SENKO SI-H100 User manual

ⓒCopyright SENKO CO., LTD.

Page 1/ 31

Sampling type Gas Detector

(SI-H100)

Operating Manual

ⓒCopyright SENKO CO., LTD.

Page 2/ 31

Table of contents

1. Description.......................................................................................................................................................4

2. Product composition..................................................................................................................................5

3. Overview ...........................................................................................................................................................6

4. Specifications .................................................................................................................................................7

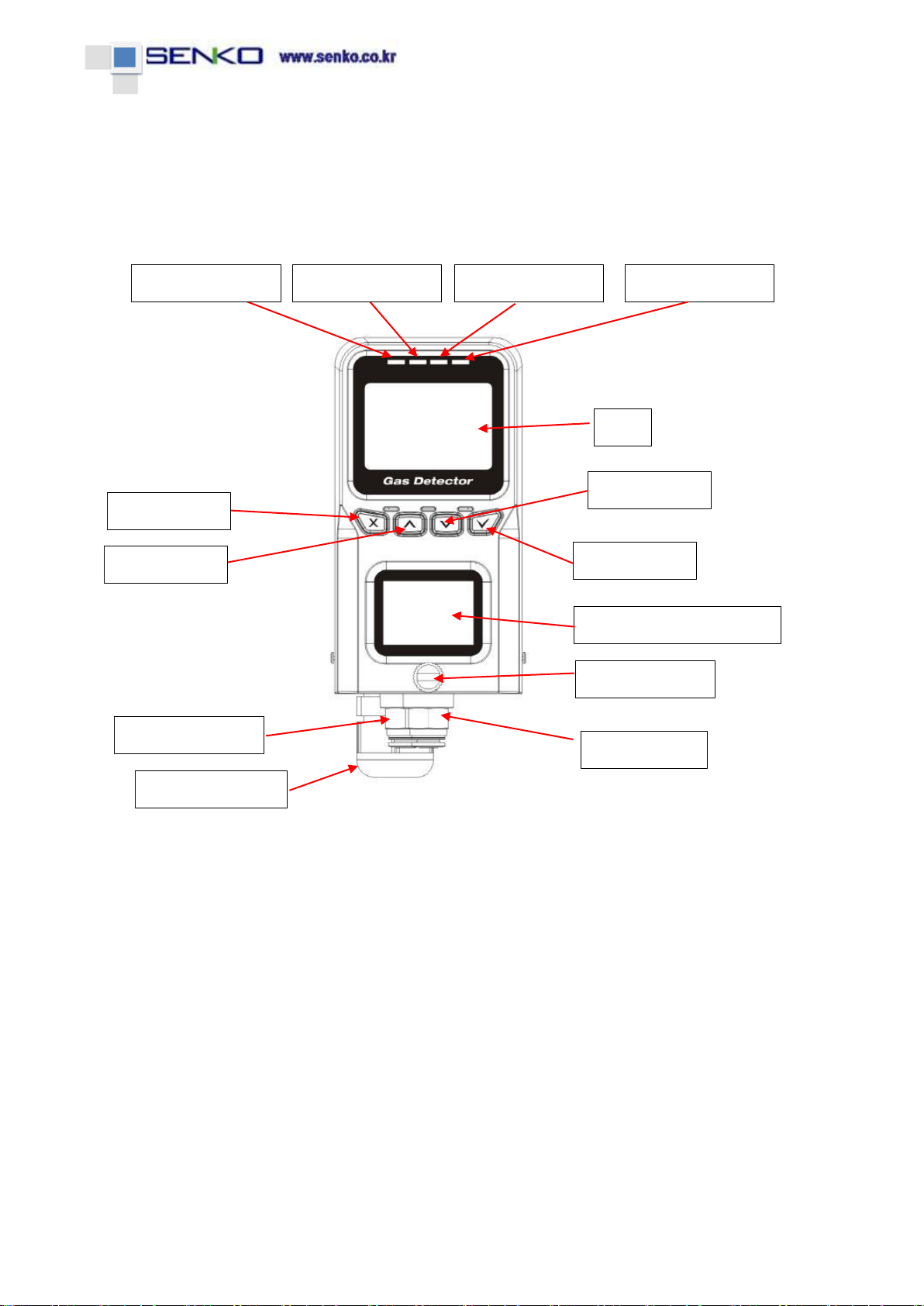

5. Composition and name of each part................................................................................................8

1) Front ............................................................................................................................................................8

