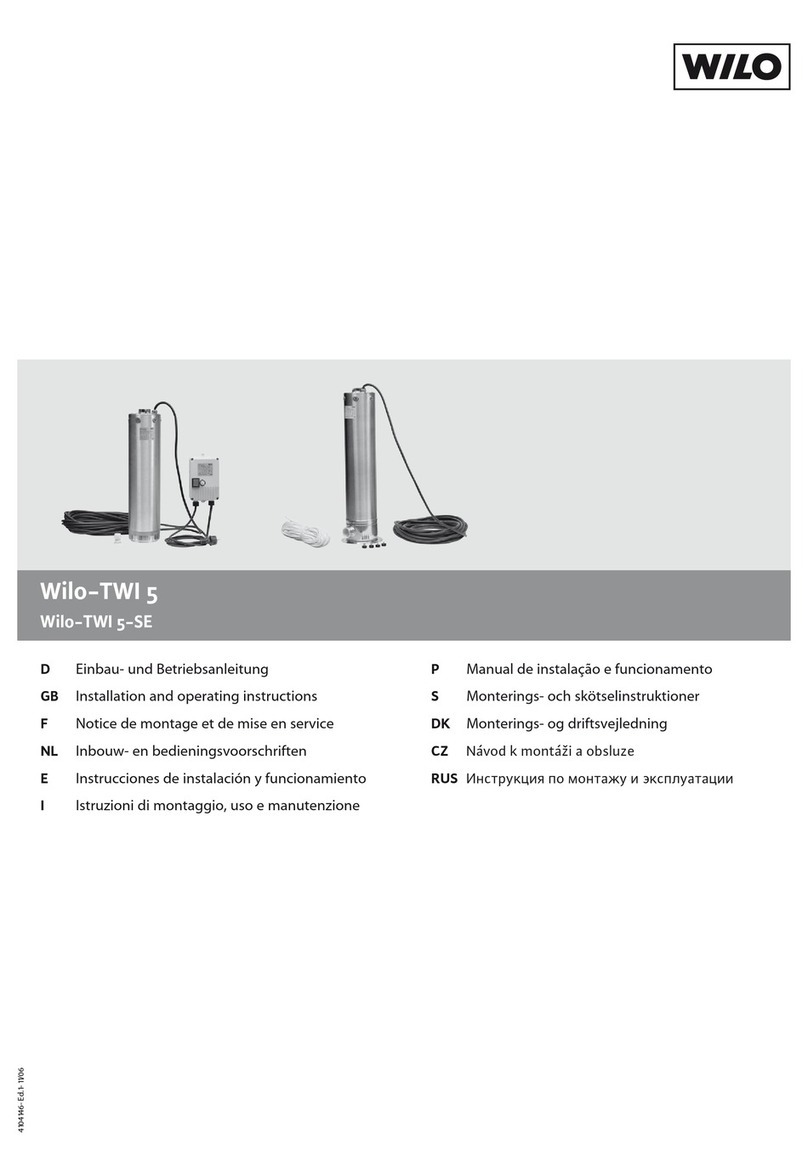

Table of contents

Table of contents

1 About this document ............................... 4

1.1 Target groups ................................. 4

1.2 Other applicable documents ................ 4

1.3 Warnings and symbols ....................... 5

2 Safety ................................................. 6

2.1 Intended use .................................. 6

2.2 General safety instructions .................. 6

2.2.1 Product safety ................................ 6

2.2.2 Operator's obligations ........................ 7

2.2.3 Obligations of personnel ..................... 7

2.3 Specific hazards .............................. 7

2.3.1 Hazardous pumped liquids .................. 7

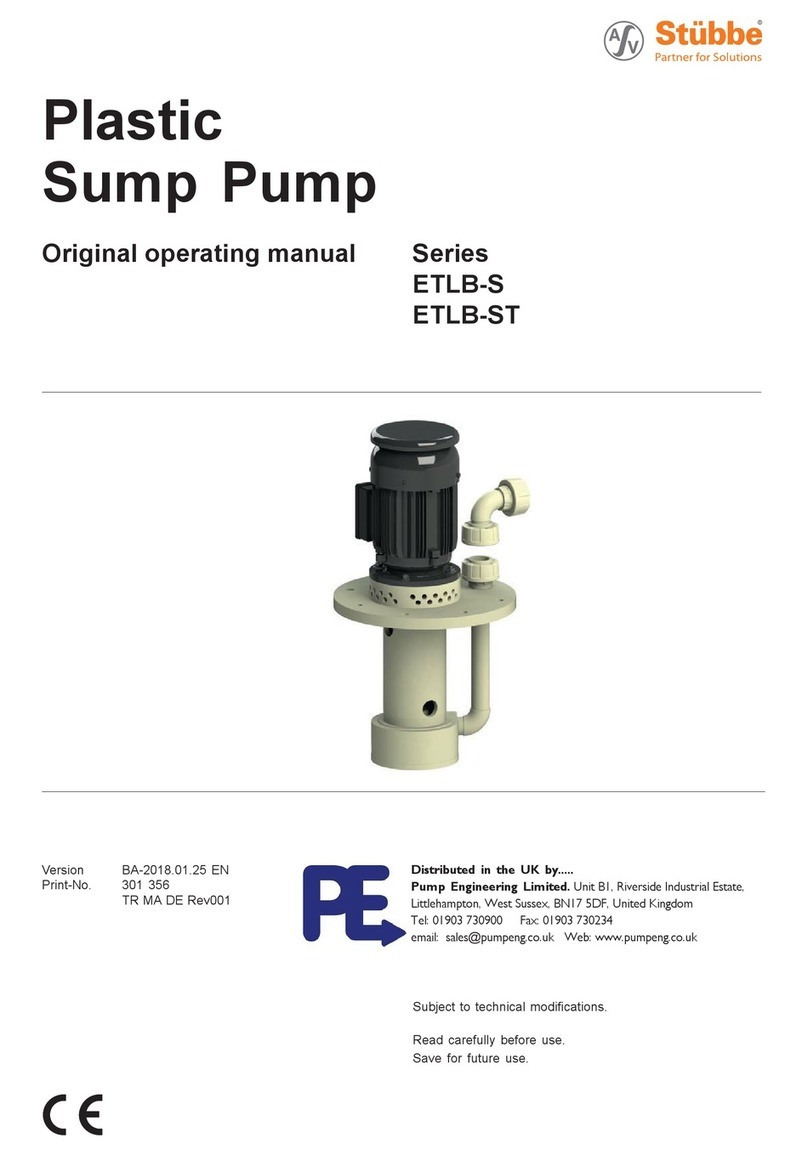

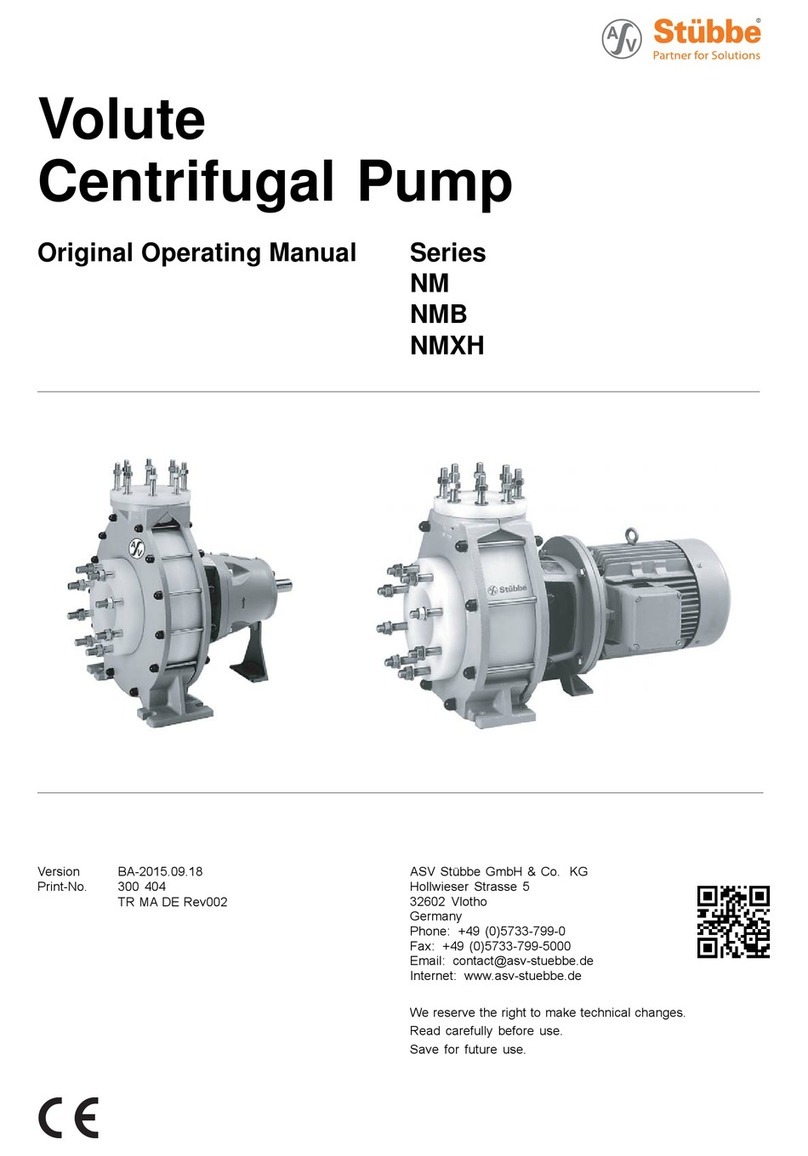

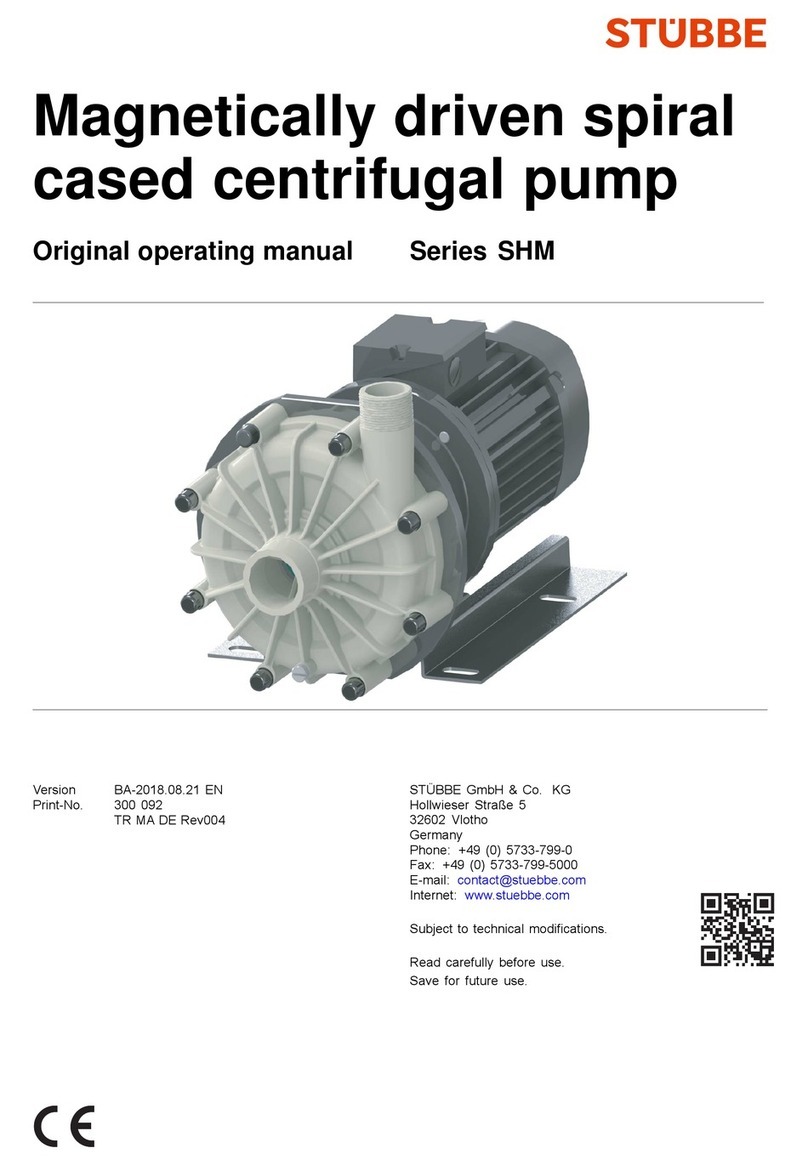

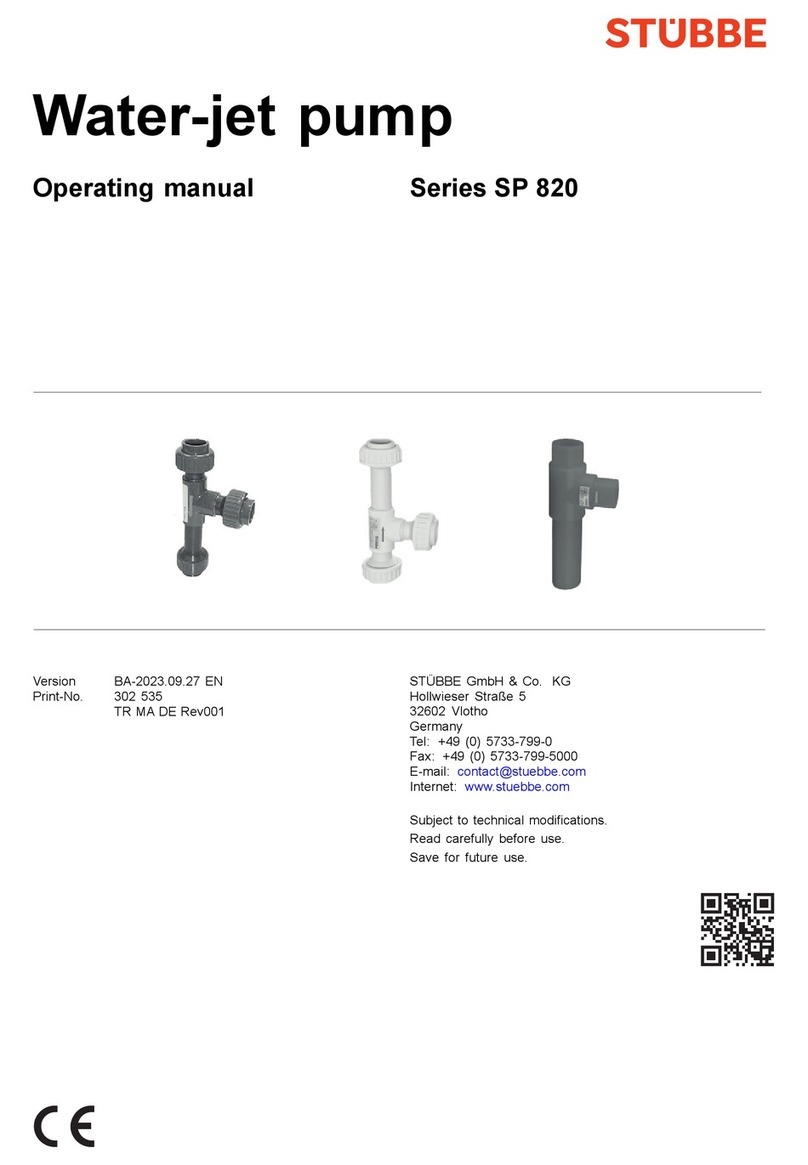

3 Layout and function ................................ 8

3.1 Labels ......................................... 8

3.1.1 Type plate ..................................... 8

