BrassCraft ProCoat CSSL User manual

THE SAFE, EASY WAY TO INSTALL HOME GAS APPLIANCES.

Coated stainless steel gas appliance connectors provide a

safe and easy method to install gas ranges, water heaters,

ovens, furnaces and gas dryers. The corrugated tube

allows the exibility you need to align the appliance to the

rigid gas supply pipe. The proprietary coating provides

excellent available corrosion protection from most harsh

household cleaning and plumbing repair chemicals.

❏Approved for use with natural, manufactured, L.P.

(propane), and L.P. air mixture gases with internal

line pressure no greater than 1/2 lb. per square

inch (psi).

❏Design certied by CSA, and listed by the New York

City Board of Standards and Appeals and the

Commonwealth of Massachusetts.

❏Designed, Machines and Assembled in the USA and

100% leak tested.

CAUTION: DO NOT INSTALL THIS PRODUCT UNTIL YOU READ AND UNDERSTAND

ALL INSTRUCTIONS. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY, PROPERTY DAMAGE OR PRODUCT FAILURE.

Even an outstanding system can become a hazard due to poor installation, inspection

or testing. Please read all precautions and installation instructions before beginning

connector installation.

SAFETY PRECAUTIONS:

❏ WARNING: Gases can be ignited by a ame or spark, which may result in an

explosion. Please follow installation instructions carefully. When in doubt, call a

licensed plumber or your local gas company.

❏ WARNING: DO NOT re-use connectors, ttings and valves; they are designed for

use on original installation only. Removal of connector and additional handling may

damage connector making it unsafe for reuse.

❏ WARNING: DO NOT use this connector if it has been in a re. Fire can damage

the connector making it unsafe for use.

❏ WARNING: DO NOT use this connector on

appliances equipped with rollers or casters.

This connector is designed for limited movement

after installation. Repeated bending, exing or

extreme vibration can cause metal fatigue. Normal

vibration and movement of standard household gas

dryer or similar appliance is okay.

❏ WARNING:

DO NOT use connectors to make a

direct connection to LP gas containers. Connection

MUST be made to the regulator device only.

❏ WARNING: DO NOT use connector on appliances

in moving vehicles such as RV’s, trailers, etc.

However, this product may be used in manufactured

housing (permanent residence mobile homes).

ProCoat®

COATED STAINLESS STEEL GAS CONNECTORS

SELECTION & INSTALLATION INSTRUCTIONS

For Residential and Commercial Gas Appliances

❏ WARNING: DO NOT use this connector with

infrared radiant tube heaters. Cyclic movement of

heater may cause connector to fail.

❏ WARNING: Keep cleaning solvents containing

ammonia or chlorine away from an uncoated

or damaged gas connector. DO NOT store these

solutions near connector or use the connector near a

swimming pool or hot tub. Water rinse the connector

thoroughly if exposed to these chemical products.

❏ WARNING: DO NOT join this connector to another connector.

❏WARNING: DO NOT stretch connector to make it t. Connector must be at least

2 to 3 inches longer than the distance from the gas supply line to appliance when

pulled out from the supply at its maximum length.

WARNING: Connector is for use in accessible locations only. DO NOT conceal

connector or run connector through enclosed outdoor BBQ pits, walls, partitions,

oors or appliance panels.

❏ WARNING: DO NOT connect gas connector nuts directly to pipe threads of gas

supply pipe or appliance. Install connector using the ttings provided. (see Figure A)

CODES AND REGULATIONS

Gas appliance and connector installation MUST conform with all local codes and

regulations including municipal and state building codes, and to all local utility

regulations. In the absence of local code, the installation must conform with the

National Fuel Gas Code ANSI Z223.1/ NFPA No. 54, Uniform Plumbing Code, or

International Fuel Gas Code. Contact your local gas company for details.

INSTALLATION INSTRUCTIONS:

WARNING: Turn off gas supply before disconnecting old appliance. In absence of

manual shut-off valve near appliance location, gas MUST be shut off at main valve,

near meter.

NOTE: Fuel gas codes require installation of a manual shut-off valve in the same

room, within easy reach of the appliance (i.e. within 6 feet).

1. Clean all pipe threads with a wire brush and rag to ensure connections are free

of any debris such as metal shavings, rust, dirt, oil or water.

2. Apply pipe thread sealant to the male pipe threads

of connection. DO NOT apply sealant or tape to are

ends of ttings or shut-off valve. Sealant and tape

will prevent this connection from sealing properly.

3. If necessary, thread new manual shut-off valve onto

gas supply pipe, wrench tighten.