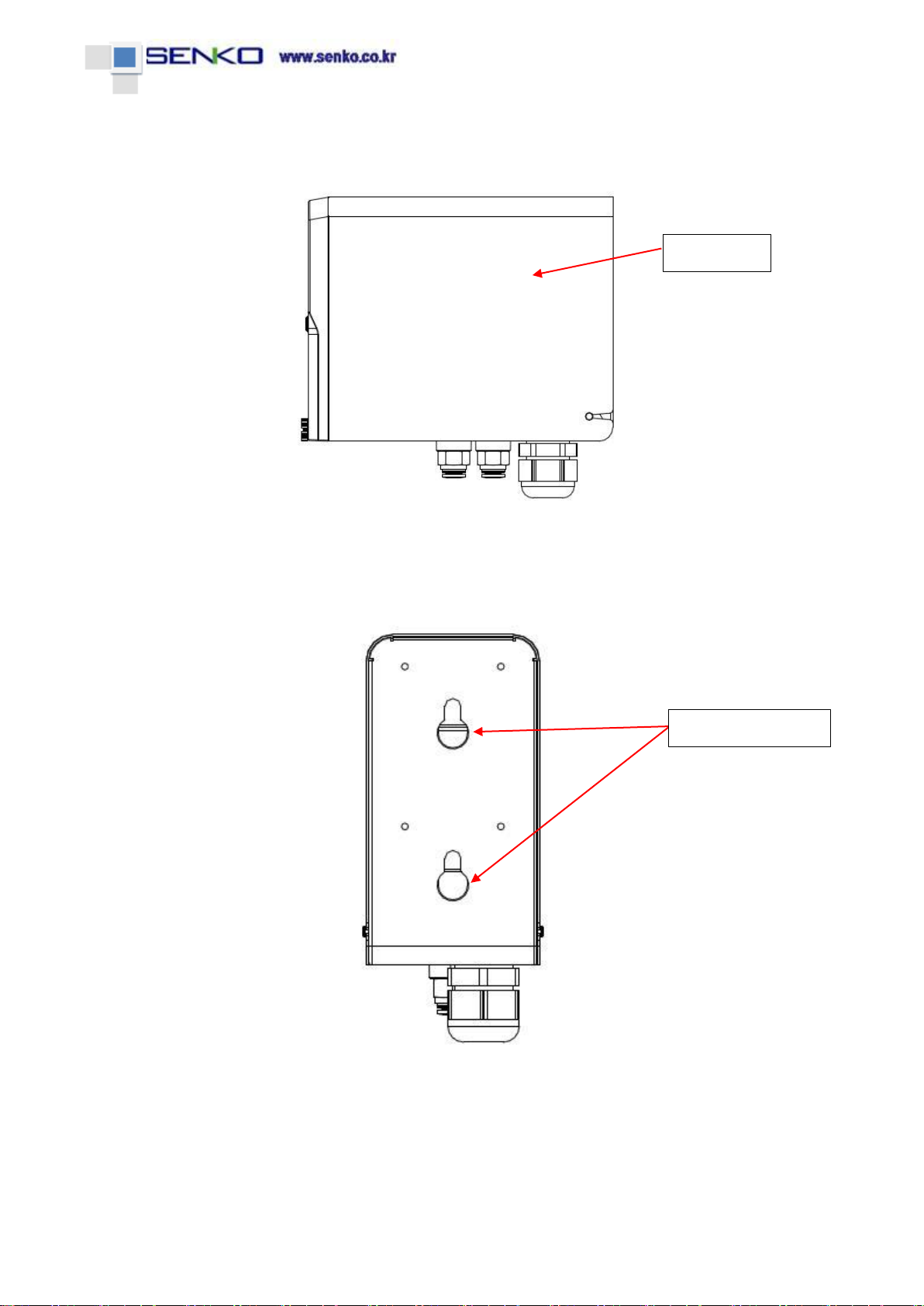

2) Side...............................................................................................................................................................9

3) Rear..............................................................................................................................................................9

4) Bottom..................................................................................................................................................... 10

5) Exploded view of the products ................................................................................................. 10

6. Cable connection (Power board)...................................................................................................... 11

7. Outside view (Dimensions).................................................................................................................. 12

8. Key information......................................................................................................................................... 13

1) Key Description .................................................................................................................................. 13

2) Key State ................................................................................................................................................ 13

9. Power On....................................................................................................................................................... 14

10. Operation Menu..................................................................................................................................... 15

1) Normal Measurement Menu....................................................................................................... 16

2) Setup/Calibration/Review List Basic.............................................................................................. 16

3) Setup/Calibration Menu Change Basic........................................................................................ 16

4) SET 1......................................................................................................................................................... 17

5) SET 2......................................................................................................................................................... 19

6) SET 3......................................................................................................................................................... 20

7) Calibration............................................................................................................................................. 22

8) Review ..................................................................................................................................................... 24

ⓒCopyright SENKO CO., LTD.

Page 3/ 31

11. MODBUS RS485 Address Map ....................................................................................................... 25

11.1 Interface setting................................................................................................................................. 25

11.2 MODBUS RS485 Register.............................................................................................................. 25

12. MODBUS TCP Address Map ............................................................................................................ 26

12.1 Interface setting................................................................................................................................. 26

12.2 MODBUS TCP Register ................................................................................................................... 26

⚫3000X Register Read.......................................................................................................................... 26

⚫4000X Register Read.......................................................................................................................... 26

⚫4000X Register Write......................................................................................................................... 28

13. Length of installed cable................................................................................................................... 28

14. Error Code.................................................................................................................................................. 30

15. Warranty..................................................................................................................................................... 31

16. Amendment history ............................................................................................................................. 31

ⓒCopyright SENKO CO., LTD.

Page 4/ 31

1. Description

Sampling type Gas Detector (SI-H100) measures sample gas by sensor cartridge in the case upon

suction remotely on a real time basis. It is a device that assists to prevent or control a variety of gas

related accidents including suffocation, intoxication, fire, explosion, corrosion, and so on in multiple

semiconductor or industrial sites.

SI-H100 measures the gas concentration on a real time basis constantly and shows alarm of

dangerous concentration, fault situation, and so on, upon attaching on the wall.

By operating four buttons in the lower part of the screen, environmental setting of the device can

be easily amended.

Measured gas concentration is transmitted with 4-20mA output on a real time basis and external

operations according to the desired situations can be variously organized by three internal relays.

In addition, it is possible to output MODBUS/TCP, and to solve data transmission and power at the

same time only with a LAN cable (PoE).

WARNING

Please be aware of the manual before using the device. This device

should be used and maintained according to the instruction and it may

cause the damage of the device, or the user’s injury or fatality in case not

to conform the instruction.

ⓒCopyright SENKO CO., LTD.

