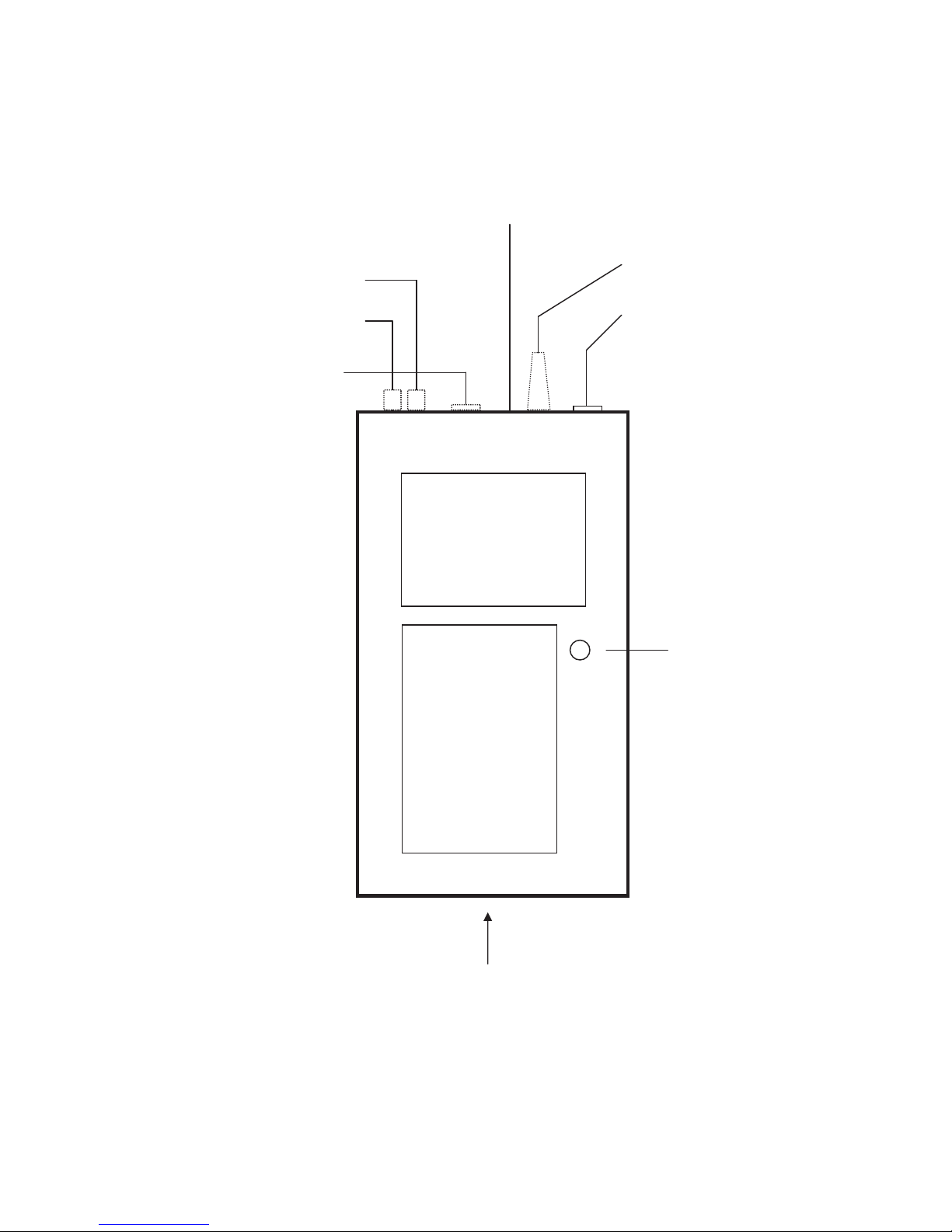

Manual C118 EN Rev04 04.2017 6

Sensors and Cables fitting the C118

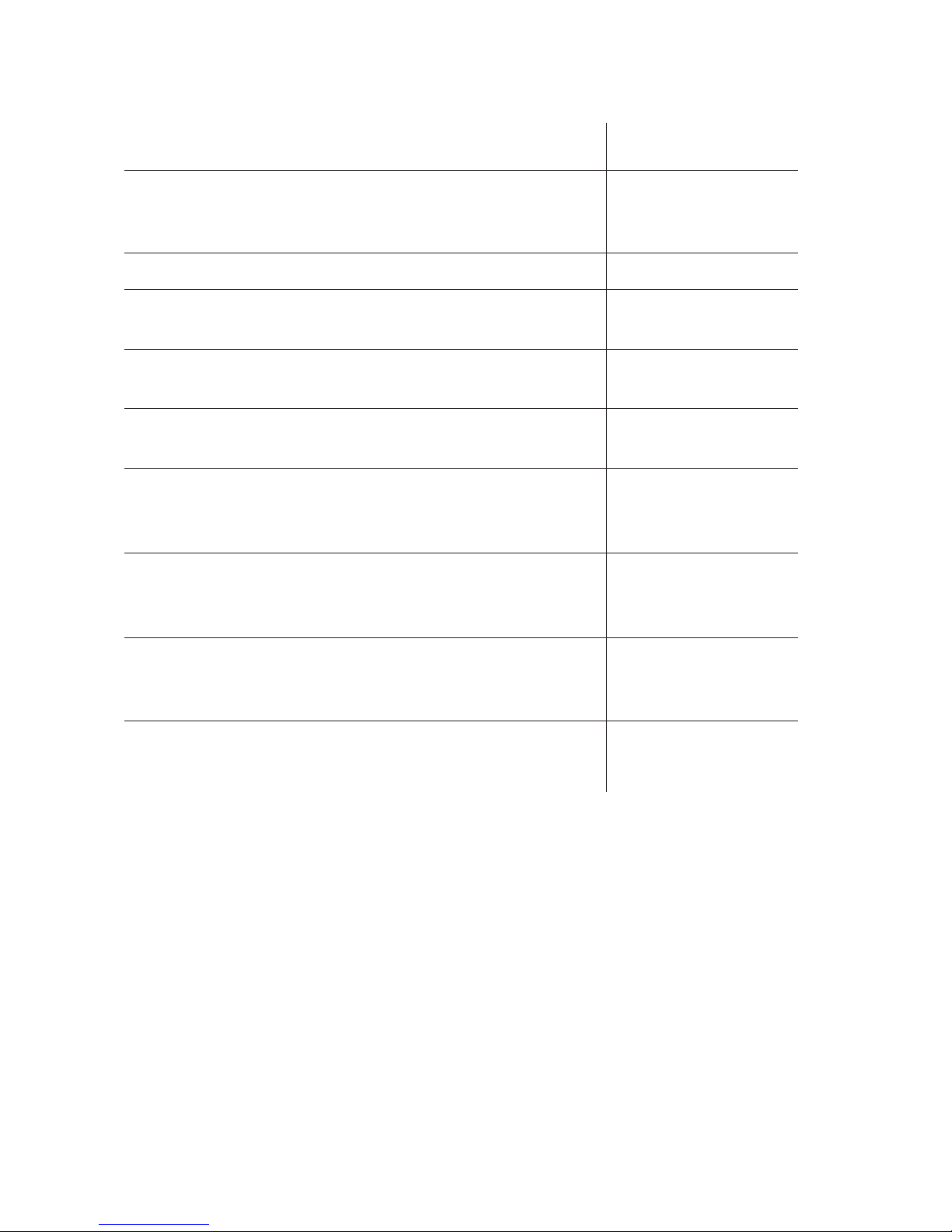

Application Characteristics Part No.

Optoelectronic Sensor as standard, 95 mm shaft

(part of equipment C118BS, C118.1BS, C118.2BS and

C118.3BS).

A1S30P95 *

same, with short shaft 35 mm. A1S30P35 *

Optosensor, with increased light intensity, with 5m

cable firmly attached (part of C118.2BP and C118.3BP).

A1S36P95-5m

same, with short shaft 35 mm, and angularly

attached cable, for narrow space applications.

A1S36WP35-5m

Laser type sensor for scanning distance up to 2 m,

target to be marked with high reflection tape U1A006.

A1S37P *

Sensing wheel, twin type, wheel 63 mm,

1000 pulses/meter for length detection,

Speed measuring range 0… 1200 m/min.

A1L04B200 **

Sensing wheel, twin type, wheel 159 mm,

1000 pulses/meter for length detection,

Speed measuring range 0… 3000 m/min.

A1L05B500-5V **

Speed sensor on differential Hall-effect basis, detecting

steel profiles, or magnets, at any speed, under tough con-

ditions, under oil or water.

A5S07B50-2mP **

Speed sensors on magnetic-inductive (active) basis,

to detect varying external magnetic fields. Specials for

speed measurement of turbochargers on ships.

Sensor series

A2S… ***

*) connection cable type SAK

(in standard equipment with 2 meters length)

**) connection cable type L3A25BP

***) connection cable type L2A16BP

All cables available with length of 2 m, 5 m, 10 m.

Notes to sensor selection and how to mark the target

Optoelectronic type sensors

There is hardly another type of sensors fitting better to var-

ying applications as the non-contact optoelectronic versions

do. The target is fast and easily prepared. The automatic

signal conditioning, incorporated with the C118, accepts a

line of paint, a hole, or a screw, or a blade as a mark.

Important however, that it has a strong contrast to the back-

ground. An excellent means is a piece of the high reflection