4. Thread steel tting to manual shut-off valve and

other steel tting onto appliance regulator.

5. Thread are nuts of gas connector onto shut-off valve and steel tting. Wrench

tighten all connections.

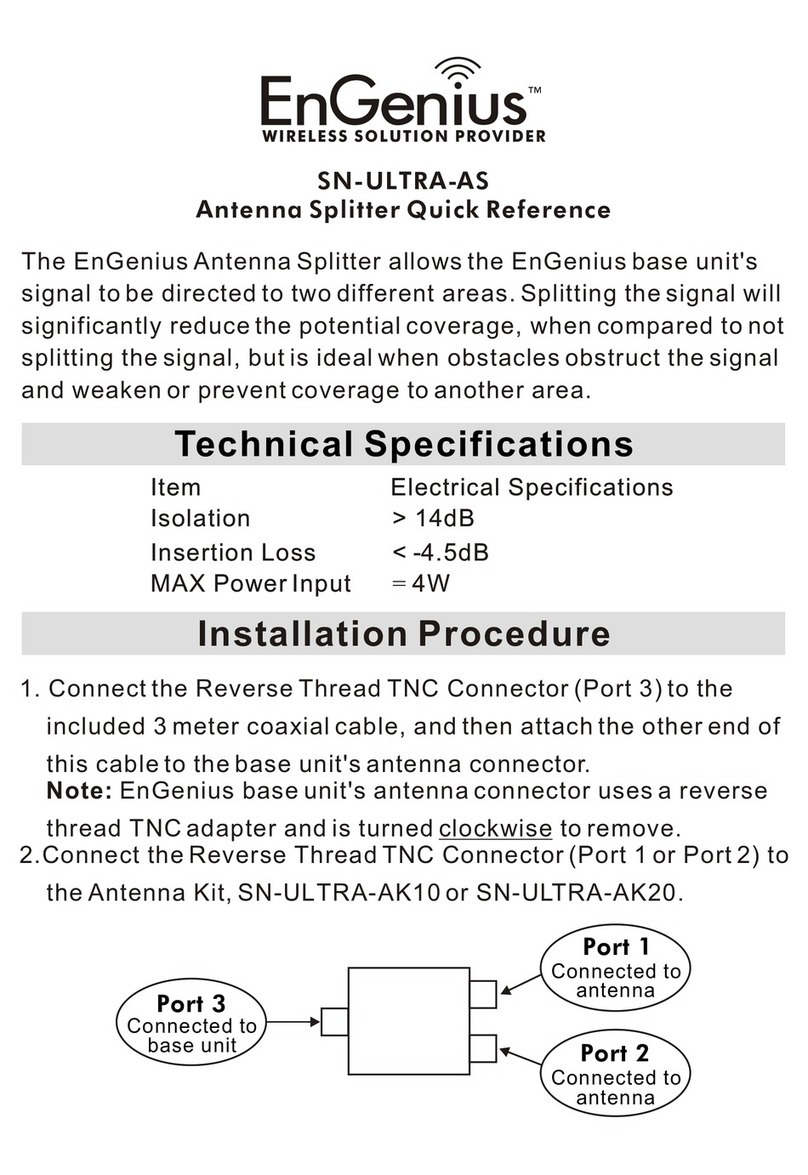

TO METER

Figure A

TO APPLIANCE

WARNING: DO NOT stretch the connector to

make it t. Connector must be long enough to

allow the appliance to be positioned at its farthest

anticipated connected distance from the gas supply

without stretching, twisting or bending smaller that a

1-1/2 internal diameter (diameter of a golf ball).

WARNING: DO NOT trap connector against sharp

edges or corners.

CAUTION: DO NOT kink, twist or bend connector sharply.

6. Turn manual shut-off valve on to allow gas to enter system.

WARNING: DO NOT TURN ON APPLIANCE until all

connections have been leak tested!

WARNING: DO NOT USE matches, candles, open

ames or other sources of ignition to leak test

connections!

7. Test all connections with leak test solution provided,

or with clear soap and water solution; bubbles will

indicate a leak. If a leak is detected, turn off gas

supply before further tightening connections. Water

rinse and towel dry connector once test is complete.

8. Wait at least 10 minutes to be certain that all vapors

have dissipated. If leak test conrms connections do

not leak gas, and you do not smell any gas,

THEN light pilot(s) and turn on appliance.