3.2 Description .................................... 8

3.3 Layout ......................................... 8

4 Transport, storage and disposal .................. 9

4.1 Transport ...................................... 9

4.1.1 Unpacking and inspection upon

delivery ........................................ 9

4.1.2 Lifting ......................................... 9

4.2 Storage ....................................... 10

4.3 Disposal ....................................... 10

5 Setup and connection .............................. 11

5.1 Preparing the setup .......................... 11

5.1.1 Check operating conditions ................. 11

5.1.2 Preparing the installation site ............... 11

5.1.3 Surface preparation .......................... 11

5.2 Setting up ..................................... 11

5.3 Planning the pipes ........................... 12

5.3.1 Specifying supports and flange

connections ................................... 12

5.3.2 Specifying nominal widths ................... 12

5.3.3 Optimizing changes of cross section and

direction ....................................... 12

5.3.4 Providing safety and control devices

(recommended) .............................. 12

5.4 Connecting the pipes ........................ 12

5.4.1 Keeping the piping clean .................... 12

5.4.2 Installing the pressure pipe .................. 12

5.4.3 Inspection for stress-free pipe

connections ................................... 12

5.5 Electrical connection ......................... 13

5.5.1 Connecting the motor ........................ 13

5.5.2 Check direction of rotation ................... 13

5.6 Performing the hydrostatic test .............. 13

6Operation............................................ 14

6.1 Preparing for commissioning ................ 14

6.1.1 Checking downtimes ......................... 14

6.1.2 Filling and bleeding .......................... 14

6.2 Commissioning ............................... 14

6.2.1 Switching on .................................. 14

6.2.2 Switching off .................................. 14

