

The Brasch Environmental Technologies GSE Generation 2 Gas Detector is designed to

function as a dual-zone standalone gas sensor and ventilation controller. The detector

consists of a sensor (or sensors), six control relays, and digital control circuitry. The unit

monitors the signal from the sensor, compares the signal to preset values, and controls relay

contacts based upon the comparison. These relay contacts then provide signals that control

ventilation components such as exhaust fans, louvers, and dampers. A four-digit display and

indicator LEDs are mounted on the front panel to provide a visual indication of the detector’s

operational condition. A linear proportional output is also included for communication with a

building management system (BMS), direct digital controls system (DDCS), or variable-

frequency drive (VFD).

The sensors used in the detector operate on the electrochemical principle and are able to

detect Carbon Monoxide or Nitrogen Dioxide. A current is produced when the target gas

reacts chemically with an electrode inside the sensor. This small current is converted to an

analog voltage, amplified, and converted to a digital signal. This signal is proportional to the

gas concentration present at the sensor and is shown on the display. After comparing the

digital signal to preset values, the unit activates the appropriate LEDs and relays. The actual

gas concentration is sampled and updated approximately every five seconds.

The detector’s circuitry consists of three or more printed circuit boards mounted inside a

polycarbonate housing. The housing has a NEMA 3R rating and is supplied with conduit

fittings so that the detector can mount directly to a standard four inch conduit box. Short

lengths of 16 AWG wire, connected to the power and relay terminals inside the housing, extend

through the conduit fittings. These wires are color-coded so that most installations will not

require opening the front panel of the detector.

Space is available in the detector housing for mounting two sensor assemblies. This allows for

local detection of two target gases. Additionally, remote sensors can be attached via a five-

conductor shielded cable. Each detector supports up to a total of four sensors mounted either

locally, remotely, or both.

IOM01

Rev 1.0 – December 22, 2020

Features and Benefits

•Comprehensive Monitoring

◦Detects CO and/or NO2

•Greater Coverage

◦Monitors up to Sensors and 36,000 sq. ft.