Page 5/ 31

2. Product composition

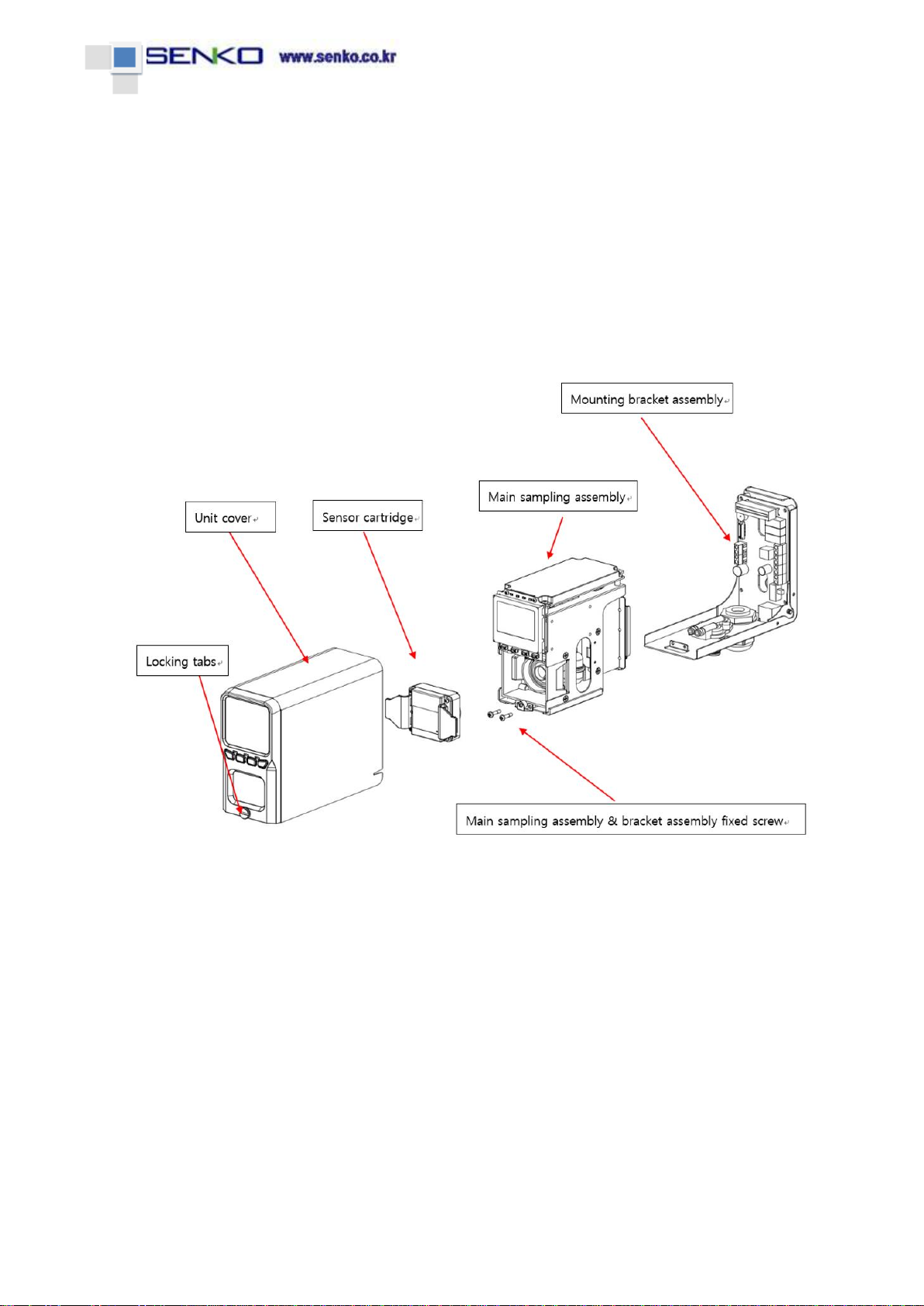

SI-H100 consists of four parts including case, sensor cartridge, main frame, and prob for installation.

Also, it contains the accessary of thermal decomposition module(Pyrolyzer) to be used upon

additional purchasing to be able to detect and measure the gas by thermal decomposition in case

of the materials without gas sensor such as NF3.

ⓒCopyright SENKO CO., LTD.