Tools Needed for Installation:

• (2) 10 in. adjustable wrenches

• Pipe dope or gas pipe thread tape

• Leak detection solution

X

©2009, 2019 Brasscraft Manufacturing Company 325.01 Rev. 11/19

Brasscraft Manufacturing Co., 39600 Orchard Hill Place Novi, Michigan 48375-5331

TOLL-FREE: 877.272.7755 FAX: 248.305.6011 www.brasscraft.com

Manufacturer assumes no responsibility for failure due to improper installation.

©2019 Brasscraft Manufacturing Company, Novi, MI 48375-5331 U.S.A.

All Rights Reserved. www.brasscraft.com BrassCraft®brand is a trademark of Brasscraft Mfg. Co.

El fabricante no asume ninguna responsabilidad si la instalación no se hace de acuerdo al instructivo.

BrassCraft®brand es una marca registrada de Brasscraft Mfg. Co.

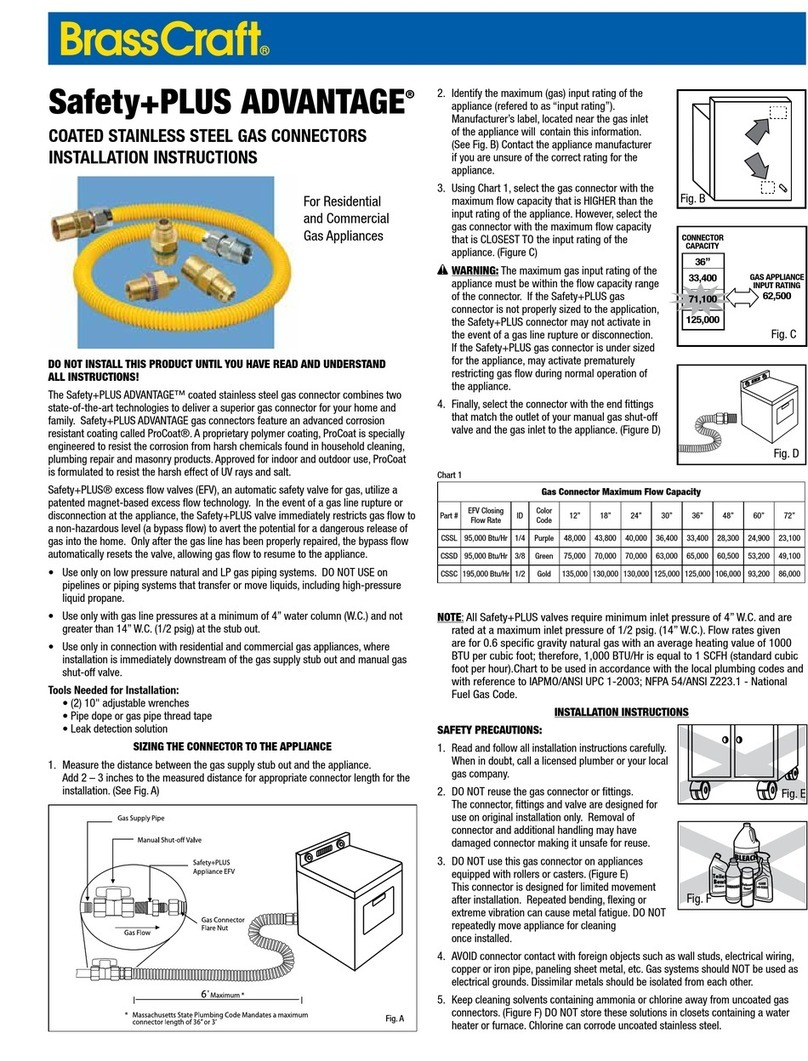

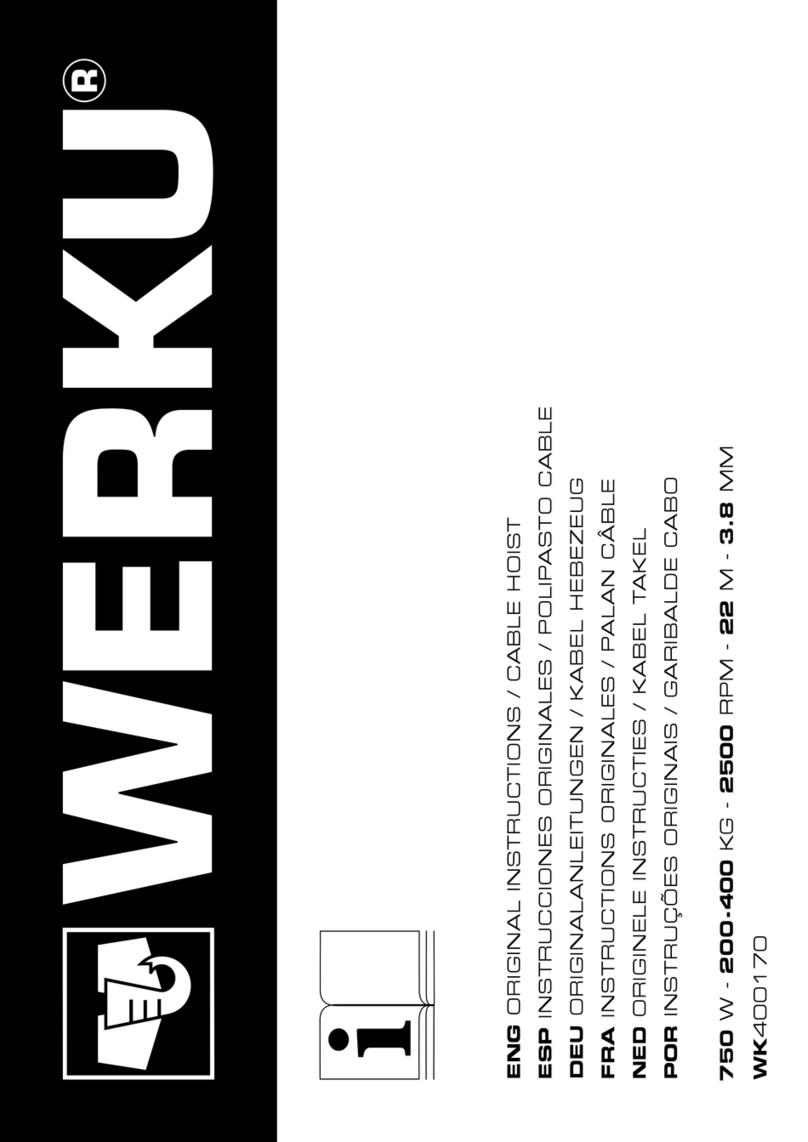

Gas Connector Maximum Flow Capacity

Part # ID

Color Code 12 in 18 in 24 in 30 in 36 in 48 in 60 in 72 in

Gas Connector with Standard Fittings

CSSL

1/4 BTU’s 48,000 43,800 40,000 36,400 33,400 28,300 24,900 23,100

Purple Watts 14,067 12,837 11,723 10,668 9,789 8,294 7,297 6,770

CSSD

3/8 BTU’s 102,000 93,100 85,000 77,100 71,100 60,500 53,200 49,100

Green Watts 29,893 27,285 24,911 22,596 20,837 17,731 15,591 14,390

CSSC

1/2 BTU’s 180,000 164,200 150,000 136,000 125,000 106,000 93,200 86,000

Gold Watts 52,752 48,122 43,961 39,858 36,634 31,066 27,314 25,204