•More Control

◦User-Adjustable Setpoints, Delays, Outputs, and Relays

◦Built-in Manual Fan Activation

•Enhanced Durability

◦Rainproof Water Resistance

◦Simple Service and Maintenance

•Simplified Installation

◦Preconfigured Wiring

◦Factory Calibration

◦Customized Programming

•Effortless Upgrade

◦Works with New and Existing Building Controls Systems

◦Fully Backwards Compatible with GSE Generation 1

IOM01

Rev 1.0 – December 22, 2020 5

Technical Specifications

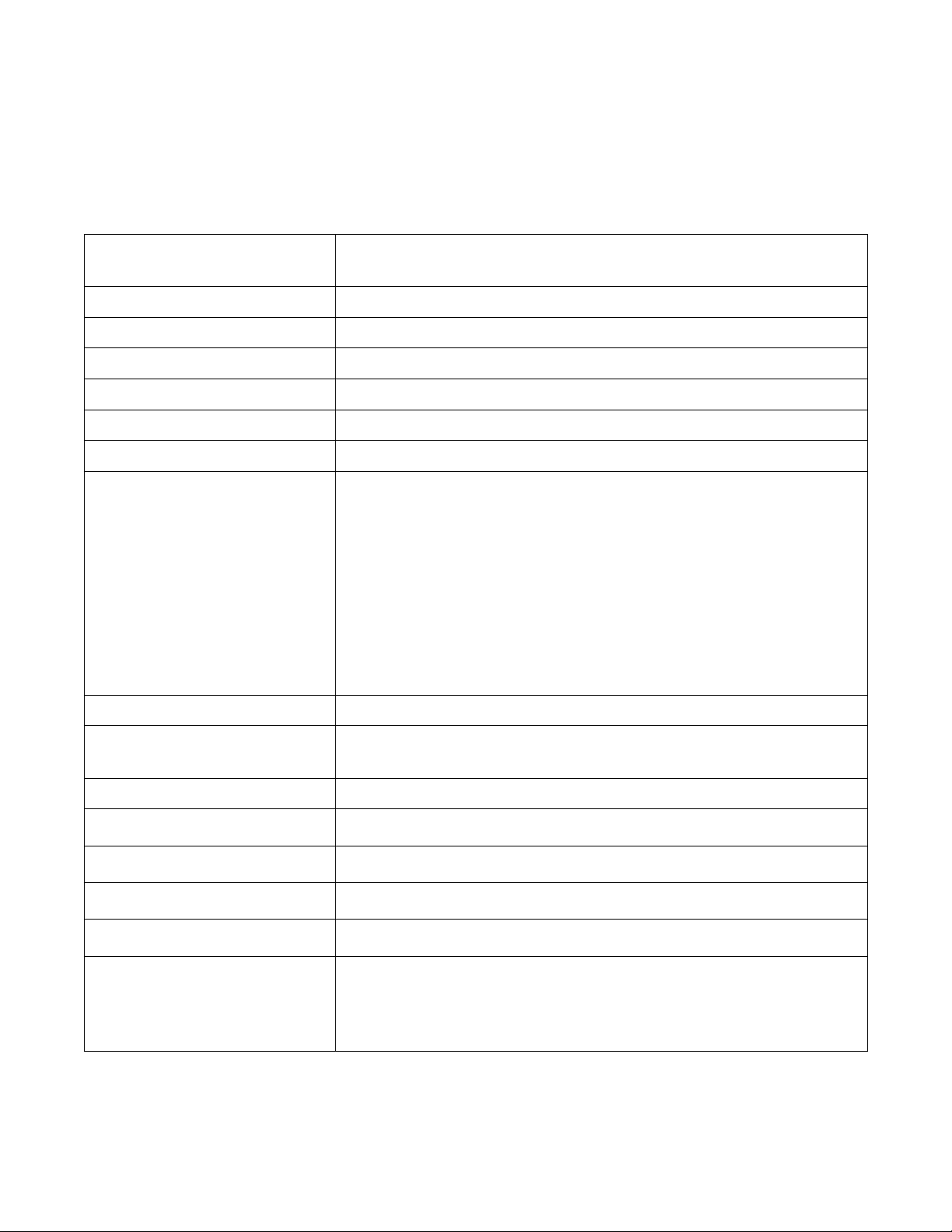

Product Specifications

Input Power

(selected at time of order)

120 VAC, 50/60 Hz, 0.2 A

2 VAC, 50/60 Hz, 1.0 A

Installation Category II (local level, over-voltage transients less than 500V)

Storage Temperature -50°C to 120°C (-58°F to 2 8°F)

Operating Temperature -20°C to 50°C (- °F to 122°F)

Humidity 10% to 90% (non-condensing)

Ventilation Control Relays 125 VAC, 50/60 Hz, 5 A resistive, 250 VA inductive

Internal Alarm 106 dB @ 10 cm, 3.8 kHz piezoelectric element

Front Panel Indicators Power (green LED)

Alert 1 (red LED)

Alert 2 (red LED)

Alarm (red LED)

Sensor 1 (yellow LED)

Sensor 2 (yellow LED)

Sensor 3 (yellow LED)

Sensor (yellow LED)

Zone 1 (yellow LED)

Zone 2 (yellow LED)

Display -digit numeric

Selectable Fan Settings 2-speed motor fans

2 individual fans

Alert Levels 8 field selectable choices

Delay Times 0 to 7 minutes, both entrance and exit

Dimensions 8.15” W x 9.93” H x 2.70” D (21 cm W x 25 cm H x 7 cm D)

Weight 5.5 lbs (2. 9 kg)

Housing Gray, NEMA 3R, polycarbonate plastic

Compliance ANSI/ISA 92.00.01-2010 (R2015)