Page 6/ 31

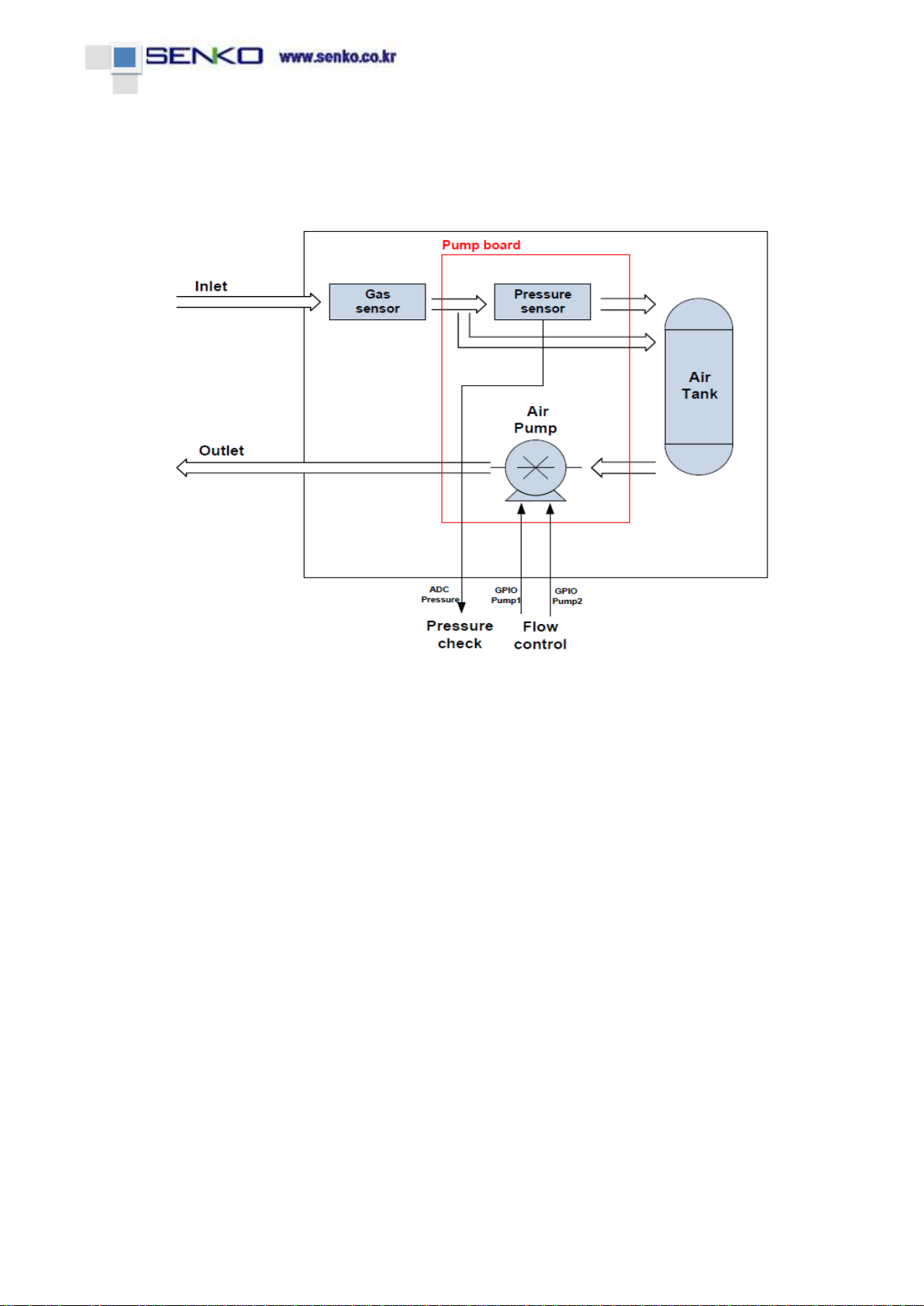

3. Overview

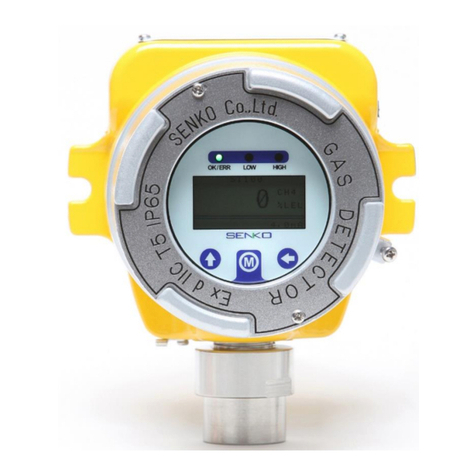

Figure 1 Overview

ⓒCopyright SENKO CO., LTD.

Page 7/ 31

4. Specifications

Item

Specification

Size

124mm(H) X 65mm(W) X 155mm(D)

Weight

2Kg

Operating voltage

DC : 24V ± 10%

PoE : 36V~57V (Typical : 48V)

Flow rate

500mL/min (MAX 900)

Power consumption

Approximately 5.0W

Measurement display

Graphic LCD (160 X 100), gas concentration, flow

rate, alarm, rear light, alarm, device abnormality

Relay

Primary Alarm, Secondary Alarm, Fault Alarm

Output signal

Analog, 4-20mA

Digital communication

RS-485, TCP Ethernet

Sampling distance

Length of input gas tube: up to 30m (FEP tube)

Length of exhaust gas tube: up to 30m (FEP tube)

input/output tube

1/4” Teflon tube

Operating temperature

0°C ~40°C

Certification

CE

Control/Set

4 Button & RS485 & Ethernet

Warranty period of the

device

2 years

Warranty period of

sensor cartridge

1 year

Remote interface

Ethernet, RS-485

Wiring

4 to 20mA / DC power / Relay: up to 14 AWG

ⓒCopyright SENKO CO., LTD.

Page 8/ 31

5. Composition and name of each part

1) Front

Power LED(Green)

Alarm1 LED(Red)

Alarm2 LED(Red)

Fault LED(Red)

LCD

Menu button

Down button

UP button

Select button

Sensor cartridge window

Thumb screw

Gas inlet port

Gas outlet port

Cable Gland

ⓒCopyright SENKO CO., LTD.

Page 9/ 31

2) Side

3) Rear

Unit cover

Mount bracket hole

cover

ⓒCopyright SENKO CO., LTD.

Page 10 / 31

4) Bottom

5) Exploded view of the products

Ethernet/PoE socket

Unit cover

Sensor cartridge

Mounting bracket assembly

Main sampling assembly

Main sampling assembly & bracket assembly fixed screw

Cable Gland

Gas inlet port

Gas outlet port

Locking tabs

ⓒCopyright SENKO CO., LTD.

Page 11 / 31

6. Cable connection (Power board)

Power ON/OFF switch

Ethernet/PoE socket

In case of power supply

with PoE, PoE switch

hub should be used.

Power cable : DC 24V

Power cable : Ground

ALARM LOW(1st) Relay

ALARM HIGH(2nd) Relay

Fault Relay

RS-485 : A

RS-485 : B

4to20mA out : Signal

4to20mA out : Ground

High(2nd) Alarm Jumper : 1-2 :NC /2-3:NO

Low(1st) Alarm Jumper : 1-2 :NC /2-3:NO

Fault Jumper : 1-2 :NC /2-3:NO

ⓒCopyright SENKO CO., LTD.

Page 12 / 31

7. Outside view (Dimensions)

ⓒCopyright SENKO CO., LTD.

Page 13 / 31

8. Key information

1) Key Description

Key

Name

Description

Menu

Menu/Cancel & Return to Previous Step

Up

Movement of List Focus and Value Change

Up Long

Movement of Focus in Screen Setting

Down

Movement of List Focus and Value Change

Down Long

Movement of Focus in Screen Setting

Select

Select and Save

2) Key State

State

Pressed Time

Description

Normal Key

100ms below

Menu and Set value Changes

Long Key

1000ms over

Movement of Focus

Forward/Backward in Each Setting

ⓒCopyright SENKO CO., LTD.

Page 14 / 31

9. Power On

1) Connect the wire after checking power voltage

2) Transit into Measure state after turning on Power LED (Green) and Version information

display

3) It takes about 15 seconds.

Booting and Warm up

Measurement

ⓒCopyright SENKO CO., LTD.

Page 15 / 31

10. Operation Menu

- Pushing Menu key, change the circulation with Normal →SET 1 →SET 2 →SET 3 →CAL

- Enter Review with Select key in Normal, return to Normal with Menu key.

[Power On]

[Normal Measure]

[SET 1]

[SET 2]

[SET 3]

[Calibration]

[Review]

ⓒCopyright SENKO CO., LTD.

