Page 3 of 11

IN0021 Rev11 Dec 2020

two leads of a three-phase motor will reverse the rotation. Momentarily start or "bump"

the motor to check the rotation of the pump shaft.

This test has be to carried out without liquid in the pump, otherwise the impeller

can be seriously damaged

IV. PRIMING

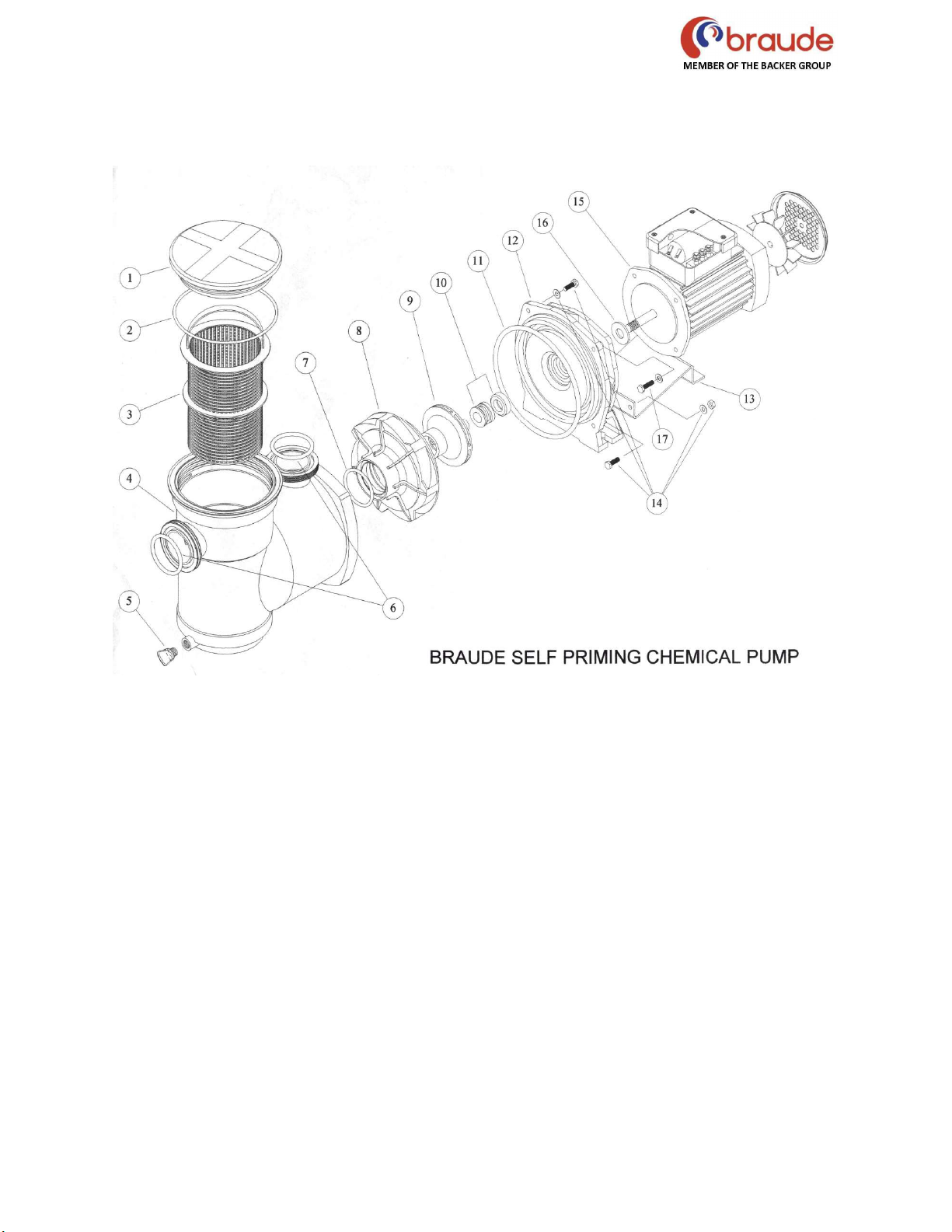

Fill the pump tank with water or the process liquid to be pumped. This may be done by

removing the strainer cover lid. When replacing this cover, caution should be taken to

avoid tightening more than "hand tight" (The pump lid may be secured firmly using the

tool supplied, taking care not to over tighten). BRAUDE Pumps prime themselves

providing the pump tank is filled with liquid.

V. OPERATION

Should you lose the priming or process liquid accidentally or by draining purposely, it

will be necessary to refill it with liquid before starting. High suction lifts, or long suction

lines, require additional time and reduce the performance of the pump. Should you have

difficulty, refer to the "Problem Solving Guide".

The latest engineering advancements have been incorporated into our self-lubricating

shaft seal. The liquid being pumped cools and lubricates the seal. Running the pump

dry will damage the seal. Always keep liquid in the pump tank. No further lubrication of

the pump end is necessary.

After the pump has been filled with liquid, and the motor started, allow a few moments

for the pump to start delivering liquid. If flow does not start within five minutes, stop

motor and determine cause (see Problem Solving Guide). Be sure all suction and

discharge valves are open when the pump is running. Operating the pump with a closed

valve in the system can cause pump damage.

VI. MAINTENANCE

The strainer built into the pump should be inspected and cleaned at regular intervals.

The strainer is easy to clean, remove the strainer cover lid to expose the strainer basket.

Remove and clean. Inspect the cover gasket 'O' ring, if damaged, replace. Replace

cover lid, “hand tight”. (The pump lid may be secured firmly using the tool supplied,

taking care not to over tighten).

When not in use if the pump is installed outside or in a position where temperatures will

drop to below freezing point, the pump should be completely drained of all liquid by

removing the drain plug, it can be stored in a strainer basket. In severe conditions and