EN 50270

FCC Part 15 Subpart B

RoHS

IOM01

Rev 1.0 – December 22, 2020 6

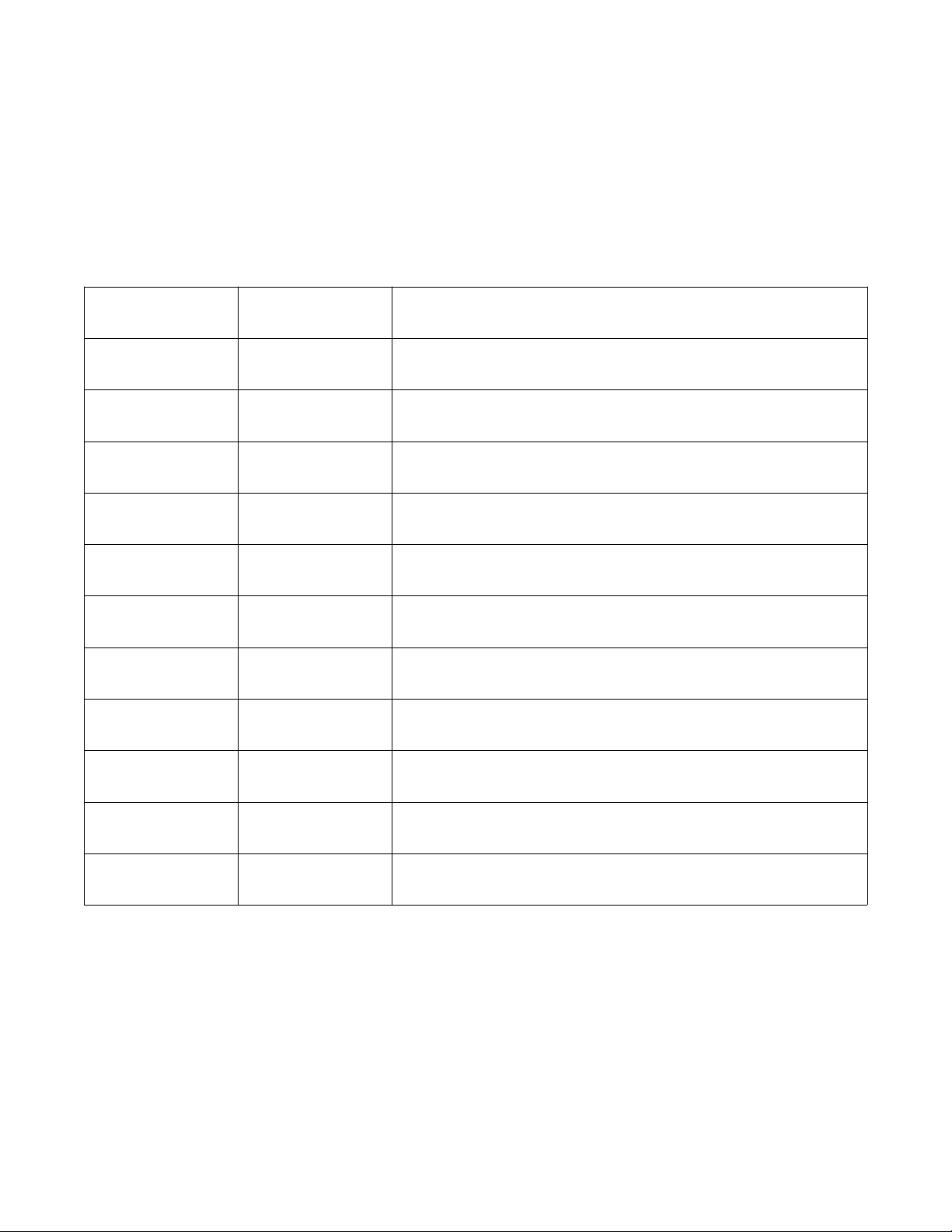

Target Gas Specifications

This Brasch Gas Detector is available for monitoring carbon monoxide and/or nitrogen dioxide

as target gases. Regulatory agencies have determined the threshold concentrations at which

the gases become dangerous. Brasch Environmental Technologies, LLC has designed their

detectors so that the measurement ranges for each target gas meet the agencies’

requirements. Each target gas, for which Brasch currently produces a detector, is listed below

along with the relevant concentration specifications.

Carbon Monoxide

Full Scale Span: 200 PPM

Resolution: 1 PPM

Minimum Accuracy*: ± 10% or 6 PPM

Low Alert Settings: Switch Position 0 1 2 3 5 6 7

PPM CO 20 25 30 35 0 5 50 55

High Alert Settings 100 PPM

Expected Lifespan 10 years

Recommended

Recalibration Time 2 years

Nitrogen Dioxide

Full Scale Span: 10 PPM

Resolution: 0.1 PPM

Minimum Accuracy*: ± 15% or 0.8 PPM

Low Alert Settings: Switch Position 0 1 2 3 5 6 7

PPM NO20.3 0.5 1.0 1.5 2.0 2.5 3.0 .0

High Alert Settings 5.0 PPM

Expected Lifespan 10 years

Recommended

Recalibration Time 2 years

*Allowable tolerance for accuracy and repeatability criteria as defined in Annex A, Item 2 of ANSI/ISA 92.00.01-2010 (R2015)

IOM01

Rev 1.0 – December 22, 2020 7

Description of Front Panel Indicators

The front panel indicators convey to the user the operational status of the detector. The

following table describes the function of each indicator. Please refer to the detector’s front

panel label for the indicator’s location.