Page 16 / 31

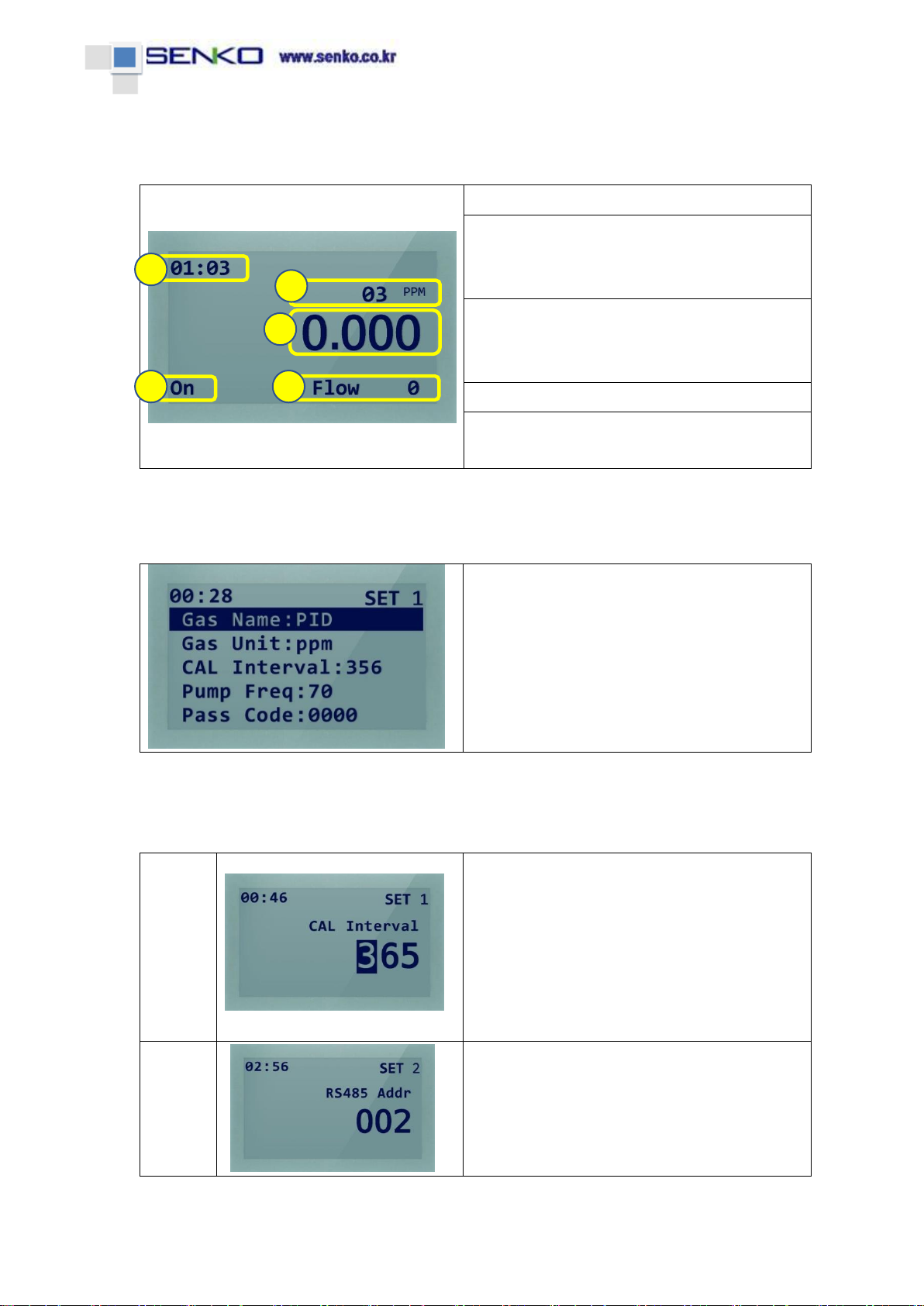

1) Normal Measurement Menu

Current time: display 24-hour system

Current sensor gas type / concentration unit

- O3: gas type in the installed sensor

- ppm: concentration unit

Concentration of measured gas

- Decimal position is changed according to the

measurement range of the sensor.

Sensor On/Off State

Pump flow rate

- Current suction flow rate

2) Setup/Calibration/Review List Basic

1. Current Menu display upper right

- SET1, SET2, SET3, CAL, REVIEW

2. Move List Focus by Up/Down Key

3. Pushing Select key, enter the setting screen

- In case the related setting is not possible, no

screen change

4. Pushing Menu key, move the next Menu

3) Setup/Calibration Menu Change Basic

Menu

with

Focus

1. Change number 0-9 with Up/Down key

2. Move Focus by Up/Down long Key

- Pushing Down Long key, Focus movement

in the order of 3 →6 →5 →3

3. If Focus is moved with the number over

setting range, it is changed into Max value or

effective value, automatically.

Menu

without

Focus

1. Change the number with Up/Down key

2. Input Up/Down Long key increases or

decreases the number continuously.

1

4

5

2

3

ⓒCopyright SENKO CO., LTD.

Page 17 / 31

4) SET 1

1) Gas Unit: Gas concentration unit

2) CAL Interval: Set calibration interval

3) Pump Freq: Control suction amount by setting Frequency of Gas Suction Pump

4) Pass Code: Set Setup and Calibration entry passcodes

5) Inhibit: Set items to inhibit

6) Buzzer: Buzzer On/Off in case of Alarm occurrences

7) Resp Factor: Value of fine control for Gas concentration

8) Sensor Off: Control the time from On to Off of Sensor automatically (for VOC sensor)

9) RS485 Addr: Set device address during RS485 communication

1) Gas Unit

▶Adjust concentration unit with Up/Down key

▶Cancel with Menu key, Save with Select key

▶Possible to set ppm/ppb/Vol/LEL

▶Default: ppm

2) CAL Interval

▶Change number 0-9 with Up/Down key

▶Move Focus with Up/Down Long key

-Up Long: Move Focus left

-Down Long: Move Focus right

▶Cancel with Menu key, Save with Select key

▶Possible to set up to 0 ~ 999 days

▶Default: 365 days

3) Pump Frequency

▶Adjust number with Up/Down key

▶Adjust number continuously with Up/Down Long key

▶Cancel with Menu key, Save with Select key

▶Flow : Display current flow rate

▶Default : 60 Hz

4) Pass Code

▶Adjust number (0-9) with Up/Down key

▶Move Focus with Up/Down Long key

-Up Long : Move Focus left

-Down Long : Move Focus right

▶Cancel with Menu key, Save with Select key

▶Set only in case of input the same Pass Code twice

▶In case of setting Pass Code with the value other than

0000, entry is possible only with input Pass Code upon

entry to setting by Menu key.

▶Default : 0000

ⓒCopyright SENKO CO., LTD.

Page 18 / 31

5) Inhibit

▶Set Inhibit item with Up/Down key

▶Cancel with Menu key, Save with Select key

▶None: No Inhibit

Alm: Alarm Inhibit

Alm&Flt: Alarm, Fault Inhibit

Full: Inhibit all items

▶Default: None

6) Buzzer

▶Set Buzzer On/Off with Up/Down key

▶Cancel with Menu key, Save with Select key

▶On: In case of Alarm, Buzzer sound

Off: In case of Alarm, no Buzzer sound

▶Default : On

7) Resp Factor

▶Adjust number (0-9) with Up/Down key

▶Move Focus with Up/Down Long key

-Up Long: Move Focus left

-Down Long: Move Focus right

▶Cancel with Menu key, Save with Select key

▶It will be output by multiplying the final concentration.