strip (U1A006) taped on the target.

The target itself may be any sized part (a wheel, shaft or

disk, for instance), made of any material, metal or plastics.

Since there is no reaction to the object under measurement,

this may be a small and light part, also running at high

speed. The only requirement is to keep the spot of meas-

urement clean.

For the mark, a length of 1 cm in direction of run (even less

at smaller shafts) will be adequate. A crooked surface (fan

or turbine blade) will best be marked by a piece of the high

reflection tape (U1A006).

If several marks are used (to get a faster reaction at a slow

motion), they should be placed with equal distances be-

tween them.

The acceptable scanning distance (clearance) widely de-

pends on the contrast of the mark. In general, it will be 0.5

to 2 cm, more with the high reflection mark applied. With

this as pre-condition, the Laser type sensor A1S37P may

achieve up to 2 meters.

The sensor A1S36P95 has been designed for heavy ambient

conditions, at paper machines (felts), for instance. The

firmly attached cable protects against humidity or steam,

and its especially intensive light may overcome a faint

marking contrast.

Oscillating light as emitted from AC-supplied illumination

may pretend a speed to the instrument (50 Hz =3000 RPM),

even if reflected somewhere. This may cause irritations,

and the sensor should be protected against.

A1S30P95,

the standard for

optoelectronic

sensing

A1S37P,

the sensor for

large distance

A1S36P95,

the sensor for

humid ambiance,

and with en-

hanced light

It is important to hold the sensor steadily (in reference to

the target). Mostly, a support to the hand will be adequate.

Critical applications (low speed, narrow clearance) may re-

quire a firm clamping of the sensor. The magneto-based ad-

justable clamp U9A001 will be a practical aid, specifically

to the Laser type sensor A1S37P.

Magneto-based

sensor clamp

U9A001