Front Panel Indicators

Indicator Color Description

Power Green Glows whenever power is on

Alert 1 Red Blinks or flashes to indicate the condition of Zone 1

Alert 2 Red Blinks or flashes to indicate the condition of Zone 2

Alarm Red Glows after remaining in High Alert for 15 minutes

Zone 1 Yellow Glows whenever the active sensor is assigned to Zone 1

Zone 2 Yellow Glows whenever the active sensor is assigned to Zone 2

Sensor 1 Yellow Glows whenever Sensor 1 is active

Sensor 2 Yellow Glows whenever Sensor 2 is active

Sensor 3 Yellow Glows whenever Sensor 3 is active

Sensor Yellow Glows whenever Sensor is active

-digit Display Red Indicates the gas concentration or error code associated

with the active sensor

IOM01

Rev 1.0 – December 22, 2020 8

Operation Safet Notice

Certain procedures and operations detailed in this manual require that specific precautions be

taken prior to beginning the procedure or operation. When precautions are required, a notice

will be printed in an appropriate location in the manual. The user is urged to read and

understand all such notices.

T pes of Notices

Three types of notices may be used in this manual to describe the severity of the situation

encountered.

WARNING: This notice indicates that conditions exist that could cause personal injury

or loss of life.

CAUTION:Conditions exist that could cause damage to the equipment or other

property.

Note: Special consideration should be given to the procedure or operation,

otherwise an unexpected operational result could occur.

IOM01

Rev 1.0 – December 22, 2020 9

Quick Start Guide

Please read this entire manual before attempting to install and operate this gas detector. This

guide is only intended to provide the basic steps necessary for installation and operation.

Each step will reference the portion of the manual where more complete information can be

obtained.

Step 1 – Mounting

Determine the location for mounting your detector(s). The location(s) may be indicated on the

architectural drawing. Also, the owner or designer of the facility may be consulted. Mounting

guidelines can be found on page 1 of this manual.

Step 2 – Input Wiring

Provide a dedicated circuit with the required operating voltage at each detector mounting

location. Follow all national and local wiring codes. The wiring should be at least 1 AWG. A

conductor connected to earth ground should also be provided. The circuit must include a

disconnect switch located within easy reach of the detector.

If the detector operates from a voltage other than 120 VAC, ensure that the step-down

transformer provides the correct secondary voltage and has the necessary volt-amp rating.

The power requirement for the detector is listed on the front-panel label.

IOM01

Rev 1.0 – December 22, 2020 10

WARNING

This detector may require the use of voltage levels high enough to cause fatal injuries.

Proper procedures must be followed any time work is performed on this unit.

Only qualified personnel should attempt to install, maintain, or service this equipment.

CAUTION

Operating this detector with the incorrect voltage and power requirements can cause internal

electrical components to overheat and fail. Operation with the wrong power requirement will

void the manufacturer’s warranty and the installer will be responsible for any damage that

occurs.

Contact Brasch Environmental Technologies, LLC before connecting power to the detector if

you are unsure of the correct power requirement.

Color-coded wires exiting the detector housing through the top, right conduit connector are

provided for connecting the operating voltage to the detector. Therefore, it should not be

necessary to open the cover on the detector when connecting the voltage supply. Connect the

hot power conductor to the black wire, the neutral conductor to the white wire, and the ground

conductor to the green wire (if present).

Refer to page 15 for further information.

Step 3 – Remote Transmitter Wiring

If remote transmitters are a part of this detector, the detector will supply the operating power to

each transmitter. Use a five-conductor shielded cable with color-coded conductors of at least

18 AWG to connect the power. Three of these connectors provide the positive voltage,

negative voltage, and reference common to the transmitter for power. The remaining

conductors carry the signal from the transmitter to the controller. See figure 10 on page 3

and figure 11 on page for details. If possible, choose a cable with color-coded conductors

that follow the suggested color scheme listed on the drawings.

The transmitter will be shipped with a cable containing five color-coded wires exiting the top of

the housing through a conduit fitting. This cable is labeled “Transmitters” to differentiate the

wiring connections from the relay wiring. If you have chosen color-coded conductors that

match the wire colors, connect the cable conductors to the wires of the same color. If your

cable conductors do not match the wire colors, assign a cable conductor color to each wire

and make a list of this assignment. Follow this color assignment when connecting any other

transmitters in the system. All transmitters share the same conductors back to the controller.

Therefore, a five-conductor cable can be connected from transmitter to transmitter, or from

transmitter to controller, as the situation dictates. Follow the wiring diagrams on page 3 and

to determine the proper connections at the controller.

IOM01

Rev 1.0 – December 22, 2020 11

CAUTION

It is very important that the power and signal connections between each transmitter and

between the transmitters and the Brasch controller be correct. If the connections are wired

incorrectly, damage to both the transmitters and the controller will occur.