▶Default : 1.00

8) Sensor Off Time

▶Adjust number with Up/Down key

▶Adjust number continuously with Up/Down Long key

▶Cancel with Menu key, Save with Select key

▶Automatic Off time: Off(Always On), 1~120 seconds

-Menu only for VOC sensor (PID)

-Sensor Power Off if the related time is passed

▶Default : Off

9) RS485 Addr

▶Adjust number with Up/Down key

▶Adjust number continuously with Up/Down Long key

▶Cancel with Menu key, Save with Select key

▶RS485 Address(ID) : 1 ~ 247

▶Default : 1

ⓒCopyright SENKO CO., LTD.

Page 19 / 31

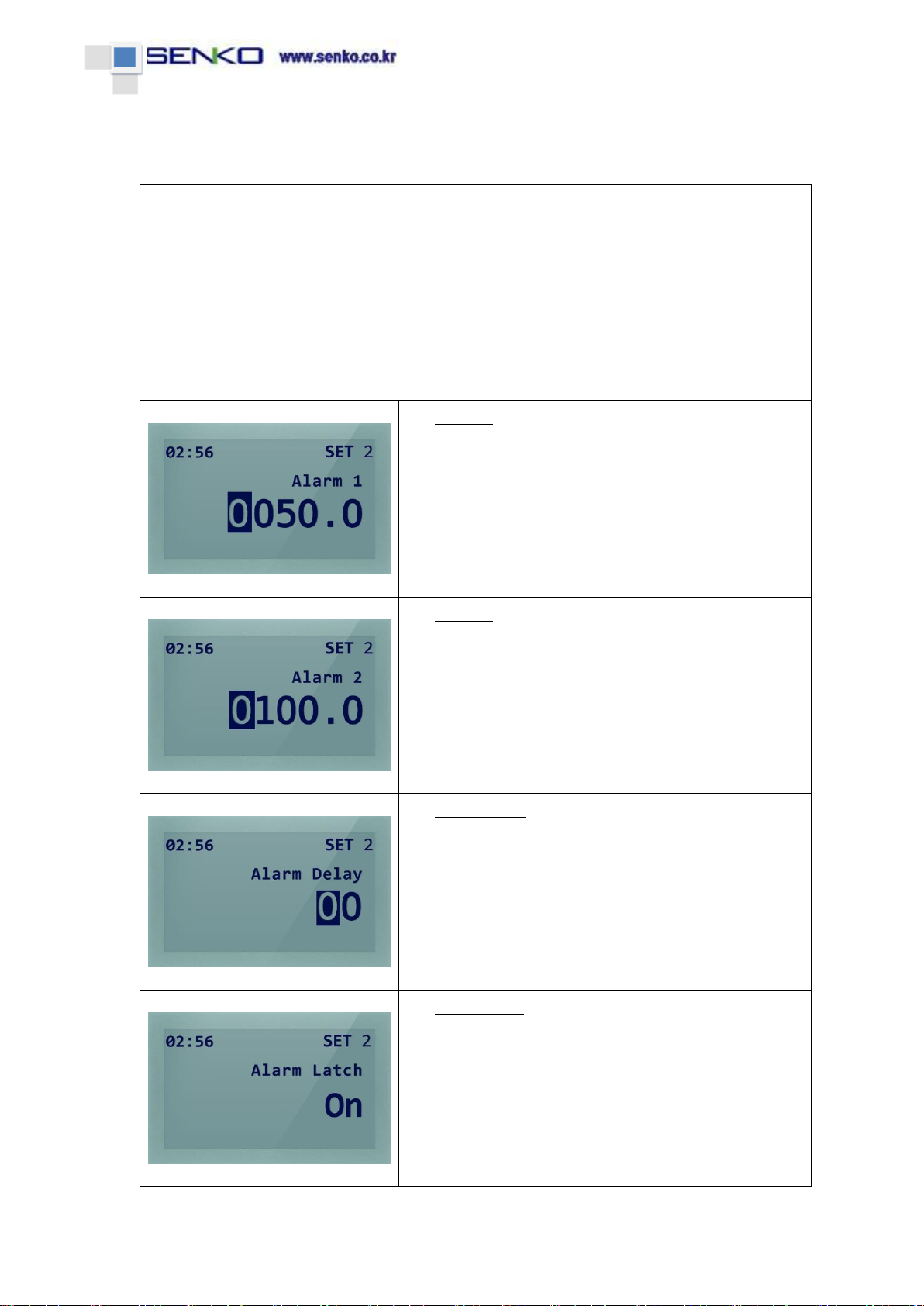

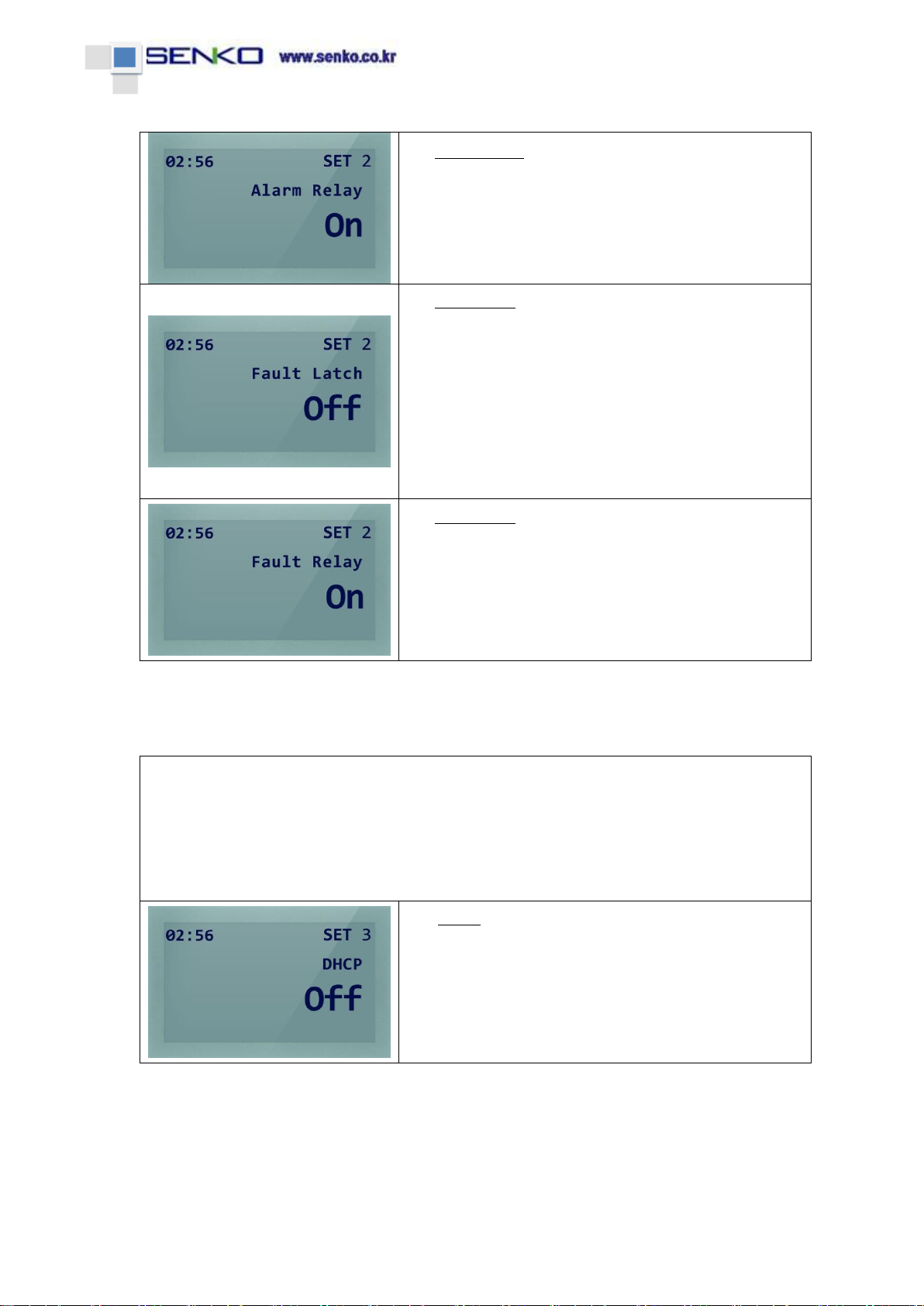

5) SET 2

1) Alarm 1: Set Alarm Level 1(Low)

2) Alarm 2: Set Alarm Level 2(High)

3) Alarm Delay: Alarm is occurred after the setting time in case achieving the concentration

of Alarm 1, 2

4) Alarm Latch: Set whether to clear Automatic or Manual after Alarm occurrence

5) Alarm Relay: Set whether to operate Relay simultaneously in case of Alarm occurrence

6) Fault Latch: Set whether to clear Automatic or Manual after Fault occurrence