Safety+Plus® (Gas Connector with Excess Flow Valve Attached)

CSSL

1/4 BTU’s 42,000* 37,400* 36,800* 36,400 33,400 28,300 24,900 23,100

Purple Watts 12,308* 10,960* 10,784* 10,668 9,789 8,294 7,297 6,770

CSSD

3/8 BTU’s 102,000 93,100 85,000 77,100 71,100 60,500 53,200 49,100

Green Watts 29,893 27,285 24,911 22,596 20,837 17,731 15,591 14,390

CSSC

1/2 BTU’s 122,000* 118,000* 115,000* 111,000* 107,000* 106,000 93,200 86,000

Gold Watts 35,754* 34,581* 33,702* 32,530* 31,358* 31,066 27,314 25,204

*

Note: Connecting the safety valve lowers these values below the Z21.24/CSA 6.10 and Z21.75/CSA 6.27 standards

Listings & Certications:

Components CSA listed to ANSI Z21.24 / CSA 6.10 standard “Connectors for

Gas Appliances”

Components CSA listed to ANSI Z21.75 / CSA 6.27 standard “Connectors for

Outdoor Gas Appliances & Manufactured Homes”

NOTE: This connector meets or exceeds the minimum allowable capacity

as determined under test conditions specified in ANSI Z21.24 • CSA 6.10.

Straight length capacity rated in BTU per hr. using: 0.64 SP. Gr., 1000 BTU per

Cu Ft. Gas at 0.50 inch Water Column Pressure Drop. The capacity at 50 Pa

(0.2 inch water column) pressure drop can be determined by multiplying the

BTU per hr. listed in the table above by 0.632

.

This manual suits for next models

2

Other BrassCraft Cables And Connectors manuals