Use a cable with color-coded conductors and make sure that the same conductor connects

to the same terminal on each transmitter and the controller.

Do not apply power to the transmitter or controller unless you are sure that the connections

are correct.

Step 4 – Rela Wiring

In most cases, wiring of the ventilation control relays can be completed without opening the

front panel of the detector. Color-coded wires connected to the internal relay terminals extend

outside the housing through the conduit connector located at the top, left of the unit. Use only

the necessary wires required for control of the ventilation components. Cover or seal the ends

of any unused wires and place them safely inside the conduit or electrical box.

Determine the type and number of fans and or make-up air units the detector will control. For

proper installation, you must first determine how and when the fans/make-up air units will

operate. Many installations have only one or two ventilation components designed to operate

simultaneously. These components usually operate from the A1 terminals of the Low Alert

relay. Other ventilation systems contain multiple components designed to operate in two

stages. Connect the primary ventilation components to the A1 terminals of the Low Alert relay

using the yellow wires and the secondary components to the A2 terminals of the High Alert

relay using the brown wires. When using multiple zones, follow the same guidelines as above

using the red wires for A1 and blue wires for A2 of Zone 2.

Do not exceed the specified voltage and power limits of the relays (see page 6). Most

installations require motor starters or larger relays to provide the necessary power

requirements for the ventilation components.

For more information concerning ventilation system operation, read page 17 of this manual.

Step 5 – External Alarms

Determine if the installation requires an external alarm. If so, provide the proper wiring and

connect the wires to the required voltage source. Connect the wiring to the Alarm relay(s)

using the gray wires for Zone 1 and purple wires for Zone 2.

Refer to page 18 for more information concerning the alarm feature.

Step 6 – Appl ing Power

Once you are sure that the wiring connections are correct, apply power to the detector circuit.

When power is first applied, the unit will begin a 150 second countdown on the display while

the indicator LEDs turn on and off in a circular pattern. This is the warm-up phase. Once the

timer reaches zero, the green Power LED will remain solid and the yellow LEDs will begin to

alternate according to how many zones and sensors are present.

See page 18 for more information concerning the initial startup.

IOM01

Rev 1.0 – December 22, 2020 12

Step 7 – Self-Test Mode

This detector is equipped with a self-test mode that can be activated any time after warm-up by

pressing the “SELF TEST” button for approximately 1 second. This mode will test the display,

indicator LEDs, relays, and buzzer for proper operation. Any ventilation components

connected to these relay terminals will operate if their power supply is active. The ventilation

component relays will remain on for 30 seconds to allow sufficient time for testing if problems

occur. There is a 30 second period between each relay actuation. At the end of this test, the

buzzer will sound for 3 seconds and the detector will resume normal operation as described in

step 6.

Page 19 contains a more complete discussion of this self-test mode.

At this point, the detector is now ready to monitor for the presence of the target gas(es) and

control the ventilation system to efficiently remove the gas from the protected area.

IOM01

Rev 1.0 – December 22, 2020 13

Installation

Mounting the Detector

The ability of the detector to sense the target gas and efficiently control the ventilation system

depends greatly upon proper selection of the mounting location. This detector monitors the

area around it by sampling the air that passes by the sensor. Since the sensor is mounted

inside a housing, air must diffuse through the intake vents and pass by the sensor on its way

out the exhaust vents. Therefore, the detector should be positioned where it can sample air

that contains a target gas concentration representative of the average value in that area.

When determining the mounting location, give special consideration to the following guidelines.

•Use one sensor per target gas for each area to be covered.

•Always prioritize locations with the highest occupation density.

•If using remote transmitters, do not locate any further than 1000 feet from the control

unit.

•The types of gases each unit is designed to monitor have densities approximately equal

to that of air. For maximum safety, mount the unit at the average breathing height –

approximately 5 to 7 feet from the floor.

•Avoid mounting locations that would not be representative of the average gas value in

that area. These include but are not limited to locations near doorways, fans, ventilation

inlets and outlets, and areas with air velocities in excess of 3.3 ft/s (1 m/s).

•Avoid locations that would allow direct contact with water. Mounting the unit near

outside garage doors may allow rain to hit the unit when the door is open.

•Avoid locations that are directly in the outlet air vents of heaters or air conditioners.

•Avoid mounting locations with normal ambient temperatures below - °F (-20°C) or

above 122°F (50°C).