7) Fault Relay: Set whether to operate Relay simultaneously in case of Fault occurrence

1) Alarm 1

▶Adjust number (0-9) with Up/Down key

▶Move Focus with Up/Down Long key

-Up Long : Move Focus left

-Down Long : Move Focus right

▶Cancel with Menu key, Save with Select key

▶Alarm Level 1 : 0 ~ 9999.9 ppm

▶Default : 50.0 ppm

2) Alarm 2

▶Adjust number (0-9) with Up/Down key

▶Move Focus with Up/Down Long key

-Up Long : Move Focus left

-Down Long : Move Focus right

▶Cancel with Menu key, Save with Select key

▶Alarm Level 2 : 0 ~ 9999.9 ppm

▶Default : 100.0 ppm

3) Alarm Delay

▶Adjust number (0-9) with Up/Down key

▶Move Focus with Up/Down Long key

-Up Long : Move Focus left

-Down Long : Move Focus right

▶Cancel with Menu key, Save with Select key

▶Alarm Delay : 0 ~ 99 seconds

▶Default : 0 second

4) Alarm Latch

▶Set Alarm Latch with Up/Down key

▶Cancel with Menu key, Save with Select key

▶On: Alarm is not cleared even if Alarm condition is

cleared after Alarm occurrence

Off: Alarm is automatically cleared if Alarm condition

is cleared after Alarm occurrence

▶Default : Off

ⓒCopyright SENKO CO., LTD.