6.3 Shutting down the pump ..................... 15

6.4 Restoring the pump to service .............. 16

6.5 Operating the stand-by pump ............... 16

7 Maintenance ......................................... 17

7.1 Inspections ................................... 17

7.2 Maintenance .................................. 17

7.2.1 Maintenance in accordance with maintenance

schedule ...................................... 17

7.2.2 Cleaning the pump ........................... 18

7.3 Dismounting .................................. 18

7.3.1 Preparations for dismounting ................ 18

7.3.2 Dismounting hydraulic system .... . . . . . . .... 18

7.3.3 Dismounting coupling and intermediate

ring ............................................ 18

7.3.4 Dismounting V-rings ......................... 19

7.3.5 Dismounting shaft bearing ................... 19

7.4 Replacement parts and return .............. 19

7.5 Installing ...................................... 20

8 Troubleshooting .................................... 21

9 Appendix ............................................. 23

9.1 Replacement parts ........................... 23

9.1.1 Part numbers and designations ... . . . ...... . 23

9.1.2 Drawing ETL 20-100 to 65-200 ............. 24

9.1.3 Drawing ETL 80-200 ......................... 25

9.2 Technical specifications ...................... 26

9.2.1 Ambient conditions ........................... 26

9.2.2 Sound pressure level ........................ 26

9.2.3 Flange tightening torques ................... 26

9.2.4 Sole plate tightening torques . . . . . . . . . .. . .. .. 26

9.2.5 Tightening torques of casing screws . . . . .... 26

9.2.6 Installation dimensions and filling

heights ........................................ 27

9.3 Maintenance plan ............................ 27

9.4 Lubrication .................................... 28

9.4.1 Lubricating points ............................ 28

9.4.2 Lubricant ...................................... 28

9.5 Declaration of conformity in accordance with

EC machinery directive ...................... 29

2 ETL BA-2015.09.17 300 106