•Do not allow exhaust from engines to flow directly on the unit. Each unit is designed to

sense gas concentrations that are 300 to 1000 times less concentrated than the gas

levels found in engine exhaust. Also, engine exhaust contains high levels of other

components. These components can shorten the useful life of the sensor if they contact

the sensor before being diluted by the room air volume.

•Avoid mounting locations where the unit may be hit by passing vehicles. If the unit must

be mounted in these locations, provide a shielding cage around the unit for protection.

IOM01

Rev 1.0 – December 22, 2020 1

•Do not restrict the air flow to the unit housing.

•Do not mount the unit in a corner.

•Do not mount the unit near containers of chemicals such as gasoline, kerosene, alcohol,

or other cleaning fluids. High level concentrations of these chemicals may be mistaken

as the target gas by the sensor and cause false readings. Also, some welding gases

may cause false readings.

The detector is attached in the mounting position in one of two ways.

•Attach the housing to a four inch conduit box using the conduit fittings supplied with the

detector. If you use this method, make sure that the four inch box is securely attached

with screws to a solid support base. Firmly tighten the threaded nuts on the conduit

fittings inside the conduit box so they will not loosen over time.

•Attach the housing to a solid support base using screws through the holes in the

mounting feet.

Find a flat area at least 8 inches high by 11 inches long and place the back of the open

housing flat against it. Using a pencil or other slender marking tool, mark the location of

the four mounting holes using the housing as a template. Start the screws without the

housing in place to avoid any possibility of damage to the housing or circuit boards.

Remove the screws, place the housing in position, and install the mounting screws. Do

not over-tighten the screws as this may crack the plastic housing.

Connecting the Power Suppl

Brasch Gas Detectors are designed to operate from either 120 VAC or 2 VAC. Selection of

the operating voltage is made by the user at the time the detector is ordered. The correct

voltage is listed on the label in the lower, left corner of the front panel.

While this detector does not require much power to operate, it is usually located near

machines that do consume large amounts of power. When these large machines operate, they

cause large voltage spikes to appear on the AC wiring. These spikes can interfere with the

proper operation of the detector. The easiest way to avoid much of this interference is by

IOM01

Rev 1.0 – December 22, 2020 15

WARNING

This detector may require the use of voltage levels high enough to cause fatal injuries.

Proper procedures must be followed any time work is performed on this unit.

Only qualified personnel should attempt to install, maintain, or service this equipment.

providing power to the detector through a dedicated circuit from the service panel. In some

very noisy situations, a line filter can be connected in the power supply circuit just ahead of the

wiring connections at the detector.

Provide a dedicated circuit at the required operating voltage at each detector mounting

location. Follow all national and local wiring codes. The wiring should be at least 1 AWG. A

conductor connected to Earth ground should also be provided. The circuit must include a

disconnect switch located within easy reach of the detector.

If the detector operates from a voltage other than 120 VAC, be sure that the step-down

transformer provides the correct secondary voltage and has the necessary volt-amp rating.

The power requirement for the detector is listed on the label in the lower, left corner of the front

panel.

Color-coded wires exiting the detector housing through the top, right conduit connector are

provided for connecting the operating voltage to the detector. Therefore, it should not be

necessary to open the front cover of the detector when connecting the voltage supply.

Connect the hot power conductor to the black wire and the neutral conductor to the white wire.

If using 120 VAC, also connect the ground conductor to the green wire.

If minor maintenance work needs to be performed on the detector, there is a power switch for

the detector to the left of the incoming power wires on the printed circuit board. By default, this

switch is in the “ON” position so that the front cover does not need to be opened during the

initial installation.

IOM01

Rev 1.0 – December 22, 2020 16

Note

Do not operate the detector on the same AC circuit as the ventilation components. Doing

this will almost always cause improper detector operation.

CAUTION

Operating this detector with the incorrect voltage and power requirement can cause internal

electrical components to overheat and fail. Operation with the wrong power requirements

will void the manufacturer’s warranty, and the installer will be responsible for any damage

that occurs.

Contact Brasch Environmental Technologies, LLC before connecting power to the detector if

you are unsure of the correct power requirement.

Connecting the Remote Transmitters

If remote transmitters are a part of this detector, the detector will supply the operating power to

each transmitter. Use a five-conductor shielded cable with color-coded conductors to connect

the power. Three of these connectors provide the positive voltage, negative voltage, and

reference common to the transmitter for power. The remaining conductors carry the signal

from the transmitter to the controller. See figure 10 on page 3 and figure 11 on page for

details. If possible, choose a cable with color-coded conductors that follow the suggested

color scheme listed on the drawings.