Page 20 / 31

5) Alarm Relay

▶Set Alarm Relay with Up/Down key

▶Cancel with Menu key, Save with Select key

▶On: Operate Relay in case of Alarm occurrence

Off: Do not operate Relay in case of Alarm occurrence

▶Default : On

6) Fault Latch

▶Set Fault Latch with Up/Down key

▶Cancel with Menu key, Save with Select key

▶On: Fault is not cleared even if Fault condition is

cleared after Fault occurrence

Off: Fault is automatically cleared if Fault condition is

cleared after Fault occurrence

▶Default : Off

7) Fault Relay

▶Set Fault Relay with Up/Down key

▶Cancel with Menu key, Save with Select key

▶On: Operate Relay in case of Fault occurrence

Off : Do not operate Relay in case of Fault occurrence

▶Default : On

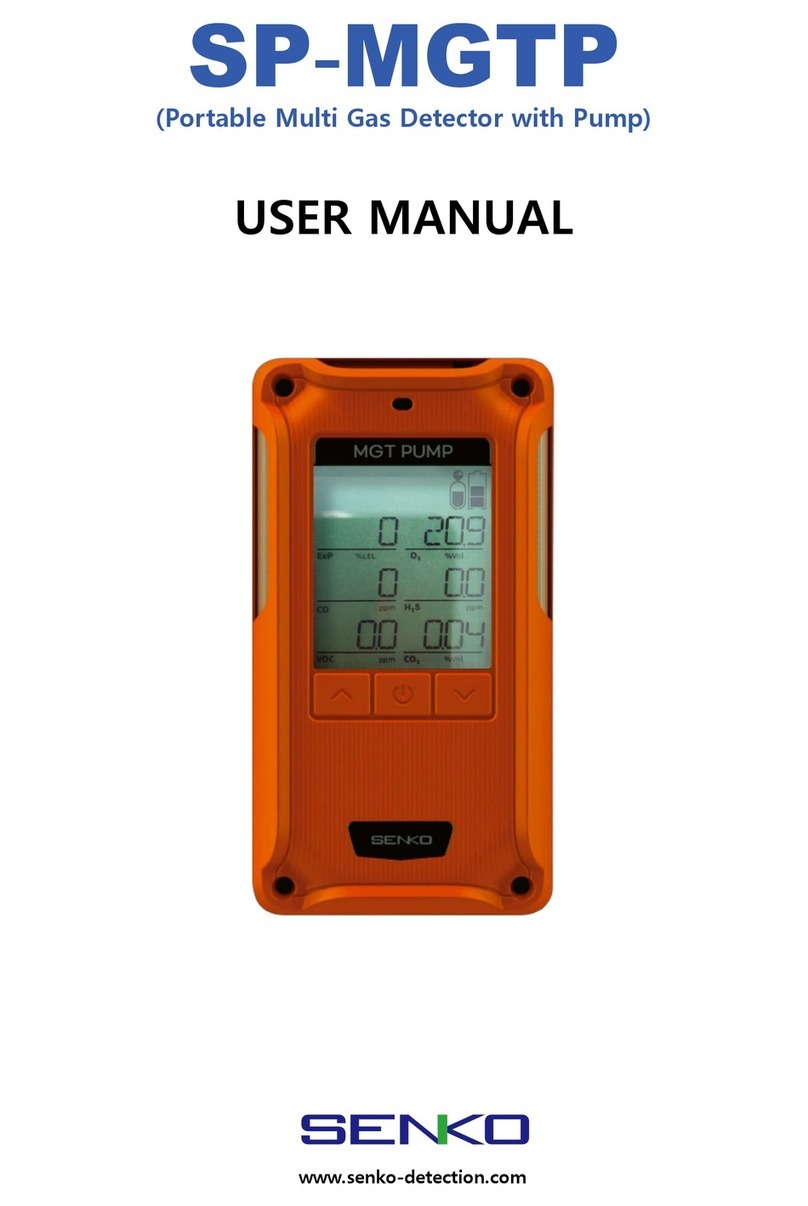

6) SET 3

1) DHCP: Set Network DHCP On/Off

2) IP Address: Set Network IP Address

3) Subnet Mask: Set Network Subnet Mask

4) Gateway: Set Network Gateway

5) Time: Set time and date

6) Backlight: Set Backlight in case of Alarm/Fault

1) DHCP

▶Set DHCP with Up/Down key

▶Cancel with Menu key, Save with Select key

▶On: Automatically allocate Network IP Address

Off: Manually allocate Network IP Address

▶Default : Off

Other manuals for SI-H100

1

Table of contents

Other SENKO Gas Detector manuals

SENKO

SENKO SP secure User manual

SENKO

SENKO SI-560D User manual

SENKO

SENKO SP-MGTP User manual

SENKO

SENKO SGT-P User manual

SENKO

SENKO iGas Detector CO2 User manual

SENKO

SENKO RAITEC SI-100D User manual

SENKO

SENKO SP-MGTP User manual

SENKO

SENKO SI-300 User manual

SENKO

SENKO SGT User manual

SENKO

SENKO MGT User manual

Popular Gas Detector manuals by other brands

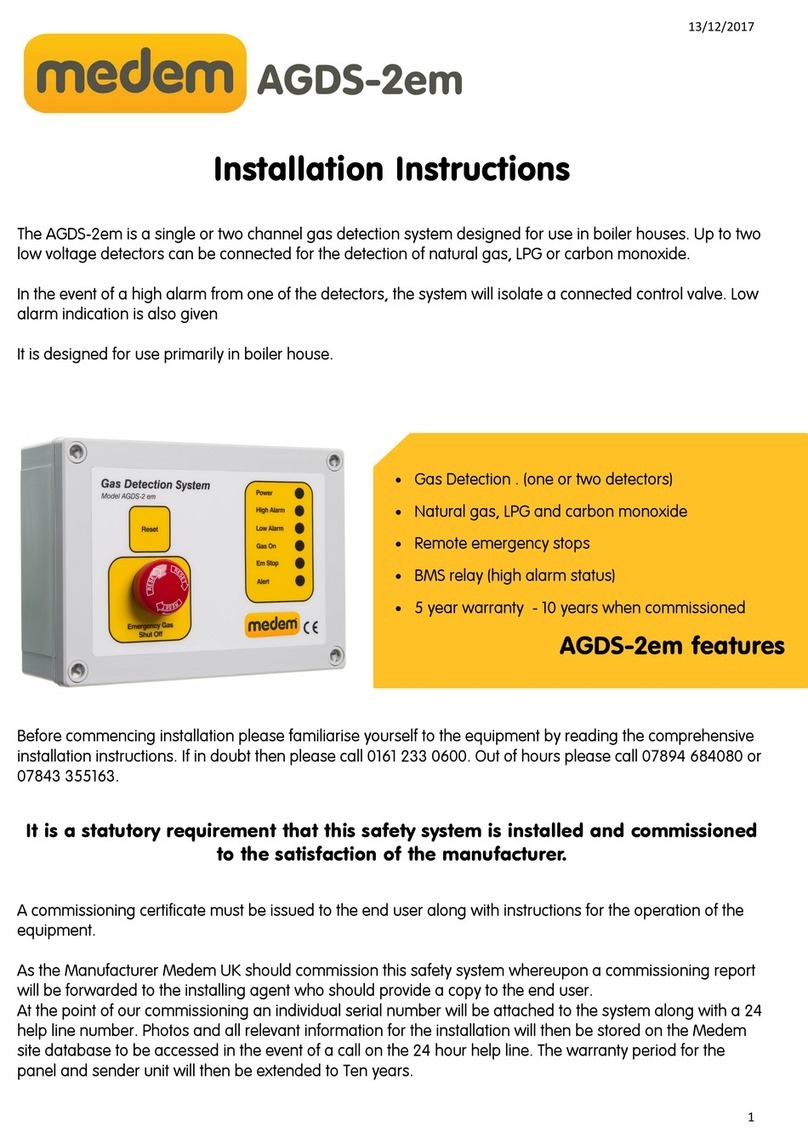

Medem

Medem AGDS-2em installation instructions

ABB

ABB 2CSE1220EL manual

Pilot Communications

Pilot Communications 2011319/716/12 Operation and maintenance manual

MSA

MSA ALTAIR4 Quick start card

S&S Northern

S&S Northern MERLIN GDP2-X Installation & operation manual

New Cosmos Electric

New Cosmos Electric ML-310 user manual