The transmitter will be shipped with a cable containing five color-coded wires exiting the side of

the housing through a conduit fitting. This cable is labeled “Transmitters” to differentiate the

wiring connections from the relay wiring. If you have chosen color-coded conductors that

match the wire colors, connect the cable conductors to the wires of the same color. If your

cable conductors do not match the wire colors, assign a cable conductor color to each wire

and make a list of this assignment. Follow this color assignment when connecting any other

transmitters in the system. All transmitters share the same conductors back to the controller.

Therefore, a five-conductor cable can be connected from transmitter to transmitter, or from

transmitter to controller, as the situation dictates. Follow the wiring diagrams on page 3 and

to determine the proper connections at the controller.

Connecting the Ventilation S stem

As an energy saving device, the main function of the Brasch Gas Detector is to operate the

ventilation system only when necessary. To accomplish this, the detector is equipped with

three control relays per zone with color-coded wires exiting the detector housing through the

top, left conduit connector. The contacts of these relays can control various ventilation system

configurations. Figures 2, 3, , and 5 on pages 21 and 22 give examples of the wiring for the

most common systems. Coil control signals on relays for damper and make-up air units can

IOM01

Rev 1.0 – December 22, 2020 17

CAUTION

It is very important that the power and signal connections between each transmitter and

between the transmitters and the Brasch controller be correct. If the connections are wired

incorrectly, damage to both the transmitters and the controller will occur.

Use a cable with color-coded conductors and make sure that the same conductor connects

to the same terminal on each transmitter and the controller.

Do not apply power to the transmitter or controller unless you are sure that the connections

are correct.

also be connected across the detector’s relay contacts so that these components actuate

simultaneously with the exhaust fans. However, do not exceed the maximum ratings of the

relays, (see page 6).

Please give special attention to the note on each wiring diagram. Jumpers JP5 and JP10 must

be in the proper configuration before power is applied or the ventilation system will not function

correctly. The factory default position for JP5 and JP10 is the “50/100” position. Therefore,

unless a two-speed motor starter is used, or a low-speed fan is to be off if a high-speed fan is

on, the ventilation wiring can be connected without opening the detector front panel cover.

JP5 and JP10 are located on the bottom, left edge of the control board (see figure 9 on page

3). To change the setting to “2-SPEED”, lift the shunt off JP5 and/or JP10 and move it one

pin towards the bottom. Then slide it back on the pins.

Connecting the External Alarm

The Brasch Gas Detector comes standard with an internally mounted alarm. If the target gas

concentration exceeds the High Alert level and remains there for more than 15 minutes, this

alarm will sound. There is also a set of external Alarm contacts that close at the same time.

These external contacts, “ALR COM” and “ALR NC”, can be used to trigger an alarm element

mounted at a remote location.

Figures 2, 3, , and 5 on pages 21 and 22 show typical alarm wiring.

Connecting the Voltage or Current Proportional Output

The Brasch GSE Generation 2 Gas Detectors include circuits that provide either a current loop

or voltage proportional output for each gas sensor. Each output produces a linear response

over the full scale range of the sensor. A detailed description of these outputs can be found

starting on page 27.

Appl ing Power For the First Time

Once all the wiring connections are complete, the detector is ready for power to be applied.

The first 2.5 minutes after the power is turned on serves as a warm-up period. During this

time, the display will count down and the indicator LEDs will cycle in a circular pattern. At the

end of this warm-up period, the detector will begin to display the target gas concentration and

the appropriate LEDs will glow to indicate the active sensor and zone. In most cases, the gas

concentration will be “0.0”. However, if the target gas is present in the monitored area, the

display will indicate the actual concentration. After this warm-up period, the self-test feature

can be activated by pressing the “SELF TEST” button for approximately one second. The

detector will then enter the test mode.

IOM01

Rev 1.0 – December 22, 2020 18

Using the Self-Test Feature

The self-test feature on this detector provides a convenient way to test the major functions of

the complete system. This feature can only be activated after the unit has completed its warm-

up phase. Activate the self-test by pressing the “SELF TEST” button for approximately one

second.

The self-test performs the following events in sequence:

1. Tests each display digit by displaying “0” through “9”

2. Activates the Zone 1 Low Alert relay and indicator LED for 30 seconds

3. Waits for 30 seconds

. Activates the Zone 1 High Alert relay and indicator LED for 30 seconds

5. Waits for 30 seconds

6. Activates the Zone 1 Alarm relay and indicator LED for 30 seconds

7. Waits for 30 seconds

8. Activates the Zone 2 Low Alert relay and indicator LED for 30 seconds

9. Waits for 30 seconds

10.Activates the Zone 2 High Alert relay and indicator LED for 30 seconds

11. Waits for 30 seconds

12.Activates the Zone 2 Alarm relay and indicator LED for 30 seconds

13.Waits for 30 seconds

1 .Activates the internal alarm for 3 seconds

15.Resumes normal operation

Before using the self-test feature, we recommend testing the ventilation system wiring for

correct connections and operating the ventilation components manually. Make any wiring

changes and replace any defective components. Any problems found during the self-test can

then be identified much easier. Although the self-test feature tests much of the detector’s

functions, it does not test the sensors’ response to the target gas. Page 30 gives hints and

procedures for testing the sensors’ response.

IOM01

Rev 1.0 – December 22, 2020 19

T pical Installation Diagrams

IOM01

Rev 1.0 – December 22, 2020 20

Figure 1: Wiring – Typical Layout

Other manuals for GSE Generation 2

1

Table of contents

Other Brasch Gas Detector manuals

Popular Gas Detector manuals by other brands

Seitron

Seitron RGY 000 MBP4 Operation, installation, and maintenance manual

Emerson

Emerson Rosemount 925FGD manual

Opera

Opera 6000 series Installation guidelines

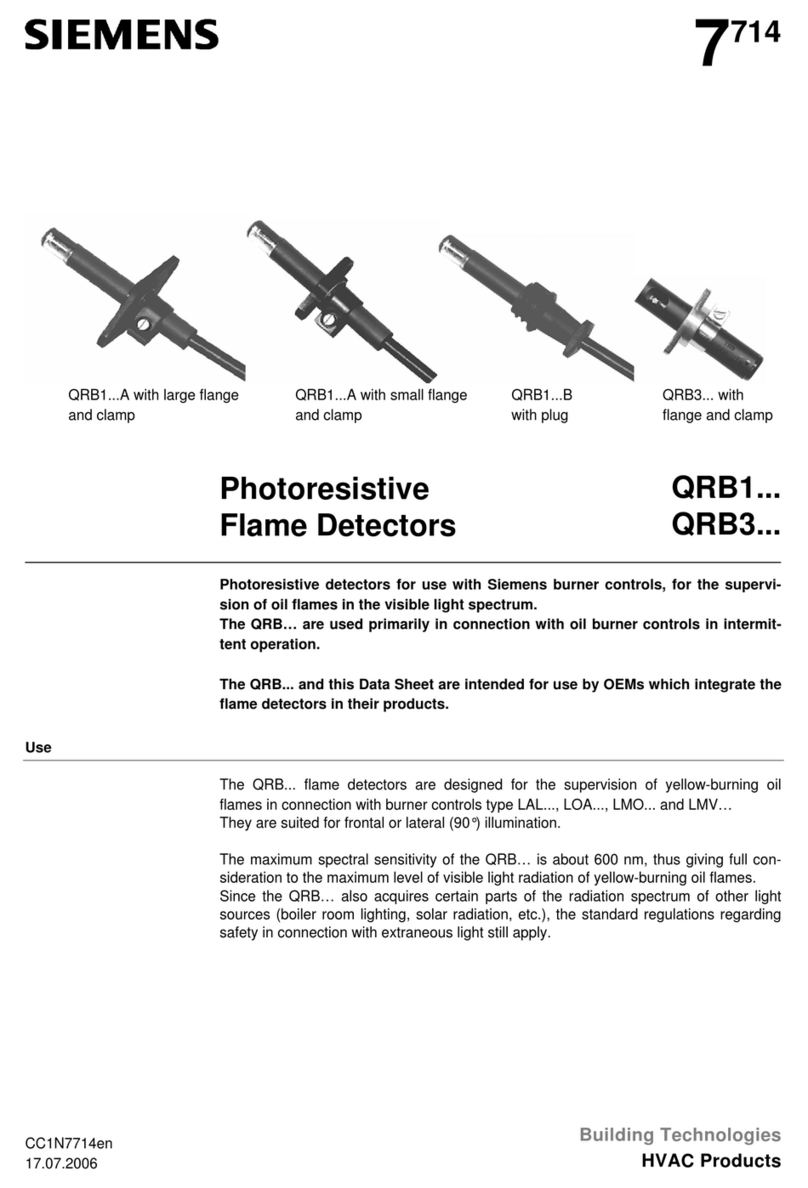

Siemens

Siemens QRB1 Series manual

Crowcon

Crowcon IRmax Installation, Operating and Maintenance Instruction

Sun Nuclear

Sun Nuclear 1029 user guide